Introduction: Navigating the Global Market for ip68 led strip lights

In today’s fast-paced global marketplace, selecting the right LED lighting solutions is paramount for businesses aiming to deliver durability, efficiency, and innovation. IP68 LED strip lights, known for their exceptional protection against dust and prolonged water immersion, have emerged as a critical component in diverse applications — from industrial installations and outdoor architectural lighting to underwater environments and harsh climatic conditions. For international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of IP68-rated LED strips is essential to secure reliable, high-performance lighting that withstands challenging environments.

This comprehensive guide offers an authoritative roadmap to mastering the complexities of IP68 LED strip lights. It covers key aspects such as types of IP68 LED strips, materials and construction techniques, manufacturing standards, and quality control protocols that ensure longevity and safety. Additionally, it delves into sourcing strategies, identifying reputable suppliers, benchmarking costs, and analyzing market trends tailored to diverse regional demands. The guide also addresses frequently asked questions, empowering buyers to make data-driven decisions and mitigate risks associated with substandard products.

By leveraging this resource, international buyers will gain actionable insights to optimize procurement processes, enhance project outcomes, and foster long-term partnerships with trusted manufacturers and distributors. Whether sourcing for infrastructure projects in Germany, outdoor retail installations in Brazil, or marine applications in South Africa, this guide equips you with the knowledge to confidently navigate the global IP68 LED strip light market and illuminate your business success.

Understanding ip68 led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fully Encapsulated Silicone IP68 | Entire strip coated with a durable, flexible silicone layer | Underwater lighting, wet outdoor environments | Pros: Excellent waterproofing, flexible; Cons: Higher cost, less heat dissipation |

| Rigid Casing IP68 | LED strip enclosed in a hard, transparent rigid tube | Architectural lighting, industrial installations | Pros: Robust protection, easy cleaning; Cons: Less flexible, bulkier installation |

| Resin Filled IP68 | LED strip embedded in a clear epoxy or polyurethane resin | Aquariums, pools, fountains | Pros: Superior waterproofing, chemical resistant; Cons: Difficult to repair, higher price |

| Hybrid IP68 with Connectors | Silicone or resin coating with waterproof connectors | Modular outdoor displays, signage | Pros: Easy to connect/disconnect, scalable; Cons: Connector points may need extra sealing |

| High-Density IP68 LED Strips | High LED count with IP68 encapsulation for intense lighting | Commercial lighting, outdoor advertising | Pros: High brightness, durable; Cons: Higher power consumption, costlier |

Fully Encapsulated Silicone IP68

This type features a continuous silicone coating enveloping the entire LED strip, providing exceptional flexibility and complete waterproof protection. It is ideal for projects requiring the strip to bend or conform to curved surfaces, such as underwater pool lighting or exterior architectural accents. B2B buyers should consider the slightly higher cost and potential heat dissipation challenges but benefit from its durability in harsh wet environments.

Rigid Casing IP68

LED strips housed within a rigid, transparent casing offer robust protection against physical impacts and water ingress. This variant suits industrial or architectural applications where durability and ease of maintenance are critical, such as factory lighting or outdoor facades. Buyers must weigh the reduced flexibility and increased installation space requirements against the ease of cleaning and longevity.

Resin Filled IP68

Encasing LED strips in epoxy or polyurethane resin creates a solid, chemical-resistant barrier, making these strips perfect for aquatic environments like aquariums or decorative fountains. Their enhanced waterproofing withstands prolonged submersion and exposure to chemicals. However, repairability is limited, and the upfront cost is higher, so buyers should plan for long-term installations.

Hybrid IP68 with Connectors

Combining waterproof coatings with specialized IP68-rated connectors, this type supports modular lighting systems that can be expanded or reconfigured easily. It is widely used in outdoor signage and large-scale displays where scalability and quick replacement are necessary. Buyers should ensure connector seals are properly maintained to prevent ingress at joint points.

High-Density IP68 LED Strips

These strips pack a higher number of LEDs per meter within an IP68 enclosure, delivering intense, uniform illumination suitable for commercial lighting or outdoor advertising. While offering superior brightness and durability, they consume more power and come at a premium price. B2B buyers focusing on impactful visual presence should balance energy costs against lighting performance.

By understanding these variations, international B2B buyers can make informed decisions aligned with their project requirements, environmental conditions, and budget constraints, ensuring optimal performance and longevity of IP68 LED strip lighting solutions.

