Guide to Ip65 Vs Ip68 (Important Ratings For Strips)

- Introduction: Navigating the Global Market for ip65 vs ip68 (important ratings for strips)

- Understanding ip65 vs ip68 (important ratings for strips) Types and Variations

- Key Industrial Applications of ip65 vs ip68 (important ratings for strips)

- Strategic Material Selection Guide for ip65 vs ip68 (important ratings for strips)

- In-depth Look: Manufacturing Processes and Quality Assurance for ip65 vs ip68 (important ratings for strips)

- Comprehensive Cost and Pricing Analysis for ip65 vs ip68 (important ratings for strips) Sourcing

- Spotlight on Potential ip65 vs ip68 (important ratings for strips) Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for ip65 vs ip68 (important ratings for strips)

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ip65 vs ip68 (important ratings for strips) Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ip65 vs ip68 (important ratings for strips)

- Strategic Sourcing Conclusion and Outlook for ip65 vs ip68 (important ratings for strips)

Introduction: Navigating the Global Market for ip65 vs ip68 (important ratings for strips)

In today’s interconnected global marketplace, selecting the right IP rating for LED strips and related enclosures is a critical factor that directly impacts product durability, safety, and compliance. For international B2B buyers—especially those operating across diverse environments in Africa, South America, the Middle East, and Europe—understanding the nuanced differences between IP65 and IP68 ratings is essential to ensure optimal performance in varying conditions. Whether your projects involve outdoor installations in harsh climates, industrial settings, or demanding marine applications, the choice between IP65 and IP68 can define the success and longevity of your electrical components.

This guide offers a comprehensive exploration of IP65 vs IP68 ratings specifically for strips, empowering procurement teams and technical buyers with actionable insights. It covers key aspects such as the types of IP-rated strips available, materials used in manufacturing, quality control benchmarks, and trusted global suppliers. Additionally, we analyze cost implications and market trends to help you balance budget considerations with performance requirements. A dedicated FAQ section addresses common concerns and technical clarifications, aiding in confident decision-making.

By leveraging this resource, international buyers from regions like Turkey, France, Brazil, Nigeria, and the UAE can confidently navigate the complexities of IP-rated products. The result is a strategic sourcing approach that mitigates risks related to water and dust ingress, improves product lifecycle, and aligns with local regulatory standards. Ultimately, this guide equips you to select the ideal IP rating that matches your operational demands and customer expectations, enhancing your competitive edge in the global supply chain.

Illustrative Image (Source: Google Search)

Understanding ip65 vs ip68 (important ratings for strips) Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IP65 Rated Strips | Dust-tight; protected against low-pressure water jets from all directions | Outdoor signage, architectural lighting, industrial environments | Pros: Cost-effective, good for splash/rain exposure. Cons: Not suitable for immersion or high-pressure water. |

| IP68 Rated Strips | Dust-tight; capable of continuous submersion in water (typically up to 1.5m for 30+ minutes) | Underwater lighting, marine equipment, wet industrial areas | Pros: Superior water resistance, ideal for harsh wet conditions. Cons: Higher cost, more complex sealing requirements. |

| IP65 with Silicone Coating | Standard IP65 rating enhanced with additional silicone layer for improved moisture resistance | Semi-outdoor installations, humid environments, food processing plants | Pros: Improved moisture resistance, easy to clean. Cons: Slightly higher price, limited submersion capability. |

| IP68 Flexible LED Strips | IP68 rating combined with flexible, bendable form factor and robust sealing | Architectural features with complex shapes, underwater decorative lighting | Pros: Highly adaptable, durable in submerged and dynamic environments. Cons: Premium pricing, specialized installation needed. |

| IP65/IP68 Hybrid Strips | Strips designed with modular sealing allowing switching between IP65 and IP68 standards | Multi-environment applications, adaptable manufacturing lines, export markets with varying requirements | Pros: Versatile, reduces inventory complexity. Cons: May require additional certification, potentially higher initial cost. |

IP65 Rated Strips

These strips provide complete protection against dust and resist low-pressure water jets, making them ideal for outdoor use where exposure to rain or splashes is expected. B2B buyers targeting markets in Africa or the Middle East, where dust and occasional rain are common, will find IP65 strips cost-effective and reliable. However, these strips are not suited for applications involving water immersion or high-pressure cleaning, which limits their use in marine or fully submerged environments.

IP68 Rated Strips

IP68 strips offer the highest level of ingress protection, fully sealing against dust and allowing continuous water submersion, typically up to depths of 1.5 meters for at least 30 minutes. This makes them essential for underwater lighting, marine equipment, or industrial settings with frequent water exposure. B2B buyers in Europe and South America, where advanced water-resistant solutions are demanded, should prioritize IP68 strips despite their higher cost, as they ensure durability and long-term performance in challenging environments.

