Introduction: Navigating the Global Market for drive led strip matrix arduino

The global demand for drive LED strip matrix Arduino solutions is rapidly expanding as industries across Africa, South America, the Middle East, and Europe embrace innovative display technologies. These versatile LED matrix modules, driven by Arduino platforms, enable dynamic visual communication, from industrial automation indicators to smart retail displays and advanced prototyping. For B2B buyers in these regions, sourcing the right products means navigating a complex landscape of technical specifications, manufacturing standards, and supplier reliability.

Understanding the nuances of LED strip matrix types, including variations in LED density, color configurations (such as WS2812B RGB LEDs), and driver compatibility, is critical for aligning product capabilities with application requirements. Material quality and manufacturing processes directly impact durability and performance, particularly in diverse climates found across these international markets. Rigorous quality control (QC) protocols ensure consistency and reduce the risk of costly failures downstream.

This comprehensive guide equips procurement professionals and technical buyers with actionable insights into the full supply chain ecosystem. It covers key considerations such as:

- Differentiating matrix types and compatible Arduino drivers

- Evaluating materials and manufacturing best practices

- Identifying trusted global suppliers with proven track records

- Analyzing cost structures and total cost of ownership

- Assessing market trends and regional demand drivers

- Addressing common technical and commercial FAQs

By leveraging this knowledge, international B2B buyers—from Egypt’s burgeoning tech hubs to Europe’s industrial centers and South America’s growing maker communities—can make well-informed sourcing decisions. This ensures they secure high-quality, cost-effective drive LED strip matrix Arduino solutions that meet their unique operational and market demands.

Understanding drive led strip matrix arduino Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| WS2812B Addressable LED Matrix | Individually addressable RGB LEDs, integrated driver chip | Interactive displays, signage, dynamic lighting | + High customization, easy daisy-chain wiring – Requires precise timing control, higher cost per LED |

| Standard 8×8 LED Matrix | Fixed single-color or RGB LEDs arranged in matrix form | Basic indicators, simple animations, status panels | + Low cost, simple control – Limited color and animation flexibility |

| Multiplexed LED Strip Matrix | LED strips arranged in rows and columns with multiplexing | Large-scale display boards, advertising panels | + Scalable, cost-effective for large displays – Complex wiring and control logic required |

| Arduino Shield Matrix Drivers | Plug-and-play driver boards designed to interface with Arduino | Rapid prototyping, modular display solutions | + Simplifies integration, reduces development time – Limited to Arduino ecosystem, less customizable |

| RGB LED Strip with External Drivers | RGB LED strips controlled via external IC drivers (e.g., TLC5947) | Architectural lighting, synchronized effects | + High brightness, flexible control – Requires additional hardware, more complex setup |

WS2812B Addressable LED Matrix

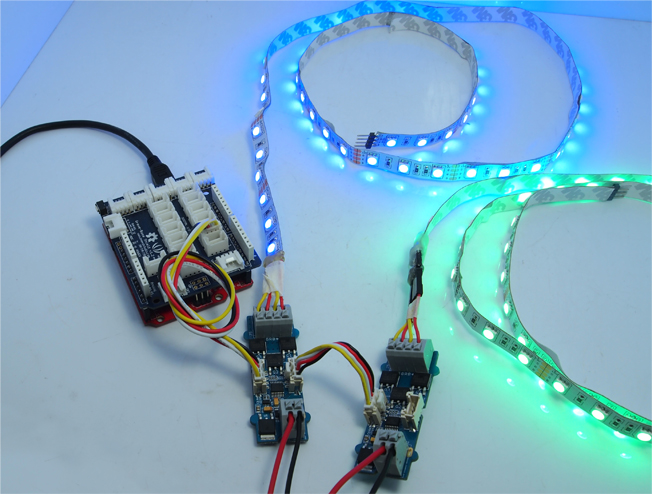

This type features individually addressable RGB LEDs embedded with driver chips, enabling precise control of each LED’s color and brightness. Ideal for dynamic, interactive displays such as promotional signage and gaming interfaces, WS2812B matrices offer extensive customization possibilities. B2B buyers should consider the need for compatible microcontrollers and programming expertise, as well as power supply capacity due to higher current demands. While cost per LED is higher, the flexibility and visual impact justify investment for premium applications.