Key Industrial Applications of ip68 led strip lights

| Industry/Sector | Specific Application of ip68 led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Offshore | Underwater vessel lighting and underwater inspection lighting | Enables durable, waterproof illumination critical for safety and operational efficiency in harsh marine environments | Verify IP68 certification for prolonged submersion; corrosion-resistant materials; compliance with maritime safety standards |

| Aquaculture | Lighting for fish farms and aquatic habitats | Promotes healthy aquatic environments and improves monitoring capabilities while withstanding continuous water exposure | Ensure LED strips are non-toxic, UV-resistant, and compatible with saltwater; long lifespan reduces maintenance costs |

| Outdoor Architectural Lighting | Illuminating fountains, pools, and water features | Enhances aesthetic appeal while ensuring longevity despite constant water contact and weather exposure | Look for high-quality waterproof encapsulation, energy efficiency, and color consistency; ease of installation in wet environments |

| Industrial Cooling Systems | Lighting inside cooling towers and humid industrial areas | Provides reliable illumination in moisture-rich environments, facilitating maintenance and safety inspections | Confirm resistance to condensation and chemicals; robust waterproofing and flexible installation options |

| Tunnel and Infrastructure | Lighting in tunnels, underpasses, and drainage systems | Guarantees consistent, waterproof lighting critical for safety and operational visibility in wet or submerged conditions | Prioritize IP68-rated strips with high durability, impact resistance, and compliance with local infrastructure standards |

Marine & Offshore Applications

In the marine and offshore industries, IP68 LED strip lights are indispensable for underwater vessel lighting and inspection tasks. These lights must withstand continuous submersion in saltwater, resist corrosion, and provide reliable illumination in challenging conditions. For international buyers, especially in regions with extensive coastlines such as South America and Europe, sourcing LED strips with verified IP68 certification and marine-grade materials ensures operational safety and reduces costly downtime due to equipment failure.

Aquaculture Industry Use

Aquaculture operations require lighting solutions that can endure constant water exposure while supporting aquatic life health and monitoring. IP68 LED strips are ideal for fish farms and aquatic habitats, as they are waterproof and often UV-resistant, preventing degradation from sunlight exposure. Buyers from Africa and the Middle East should focus on sourcing LED strips that are non-toxic and designed for saltwater environments to maintain sustainability and minimize maintenance efforts.

Outdoor Architectural Lighting

For architectural projects involving water features such as fountains and pools, IP68 LED strip lights provide vibrant, weatherproof illumination that enhances visual appeal. These strips must maintain performance despite continuous water contact and outdoor weather fluctuations. European and Australian buyers should emphasize energy efficiency, color stability, and ease of installation when selecting these lights to meet stringent environmental regulations and aesthetic standards.

Industrial Cooling Systems

Industrial cooling towers and humid environments demand lighting that can resist moisture, condensation, and chemical exposure. IP68 LED strip lights meet these requirements by offering robust waterproofing and flexible installation options that facilitate maintenance and safety inspections. International buyers in industrial sectors should verify chemical resistance and durability to ensure long-term reliability under harsh conditions.

Tunnel and Infrastructure Lighting

Tunnels, underpasses, and drainage infrastructure require IP68 LED strip lighting to provide consistent illumination in wet or submerged conditions, enhancing safety and operational visibility. Buyers from regions with extensive infrastructure development like Europe and South America must prioritize products with high impact resistance, compliance with local standards, and proven waterproof performance to ensure durability and regulatory adherence.

Related Video: How to make IP68 Silicon Waterproof LED Strip Light in workshop

Strategic Material Selection Guide for ip68 led strip lights

When selecting materials for IP68 LED strip lights, understanding the interplay between material properties and environmental demands is crucial. IP68-rated strips are designed for continuous submersion and harsh conditions, so the materials used must ensure long-term reliability, safety, and compliance with international standards. Below is an analysis of four common materials used for IP68 LED strip light encapsulation and housing, tailored for international B2B buyers from diverse regions including Africa, South America, the Middle East, and Europe.

Silicone Rubber

Key Properties:

Silicone rubber offers excellent flexibility, high thermal stability (operating temperatures typically from -60°C to +200°C), and outstanding resistance to UV radiation and ozone. It is chemically inert, providing strong resistance to water, salt, and many industrial chemicals, which is essential for IP68 applications involving prolonged water exposure.

Pros & Cons:

– Pros: Highly durable under extreme temperatures and UV exposure; excellent waterproof sealing; flexible for varied installation surfaces; resistant to corrosion and aging.

– Cons: Higher manufacturing costs compared to simpler plastics; requires specialized molding processes; may have lower mechanical strength compared to rigid materials.

Impact on Application:

Silicone rubber is ideal for underwater and outdoor installations where flexibility and extreme environmental resistance are needed, such as marine lighting or outdoor architectural accents. Its chemical resistance makes it suitable for coastal and industrial environments common in Middle Eastern and South American markets.

International Buyer Considerations:

Silicone rubber products often comply with ASTM D2000 and ISO 10993 standards, which are widely recognized in Europe (DIN standards) and Australia. Buyers should ensure suppliers provide certification for biocompatibility and environmental resistance. Its premium cost is justified by longevity and reduced maintenance in harsh climates.

Polyurethane (PU)

Key Properties:

Polyurethane encapsulants offer excellent abrasion resistance, good flexibility, and moderate thermal stability (typically -40°C to +120°C). PU has good resistance to oils and solvents but is less UV stable than silicone, which can lead to degradation under prolonged sun exposure.