IP65 with Silicone Coating

A variation of the IP65 strip enhanced with a silicone coating to improve resistance against moisture and humidity. This type is well-suited for semi-outdoor or high-humidity environments such as food processing plants or humid climates common in parts of Africa and South America. Buyers benefit from improved cleaning ease and extended lifespan over standard IP65 strips, although they must consider the slightly increased price and the fact that these strips are still not designed for immersion.

IP68 Flexible LED Strips

Combining IP68 waterproofing with flexibility, these strips are engineered for complex architectural designs and submerged applications requiring bending or shaping. Their robust sealing ensures durability in dynamic environments such as underwater decorative lighting or curved installations. For B2B buyers in markets like France or Turkey, where aesthetic versatility and high environmental resistance are key, these strips offer premium performance but necessitate skilled installation and come at a premium price.

IP65/IP68 Hybrid Strips

Hybrid strips offer modular sealing systems that can be adjusted to meet either IP65 or IP68 standards, providing adaptability for diverse operational environments or export markets with varying regulatory requirements. This flexibility benefits manufacturers and distributors aiming to streamline inventory and cater to multiple client needs across Africa, the Middle East, and Europe. However, buyers should weigh potential additional certification requirements and initial investment costs against the operational advantages.

Key Industrial Applications of ip65 vs ip68 (important ratings for strips)

| Industry/Sector | Specific Application of ip65 vs ip68 (important ratings for strips) | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | LED indicator strips for solar panel arrays and wind turbines | Ensures durability and uninterrupted operation in harsh outdoor conditions | UV resistance, waterproofing depth, compatibility with renewable tech |

| Food & Beverage | Hygienic LED lighting strips in processing and packaging lines | Maintains sanitation standards while providing reliable illumination | Food-grade certification, IP rating for washdown environments |

| Marine & Offshore | Lighting and signaling strips on vessels and offshore platforms | Provides corrosion resistance and continuous operation under immersion | Saltwater resistance, corrosion-proof materials, certified IP68 rating |

| Transportation & Logistics | LED strips in outdoor loading docks, vehicle exteriors, and warehouses | Enhances safety and operational efficiency in dusty and wet environments | Robustness against dust ingress, impact resistance, ease of installation |

| Industrial Automation | Protective LED strips in factory floors and control panels exposed to dust and water | Minimizes downtime and maintenance costs by preventing ingress damage | Compliance with industrial standards, ease of replacement, long lifespan |

In the Renewable Energy sector, IP65 and IP68 rated LED strips are critical for outdoor solar panel arrays and wind turbines, which face continuous exposure to dust, rain, and UV radiation. IP65-rated strips offer protection against water jets and dust, suitable for less submerged or splash-prone environments. For applications where temporary submersion or heavy rain is expected, IP68-rated strips provide superior protection, ensuring uninterrupted signaling and status indication. Buyers from regions such as Africa and South America, where solar energy is expanding rapidly, should prioritize UV-resistant materials and durable waterproofing to withstand local climate challenges.

In Food & Beverage processing plants, LED strips with IP65 or higher ratings are essential in wet and washdown areas to maintain hygiene and safety. IP65 strips are typically sufficient for splash zones, while IP68 strips are preferred for sections exposed to water jets or occasional immersion during cleaning. International buyers, especially from Europe and the Middle East, must ensure the strips comply with food-grade standards and are easy to sanitize, reducing contamination risks and meeting stringent regulatory requirements.

For Marine & Offshore applications, IP68-rated LED strips are indispensable due to their ability to withstand full water immersion and resist saltwater corrosion. These strips are used for deck lighting, signaling, and safety indicators on ships and oil platforms. Businesses sourcing from Turkey or coastal African countries should focus on corrosion-resistant materials and certifications that guarantee performance in harsh marine environments, reducing maintenance frequency and operational risks.

In Transportation & Logistics, IP65 strips are commonly installed in outdoor loading docks and vehicle exteriors to provide visibility and safety lighting. In scenarios where strips might face heavy rain or dust storms, IP68 strips offer enhanced protection. Buyers in South America and the Middle East should evaluate the ease of installation and replacement, as well as the strips’ resistance to dust ingress and mechanical impacts, to maintain operational continuity in challenging logistics hubs.

Within Industrial Automation, LED strips with IP65 and IP68 ratings protect control panels and factory floor lighting from dust and water ingress, critical in maintaining uninterrupted production. IP65 strips are adequate for most indoor industrial environments, while IP68 is necessary where water spills or washdowns occur. International buyers from diverse climates should consider compliance with local industrial standards, product longevity, and availability of support services to minimize downtime and maintenance costs.

Related Video: Iran Uses Its Largest-Ever Missile For Revenge Attack Over US Strike: Khorramshahr-4 Specs | Israel

Strategic Material Selection Guide for ip65 vs ip68 (important ratings for strips)

When selecting materials for strips with IP65 and IP68 ratings, international B2B buyers must carefully consider the operational environment, durability requirements, and compliance with regional standards. The choice of material directly impacts the enclosure’s ability to resist dust, water ingress, and mechanical stresses, which is crucial for maintaining the integrity of IP-rated strips in diverse industrial and commercial applications.