Standard 8×8 LED Matrix

A traditional matrix composed of single-color or simple RGB LEDs arranged in an 8×8 grid, this type suits straightforward applications like status indicators or basic animations. Its low cost and ease of integration make it attractive for businesses requiring simple visual feedback without complex programming. Buyers should note the limited color range and static display capabilities, which may restrict usage in more sophisticated projects. It remains a reliable choice for budget-conscious deployments.

Multiplexed LED Strip Matrix

This variation involves arranging LED strips into matrix formations controlled via multiplexing techniques to reduce wiring complexity and cost. It is well-suited for large-scale advertising boards and information displays where scalability is crucial. B2B buyers must evaluate the increased complexity in control logic and wiring, which may necessitate specialized engineering support. However, the cost efficiency and ability to manage large displays make it appealing for enterprises focused on expansive visual installations.

Arduino Shield Matrix Drivers

These are specialized driver boards designed to interface seamlessly with Arduino platforms, providing a modular and plug-and-play solution for LED matrix control. Perfect for rapid prototyping and modular display setups, these shields simplify hardware integration and reduce development time. Buyers from industries emphasizing quick turnaround and flexible experimentation will find this advantageous. Limitations include dependency on the Arduino ecosystem and potentially less flexibility for custom hardware configurations.

RGB LED Strip with External Drivers

Utilizing RGB LED strips controlled by external driver ICs such as the TLC5947, this type offers high brightness and fine-grained control over LED behavior. It is commonly used in architectural lighting and synchronized visual effects where brightness and uniformity are key. For B2B buyers, considerations include the need for additional driver hardware and more complex setup procedures, which may increase initial costs and require technical expertise. Nonetheless, the enhanced performance and scalability justify these investments in demanding environments.

Related Video: Gaussian Mixture Models (GMM) Explained

Key Industrial Applications of drive led strip matrix arduino

| Industry/Sector | Specific Application of drive led strip matrix arduino | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Advertising | Dynamic digital signage and interactive advertising displays | Enhances customer engagement with customizable, vibrant visuals | Durability, ease of integration with existing systems, scalability, and power efficiency |

| Industrial Automation | Status indication and machine feedback through LED matrices on factory floors | Improves operational efficiency and real-time monitoring | Robustness for harsh environments, compatibility with industrial control systems, and reliability |

| Smart Cities & Infrastructure | Public information displays and traffic signal visualization using LED matrices | Facilitates timely communication and enhances urban management | Weather resistance, energy consumption, and ease of maintenance |

| Education & Training | Interactive learning tools and embedded system prototyping with LED matrices | Accelerates skill development and prototyping in electronics and coding | Availability of development kits, documentation quality, and technical support |

| Entertainment & Events | Stage lighting effects and programmable LED displays for live events | Creates immersive experiences and flexible visual effects | Flexibility in programming, color accuracy, and integration with event control systems |

Retail & Advertising

In retail environments across Africa, South America, the Middle East, and Europe, drive LED strip matrix Arduino solutions enable the creation of dynamic digital signage that attracts and retains customer attention. These systems provide vivid, programmable displays that can be updated in real-time to showcase promotions, product information, or brand messaging. For B2B buyers, ensuring the LED matrix modules are scalable and compatible with existing digital infrastructure is crucial, as is sourcing components with high color fidelity and low power consumption to reduce operational costs.

Industrial Automation

Manufacturing and processing plants utilize drive LED strip matrix Arduino setups for machine status displays and alert systems. These matrices serve as visual indicators for equipment operation, fault detection, and process stages, enhancing workplace safety and reducing downtime. B2B buyers in industrial sectors need LED matrices that withstand dust, moisture, and vibration typical in factory settings, along with seamless integration capabilities with PLCs and industrial controllers common in European and Middle Eastern factories.

Smart Cities & Infrastructure

Municipalities and infrastructure projects leverage LED strip matrices driven by Arduino for public information boards, traffic signal displays, and environmental monitoring dashboards. These applications require durable, weatherproof LED matrices that operate reliably outdoors, with energy-efficient designs to support sustainable urban initiatives. International buyers, especially in regions with extreme climates like parts of Africa and the Middle East, should prioritize sourcing LED matrices with IP-rated enclosures and robust power regulation features.