Pros & Cons:

– Pros: Strong mechanical protection; good adhesion to LED components; cost-effective compared to silicone; suitable for moderately harsh environments.

– Cons: Susceptible to yellowing and brittleness under UV exposure; limited temperature range; less chemically inert than silicone.

Impact on Application:

PU is often used in industrial or indoor IP68 LED strips where mechanical protection is critical but UV exposure is limited, such as in enclosed water tanks or underground installations. Its abrasion resistance is valuable in areas with particulate matter, common in mining regions of Africa and South America.

International Buyer Considerations:

Polyurethane materials should meet ASTM D412 and ISO 37 for tensile properties. Buyers in Europe and Australia should verify UV stabilization additives are used to meet local durability expectations. PU offers a balance between cost and durability for projects with moderate environmental stress.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a rigid or flexible plastic with good chemical resistance and moderate thermal tolerance (-20°C to +60°C). It is inherently waterproof but less flexible than silicone or PU and can become brittle in cold climates.

Pros & Cons:

– Pros: Low cost and widely available; good chemical resistance; easy to extrude and mold; suitable for mass production.

– Cons: Limited flexibility and thermal resistance; potential environmental and health concerns due to plasticizers; less durable under UV exposure without additives.

Impact on Application:

PVC is often chosen for budget-sensitive projects where the LED strips are submerged in fresh water or installed indoors with minimal temperature variation, such as decorative aquarium lighting or indoor fountains. Its rigidity can be a limitation in curved or uneven installations.

International Buyer Considerations:

PVC products should comply with RoHS and REACH regulations, especially in European markets. Buyers in Africa and South America benefit from PVC’s low cost but should consider the material’s environmental impact and shorter lifespan in outdoor applications.

Epoxy Resin

Key Properties:

Epoxy resin provides a hard, transparent, and chemically resistant coating with excellent adhesion to LED components. It has good thermal conductivity and can withstand temperatures up to 150°C. However, it is rigid and prone to cracking under mechanical stress or thermal cycling.

Pros & Cons:

– Pros: Superior waterproof sealing; high chemical resistance; excellent optical clarity; good thermal stability.

– Cons: Brittle and less flexible; prone to yellowing over time; complex curing process; higher manufacturing complexity and cost.

Impact on Application:

Epoxy resin is suitable for fixed installations where LED strips require robust protection against chemicals and water, such as in industrial or underwater lighting in controlled environments. Its rigidity limits use in flexible or curved applications.

International Buyer Considerations:

Epoxy materials often meet ASTM D256 and DIN EN ISO 175 standards for mechanical and chemical resistance. Buyers from Europe and Australia prioritize epoxy for high-performance industrial lighting, while those in Africa and the Middle East may use epoxy-coated strips in harsh chemical environments.

Summary Table

| Material | Typical Use Case for ip68 led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Rubber | Underwater, outdoor, flexible installations, marine lighting | Excellent flexibility and UV resistance | Higher cost and specialized manufacturing | High |

| Polyurethane | Industrial, indoor water tanks, abrasion-prone environments | Strong mechanical protection and cost-effective | UV degradation and limited temperature range | Medium |

| Polyvinyl Chloride (PVC) | Budget indoor/outdoor fresh water, decorative applications | Low cost and chemical resistance | Limited flexibility and thermal tolerance | Low |

| Epoxy Resin | Fixed industrial/underwater installations requiring chemical resistance | Superior waterproof sealing and optical clarity | Brittle, prone to yellowing, complex curing | High |

This guide equips international B2B buyers with a clear understanding of material options for IP68 LED strip lights, enabling informed procurement decisions aligned with environmental conditions, regulatory standards, and project budgets.

In-depth Look: Manufacturing Processes and Quality Assurance for ip68 led strip lights

Manufacturing Process of IP68 LED Strip Lights

The production of IP68 LED strip lights involves a series of carefully controlled stages designed to ensure durability, waterproofing, and high performance. For international B2B buyers, understanding these stages offers insight into product quality and supplier reliability.

1. Material Preparation

- Substrate Selection: High-quality flexible PCB (Printed Circuit Board) material is chosen, typically made from fiberglass or polyimide, which must be resistant to moisture and mechanical stress.

- LED and Component Procurement: LEDs, resistors, and IC chips undergo strict quality vetting. For IP68 products, components must be rated for high durability and thermal stability.

- Waterproofing Materials: Silicone or polyurethane resins, along with specialized waterproof coatings and encapsulants, are sourced to provide the IP68-level sealing.

2. PCB Forming and Circuit Printing

- Circuit Design and Etching: The PCB undergoes photolithography and etching to form precise electrical pathways. This process must ensure minimal defects to prevent failures under waterproof conditions.

- Solder Mask Application: A protective solder mask is applied to prevent corrosion and short circuits.

