Guide to Flexible Neon Light

- Introduction: Navigating the Global Market for flexible neon light

- Understanding flexible neon light Types and Variations

- Key Industrial Applications of flexible neon light

- Strategic Material Selection Guide for flexible neon light

- In-depth Look: Manufacturing Processes and Quality Assurance for flexible neon light

- Comprehensive Cost and Pricing Analysis for flexible neon light Sourcing

- Spotlight on Potential flexible neon light Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for flexible neon light

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the flexible neon light Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of flexible neon light

- Strategic Sourcing Conclusion and Outlook for flexible neon light

Introduction: Navigating the Global Market for flexible neon light

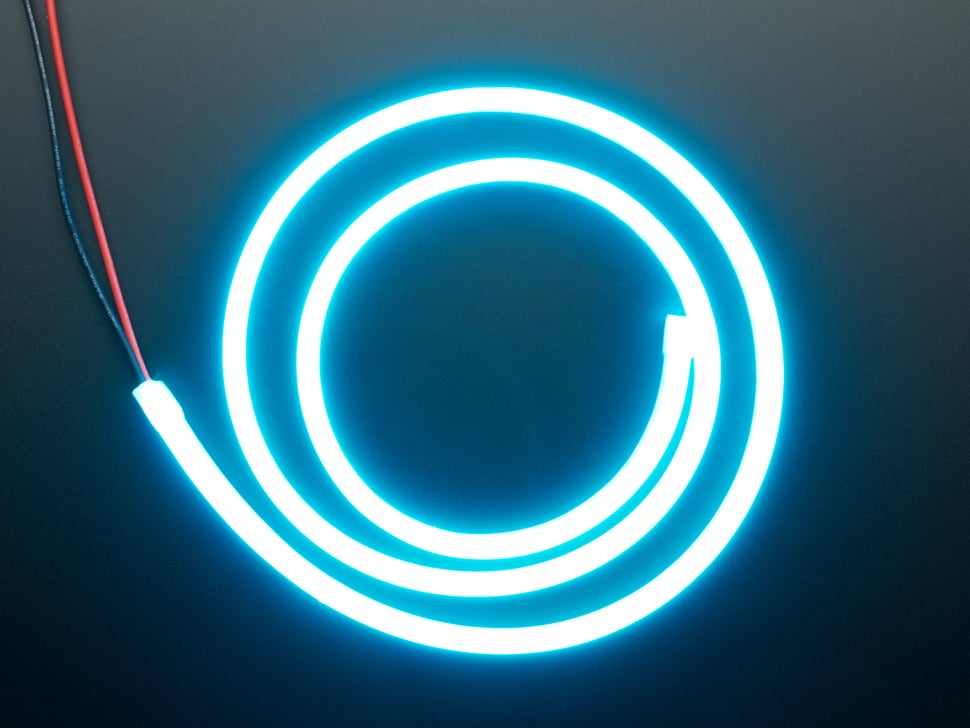

Flexible neon lighting is revolutionizing the way businesses approach illumination, combining the iconic appeal of traditional neon with modern advancements in energy efficiency, durability, and design versatility. For B2B buyers across Africa, South America, the Middle East, and Europe—including dynamic markets such as Kenya and Indonesia—flexible neon lights represent a strategic asset for enhancing commercial signage, architectural features, retail environments, and event spaces with vibrant, customizable lighting solutions.

The growing global demand for flexible neon lighting underscores its critical role in delivering visually striking, cost-effective, and sustainable lighting that adapts to diverse applications and climates. However, navigating this complex market requires a thorough understanding of product variations, material technologies, manufacturing processes, and quality assurance standards that directly influence performance and longevity.

This guide offers an authoritative roadmap for international buyers, covering essential aspects such as:

- Types and variations of flexible neon lights, including single-color, RGB, waterproof, and digitally controllable options

- Material selection insights focusing on silicone, PVC, and polyurethane casings that affect flexibility and durability

- Manufacturing and quality control processes that ensure consistent brightness, weather resistance, and safety compliance

- Supplier evaluation strategies emphasizing reliability, certifications, and customization capabilities

- Comprehensive cost analysis to optimize budgeting and negotiate favorable terms

- Market dynamics and sourcing trends tailored to regional demands and regulatory frameworks

- Frequently asked questions addressing common procurement challenges and technical considerations

By leveraging this knowledge, B2B buyers can confidently identify high-quality flexible neon lighting solutions that meet stringent international standards and local market requirements. This empowers businesses to reduce procurement risks, enhance project outcomes, and foster sustainable supplier partnerships in an increasingly competitive global landscape.