Polyvinyl Chloride (PVC)

Key Properties: PVC is widely used for IP-rated strips due to its excellent chemical resistance, moderate temperature tolerance (typically -20°C to 60°C), and good electrical insulation properties. It offers solid resistance against dust and low-pressure water jets, making it suitable for IP65 applications.

Pros & Cons: PVC is cost-effective and easy to manufacture, allowing for flexible designs and customization. However, it has limited UV resistance and can become brittle under prolonged exposure to harsh sunlight or extreme temperatures, which may reduce its suitability for outdoor IP68 applications requiring submersion.

Impact on Application: PVC is ideal for indoor or sheltered outdoor environments where exposure to water is limited to splashes or rain. It is compatible with many industrial chemicals but less suitable for continuous water immersion or high-pressure washing.

International Considerations: PVC complies with ASTM D1784 and DIN standards, commonly accepted in Europe and the Middle East. Buyers in Africa and South America should verify local certifications, especially for outdoor use, due to varying climatic conditions that affect PVC longevity.

Silicone Rubber

Key Properties: Silicone rubber offers excellent flexibility, high temperature resistance (up to 200°C), and superior waterproofing capabilities, making it a preferred choice for IP68-rated strips that require submersion protection.

Pros & Cons: Its durability against UV radiation, ozone, and extreme temperatures makes silicone highly reliable for harsh environments. The main drawback is its higher cost and more complex manufacturing process compared to PVC, which can impact budget-sensitive projects.

Impact on Application: Silicone rubber is suitable for strips used in marine, industrial, and outdoor environments where continuous water exposure or immersion is expected. It maintains elasticity and sealing performance even after prolonged use.

International Considerations: Silicone meets ISO 10993 and ASTM D2000 standards, widely recognized in Europe and increasingly adopted in Middle Eastern and South American markets. African buyers should consider suppliers with certifications aligned with local regulatory frameworks for medical or food-grade applications.

Polyurethane (PU)

Key Properties: PU is known for its excellent abrasion resistance, good flexibility, and moderate chemical resistance. It performs well in temperature ranges from -40°C to 90°C and offers good waterproofing suitable for IP65 and some IP68 applications.

Pros & Cons: PU provides a balance between durability and cost, with better mechanical resistance than PVC but less temperature tolerance than silicone. It can degrade under prolonged UV exposure unless specially treated.

Impact on Application: PU strips are often used in industrial machinery and outdoor equipment where abrasion and impact resistance are important. They are suitable for environments with intermittent water exposure but may require additional UV protection for long-term outdoor use.

International Considerations: PU materials typically conform to DIN 53505 and ASTM D412 standards. Buyers in Europe and Turkey value PU for its mechanical robustness, while African and South American markets may prioritize cost-effective variants with adequate UV stabilization.

Thermoplastic Elastomers (TPE)

Key Properties: TPE combines the elasticity of rubber with the processing advantages of plastics. It offers good resistance to water, dust, and chemicals, with temperature tolerance generally between -50°C and 120°C.

Pros & Cons: TPE is recyclable and offers good environmental resistance, making it attractive for sustainable product lines. However, its water resistance varies by formulation, and not all TPE grades meet IP68 submersion requirements.

Impact on Application: TPE strips are well-suited for IP65-rated products exposed to dust and water jets but may require validation for continuous submersion scenarios. Their flexibility and ease of molding allow for complex strip designs.

International Considerations: TPE materials are compliant with ASTM D4101 and ISO 37 standards, recognized internationally. European and Middle Eastern buyers often prefer TPE for eco-friendly solutions, while buyers in Africa and South America should confirm material certifications and performance under local environmental conditions.

| Material | Typical Use Case for ip65 vs ip68 (important ratings for strips) | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Indoor/outdoor strips resistant to dust and water jets (IP65) | Cost-effective, good chemical resistance | Limited UV and temperature resistance | Low |

| Silicone Rubber | Strips requiring continuous water submersion and high durability (IP68) | Excellent waterproofing and temperature tolerance | Higher cost and complex manufacturing | High |

| Polyurethane (PU) | Abrasion-resistant strips in industrial/outdoor environments (IP65/IP68) | Good mechanical and abrasion resistance | Susceptible to UV degradation without treatment | Medium |

| Thermoplastic Elastomers (TPE) | Flexible strips for dust and water jet protection, eco-friendly options (IP65) | Recyclable, good environmental resistance | Variable water resistance, may not suit IP68 | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for ip65 vs ip68 (important ratings for strips)

Manufacturing Processes for IP65 and IP68 Rated Strips

The production of LED strips or electrical strips with IP65 and IP68 ratings involves meticulous manufacturing steps designed to meet specific ingress protection standards. Understanding these processes enables B2B buyers to assess supplier capabilities and ensure product reliability for demanding environments across Africa, South America, the Middle East, and Europe.