- Surface Mount Technology (SMT): LEDs and electronic components are placed and soldered onto the PCB using automated SMT machines, ensuring consistent placement and solder joint quality.

3. Assembly and Waterproofing

- Encapsulation: This is a critical step for IP68 compliance. The assembled LED strips are encapsulated with a thick layer of silicone or polyurethane gel that completely seals the strip against dust and water ingress.

- Coating and Sealing: Additional layers of waterproof coatings may be applied, including parylene or other nano-coatings, to enhance durability.

- Connector Installation: Waterproof connectors and cables are fitted, often with rubber gaskets or heat-shrink tubing to maintain the IP68 rating at connection points.

- Curing and Drying: The encapsulated strips are cured in controlled environments to solidify the sealants without introducing bubbles or gaps.

4. Finishing and Packaging

- Cutting and Marking: LED strips are cut to standard lengths or customized sizes, with clear markings for cutting points.

- Final Inspection: Visual inspections verify the uniformity of encapsulation and absence of defects.

- Protective Packaging: IP68 LED strips are packaged in moisture-resistant and anti-static materials to preserve quality during shipping.

Quality Assurance and Control (QA/QC) for IP68 LED Strip Lights

Robust QA/QC protocols are essential to guarantee the performance and reliability of IP68 LED strips, especially for demanding international markets.

Relevant International and Industry Standards

- ISO 9001: This global quality management standard ensures consistent manufacturing processes and continuous improvement. Suppliers certified with ISO 9001 demonstrate adherence to internationally recognized quality frameworks.

- CE Marking: Mandatory for the European market, CE certification confirms compliance with EU safety, health, and environmental requirements.

- RoHS Compliance: Restricts hazardous substances, ensuring environmental safety.

- UL and ETL Certifications: Important for North American and some international buyers, indicating electrical safety.

- IP Rating Verification: Testing must confirm the IP68 rating according to IEC 60529 standards, ensuring dust-tightness and protection against continuous immersion.

- Additional Regional Certifications: Buyers in the Middle East, Africa, and South America may require compliance with local standards such as SASO (Saudi Arabia), INMETRO (Brazil), or SABS (South Africa).

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components for defects, dimensions, and compliance with specifications. This includes testing LED brightness, color consistency, and waterproof materials.

- In-Process Quality Control (IPQC): Continuous monitoring during PCB assembly, soldering quality, encapsulation uniformity, and waterproofing application to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products, including visual inspections, IP68 waterproof tests, electrical performance, and longevity tests.

Common Testing Methods

- Waterproof Testing: Submersion tests under specified depths and durations per IP68 requirements to verify no water ingress.

- Thermal Cycling: Simulates temperature fluctuations to ensure materials and solder joints withstand environmental stress.

- Electrical Testing: Checks for shorts, open circuits, and LED functionality under rated voltage.

- Mechanical Stress Testing: Bending and vibration tests to ensure flexibility and durability without compromising waterproof seals.

- Photometric Testing: Measures luminous intensity, color temperature, and uniformity to meet project specifications.

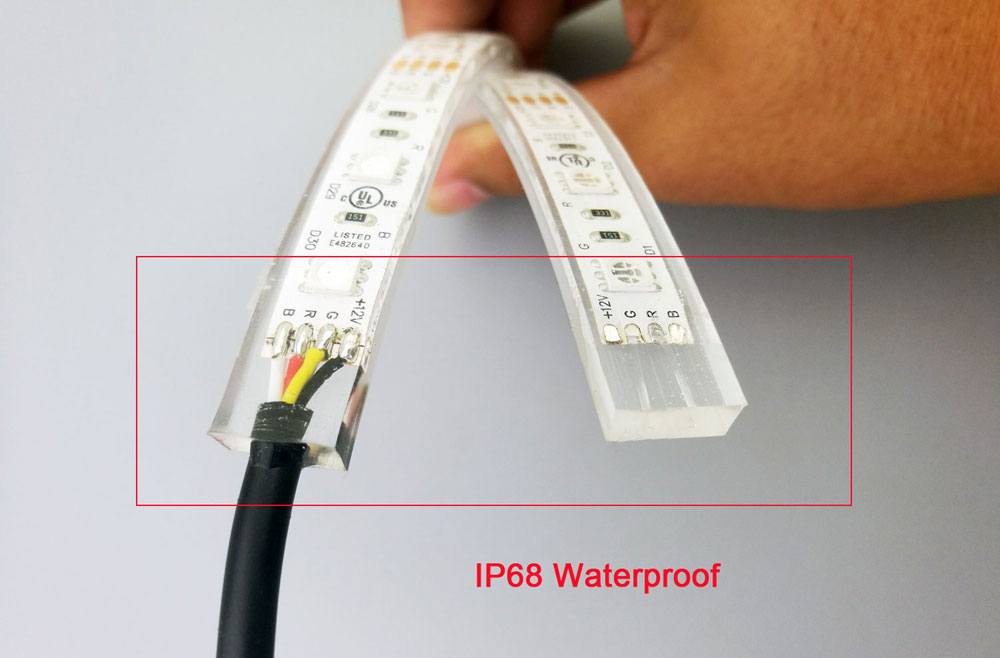

Illustrative Image (Source: Google Search)

How B2B Buyers Can Verify Supplier Quality

For buyers from Africa, South America, the Middle East, and Europe, ensuring product quality from overseas suppliers demands strategic verification methods:

- Factory Audits: Conduct or commission on-site factory audits assessing manufacturing processes, quality systems (ISO 9001), and working conditions. Audits can be performed by third-party inspection firms specializing in LED lighting.