Understanding flexible neon light Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicone Encased LED Neon Flex | Flexible LED strip encased in durable silicone for smooth light diffusion | Architectural lighting, outdoor signage, retail displays | + High durability and weather resistance – Higher cost than PVC options |

| PVC Encased Flexible Neon | LED strips protected by PVC casing, offering good flexibility and cost-effectiveness | Indoor signage, home décor, event lighting | + Cost-effective, good flexibility – Less durable outdoors, lower heat resistance |

| RGB Flexible Neon Strip | Multi-color LED strips capable of dynamic color changes and effects | Dynamic signage, event lighting, entertainment venues | + Versatile color options, customizable – Requires compatible controllers, higher price |

| Waterproof IP65/IP68 Flexible Neon | Neon flex with enhanced waterproofing for harsh environments | Outdoor signage, marine applications, architectural façades | + Suitable for wet environments, robust – Slightly bulkier, premium pricing |

| Miniature Diameter Flexible Neon | Slim and ultra-flexible neon strips for intricate designs | Fine-detail signage, custom art installations | + Enables complex shapes, discreet lighting – More fragile, specialized handling needed |

Silicone Encased LED Neon Flex

This type features a flexible LED strip encased in silicone, providing excellent light diffusion and high durability. It is well-suited for demanding environments including outdoor architectural lighting and commercial signage. For B2B buyers, silicone encased neon flex offers superior weather resistance and longevity, making it a worthwhile investment for projects requiring robust, long-lasting illumination. Consider the higher initial cost balanced against lower maintenance and replacement expenses.

PVC Encased Flexible Neon

PVC encased flexible neon lights are a budget-friendly option, widely used in indoor applications such as retail displays, event décor, and residential lighting. While offering good flexibility and ease of installation, PVC casings have lower heat resistance and are less durable outdoors. Buyers targeting indoor or short-term projects benefit from the cost-efficiency of PVC neon flex but should avoid harsh or prolonged outdoor exposure.

RGB Flexible Neon Strip

RGB flexible neon strips allow full-color customization through integrated red, green, and blue LEDs, controlled via compatible systems. This type is ideal for dynamic signage, entertainment venues, and event lighting where color versatility enhances visual impact. B2B buyers should evaluate the additional costs of controllers and ensure supplier support for customization. The flexibility in design and color makes RGB strips a premium choice for high-visibility applications.

Waterproof IP65/IP68 Flexible Neon

Designed with advanced waterproofing standards, these flexible neon strips are perfect for outdoor environments exposed to rain, humidity, or marine conditions. Their robust casing protects against dust and water ingress, ensuring reliable performance in harsh climates. B2B buyers in regions with challenging weather conditions, such as coastal areas in Africa or the Middle East, should prioritize IP-rated neon flex for durability and compliance with safety standards.

Miniature Diameter Flexible Neon

This variation boasts a slim profile and exceptional flexibility, enabling intricate shapes and fine detailing in signage or artistic installations. It suits projects demanding subtle, precise lighting effects, such as boutique retail branding or custom architectural accents. Buyers should note the increased fragility and need for careful handling during installation. Sourcing from experienced manufacturers who provide technical support is crucial for successful deployment.

Related Video: How to Cut and Connect Led Neon strip Flexible Strip Light | Neon Home Decor | RGB | Rope Light |

Key Industrial Applications of flexible neon light

| Industry/Sector | Specific Application of flexible neon light | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Hospitality | Storefront and interior accent lighting | Enhances brand visibility and customer experience | Durability for indoor/outdoor use, color customization, energy efficiency |

| Architecture & Urban Design | Architectural contour and façade illumination | Highlights building features, adds aesthetic appeal | Weather resistance, flexible installation options, compliance with local codes |

| Events & Entertainment | Dynamic event lighting and stage design | Creates immersive atmospheres, easy customization | Flexibility, ease of installation/removal, vibrant color options |

| Advertising & Signage | Outdoor signage and promotional displays | Increases visibility and brand recall | UV resistance, waterproof rating, long lifespan, certification compliance |

| Transportation & Infrastructure | Safety and guidance lighting in tunnels, stations, and terminals | Improves safety with clear, continuous illumination | High durability, compliance with safety standards, energy efficiency |

Flexible neon lights are extensively used in retail and hospitality sectors to create captivating storefronts and interior accent lighting that draw customers and enhance brand identity. These lights offer vibrant, continuous illumination that can be customized to match brand colors, providing an energy-efficient alternative to traditional neon. For international buyers in regions like Africa and South America, sourcing flexible neon lights that withstand local environmental conditions and offer ease of installation is crucial to maximize return on investment and ensure long-term performance.

Illustrative Image (Source: Google Search)

In architecture and urban design, flexible neon lights are employed to accentuate building contours, facades, and public spaces. Their flexibility allows designers to follow complex shapes and edges, adding modern aesthetic value while improving nighttime visibility. Buyers from Europe and the Middle East must prioritize products with strong weather resistance and compliance with local building regulations to ensure durability and legal conformity in outdoor applications.

The events and entertainment industry leverages flexible neon lights for dynamic stage lighting and immersive event environments. The ability to easily shape and install these lights enables rapid setup and teardown, critical for temporary venues and festivals. For buyers from emerging markets such as Kenya or Indonesia, sourcing lightweight, flexible, and color-rich lighting solutions that can withstand frequent handling and transport is essential.