1. Material Preparation

- Substrate Selection: High-quality flexible printed circuit boards (FPCBs) or rigid substrates are chosen based on application needs. For IP65 and IP68 strips, substrates must withstand moisture and temperature variations.

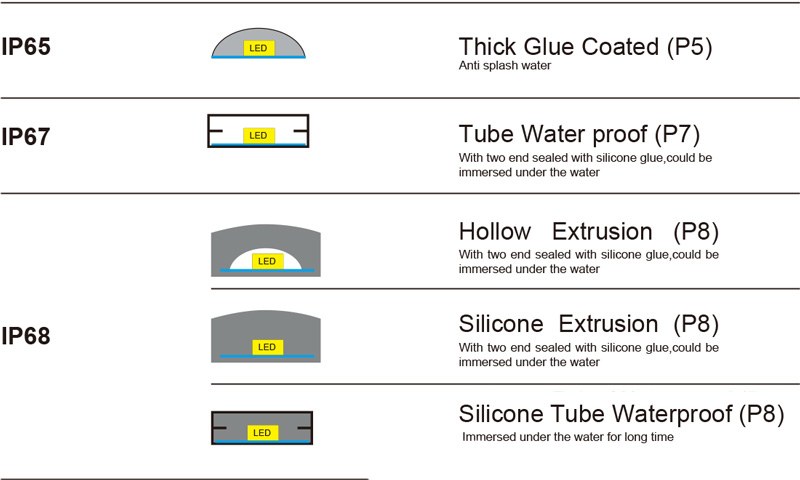

- Coating Materials: Silicone, polyurethane, or epoxy compounds are prepared for encapsulation. IP65 typically uses a silicone coating that offers splash protection, while IP68 requires full potting or encapsulation with waterproof resins to ensure submersion resistance.

- Component Sourcing: LEDs, resistors, connectors, and other electronic components are procured with certifications to meet international standards (e.g., RoHS compliance). Traceability in sourcing is critical for quality assurance.

2. Forming and Assembly

- Circuit Printing & Soldering: Precision soldering techniques, such as reflow soldering or wave soldering, are used to mount LEDs and components on the substrate. Automated assembly lines ensure consistency and reduce defects.

- Encapsulation Process:

- IP65 Strips: A thin layer of silicone coating is applied to protect against dust and water jets. This coating is typically spray-applied or dip-coated and then cured under controlled conditions.

- IP68 Strips: These require full encapsulation or potting. The strip is immersed in a silicone or polyurethane compound and cured to form a robust waterproof barrier. This process often involves vacuum degassing to eliminate air bubbles, ensuring complete waterproofing.

- Cutting and Packaging: Strips are cut to specified lengths with clean edges to maintain sealing integrity. Packaging is designed to prevent damage during transit and to preserve the IP rating until installation.

3. Finishing

- Surface Treatment: Additional surface finishing may include UV-resistant coatings or protective films, especially for outdoor applications in harsh climates.

- Connector Sealing: Connectors are sealed with rubber gaskets or heat-shrink tubing to maintain ingress protection.

- Labeling: Clear markings for voltage, wattage, and IP rating are applied for compliance and easy identification.

Quality Assurance (QA) and Quality Control (QC) Protocols

For international B2B buyers, especially those operating in diverse regulatory environments like Africa, South America, the Middle East, and Europe, verifying a supplier’s QA/QC processes is paramount. This ensures that IP65 and IP68 rated strips meet performance and safety expectations.

Relevant International and Industry Standards

- ISO 9001: The foundational quality management system standard, ensuring consistent process control and continuous improvement.

- IEC 60529: Defines the IP (Ingress Protection) ratings, crucial for validating the dust and water resistance of strips.

- RoHS (Restriction of Hazardous Substances): Particularly important for European markets, ensuring products are free from harmful substances.

- CE Marking: Required for products sold within the European Economic Area, confirming compliance with safety, health, and environmental protection standards.

- Other Certifications: Depending on the sector, buyers may look for API (American Petroleum Institute) approvals for marine or industrial applications, UL listing for safety, or ATEX certification for explosive atmospheres.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Verification of raw materials and components before production begins. This includes testing silicone or polyurethane batches for consistency and inspecting electronic parts for conformity with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, such as solder joint inspections, coating thickness measurements, and curing process validation. IPQC ensures defects are caught early, preventing costly rework.

- Final Quality Control (FQC): Comprehensive testing of finished strips, including visual inspections, functional tests, and IP rating verification.

Common Testing Methods

- Dust and Water Ingress Testing: Simulating real-world conditions using standardized test chambers. For IP65 strips, tests involve exposure to water jets at specific pressures and angles. For IP68, strips undergo prolonged submersion tests, often at depths and durations specified by the manufacturer.

- Electrical Performance Testing: Verifying voltage, current, and luminous intensity to ensure strips meet technical specifications.

- Mechanical and Environmental Stress Testing: Assessing resistance to vibration, temperature extremes, UV exposure, and chemical agents.