Education & Training

Educational institutions and technical training centers use drive LED strip matrix Arduino kits to teach embedded systems, programming, and electronics prototyping. These interactive tools facilitate hands-on learning, allowing students to visualize coding outcomes immediately. For B2B buyers supplying educational sectors in South America and Europe, key considerations include comprehensive documentation, availability of support resources, and modular kits that can be expanded as curricula evolve.

Entertainment & Events

Event organizers and entertainment venues incorporate Arduino-controlled LED strip matrices for stage lighting, dynamic backdrops, and special effects. These matrices offer programmable flexibility to create synchronized lighting sequences and vibrant displays that enhance audience experience. Buyers in this sector, including those operating in Australia and Europe, must focus on sourcing LED strips with high refresh rates, accurate color rendering, and compatibility with common event control protocols to ensure seamless integration and reliability during live performances.

Related Video: How to use WS2812B RGB LED strip with Arduino | ws2811 ws2812 ws2813 ws2815 sk6812 sk9822 neopixel

Strategic Material Selection Guide for drive led strip matrix arduino

When selecting materials for driving LED strip matrices with Arduino, especially in international B2B contexts, understanding the interplay between material properties and application requirements is crucial. This ensures product reliability, cost-effectiveness, and compliance with regional standards across diverse markets such as Africa, South America, the Middle East, and Europe.

1. FR4 (Flame Retardant 4) PCB Material

Key Properties:

FR4 is a widely used glass-reinforced epoxy laminate with excellent electrical insulation, moderate thermal resistance (typically up to 130°C), and good mechanical strength. It offers decent moisture resistance but can degrade under prolonged exposure to high humidity or corrosive environments.

Pros & Cons:

– Pros: Cost-effective, easily manufacturable, and compatible with standard PCB fabrication processes. It supports fine-pitch components and is globally standardized (e.g., IPC-4101).

– Cons: Limited thermal conductivity can cause heat buildup in high-power LED strips. Susceptible to moisture absorption in humid climates, potentially affecting long-term reliability.

Impact on Application:

FR4 suits most indoor LED strip matrix applications where ambient temperatures are controlled. However, for outdoor or high-temperature environments, additional thermal management or protective coatings may be necessary.

International B2B Considerations:

Buyers in humid regions like parts of Africa and South America should verify moisture resistance grades and consider conformal coatings. Compliance with IPC standards and local certifications (e.g., CE in Europe, IEC standards in the Middle East) is essential. FR4’s widespread use ensures availability and cost advantages globally.

2. Aluminum PCB Substrate

Key Properties:

Aluminum substrates offer superior thermal conductivity (up to 2-3 W/mK) compared to FR4, excellent heat dissipation, and good mechanical rigidity. They typically withstand higher operating temperatures (up to 150°C or more) and provide enhanced corrosion resistance when properly anodized.

Pros & Cons:

– Pros: Ideal for high-power LED strip matrices requiring efficient heat management, improving LED lifespan and performance. Durable under harsh environmental conditions.

– Cons: Higher cost and more complex manufacturing processes than FR4. Limited flexibility restricts use in curved or flexible matrix designs.

Impact on Application:

Aluminum PCBs are preferred for outdoor LED displays or industrial applications where thermal management is critical. Their robustness suits markets with extreme temperature fluctuations, such as the Middle East or parts of Australia.

International B2B Considerations:

Buyers should ensure the aluminum substrate meets regional corrosion resistance standards (e.g., ASTM B209 for aluminum sheets). The higher upfront cost must be balanced against longer-term reliability and reduced maintenance. European and Middle Eastern buyers often require RoHS and REACH compliance for aluminum PCBs.

3. Flexible Polyimide (PI) Substrate

Key Properties:

Polyimide substrates are flexible, lightweight, and exhibit excellent thermal stability (up to 260°C), chemical resistance, and electrical insulation. They allow bending and folding without damage, making them suitable for dynamic or compact LED matrix designs.

Pros & Cons:

– Pros: Enables innovative, space-saving LED matrix configurations. High temperature tolerance supports soldering and harsh operating conditions.

– Cons: Higher material and fabrication costs compared to rigid PCBs. Requires specialized manufacturing capabilities, which may limit sourcing options in some regions.