In advertising and signage, flexible neon lights replace traditional neon tubes to provide eye-catching, energy-efficient outdoor displays. Their superior UV and waterproof properties ensure longevity under harsh sun and rain conditions common in many African and South American climates. B2B buyers should focus on certifications related to safety and weatherproofing to guarantee reliable performance and compliance with regional standards.

Finally, in transportation and infrastructure, flexible neon lights serve as safety and guidance lighting in tunnels, train stations, and airports. Their continuous illumination and flexibility help create clear, visible pathways that enhance passenger safety and operational efficiency. Buyers from Europe and the Middle East must ensure these lights meet stringent safety regulations and offer robust energy efficiency to support sustainable infrastructure development.

Related Video: LED Flexible Neon Strip Light Installation Instruction

Strategic Material Selection Guide for flexible neon light

When selecting materials for flexible neon lights, international B2B buyers must carefully evaluate key material properties, manufacturing implications, and regional compliance requirements. The choice of material directly affects product durability, light diffusion quality, environmental resistance, and installation versatility. Below is an in-depth analysis of four common materials used in flexible neon light construction: Silicone, PVC, Polyurethane (PU), and Thermoplastic Elastomer (TPE).

Silicone

Key Properties: Silicone is highly flexible, with excellent thermal stability typically ranging from -60°C to +230°C. It offers superior UV resistance, weatherproofing, and chemical inertness, making it ideal for outdoor and harsh environment applications. Silicone’s excellent light diffusion properties ensure a smooth and consistent glow.

Pros & Cons: Silicone’s durability and resistance to temperature extremes and environmental factors make it a premium choice. However, it tends to have a higher raw material cost and requires more sophisticated extrusion equipment, which can increase manufacturing complexity and lead times. Its elasticity also helps prevent cracking or deformation over long-term use.

Impact on Application: Silicone is well-suited for outdoor signage, architectural lighting, and applications requiring exposure to sunlight, moisture, or temperature fluctuations. Its resistance to corrosion and UV degradation makes it a preferred material in tropical and desert climates common in parts of Africa, the Middle East, and South America.

Considerations for B2B Buyers: Buyers in regions like Kenya, South Africa, Brazil, and the Middle East should verify compliance with international standards such as ASTM D2000 (rubber specifications) and IEC 60598 (luminaire safety). Silicone materials often meet stringent fire retardancy and environmental certifications, which are increasingly demanded in European markets. The higher upfront cost is offset by longevity and reduced maintenance.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a widely used thermoplastic with good mechanical strength and moderate flexibility. It typically withstands temperatures from -15°C to +60°C and offers decent resistance to water and chemicals, though it is less UV stable than silicone.

Pros & Cons: PVC is cost-effective and easier to process, making it attractive for large-volume production. However, it is prone to yellowing and brittleness under prolonged UV exposure, limiting outdoor lifespan unless treated with UV stabilizers. PVC also has lower heat resistance and may emit harmful fumes if burned.

Impact on Application: PVC is commonly used for indoor flexible neon lights or short-term outdoor installations where cost constraints are critical. It is suitable for retail displays, event lighting, and indoor architectural accents.

Considerations for B2B Buyers: Buyers in emerging markets with budget constraints, such as parts of Africa and South America, often favor PVC for its affordability. However, they should ensure suppliers provide UV-stabilized grades and verify compliance with RoHS and REACH regulations to avoid hazardous substances. European buyers typically require PVC materials with enhanced fire safety ratings (e.g., UL94 V-0).

Polyurethane (PU)

Key Properties: PU offers excellent abrasion resistance, flexibility, and chemical resistance. It generally withstands temperatures between -40°C and +90°C and provides good resistance to oils and solvents. PU coatings enhance mechanical protection without sacrificing flexibility.

Pros & Cons: PU materials are more durable than PVC and can maintain flexibility over a wider temperature range. The manufacturing process is moderately complex, requiring precise control during coating or extrusion. PU tends to be more expensive than PVC but less costly than high-grade silicone.

Impact on Application: PU is ideal for flexible neon lights exposed to mechanical stress or chemical exposure, such as in industrial signage or outdoor retail environments. Its abrasion resistance makes it suitable for installations in high-traffic areas.

Considerations for B2B Buyers: For buyers in regions with industrial pollution or harsh environmental conditions (e.g., Middle East urban centers, South American industrial zones), PU offers a balanced solution. Compliance with ISO 9001 manufacturing standards and local environmental regulations should be verified. PU’s moderate cost and durability make it a versatile choice for mid-tier projects.

Thermoplastic Elastomer (TPE)

Key Properties: TPE combines the elastic properties of rubber with the recyclability of plastics. It offers good flexibility, chemical resistance, and can operate in temperature ranges from -50°C to +120°C. TPE is also lightweight and can be formulated to provide varying degrees of hardness.