- Adhesion and Durability Tests: Especially important for coatings and encapsulations to ensure longevity in harsh environments.

Verifying Supplier Quality: Best Practices for B2B Buyers

International buyers should adopt a proactive approach to supplier verification to mitigate risks and ensure product compliance.

- Factory Audits: Conduct or commission third-party audits focusing on manufacturing capabilities, QA/QC processes, and certification authenticity. Audits should include process walkthroughs and document reviews.

- Review of QC Documentation: Request detailed test reports, including IP ingress test results, batch traceability, and compliance certificates. Authentic documentation confirms adherence to standards.

- Third-Party Inspection: Engage independent inspection agencies to perform random sampling and testing of products before shipment.

- Sample Testing: Obtain product samples for in-house or local laboratory testing to verify IP ratings and electrical performance.

- Ongoing Quality Monitoring: Establish clear quality agreements and periodic reviews to maintain standards over time, especially important for long-term contracts.

QC and Certification Nuances for Specific Regions

- Africa & South America: Infrastructure and climate challenges (high humidity, dust storms) demand robust IP68 rated strips for outdoor and industrial use. Buyers should prioritize suppliers with proven environmental testing and certifications recognized locally or internationally.

- Middle East: High temperatures and dust levels necessitate high-quality coatings and encapsulations. Certifications like IEC and ATEX are crucial for oil, gas, and petrochemical industries.

- Europe (Turkey, France, etc.): Stringent regulations require full compliance with CE marking and RoHS directives. Emphasis is on sustainability and environmental compliance, so suppliers with ISO 14001 and sustainability certifications gain preference.

Key Takeaways for B2B Buyers

- Understand the manufacturing nuances between IP65 and IP68 rated strips, especially encapsulation techniques and materials.

- Demand comprehensive QA/QC protocols aligned with international standards and industry-specific certifications.

- Verify supplier quality rigorously through audits, documentation review, and independent testing.

- Consider regional environmental and regulatory requirements when selecting products and suppliers.

- Establish clear quality agreements to ensure consistent supply of compliant, durable, and high-performance IP rated strips.

By prioritizing these aspects, B2B buyers can confidently source IP65 and IP68 rated strips that meet stringent quality demands and perform reliably in diverse global markets.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for ip65 vs ip68 (important ratings for strips) Sourcing

Cost Components in IP65 vs IP68 Rated Strip Sourcing

Understanding the breakdown of costs in sourcing IP65 and IP68 rated strips is essential for international B2B buyers to optimize procurement strategies. The primary cost components include:

- Materials: IP68 rated strips generally require higher-grade sealing materials such as advanced silicone or polyurethane to ensure submersion resistance, while IP65 strips use standard sealing suitable for splash and dust protection. This difference significantly impacts raw material costs.

- Labor: Manufacturing IP68 strips often involves more precise assembly and sealing processes, which can increase labor time and costs compared to IP65-rated products.

- Manufacturing Overhead: Facilities with specialized equipment for testing submersion resistance and tighter quality control contribute to higher overhead costs for IP68 products.

- Tooling: Custom tooling for precise sealing and encapsulation is often more complex and expensive for IP68-rated strips, especially when accommodating specific strip dimensions or flexible circuit designs.

- Quality Control (QC): IP68 products require rigorous water submersion testing and dust ingress verification, increasing QC expenses relative to IP65.

- Logistics: Due to delicate sealing and sometimes heavier packaging for protection, IP68 strips may incur slightly higher shipping and handling costs.

- Margin: Suppliers typically apply higher margins on IP68 products reflecting the increased complexity and value provided.

Key Price Influencers for International Buyers

Several factors influence the final pricing of IP65 and IP68 rated strips, particularly for buyers in Africa, South America, the Middle East, and Europe:

- Volume and Minimum Order Quantity (MOQ): Larger orders often attract volume discounts. For smaller buyers or those requiring customization, MOQ requirements can drive unit prices higher.

- Specifications and Customization: Custom lengths, color options, integrated connectors, or specific voltage/current ratings add to costs. IP68 customization is usually more expensive due to the need for maintaining waterproof integrity.

- Materials Quality and Certifications: Strips made from certified materials compliant with international standards (e.g., RoHS, CE) will cost more but reduce risks related to compliance and reliability.

- Supplier Factors: Established suppliers with proven track records, local presence, or distribution hubs in target regions might offer better pricing and reduced lead times.

- Incoterms: Delivery terms (FOB, CIF, DDP) significantly affect landed costs. Buyers should factor in import duties, taxes, and customs clearance fees, which vary by country and region.

Strategic Buyer Tips for Cost-Efficient Sourcing

- Negotiate Beyond Price: Engage suppliers on lead times, payment terms, and after-sales service to improve overall value.

- Evaluate Total Cost of Ownership (TCO): Consider installation, maintenance, and potential downtime costs. Investing in IP68 strips may reduce replacement frequency in harsh environments common in regions like the Middle East or coastal parts of South America.