- Review of QC Documentation: Request detailed QC reports including IP testing certificates, batch test results, and compliance certificates (CE, RoHS, etc.).

- Third-Party Testing: Engage independent labs to test product samples for waterproof rating, electrical safety, and photometric performance before bulk ordering.

- Sample Evaluation: Obtain pre-production and final product samples for in-house testing to verify performance claims and durability.

- Ongoing Quality Monitoring: Negotiate terms for periodic quality checks during production runs, especially for large or repeated orders.

QC and Certification Nuances for International B2B Buyers

- Regional Compliance Sensitivities: European buyers, particularly in Germany, prioritize CE and RoHS certifications due to strict regulatory frameworks. Buyers in Australia often require additional compliance with local electrical safety standards.

- Environmental and Operational Conditions: African and Middle Eastern markets may expose LED strips to extreme heat and dust, making adherence to IP68 waterproofing and thermal testing critical.

- Supply Chain Transparency: Buyers should demand traceability of raw materials and components to avoid counterfeit or substandard parts, a common risk in emerging markets.

- Warranty and After-Sales Support: Reputable suppliers offer warranties backed by robust QA/QC processes, essential for long-term business partnerships.

- Documentation and Traceability: Ensure suppliers provide complete documentation packages including material certificates, test reports, and quality control checklists for customs clearance and regulatory audits.

By comprehending the detailed manufacturing processes and stringent quality assurance measures behind IP68 LED strip lights, international B2B buyers can make informed procurement decisions. Prioritizing suppliers with certified quality systems, transparent QC practices, and proven testing protocols ensures investment in durable, reliable lighting solutions suited for diverse global environments.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for ip68 led strip lights Sourcing

Cost Structure Breakdown for IP68 LED Strip Lights

When sourcing IP68 LED strip lights, understanding the detailed cost components is crucial to making informed purchasing decisions:

-

Materials: High-grade raw materials such as flexible PCBs, high-quality LEDs, silicone or epoxy encapsulation for waterproofing, and corrosion-resistant connectors significantly influence costs. IP68 rating requires premium waterproofing materials that can withstand prolonged submersion, leading to higher material expenses compared to lower IP ratings.

-

Labor: Skilled labor is required for precise assembly, encapsulation, and testing to ensure the waterproof integrity and electrical safety of the strips. Labor costs vary by manufacturing country and impact the final price.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Advanced production lines with automated coating or encapsulation processes may increase overhead but improve consistency and yield.

-

Tooling: Initial setup costs such as molds for silicone coating and custom extrusion tooling can be substantial, especially for customized or proprietary designs. These costs are amortized over production runs and affect unit pricing.

-

Quality Control (QC): Rigorous QC protocols are essential for IP68 products due to their demanding waterproof standards. This includes pressure testing, electrical testing, and durability assessments, adding to the cost but reducing returns and failures.

-

Logistics: Shipping costs, import duties, and insurance must be factored in, particularly for international buyers. IP68 LED strips are often shipped in protective packaging to prevent damage, which can increase freight costs.

-

Profit Margin: Suppliers typically add a margin reflecting market demand, brand positioning, and competitive landscape. Margins can fluctuate widely depending on supplier reputation and buyer-supplier relationships.

Key Pricing Influencers for IP68 LED Strip Lights

Several factors influence the final price, making it essential for buyers to evaluate them carefully:

-

Order Volume / Minimum Order Quantity (MOQ): Larger orders usually yield better per-unit pricing. MOQ requirements vary by supplier and can impact overall procurement strategy, especially for smaller businesses or pilot projects.

-

Product Specifications and Customization: Custom color temperatures, LED densities, lengths, and connectors increase costs. Higher IP68 performance may require thicker encapsulation or specialized materials, pushing prices upward.

-

Material Quality and Certifications: LEDs with higher lumen output, better color rendering index (CRI), and certified waterproofing (e.g., UL, CE, RoHS) command premium pricing but ensure longevity and compliance with international standards.

-

Supplier Factors: Established manufacturers with proven IP68 expertise may charge more but provide better reliability and after-sales support. New or less-known suppliers might offer lower prices but carry higher risks.

-

Incoterms and Delivery Terms: Buyers should clarify Incoterms (e.g., FOB, CIF, DDP) as they significantly affect logistics costs and responsibility. For international buyers in Africa, South America, the Middle East, and Europe, understanding these terms helps avoid unexpected fees.