Impact on Application:

Flexible PCBs are ideal for wearable LED matrices, curved displays, or applications with mechanical stress. They expand design possibilities but need careful handling and protection against mechanical fatigue.

International B2B Considerations:

Procurement from regions with advanced PCB fabrication (Europe, select Middle Eastern countries) is recommended. Buyers in emerging markets like Africa and South America should assess supplier capabilities and lead times. Compliance with IPC-4204 (flexible base materials) and local environmental regulations is critical.

4. Copper Clad Laminate (CCL) with High-Tg Epoxy Resin

Key Properties:

High-Tg (glass transition temperature) epoxy resins in CCLs provide enhanced thermal stability (up to 180°C), improved mechanical strength, and better resistance to thermal cycling compared to standard FR4.

Pros & Cons:

– Pros: Suitable for medium to high-power LED matrices with increased thermal demands. Offers a balance between cost and performance.

– Cons: More expensive than standard FR4 and may require updated manufacturing processes. Limited flexibility restricts use in bendable designs.

Impact on Application:

High-Tg CCLs are a middle ground for applications needing better heat resistance without the full cost of aluminum substrates. They improve reliability in environments with temperature fluctuations.

International B2B Considerations:

Buyers should verify compliance with ASTM D3418 (Tg measurement) and regional quality certifications. This material is well-suited for European and Middle Eastern markets where quality and durability standards are stringent. African and South American buyers should weigh cost against performance benefits.

Summary Table

| Material | Typical Use Case for drive led strip matrix arduino | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| FR4 | Standard indoor LED strip matrices with moderate power levels | Cost-effective, widely available, easy to manufacture | Limited thermal conductivity, moisture sensitivity | Low |

| Aluminum PCB Substrate | High-power or outdoor LED matrices requiring efficient cooling | Excellent heat dissipation and durability | Higher cost, rigid, complex manufacturing | High |

| Flexible Polyimide (PI) Substrate | Wearable, curved, or compact LED matrix designs | High thermal stability and flexibility | Higher cost, specialized fabrication needed | High |

| Copper Clad Laminate (High-Tg) | Medium/high power LED matrices needing enhanced thermal stability | Improved thermal resistance over FR4 | More expensive than FR4, limited flexibility | Medium |

This guide assists international B2B buyers in selecting optimal materials tailored to their LED strip matrix Arduino projects, balancing performance, cost, and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for drive led strip matrix arduino

Overview of Manufacturing Processes for Drive LED Strip Matrix Arduino

The manufacturing of drive LED strip matrix Arduino devices involves a series of precise and controlled stages to ensure high reliability and performance. Understanding these stages helps B2B buyers evaluate potential suppliers and ensure product consistency tailored to their market needs, especially across diverse regions such as Africa, South America, the Middle East, and Europe.

1. Material Preparation

Material preparation is the foundational step where raw materials and components are sourced, inspected, and pre-processed. For drive LED strip matrices, key materials include:

- LED components such as WS2812B or similar smart RGB LEDs.

- Flexible PCB substrates or rigid boards designed to accommodate LED placement and circuitry.

- Microcontrollers or driver ICs, commonly Arduino-compatible chips.

- Connectors, resistors, capacitors, and solder materials with high purity and compliance to avoid signal interference.

Suppliers typically conduct Incoming Quality Control (IQC) here, verifying material certifications, batch traceability, and conformance to specifications to prevent defects early in the process.

2. Forming and PCB Fabrication

In this stage, printed circuit boards (PCBs) are fabricated or flexed to the desired shape and size, often customized for LED strip layouts. Techniques include:

- Photolithography and etching to create precise copper traces for electrical pathways.

- Solder mask application to protect circuits and prevent shorts.

- Surface finish processes such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) to enhance solderability and corrosion resistance.

For LED strips, flexible PCBs often require specialized bending and cutting processes to maintain integrity and flexibility without damaging circuits.

3. Assembly

Assembly combines all components onto the PCB. This includes:

- Pick and place machines for accurate LED and component placement.

- Soldering processes, predominantly Surface Mount Technology (SMT), including reflow soldering to ensure solid electrical and mechanical connections.