Pros & Cons: TPE is recyclable and environmentally friendlier compared to PVC. It allows for easy color customization and has good resistance to UV and weathering, though not as robust as silicone. Manufacturing TPE flexible neon lights is relatively straightforward, but material costs can vary widely depending on formulation.

Impact on Application: TPE is increasingly used in markets prioritizing sustainability and environmental compliance, such as Europe. It suits indoor and semi-outdoor applications where moderate durability and eco-friendliness are valued, including retail and hospitality sectors.

Considerations for B2B Buyers: Buyers from Europe and environmentally conscious markets should consider TPE for compliance with evolving environmental directives (e.g., EU REACH, WEEE). In Africa and South America, TPE can be a competitive alternative if suppliers offer cost-effective formulations. Verifying supplier certifications and material traceability is critical to ensure consistent quality.

Summary Table of Materials for Flexible Neon Light

| Material | Typical Use Case for flexible neon light | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Outdoor signage, architectural lighting, harsh environments | Excellent thermal stability and UV resistance | Higher cost and complex manufacturing | High |

| PVC | Indoor lighting, event décor, budget-sensitive projects | Cost-effective and easy to manufacture | Poor UV stability, limited temperature range | Low |

| Polyurethane (PU) | Industrial signage, abrasion-prone outdoor installations | High abrasion and chemical resistance | Moderate cost, manufacturing complexity | Medium |

| Thermoplastic Elastomer (TPE) | Sustainable indoor and semi-outdoor lighting | Recyclable, flexible, good environmental profile | Variable cost, less UV resistant than silicone | Medium |

This guide equips B2B buyers across Africa, South America, the Middle East, and Europe with actionable insights to select materials that balance performance, cost, and regional compliance. Prioritizing material properties aligned with application environments and market regulations will ensure procurement of flexible neon lights that deliver durability, safety, and aesthetic appeal.

In-depth Look: Manufacturing Processes and Quality Assurance for flexible neon light

Flexible neon lights, often realized through LED neon flex technology, are crafted through meticulous manufacturing stages that emphasize precision, durability, and aesthetic quality. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding these processes and quality assurance measures is crucial to sourcing products that meet stringent performance and regulatory requirements.

Manufacturing Process Overview

The production of flexible neon lights involves several core stages, each critical to ensuring the final product’s flexibility, brightness, and longevity.

1. Material Preparation

- LED Strip Fabrication: The foundation is a flexible LED strip, typically made of high-quality SMD (Surface Mounted Device) LEDs mounted on a flexible printed circuit board (FPCB). These strips are designed for uniform light distribution and energy efficiency.

- Silicone or PVC Compound Preparation: The outer casing, usually made from silicone or PVC, is prepared by mixing base materials with diffusion powders or pigments. This step controls the light transmission properties and mechanical flexibility.

- Copper Wire and Conductors: High-purity copper wires are prepped for optimal electrical conductivity and corrosion resistance, important for durability in diverse climatic conditions.

Illustrative Image (Source: Google Search)

2. Forming and Extrusion

- Integrated Extrusion Process: The LED strip is fed into an extrusion machine where the silicone or PVC material is co-extruded around the strip. This process encapsulates the LEDs within a flexible, weatherproof sheath, ensuring consistent light diffusion and protection against environmental factors like UV radiation and moisture.

- Manual Insertion (Alternative Method): Some manufacturers opt for manually inserting LED strips into pre-formed silicone tubes, which allows for smaller production runs or custom designs but may affect uniformity and durability.

3. Assembly

- Cutting and Soldering: After extrusion, the flexible neon lights are cut to precise lengths at designated points. Connection terminals are soldered, and connectors or power supplies are attached according to customer specifications.

- Sealing and End-Capping: Ends are sealed with silicone plugs or plastic caps to prevent ingress of dust and water, critical for outdoor or industrial applications.

4. Finishing and Packaging

- Surface Inspection and Cleaning: The lights undergo surface inspections for defects like bubbles, discoloration, or uneven extrusion. They are cleaned and dried to ensure no contaminants affect performance.

- Packaging: Products are carefully coiled or laid flat, then packaged with protective materials to prevent deformation during transit. Customized packaging may be offered to meet import regulations or branding requirements.

Quality Assurance and Control (QA/QC)

Ensuring consistent quality in flexible neon lights requires adherence to international standards and rigorous testing throughout the manufacturing cycle.

Key International Standards

- ISO 9001: This standard governs quality management systems and ensures manufacturers have processes to consistently meet customer and regulatory requirements.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, important for buyers targeting environmentally conscious markets.

- IP Ratings (Ingress Protection): IP65 to IP68 ratings confirm water and dust resistance, vital for outdoor and harsh environment applications.

- Additional Certifications: Depending on region, certifications such as UL (North America), SAA (Australia), or regional electrical safety marks may be relevant.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Raw materials such as LEDs, silicone compounds, and copper wires are inspected for compliance with specifications before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during extrusion, soldering, and assembly stages to detect issues like LED alignment, silicone integrity, and solder joint quality.