Practical Tips for International B2B Buyers

-

Negotiate Volume Discounts: Leverage bulk purchasing to negotiate better prices. Even incremental increases in order volume can unlock substantial savings.

-

Assess Total Cost of Ownership (TCO): Don’t focus solely on unit price. Include installation costs, expected lifespan, energy efficiency, maintenance, and warranty terms to evaluate long-term value.

-

Request Detailed Quotes: Obtain comprehensive pricing breakdowns from suppliers to identify hidden charges such as tooling fees, testing costs, or packaging expenses.

-

Understand Regional Logistics: Shipping to Africa, South America, the Middle East, or Europe involves varying customs duties, VAT, and import regulations. Partner with freight forwarders experienced in your target region to optimize costs and delivery times.

-

Prioritize Quality and Certifications: In markets with strict regulatory environments (e.g., Germany, Australia), insist on certified products to avoid compliance issues that could result in costly delays or penalties.

-

Consider Lead Times: Longer lead times might reduce costs but can impact project schedules. Balance cost savings with delivery urgency.

-

Build Strong Supplier Relationships: Trusted suppliers often provide better pricing flexibility, technical support, and faster resolution of issues, crucial for complex IP68 LED strip projects.

Indicative Pricing Disclaimer

Prices for IP68 LED strip lights can vary widely based on specifications, quantities, and supplier location. As a guideline, typical unit costs may range from $8 to $25 per meter, depending on customization and certification levels. Buyers should treat these figures as indicative and engage directly with suppliers for precise quotations tailored to their project requirements.

Illustrative Image (Source: Google Search)

By carefully analyzing the cost components and pricing influencers outlined above, international B2B buyers can optimize their sourcing strategy for IP68 LED strip lights, ensuring cost-efficiency without compromising on quality and performance.

Spotlight on Potential ip68 led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ip68 led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ip68 led strip lights

Critical Technical Properties of IP68 LED Strip Lights

1. Ingress Protection (IP) Rating – IP68

The hallmark of these LED strips is their IP68 rating, signifying complete protection against dust ingress (6) and the ability to withstand continuous submersion in water beyond 1 meter depth (8). For B2B buyers, this means the product is suitable for harsh outdoor environments, underwater installations, and industrial settings where exposure to moisture and dust is unavoidable. Choosing IP68-rated strips ensures durability and reduces maintenance costs over the product lifecycle.

2. Material Grade and Encapsulation

High-grade materials such as UV-resistant silicone or polyurethane encapsulate the LED strip, providing flexibility and robust waterproofing. These materials also protect against chemical corrosion and temperature fluctuations. For international buyers, especially in regions with strong sun exposure (e.g., Middle East, Africa) or variable climates (e.g., Europe), selecting strips with superior encapsulation guarantees longer service life and sustained light quality.

3. Voltage and Power Tolerance

Typical IP68 LED strips operate at 12V or 24V DC with a power tolerance range of ±10%. Power tolerance indicates how well the strip maintains performance despite voltage fluctuations common in certain markets. Understanding this helps buyers specify compatible power supplies and avoid premature LED failure, ensuring reliability in diverse electrical infrastructures.

4. Color Rendering Index (CRI) and Luminous Efficiency

CRI measures how accurately the LED light renders colors compared to natural light, with values above 80 being preferable for commercial and decorative applications. Luminous efficiency (measured in lumens per watt) reflects energy efficiency. For B2B buyers, balancing high CRI and luminous efficiency ensures visually appealing lighting that meets energy-saving regulations, which vary across regions like the EU and Australia.

5. Operating Temperature Range

IP68 LED strips are designed to function within broad temperature ranges, often from -20°C to +50°C or higher. This property is critical for installations in extreme climates, such as the hot deserts of Africa or cold European winters. Specifying the correct operating temperature range prevents performance degradation and extends operational lifespan.

6. Adhesive Backing and Mounting Options

Quality IP68 LED strips come with industrial-grade adhesive tapes (e.g., 3M) or mounting channels to facilitate secure installation on various surfaces, including metal, glass, or concrete. This feature is essential for ease of deployment in commercial projects, reducing labor costs and installation time.

Common Industry and Trade Terminology for IP68 LED Strip Lights

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that other brands repackage under their own labels. For B2B buyers, partnering with OEMs can provide cost-effective, customizable solutions tailored to specific project requirements, including branding and technical specs.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order. Understanding MOQ is vital for budget management and inventory planning, especially for buyers in emerging markets or those testing new products before scaling.

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specific products. RFQs are the starting point for negotiation and vendor comparison, enabling buyers to make informed purchasing decisions based on cost-effectiveness and supplier reliability.

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce (ICC) that define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common terms include FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps B2B buyers from different regions coordinate logistics and control costs effectively.

Lumens (lm)

A measure of total visible light output from the LED strip. Higher lumens mean brighter light, which is crucial for applications needing high visibility, such as signage or outdoor architectural lighting.