- Manual inspection and touch-up for components that are sensitive or require additional handling.

Automated assembly lines improve consistency and reduce human error, critical for LED matrices where pixel uniformity impacts display quality.

4. Finishing and Packaging

The finishing process includes:

- Conformal coating or protective encapsulation to shield against moisture, dust, and mechanical stress.

- Functional testing, firmware programming, and calibration to ensure the drive logic for the LED matrix operates correctly.

- Labeling and packaging tailored to shipping requirements and regional compliance.

Proper packaging protects against static discharge and physical damage during transport, which is especially important for international buyers.

Quality Assurance and Control: Ensuring Reliable Drive LED Strip Matrix Arduino Products

Quality assurance (QA) and quality control (QC) are integral to manufacturing drive LED strip matrix Arduino systems, ensuring that products meet international standards and customer expectations.

Relevant International and Industry Standards

- ISO 9001: This is the global benchmark for quality management systems, ensuring that suppliers implement consistent processes and continuous improvement.

- CE Marking: Essential for European markets, it certifies conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical and electronic equipment, a key requirement in Europe and increasingly in other regions.

- UL Certification: Important for electrical safety, especially relevant when products are shipped to regions with strict electrical regulations.

- Industry-specific standards: Depending on application, certifications like API (American Petroleum Institute) or IEC (International Electrotechnical Commission) standards may apply, especially for industrial or outdoor use.

B2B buyers should verify that suppliers maintain current certifications and understand regional regulatory nuances.

Critical QC Checkpoints Throughout Manufacturing

- Incoming Quality Control (IQC): Inspection of raw materials and components upon receipt to detect defects early.

- In-Process Quality Control (IPQC): Monitoring during assembly, including solder joint inspections, component placement accuracy, and functional sub-tests.

- Final Quality Control (FQC): Comprehensive testing of the finished product, including electrical testing, firmware validation, and visual inspections.

Each checkpoint typically involves sampling plans, defect tracking, and corrective action processes to minimize defects.

Common Testing Methods for Drive LED Strip Matrix Arduino

- Electrical Testing: Verifies voltage, current, and signal integrity for each LED and control circuit.

- Functional Testing: Ensures the microcontroller and LED drivers correctly respond to commands, often using automated test benches.

- Environmental Testing: Simulates operating conditions such as temperature cycling, humidity exposure, and vibration to assess durability.

- Optical Testing: Measures LED brightness, color accuracy, and uniformity across the matrix.

- Solder Joint Inspection: Uses X-ray or automated optical inspection (AOI) systems to detect solder defects.

These tests are vital for reducing field failures and maintaining brand reputation.

How B2B Buyers Can Verify Supplier Quality Control

For buyers, especially from emerging markets and diverse regions, verifying supplier QC processes is crucial to avoid costly issues. Recommended strategies include:

- Supplier Audits: Conduct on-site or third-party audits focusing on process adherence, equipment condition, workforce skill, and documentation.

- Review of QC Reports: Request detailed IQC, IPQC, and FQC reports, including defect rates, test results, and corrective actions taken.

- Third-Party Inspections: Employ independent inspection agencies to perform random sampling and verification before shipment.

- Sample Testing: Order pre-production or pilot samples for in-house testing to validate quality claims.

- Certification Verification: Confirm that all relevant certifications (ISO 9001, CE, RoHS, UL) are valid and issued by accredited bodies.

International buyers should also ensure suppliers understand import regulations and standards relevant to their country, such as Egypt’s ECA requirements or Australia’s electrical safety standards.

QC and Certification Nuances for International B2B Buyers

- Regional Compliance: Different regions have varying certification requirements; for example, CE marking is mandatory in Europe but not in many African or South American countries. Buyers should work with suppliers who can customize compliance documentation accordingly.

- Language and Documentation: Ensure all QC documentation, manuals, and certificates are provided in languages suitable for your market or include English as a standard.

- After-Sales Support: Reliable suppliers offer warranty terms, repair services, and technical support, which are critical for markets with limited local expertise.

- Customs and Import Regulations: Some countries require pre-shipment inspections or conformity assessments, so suppliers experienced with international logistics and documentation will ease market entry.

- Environmental and Safety Standards: For buyers in regions with stringent environmental policies (e.g., EU’s WEEE directive), ensure the supplier’s products and packaging meet recycling and disposal requirements.