- Final Quality Control (FQC): Comprehensive testing of finished products including visual inspection, electrical performance, and physical durability tests.

Common Testing Methods

- Electrical Testing: Voltage, current, and power consumption are measured to ensure efficiency and safety.

- Light Uniformity and Brightness: Photometric testing verifies that the neon light emits consistent and vibrant illumination without dark spots.

- Durability Tests: Flexibility tests simulate bending and twisting to confirm the neon light maintains functionality under mechanical stress.

- Environmental Resistance: Samples undergo water immersion, UV exposure, and temperature cycling to validate IP ratings and material robustness.

- Safety Tests: Insulation resistance, dielectric strength, and flame retardancy are evaluated to prevent electrical hazards.

How B2B Buyers Can Verify Supplier Quality

For buyers, especially in regions with varying regulatory environments like Africa (e.g., Kenya), South America, the Middle East, and Europe, validating a supplier’s QC processes is critical to mitigate risks.

- Factory Audits: Conduct on-site or third-party audits focusing on production capabilities, quality management systems, and compliance with international standards.

- Review of QC Documentation: Request detailed inspection reports, test certificates (e.g., CE, RoHS), and batch traceability documents to confirm consistent quality.

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing before shipment to ensure products meet contractual requirements.

- Pilot Orders and Samples: Evaluate product samples under real-use conditions, focusing on flexibility, brightness, and durability.

- Supplier Certifications: Verify validity and scope of certifications through official registries or issuing bodies.

QC and Certification Nuances for International Buyers

- Regional Regulatory Compliance: Buyers must ensure products comply with local regulations, which may differ significantly. For instance, European markets demand CE and RoHS compliance, while Middle Eastern buyers may require SASO certification.

- Environmental and Energy Efficiency Standards: Increasingly, buyers in Europe and parts of South America seek products with low energy consumption and environmentally friendly materials to align with sustainability goals.

- Customs and Import Documentation: Proper certification expedites customs clearance and avoids penalties. Buyers should clarify documentation requirements upfront with suppliers.

- After-Sales Support and Warranty: Robust warranties and supplier responsiveness to defects are key indicators of QC commitment, influencing long-term procurement decisions.

By gaining a thorough understanding of the manufacturing and quality assurance landscape of flexible neon lights, international B2B buyers can confidently navigate supplier selection, ensure regulatory compliance, and secure high-performance products tailored to diverse market needs. This knowledge is especially valuable in emerging and established markets where lighting solutions play a pivotal role in infrastructure, retail, and architectural innovation.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for flexible neon light Sourcing

Breakdown of Cost Components in Flexible Neon Light Sourcing

When sourcing flexible neon lights, understanding the underlying cost structure is essential for effective budgeting and supplier negotiation. The primary cost components include:

-

Materials: The cost of raw materials—primarily LED chips, silicone or PVC casings, flexible PCB substrates, and diffusion powders—forms the bulk of the expense. High-quality, durable materials that ensure longevity and vibrant illumination typically command higher prices but reduce replacement frequency.

-

Labor: Skilled labor is required for LED strip assembly, silicone extrusion, soldering, and quality checks. Labor costs vary significantly by manufacturing location, affecting overall pricing especially for buyers sourcing from countries with higher wages.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor costs related to production management, contributing to the per-unit cost.

-

Tooling and Equipment: Investment in extrusion dies, soldering machines, and testing equipment is amortized across production volumes. Custom tooling for unique designs or specifications increases upfront costs.

-

Quality Control (QC): Rigorous inspection processes, including photometric testing, waterproofing verification, and compliance checks for certifications (e.g., CE, RoHS), add to the cost but are critical for ensuring product reliability.

-

Logistics and Shipping: Freight charges, customs duties, and import taxes vary by origin and destination, impacting landed cost. International buyers should factor in insurance and potential delays.

-

Supplier Margin: Margins depend on supplier positioning, brand reputation, and market demand. Established suppliers with certifications and after-sales service generally price higher.

Key Pricing Influencers for Flexible Neon Lights

Pricing is dynamic and influenced by several factors that B2B buyers must evaluate carefully:

-

Order Volume and MOQ: Larger orders typically yield better unit prices due to economies of scale. However, minimum order quantities (MOQs) can be a barrier for smaller buyers, especially startups or regional distributors.

-

Customization and Specifications: Custom colors, shapes, lengths, and integrated control features (e.g., DMX compatibility) increase complexity and cost. Buyers should assess whether standard models meet their needs to optimize pricing.

-

Material Quality and Certifications: Higher-grade LEDs and silicone, alongside international certifications (UL, CE, RoHS), increase cost but improve product lifespan and legal compliance in various markets.

-

Supplier Reliability and Location: Suppliers closer to the buyer or with established logistics networks can reduce shipping times and costs. Conversely, sourcing from distant manufacturers may lower product cost but increase shipping and risk exposure.