CRI (Color Rendering Index)

A scale from 0 to 100 that indicates how true colors appear under the LED light. A higher CRI is important for retail, hospitality, and design industries where accurate color perception impacts customer experience and product display.

By grasping these technical properties and trade terms, international B2B buyers can confidently select IP68 LED strip lights that meet their project’s environmental demands, regulatory requirements, and commercial objectives. This knowledge reduces risks, optimizes procurement, and ensures the success of lighting installations across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ip68 led strip lights Sector

Market Overview & Key Trends

The IP68 LED strip lights sector has witnessed robust global growth, driven by increasing demand for durable, high-performance lighting solutions suitable for harsh environments. IP68-rated strips are uniquely positioned for applications requiring full dust protection and prolonged water submersion resistance, making them ideal for outdoor, marine, industrial, and architectural projects. This robust ingress protection appeals strongly to international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, where climate variability and infrastructure demands necessitate resilient lighting.

Key market drivers include expanding smart city initiatives, infrastructure modernization, and the rise of outdoor advertising and architectural lighting projects. In Europe and Australia, stringent safety and quality standards encourage procurement of IP68 LED strips that comply with international certifications, ensuring longevity and reliability. Meanwhile, emerging markets in Africa and South America are rapidly adopting IP68 lighting for energy-efficient public lighting, mining, and agricultural applications, emphasizing durability and maintenance cost reduction.

From a sourcing perspective, B2B buyers increasingly prioritize suppliers who offer customization, advanced waterproofing techniques (e.g., silicone encapsulation, parylene coatings), and integration capabilities with IoT and smart controls. The rise of digital procurement platforms and transparent supply chains also facilitates easier cross-border transactions and quality assurance. Moreover, manufacturers are focusing on modular designs and standardized connectors to simplify installation and reduce downtime, key concerns for large-scale commercial projects.

In summary, successful B2B sourcing in the IP68 LED strip light market hinges on understanding regional environmental challenges, compliance with local regulations, and leveraging emerging smart lighting technologies to future-proof investments.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor in the procurement of IP68 LED strip lights, with buyers demanding transparency around environmental impact and ethical supply chains. The production of LED strips involves materials such as semiconductors, plastics, and metals, which can contribute to resource depletion and electronic waste if not responsibly managed. For B2B buyers, especially in Europe and Australia where regulatory pressure is high, sourcing from manufacturers who adhere to green certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 environmental management standards is essential.

Ethical sourcing also encompasses labor practices, with buyers increasingly scrutinizing supply chains to ensure fair working conditions and avoidance of conflict minerals. Certifications such as SA8000 or adherence to UN Global Compact principles can provide assurance of responsible manufacturing.

Material innovation is another sustainability trend. Suppliers are developing LED strips using recyclable components, biodegradable encapsulants, and low-VOC (volatile organic compound) coatings that reduce environmental footprint. Additionally, the inherent energy efficiency of LED technology supports sustainability goals by lowering operational energy consumption, a significant advantage for projects in energy-conscious markets like Germany and the EU.

For international buyers, partnering with suppliers who offer transparent lifecycle assessments and take-back or recycling programs can enhance corporate social responsibility profiles while mitigating long-term environmental risks.

Evolution of IP68 LED Strip Lights in the B2B Context

The evolution of IP68 LED strip lights reflects broader advances in LED technology and waterproofing engineering. Initially, LED strips were primarily designed for indoor, dry environments (IP20). As outdoor and industrial applications expanded, demand grew for higher ingress protection levels, culminating in the development of IP67 and IP68 ratings.

IP68 LED strips represent the pinnacle of waterproofing, capable of continuous submersion and total dust ingress protection. This capability was achieved through innovations like multi-layer silicone encapsulation, resin potting, and advanced sealing techniques that protect delicate LED diodes and circuitry from moisture and contaminants.

For B2B buyers, this evolution means access to lighting solutions capable of withstanding extreme environments—ranging from underwater architectural lighting to mining operations—while offering enhanced durability and reduced maintenance costs. The maturation of IP68 LED strips has opened new markets and use cases, solidifying their role as essential components in resilient, energy-efficient lighting systems worldwide.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of ip68 led strip lights

-

How can I effectively vet suppliers of IP68 LED strip lights for international B2B sourcing?

When vetting suppliers, prioritize those with verifiable certifications such as CE, RoHS, and ISO to ensure product quality and compliance with international standards. Request detailed technical datasheets and sample products for inspection. Check supplier history through trade platforms, references, and customer reviews, especially from buyers in your region (Africa, South America, Middle East, Europe). Confirm their production capacity aligns with your volume needs. Additionally, assess communication responsiveness and after-sales support, as these are critical for smooth cross-border transactions and ongoing partnerships. -

What customization options are typically available for IP68 LED strip lights, and how can I ensure they meet my project’s specifications?