Final Recommendations for B2B Buyers

- Prioritize suppliers with transparent manufacturing processes and robust QC systems aligned with international standards.

- Leverage supplier audits and third-party inspections as part of your due diligence to mitigate risks.

- Confirm that production capabilities include advanced PCB fabrication and SMT assembly to ensure quality and scalability.

- Assess supplier experience in serving your specific regional market to benefit from their knowledge of local compliance and logistical challenges.

- Establish clear quality agreements and KPIs with suppliers, including defect thresholds, testing protocols, and corrective action timelines.

By thoroughly understanding manufacturing and quality assurance practices, B2B buyers can confidently source drive LED strip matrix Arduino products that meet performance expectations and regulatory requirements worldwide.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for drive led strip matrix arduino Sourcing

Understanding the cost and pricing dynamics of sourcing a drive LED strip matrix for Arduino applications is crucial for international B2B buyers aiming to optimize procurement strategies. The pricing structure is multifaceted, influenced by a combination of direct and indirect factors that affect the final purchase cost and overall value.

Key Cost Components in Drive LED Strip Matrix Arduino Sourcing

-

Materials: The primary cost driver includes high-quality WS2812B or similar RGB LEDs, flexible PCBs, microcontrollers, resistors, and connectors. Material costs fluctuate with global semiconductor and raw material markets, impacting LED chip prices and PCB substrate costs.

-

Labor: Skilled labor for assembly, soldering, and quality inspection contributes to unit cost. Regions with higher labor costs (e.g., Europe, Australia) generally see increased pricing compared to manufacturing hubs in Asia.

-

Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with automation can reduce overhead, lowering the price per unit.

-

Tooling and Setup: Initial tooling for PCB fabrication, stencil creation, and component programming is a one-time or amortized cost that influences pricing, particularly for small to medium batch orders.

-

Quality Control (QC): Rigorous testing for LED functionality, color consistency, and electrical safety adds to cost but ensures product reliability, crucial for professional and industrial applications.

-

Logistics and Import Duties: Shipping, customs clearance, and local taxes affect landed costs. For buyers in Africa, South America, and the Middle East, logistics can be a significant factor due to longer supply chains and variable import tariffs.

-

Supplier Margin: Suppliers factor in profit margins based on market positioning, brand reputation, and service levels including after-sales support and warranty.

Influential Pricing Factors to Consider

-

Order Volume and Minimum Order Quantities (MOQ): Higher volumes typically secure lower per-unit prices due to economies of scale. Some suppliers enforce MOQs that may impact initial capital outlay but improve unit pricing.

-

Customization and Technical Specifications: Custom PCB sizes, specific LED densities, or integrated driver circuits increase complexity and cost. Buyers requiring tailored firmware or expanded functionality should anticipate premium pricing.

-

Material Quality and Certifications: Components certified for industrial, automotive, or medical use command higher prices due to stringent testing and compliance costs. Certifications like RoHS, CE, or UL enhance product acceptance in regulated markets.

-

Supplier Reliability and Location: Established suppliers with proven quality records may price higher but reduce risk. Sourcing closer to the buyer’s region can reduce lead times and freight costs, benefiting markets in Europe or the Middle East.

-

Incoterms and Payment Terms: The choice of Incoterms (e.g., FOB, CIF, DDP) directly affects the buyer’s responsibility for shipping and customs, impacting overall cost and risk. Favorable payment terms can improve cash flow but may influence pricing.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Based on Total Cost of Ownership (TCO): Beyond unit price, consider warranty, expected lifespan, energy efficiency, and after-sales service. A slightly higher upfront cost may yield better value over time.

-

Leverage Volume Discounts and Flexible MOQs: Engage suppliers in transparent discussions about scaling orders and potential price breaks for future business to optimize procurement budgets.

-

Assess Quality vs. Cost Trade-offs: For markets like Africa and South America, balancing cost with durability and environmental resistance is key due to harsher operating conditions and limited local support infrastructure.

-

Understand Import Regulations and Logistics Nuances: Factor in local duties, certification requirements, and potential customs delays to avoid unexpected costs or shipment hold-ups.