-

Incoterms and Payment Terms: Terms like FOB, CIF, or DDP influence who bears shipping and customs costs. Negotiating favorable terms and payment conditions (e.g., letters of credit) can optimize cash flow and reduce total expenses.

Strategic Buyer Tips for Cost-Efficient Flexible Neon Light Procurement

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following strategies are crucial:

-

Negotiate Beyond Price: Engage suppliers on MOQ flexibility, lead times, warranty terms, and after-sales support. Sometimes a slightly higher price with better service reduces total cost of ownership.

-

Evaluate Total Cost of Ownership (TCO): Consider energy efficiency, durability, and maintenance costs alongside purchase price. Investing in quality materials and certifications can minimize long-term expenses.

-

Leverage Group Buying or Partnerships: Collaborate with other buyers or local distributors to aggregate orders and negotiate volume discounts, especially where MOQs are high.

-

Understand Regional Import Regulations: Compliance with local certification requirements avoids costly delays or product rejections at customs.

-

Request Detailed Quotes: Ensure quotes itemize costs—materials, labor, shipping, taxes—to identify negotiation levers and avoid hidden fees.

-

Plan for Currency Fluctuations: Exchange rate volatility can affect landed cost; locking prices through contracts or hedging strategies may provide cost stability.

Important Pricing Disclaimer

Pricing for flexible neon lights varies widely based on specifications, volumes, supplier location, and market conditions. The figures discussed serve as indicative guidance only. Buyers should conduct direct supplier inquiries and obtain formal quotations tailored to their project requirements for accurate budgeting.

By thoroughly analyzing these cost and pricing factors, international B2B buyers can optimize procurement strategies, reduce risks, and secure flexible neon lighting solutions that align with both budgetary constraints and quality expectations.

Spotlight on Potential flexible neon light Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘flexible neon light’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for flexible neon light

Critical Technical Properties of Flexible Neon Light

Understanding the key technical specifications of flexible neon lights is essential for B2B buyers aiming to source products that meet quality, durability, and performance requirements in diverse international markets.

-

Material Grade (Silicone, PVC, PU):

The outer casing material affects flexibility, weather resistance, and light diffusion. High-grade silicone offers superior UV resistance and durability, making it ideal for outdoor applications in harsh climates such as those in Africa or the Middle East. PVC and PU provide cost-effective alternatives but may degrade faster under intense sunlight or extreme temperatures. Selecting the right material grade ensures long-term performance and lowers maintenance costs. -

Ingress Protection (IP Rating):

The IP rating (e.g., IP65, IP67, IP68) indicates the light’s resistance to dust and water. For outdoor or wet environment installations common in South America and coastal Europe, choosing a minimum of IP65 is critical to prevent moisture ingress that can cause electrical failure. Higher IP ratings are recommended for submerged or heavy-rain conditions. -

Voltage and Power Consumption:

Flexible neon lights typically operate at low voltages (12V or 24V DC), enhancing safety and energy efficiency. Buyers should verify the voltage compatibility with local electrical standards and assess power consumption metrics to optimize energy costs. Low power usage also contributes to sustainability goals, increasingly important in European markets. -

Bending Radius and Flexibility:

This defines how tightly the neon light can be bent without damaging internal LEDs or circuitry. A smaller minimum bending radius allows more creative and complex installations, such as intricate signage or architectural highlights. Buyers should confirm this property to ensure compatibility with their design needs. -

Luminous Intensity and Color Consistency:

Measured in lumens per meter (lm/m), this indicates brightness. Consistent color temperature and smooth light diffusion are crucial for aesthetic appeal, especially in retail and hospitality sectors. Buyers must request samples or photometric data to verify the uniformity and intensity meet project specifications. -

Cutting and Connection Tolerance:

Flexible neon lights are often cut to length on-site. Clear marking of cutting points and standardized connector types simplify installation and reduce labor costs. Verifying these tolerances prevents damage and ensures seamless electrical connections, crucial for large-scale projects across regions with varying technical expertise.

Common Industry and Trade Terminology for Flexible Neon Light Sourcing

Familiarity with these terms will help buyers communicate effectively with suppliers, negotiate contracts, and manage procurement processes smoothly.

-

OEM (Original Equipment Manufacturer):

Refers to suppliers who produce flexible neon lights based on the buyer’s design and specifications. OEM partnerships enable customization, branding, and exclusivity, which is valuable for companies seeking unique product offerings or private-label solutions. -

MOQ (Minimum Order Quantity):

The smallest order size a supplier is willing to accept. Understanding MOQ helps buyers plan inventory and cash flow. Some manufacturers may offer lower MOQs for sample or pilot orders, which is beneficial for testing new markets in regions like Kenya or Brazil. -

RFQ (Request for Quotation):

A formal inquiry sent to suppliers asking for pricing, lead times, and terms based on specified product requirements. A detailed RFQ ensures buyers receive accurate and comparable offers, aiding in transparent supplier evaluation. -

Incoterms (International Commercial Terms):

Standardized trade terms (e.g., FOB, CIF, DDP) that define responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Knowing Incoterms helps buyers from different continents negotiate logistics effectively and avoid unexpected costs. -

CRI (Color Rendering Index):

A measure of how accurately a light source displays colors compared to natural light. Higher CRI (above 80) is preferred for retail and design applications where color accuracy enhances visual appeal. -

Lifetime (Rated Hours):

Indicates the expected operational life of the flexible neon light, usually ranging from 30,000 to 50,000 hours. Longer lifetimes reduce replacement frequency and total cost of ownership, a key consideration for large installations in commercial or public spaces.