- Leverage Regional Trade Agreements: Buyers in Europe (e.g., France, Turkey) can benefit from EU trade agreements or customs unions to lower import tariffs.

- Request Samples and Certifications: Prioritize suppliers who provide product samples and verifiable certifications to avoid costly quality issues post-purchase.

- Consider Logistics Partners: Use freight forwarders familiar with regional logistics challenges to reduce delays and unexpected charges.

- Plan for Seasonality and Demand Fluctuations: Bulk purchasing ahead of peak demand seasons (e.g., rainy seasons in Africa) can secure better pricing and avoid supply shortages.

Indicative Pricing Disclaimer

Pricing for IP65 and IP68 rated strips varies widely based on technical specifications, supplier location, order volume, and customization. As a guideline, IP68 strips generally command a premium of 15-40% over IP65 due to enhanced material and testing requirements. Buyers should request detailed quotations and validate all costs, including hidden fees related to international shipping and local import regulations.

By comprehensively analyzing cost components and price influencers, international B2B buyers can make informed sourcing decisions that balance upfront costs with long-term reliability and operational efficiency.

Spotlight on Potential ip65 vs ip68 (important ratings for strips) Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘ip65 vs ip68 (important ratings for strips)’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ip65 vs ip68 (important ratings for strips)

Critical Technical Properties for IP65 vs IP68 Rated Strips

When sourcing IP65 or IP68 rated strips, understanding the essential technical properties is crucial for ensuring product performance and compliance with your application needs.

-

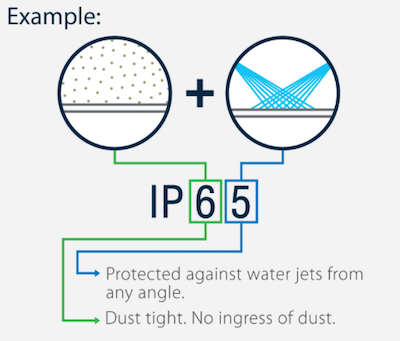

Ingress Protection (IP) Rating

The IP rating is a two-digit code defining dust and water resistance. For strips, IP65 ensures total dust ingress protection and resistance to water jets, suitable for outdoor splash or rain exposure. IP68 offers complete dust protection plus continuous immersion in water (typically up to 1.5 meters for 30 minutes or more). Selecting the correct IP rating depends on your environmental exposure risks. -

Material Grade and Durability

Materials like silicone, PVC, or polyurethane are common for rated strips. The chosen material must maintain flexibility, UV resistance, and chemical stability under operating conditions. For harsh climates in regions like the Middle East or coastal Africa, UV and saltwater resistance are especially important to prevent degradation. -

Tolerance and Dimensional Precision

Tight manufacturing tolerances ensure consistent fit and sealing performance, critical for maintaining IP ratings. Variations can compromise enclosure integrity, allowing dust or water ingress. Buyers should verify tolerance specifications and quality control measures with suppliers. -

Temperature Range

Rated strips must operate reliably within specified temperature ranges. This is vital for markets with extreme weather variations such as parts of South America or Turkey. Materials that become brittle in cold or soften in heat risk IP seal failure. -

Chemical and Abrasion Resistance

Exposure to industrial chemicals, oils, or pollutants can degrade sealing strips. Resistance to such agents prolongs product life and reduces maintenance costs. This property is crucial for industrial and marine applications common in Europe and the Middle East. -

Compression Set and Recovery

This measures the strip’s ability to return to its original shape after compression, impacting long-term sealing effectiveness. A low compression set value means the strip maintains a reliable seal over time, reducing replacement frequency.

Key Trade Terminology for International B2B Buyers

Navigating the procurement process for IP-rated strips involves understanding common industry jargon. Here are terms frequently encountered in international B2B transactions:

-

OEM (Original Equipment Manufacturer)

Refers to companies producing parts or products that are branded and sold by another company. When sourcing IP65/IP68 strips, OEMs may offer customized solutions or bulk pricing advantageous for large-scale projects. -

MOQ (Minimum Order Quantity)

The smallest amount of product a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory planning, especially for buyers in emerging markets with limited storage capacity. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specific products. Detailed RFQs help suppliers provide accurate quotes and enable buyers to compare offers effectively. -

Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Knowing Incoterms ensures clarity on cost and risk allocation during import/export. -

Lead Time

The duration from order placement to product delivery. For critical applications, shorter lead times reduce downtime. Buyers should confirm lead times upfront, considering potential delays in customs or logistics, especially in regions like South America or Africa. -

Compliance Certificates

Documents certifying that products meet relevant standards (e.g., IEC IP ratings, RoHS, REACH). Requesting compliance certificates safeguards quality and regulatory adherence, which is vital when importing to Europe or the Middle East.