Most manufacturers offer customization in LED color temperature, length, waterproof coating materials, and power consumption. For IP68 strips, customization might include tailored silicone encapsulation thickness or connector types suitable for harsh environments. Clearly define your technical and environmental requirements upfront, including voltage, IP rating specifics, and expected operational conditions. Work closely with suppliers to obtain prototypes or samples to validate design and durability before bulk orders, ensuring the product fits your exact application and regional compliance needs. -

What are the standard MOQ and lead times for IP68 LED strip light orders, and how can I negotiate favorable terms?

Minimum order quantities (MOQs) for IP68 LED strips vary but typically range from 500 to 1000 meters depending on customization level and supplier scale. Lead times usually span 3 to 6 weeks, factoring in production, quality checks, and shipping. To negotiate better terms, leverage volume commitments or multi-order agreements. Emphasize your intent for long-term collaboration to encourage suppliers to offer flexible MOQs or expedited production. Also, consider buffer stock planning to accommodate international shipping delays common in Africa, South America, and the Middle East. -

Which quality assurance (QA) measures and certifications should I require to ensure IP68 LED strips are reliable and compliant?

Demand robust QA protocols including in-line inspections, waterproof testing (immersion and pressure), and electrical safety tests before shipment. Certifications such as IP68 rating verification, CE (for Europe), RoHS (hazardous substances compliance), and UL (for electrical safety) are essential. For Middle Eastern and African markets, ensure compliance with any regional standards or customs requirements. Request QA reports and test certificates with each batch, and consider third-party inspections or audits to mitigate risks associated with overseas manufacturing. -

What are the best logistics practices for importing IP68 LED strip lights into regions like Africa, South America, and the Middle East?

Select freight options balancing cost, speed, and product protection—sea freight is economical for large volumes but slower; air freight offers faster delivery for urgent shipments but at higher costs. Use reliable freight forwarders experienced in handling electronic goods and customs clearance in your target regions. Ensure packaging is robust and moisture-resistant to preserve the IP68 integrity during transit. Additionally, understand import duties, taxes, and certification requirements to avoid delays. Establish clear Incoterms with suppliers to define responsibility during shipping. -

How should I handle payment terms and currency risks when purchasing IP68 LED strip lights internationally?

Common payment terms include 30% deposit upfront and 70% balance before shipment or upon delivery. Negotiate terms that balance supplier trust and your cash flow, such as letters of credit or escrow services for added security. Use currency hedging or transact in stable currencies like USD or EUR to minimize foreign exchange risks, especially when dealing with suppliers in China or Southeast Asia. Clear contractual terms on payment schedules and penalties for delays protect both parties and facilitate smoother international transactions. -

What steps can I take to resolve disputes related to product quality or delivery delays in international IP68 LED strip light orders?

Start with direct negotiation and documented communication to clarify issues. Utilize inspection reports and contractual terms as evidence. Engage third-party arbitration services or dispute resolution platforms if amicable solutions fail. Include clear dispute resolution clauses in your contract specifying jurisdiction and applicable law. For recurring suppliers, consider establishing a quality assurance agreement or penalties for non-compliance. Building strong relationships and transparent communication channels reduces the likelihood and impact of disputes. -

How can I ensure the long-term reliability of IP68 LED strip lights in harsh environments typical of Africa, the Middle East, and South America?

Select products with proven IP68 certification tested under real-world conditions, including prolonged water immersion and dust exposure. Confirm the use of high-grade silicone or polyurethane encapsulation and corrosion-resistant connectors. Implement regular maintenance schedules and provide installation guidelines tailored to local climate challenges. Collaborate with suppliers for technical support and warranty coverage that reflects environmental stressors. This proactive approach safeguards your investment and minimizes operational disruptions in demanding international markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ip68 led strip lights

Key Takeaways for Strategic Sourcing of IP68 LED Strip Lights

For international B2B buyers, especially those operating in diverse climates across Africa, South America, the Middle East, and Europe, understanding the IP68 rating is crucial. IP68 LED strip lights offer superior dust-tight protection and the ability to withstand continuous submersion in water, making them ideal for demanding outdoor, underwater, and industrial applications. This high level of durability ensures longevity and reduces maintenance costs, a critical factor in large-scale commercial projects.

When sourcing IP68 LED strips, buyers should prioritize suppliers with proven expertise in waterproof sealing technologies, quality certifications, and strong supply chain reliability. Strategic sourcing involves evaluating product customization options, compliance with international standards, and after-sales support to mitigate risks associated with environmental exposure. Additionally, leveraging supplier partnerships can unlock competitive pricing and innovation advantages.

Looking ahead, the demand for IP68-rated LED strips is expected to grow with rising infrastructure development and smart city initiatives worldwide. Buyers are encouraged to invest in long-term supplier relationships and to stay informed about emerging technologies such as enhanced energy efficiency and smart connectivity features. By doing so, international buyers will not only secure resilient lighting solutions but also position themselves at the forefront of the evolving LED lighting market.