By focusing on these technical properties and understanding essential trade terms, international B2B buyers can make informed decisions, ensuring their flexible neon light purchases align with project requirements, budget constraints, and regional market conditions. This knowledge helps optimize supplier selection, reduce risks, and achieve competitive advantages in dynamic global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the flexible neon light Sector

Market Overview & Key Trends

The global flexible neon light market is witnessing robust growth driven by increasing demand for energy-efficient, customizable, and visually appealing lighting solutions. This growth is propelled by sectors such as retail, hospitality, architecture, and events, where dynamic lighting is integral to customer engagement and brand differentiation. International B2B buyers from regions including Africa, South America, the Middle East, and Europe—countries like Kenya, Brazil, Saudi Arabia, and Germany—are actively seeking flexible neon lighting solutions that combine durability, ease of installation, and advanced features.

Key market dynamics include the transition from traditional glass neon to LED-based flexible neon lights, which offer superior energy efficiency, longer lifespan, and enhanced safety. The flexibility of these lights allows for creative applications in complex designs and curved architectural structures, expanding their use beyond signage to interior décor and outdoor installations. Technological advancements such as addressable LEDs, integration with smart lighting controls, and waterproof designs are emerging trends that enable customized lighting experiences and remote management, appealing to sophisticated commercial projects globally.

Sourcing trends reveal a strong preference for suppliers who offer scalable customization, rapid prototyping, and compliance with international certifications (e.g., CE, RoHS). Buyers in emerging markets are increasingly focused on suppliers who can provide competitive pricing without compromising quality, especially when importing from Asia and Europe. Additionally, supply chain resilience has become critical amid geopolitical uncertainties and logistics challenges, pushing buyers to diversify supplier bases and prioritize transparency in production timelines and material sourcing.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration for B2B buyers in the flexible neon light sector. LED neon flex lights inherently consume less power than traditional neon, contributing to reduced carbon footprints for commercial projects. However, the environmental impact extends beyond energy efficiency to include raw material sourcing, manufacturing processes, and end-of-life disposal. Buyers are increasingly demanding products manufactured with eco-friendly materials such as recyclable PVC or silicone and low-toxicity components that minimize harmful emissions during production and usage.

Ethical sourcing is gaining traction as businesses commit to responsible supply chains that ensure fair labor practices and compliance with environmental regulations. Certifications such as ISO 14001 (Environmental Management) and adherence to the Restriction of Hazardous Substances (RoHS) directive are critical benchmarks for suppliers. Furthermore, international buyers are encouraged to verify suppliers’ transparency regarding their carbon footprint, waste management policies, and use of renewable energy in manufacturing. Sustainable packaging and reduction of single-use plastics in shipping also enhance a supplier’s appeal.

For markets in Africa and South America, where environmental regulations are evolving, partnering with suppliers who prioritize sustainability can offer competitive advantages and future-proof projects against regulatory risks. In Europe and the Middle East, where green building certifications like LEED and BREEAM influence procurement decisions, sourcing flexible neon lights that contribute to these standards is increasingly mandatory. Ultimately, sustainable and ethical sourcing not only aligns with corporate social responsibility goals but also mitigates supply chain risks and enhances brand reputation.

Brief Evolution of Flexible Neon Lights

Flexible neon lighting has evolved significantly over the last two decades, transitioning from fragile, gas-filled glass tubes to resilient, LED-based neon flex solutions. Traditional neon lights, while iconic for their bright and vibrant glow, posed challenges including high energy consumption, fragility, and complex installation. The introduction of flexible LED neon lights, encased in silicone or PVC, revolutionized the sector by offering a bendable, lightweight alternative that replicates neon’s aesthetic with enhanced durability.

The evolution was fueled by advances in LED technology, extrusion processes, and material science, enabling mass production of flexible neon lights with consistent brightness and color uniformity. Innovations such as addressable LEDs and waterproof coatings expanded their applications from indoor décor to demanding outdoor environments. This technological progression has empowered B2B buyers worldwide to incorporate flexible neon lighting into diverse projects with greater design freedom, cost-effectiveness, and sustainability.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of flexible neon light

-

How can I effectively vet suppliers of flexible neon lights for international B2B purchases?