Actionable Insight:

For buyers in Africa, South America, the Middle East, and Europe, focusing on these technical properties and mastering trade terminology streamlines supplier evaluation and procurement efficiency. Request detailed product datasheets and certifications, clarify MOQ and lead times early, and confirm Incoterms to avoid unexpected costs or delays. This approach ensures you procure IP65 or IP68 strips that meet both performance and commercial requirements in your target markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ip65 vs ip68 (important ratings for strips) Sector

Market Overview & Key Trends

The global market for IP65 and IP68 rated strips is experiencing robust growth driven by rising industrial automation, expanding outdoor infrastructure projects, and increasing demand for durable electronic components across various sectors. For international B2B buyers, especially in Africa, South America, the Middle East, and Europe (notably Turkey and France), understanding the nuances of these ingress protection ratings is critical to sourcing the right products for region-specific environmental challenges.

Key Market Drivers:

- Industrial Expansion: Emerging economies in Africa and South America are investing heavily in manufacturing and infrastructure, creating a demand for ruggedized strips and enclosures that can withstand dust and water exposure.

- Smart Cities & IoT Growth: Europe and the Middle East are at the forefront of smart city initiatives, driving the need for IP65/IP68 rated components in outdoor lighting, signage, and sensor networks.

- Climate Adaptation: Regions with harsh climates, such as the Middle East’s arid environments or South America’s tropical conditions, require strips with higher ingress protection to ensure longevity and reduce maintenance costs.

Emerging B2B Sourcing Trends:

- Customization & Modular Solutions: Buyers increasingly seek suppliers offering tailored IP65/IP68 strips to fit specific project needs, especially in sectors like telecommunications and energy.

- Digital Procurement Platforms: International buyers are leveraging online sourcing platforms that provide detailed technical specifications and certifications, enhancing transparency and supplier comparison.

- Focus on Total Cost of Ownership (TCO): Beyond upfront costs, buyers prioritize durability and maintenance savings, favoring IP68-rated strips for applications involving submersion or heavy moisture exposure, while opting for IP65 where splash resistance suffices.

Market Dynamics:

- Supply Chain Localization: To mitigate risks from global disruptions, buyers in Europe and the Middle East are favoring regional manufacturers or distributors who provide faster lead times and localized support.

- Compliance with Standards: Ensuring compliance with international standards (IEC, NEMA) and local regulations is a critical factor influencing supplier selection.

- Competitive Pricing Pressure: Emerging markets often balance between cost constraints and the need for quality, making supplier negotiation and volume-based pricing essential considerations.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal factor in procurement decisions for IP65 and IP68 rated strips, driven by regulatory pressures and corporate social responsibility mandates across regions. International buyers are increasingly scrutinizing the environmental impact of materials and manufacturing processes used in these products.

Environmental Impact Considerations:

- Material Selection: Preference is shifting towards strips made from recyclable or biodegradable materials, and coatings that minimize toxic chemicals, reducing environmental footprint during production and disposal.

- Energy Efficiency: Suppliers incorporating energy-efficient manufacturing techniques and renewable energy sources are gaining favor among eco-conscious buyers.

- Waste Reduction: Modular and repairable designs help extend product lifecycle, reducing electronic waste, a growing concern in all target regions.

Ethical Supply Chains:

- Transparency and Traceability: Buyers demand visibility into the entire supply chain to ensure compliance with labor standards and fair trade practices, especially when sourcing from regions with less regulated manufacturing environments.

- Green Certifications: Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 environmental management certification are increasingly required by buyers to validate sustainability claims.

- Circular Economy Integration: Leading suppliers are adopting circular economy principles, offering take-back programs and refurbishing services that align with sustainability goals.

For B2B buyers in Africa, South America, the Middle East, and Europe, integrating these sustainability criteria into procurement strategies not only enhances brand reputation but also reduces long-term operational risks and costs.

Brief Evolution and History of IP Ratings Relevant to Strips

The IP (Ingress Protection) rating system was established by the International Electrotechnical Commission (IEC) to provide a standardized way to classify the degree of protection electronic enclosures and strips offer against dust and water ingress. Since its inception in the mid-20th century, the IP rating system has become a global benchmark for product durability, particularly in industrial and outdoor applications.

Initially, IP ratings focused on basic dust and water resistance, but evolving industry demands led to the introduction of higher protection levels such as IP65 and IP68. IP65 emerged as a popular standard for devices requiring protection against dust and low-pressure water jets, while IP68 was developed to certify equipment capable of continuous immersion in water, catering to more extreme environments.

Over time, this evolution has enabled manufacturers to innovate with advanced sealing technologies and materials, resulting in strips and enclosures that meet increasingly stringent performance requirements. For B2B buyers, understanding this historical context underscores the importance of selecting products with appropriate IP ratings aligned with their application environments and operational longevity goals.

Related Video: Crude Oil Prices & Global Trade Market Seen Stabilising After Trump Announced Iran Israel Ceasefire

Frequently Asked Questions (FAQs) for B2B Buyers of ip65 vs ip68 (important ratings for strips)

-

How can I effectively vet suppliers of IP65 and IP68 rated strips for international B2B sourcing?