To vet suppliers, prioritize those with verifiable certifications such as ISO 9001 and CE that demonstrate adherence to quality standards. Request detailed product datasheets and samples to assess light quality and durability. Check supplier references and past export records, especially to markets similar to yours (Africa, South America, Middle East, Europe). Utilize third-party inspection services to audit factories and production processes. Transparency in communication, clear MOQ policies, and willingness to provide customization options are strong indicators of a reliable supplier. -

What customization options are typically available for flexible neon lights, and how should I approach them?

Most manufacturers offer customization in color, length, brightness, silicone casing hardness, and IP rating for water resistance. Some also provide tailored connectors and control systems (e.g., DMX, remote RGB control). Clearly define your technical and design requirements upfront and request prototypes before bulk ordering. Confirm that the supplier can meet your local electrical standards and certifications. Custom orders often require longer lead times and higher MOQs, so plan procurement schedules accordingly. -

What are common minimum order quantities (MOQs) and lead times for flexible neon light orders from international suppliers?

MOQs typically range from 100 to 500 meters per color or design variant, but some suppliers accommodate smaller trial orders for new buyers. Lead times usually span 3 to 6 weeks, influenced by order size, customization, and production schedules. Seasonal demand fluctuations can extend lead times. Negotiate MOQs based on your market size and budget, and confirm shipment timelines early to align with project deadlines. Consolidating orders can help optimize costs and shipping. -

Which payment terms and methods are safest and most practical for international flexible neon light transactions?

Common payment methods include Telegraphic Transfer (T/T), Letter of Credit (L/C), and Escrow services. For first-time suppliers, a 30% upfront deposit with balance upon inspection or delivery is standard. Letters of Credit provide added security but involve higher bank fees. Use trade assurance platforms or reputable escrow services when possible. Always confirm payment terms in writing within contracts, and avoid full prepayment without verified supplier credibility. -

What quality assurance (QA) measures and certifications should I require for flexible neon lights?

Demand product certifications such as CE, RoHS, UL, and FCC to ensure compliance with safety, environmental, and electrical standards. Insist on factory QA protocols including IP testing for waterproof ratings, LED lifespan tests, and color consistency checks. Request batch test reports and warranty terms—typically 2 to 3 years for flexible neon lights. Third-party lab testing or on-site inspections enhance confidence in product integrity and reduce post-shipment disputes. -

How should I plan logistics and shipping for flexible neon light imports to regions like Africa, South America, or the Middle East?

Flexible neon lights are lightweight but bulky; optimize packaging to reduce volumetric freight costs. Choose shipping methods based on urgency and budget—sea freight for large, less urgent orders; air freight for smaller, time-sensitive shipments. Verify customs clearance requirements and import duties specific to your country. Collaborate with freight forwarders experienced in handling lighting products internationally. Ensure proper insurance coverage to mitigate risks during transit. -

What strategies can I use to manage disputes or quality issues with flexible neon light suppliers?

Establish clear contracts outlining product specifications, quality standards, inspection processes, and penalties for non-compliance. Use third-party inspection services before shipment to identify defects early. Maintain detailed documentation—photos, test reports, and communication logs. Negotiate amicable resolutions such as partial refunds, replacements, or discounts. If disputes escalate, consider arbitration under international trade laws or involving chambers of commerce relevant to supplier and buyer locations. -

Are there any regional compliance considerations I should be aware of when importing flexible neon lights?

Yes, compliance varies by region. Europe requires CE marking and RoHS compliance; Middle East markets often demand SASO certification; Africa may require local import permits and adherence to electrical safety codes. Verify voltage compatibility (e.g., 110V vs. 220V) and ensure suppliers provide appropriate power adapters or transformers. Staying informed about evolving regional regulations prevents shipment rejections and costly delays. Engage local consultants or trade bodies for up-to-date compliance guidance.

Strategic Sourcing Conclusion and Outlook for flexible neon light

Flexible neon lights represent a dynamic fusion of innovation, energy efficiency, and aesthetic versatility that is reshaping commercial and architectural lighting worldwide. For B2B buyers across Africa, South America, the Middle East, and Europe, understanding the nuances of material quality, manufacturing processes, and supplier reliability is essential to unlocking their full potential. Strategic sourcing not only ensures access to cutting-edge flexible neon solutions but also guarantees compliance with regional standards and cost-effective scalability.

Key takeaways emphasize the importance of selecting suppliers who provide high-grade silicone or PVC casings, advanced extrusion manufacturing, and rigorous quality assurance. Prioritizing flexibility, durability, and vibrant light diffusion will enable buyers to meet diverse market demands—from retail signage and event lighting to architectural accents. Additionally, leveraging supplier partnerships that offer customization and transparent MOQ policies can significantly enhance supply chain agility and product differentiation.

Looking ahead, the flexible neon light market is poised for continued growth driven by sustainability trends and expanding applications. International buyers are encouraged to proactively engage with trusted manufacturers, invest in comprehensive product testing, and explore innovative designs to stay competitive. Embracing strategic sourcing today will empower your business to illuminate tomorrow’s opportunities with confidence and distinction.