When sourcing IP65 or IP68 rated strips, especially from regions like Africa, South America, or the Middle East, conduct thorough due diligence. Verify supplier certifications such as ISO 9001 and relevant IP testing reports. Request samples to assess product quality firsthand. Use trade references and check their export experience to your target markets (e.g., Turkey, France). Engaging suppliers with transparent communication and a proven track record reduces risks related to product authenticity and compliance. -

Is it possible to customize IP ratings or strip designs to meet specific application needs?

Yes, many manufacturers offer customization for IP-rated strips, including modifications to length, adhesive backing, LED density, and IP enclosure materials. For international buyers, ensure the supplier understands your environmental and regulatory requirements, such as exposure to dust or water depth. Customization often requires clear technical specifications upfront and may affect lead times and pricing, so negotiate these terms early in the procurement process. -

What are typical minimum order quantities (MOQs) and lead times for IP65 vs IP68 rated strips in international B2B trade?

MOQs can vary widely depending on manufacturer capacity and customization level. Standard IP65 strips usually have lower MOQs (e.g., 100-500 meters), while IP68 rated strips, given their more complex sealing, may require higher MOQs or batch sizes. Lead times typically range from 3 to 8 weeks, factoring in production and testing. Buyers should clarify MOQs and lead times during contract negotiation to align with project timelines and cash flow management.

Illustrative Image (Source: Google Search)

-

Which payment terms are common and advisable for international purchases of IP65 and IP68 strips?

For international B2B transactions, especially with suppliers in emerging markets, payment terms often include a 30% advance deposit with the balance paid upon shipment or delivery. Letters of credit (LC) or escrow services can offer additional security. Buyers from Europe or the Middle East should negotiate terms that balance supplier trust and their risk tolerance, ensuring that payment milestones align with quality inspections and shipment schedules. -

What quality assurance and certifications should international buyers demand for IP65 and IP68 strips?

Buyers should insist on third-party certifications such as IEC standards compliance for IP ratings, RoHS for hazardous substances, and CE marking for European markets. Factory inspection reports and batch test results for waterproofing and dustproofing are critical. For high-volume or critical applications, consider requesting sample testing by independent labs to verify claims. Robust QA documentation supports smoother customs clearance and market acceptance. -

How can international buyers manage logistics challenges when importing IP-rated strips from diverse regions?

Plan for potential customs delays, especially for shipments to Africa or South America where import regulations may vary. Use freight forwarders familiar with your destination countries and consider consolidated shipments to optimize costs. Verify packaging standards to protect IP-rated strips from damage during transit. Additionally, understanding Incoterms (e.g., FOB, CIF) is essential to define responsibility for shipping risks and costs clearly. -

What strategies can help resolve disputes related to product quality or delivery delays in cross-border IP strip procurement?

Establish clear contractual terms including specifications, delivery schedules, and penalty clauses. Use arbitration clauses specifying neutral venues and governing law favorable to both parties. Maintain detailed communication records and inspection reports. Early engagement with suppliers upon identifying issues often facilitates amicable resolutions. For persistent problems, leveraging trade associations or local chambers of commerce in supplier countries can provide mediation support. -

How do IP65 and IP68 ratings impact after-sales service and warranty considerations for international buyers?

Higher IP ratings like IP68 often come with stricter warranty conditions due to the complexity of waterproofing. Buyers should confirm warranty terms explicitly cover environmental exposures expected in their markets, such as heavy rains in Africa or marine conditions in the Middle East. After-sales support including replacement policies, technical assistance, and local service partnerships can significantly reduce downtime and total cost of ownership. Negotiate these service elements before finalizing purchase agreements.

Strategic Sourcing Conclusion and Outlook for ip65 vs ip68 (important ratings for strips)

Choosing between IP65 and IP68 ratings for strips hinges on understanding your specific operational environment and protection requirements. IP65 is ideal for applications needing robust dust protection and resistance against water jets or splashes, making it suitable for many outdoor or industrial settings where immersion is unlikely. In contrast, IP68 offers superior protection, guaranteeing dust-tight integrity and the ability to withstand continuous submersion, which is critical for harsh environments such as marine, heavy industrial, or outdoor installations subject to flooding.

For international B2B buyers across Africa, South America, the Middle East, and Europe, strategic sourcing of IP-rated strips should prioritize not only compliance with these protection standards but also factors such as supplier reliability, certification authenticity, customization capabilities, and after-sales support. Sourcing partners that offer tailored solutions and local service presence can significantly reduce risk and total cost of ownership.

Looking ahead, the demand for high-performance, durable strips with precise IP ratings will grow alongside expanding industrial automation and outdoor infrastructure projects worldwide. Buyers are encouraged to engage closely with manufacturers who demonstrate innovation in enclosure technology and sustainability practices. Proactively aligning your procurement strategy with evolving IP standards ensures resilience, operational continuity, and competitive advantage in diverse markets.