-

Request Samples and Pilot Runs: Before committing to large orders, validate product quality and compatibility to mitigate risks associated with new suppliers or custom specifications.

-

Consider Regional Supplier Partnerships: Where possible, identify suppliers or distributors with local presence or regional warehouses to reduce lead times and simplify after-sales support.

Indicative Pricing Disclaimer

Prices for drive LED strip matrices compatible with Arduino vary widely based on specifications, volume, and supplier. As a guideline, basic modules with WS2812B LEDs can range from approximately USD 5 to USD 20 per unit in small quantities, with unit costs decreasing significantly at higher volumes. Buyers should request detailed quotes tailored to their exact requirements and consider all cost factors outlined above.

By comprehensively analyzing these cost components and pricing influencers, international B2B buyers can make informed decisions that optimize procurement efficiency and product quality for drive LED strip matrix Arduino solutions in diverse global markets.

Spotlight on Potential drive led strip matrix arduino Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘drive led strip matrix arduino’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for drive led strip matrix arduino

Critical Technical Properties of Drive LED Strip Matrix Arduino

When sourcing drive LED strip matrix components for Arduino-based applications, understanding the essential technical properties is crucial for ensuring product quality, compatibility, and operational reliability. Here are key specifications B2B buyers should prioritize:

-

LED Type and Material Grade

The LED strips often use WS2812B or similar addressable RGB LEDs. The material grade refers to the quality of semiconductor and encapsulation materials, impacting brightness, color consistency, and lifespan. High-grade LEDs ensure uniform illumination and longer operational life, reducing replacement costs and downtime in commercial deployments. -

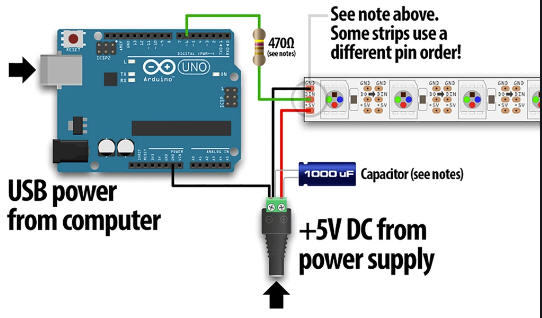

Voltage and Current Ratings

Typical LED strips operate at 5V DC, with current consumption per LED ranging from 20mA to 60mA depending on brightness and color intensity. Precise voltage and current specifications are vital for designing appropriate power supplies and avoiding damage. Buyers must confirm ratings to ensure compatibility with Arduino driver circuits and prevent system failures. -

Pixel Density and Resolution

Pixel density, often expressed as LEDs per meter or per matrix unit (e.g., 8×8), affects display clarity and visual effects. Higher resolution LED matrices enable more detailed graphics but require more processing power and complex driving circuits. For B2B buyers, matching pixel density with application needs is essential for cost-effective solutions. -

Signal Protocol and Timing Tolerance

Addressable LEDs like WS2812B use a specific one-wire communication protocol with strict timing requirements (e.g., 800kHz data rate). Timing tolerance affects signal integrity and synchronization across the matrix. Ensuring that LED strips meet protocol standards guarantees seamless integration with Arduino controllers and reliable display performance. -

Thermal Management and Operating Temperature Range

LEDs generate heat during operation, which can degrade performance if not properly managed. Specifications on thermal resistance and recommended operating temperature range help buyers select LED strips suitable for their environment, especially in regions with extreme climates such as parts of Africa or the Middle East. -

Physical Dimensions and Connector Types

The physical size of the LED strip matrix and the types of connectors (e.g., JST, Dupont) influence installation flexibility and system design. For large-scale or custom projects, modularity and ease of assembly are important to reduce labor costs and simplify maintenance.

Common Industry and Trade Terminology for B2B Buyers

Navigating global procurement for drive LED strip matrix Arduino components requires familiarity with key trade terms to optimize purchasing and contractual arrangements:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products to be branded and sold by other businesses. B2B buyers often work with OEMs to customize LED matrices for specific applications, ensuring product differentiation and supply chain control. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory and budget effectively, especially important for startups or small enterprises in emerging markets to avoid overstocking. -

RFQ (Request for Quotation)

A formal process where buyers invite suppliers to submit price and delivery proposals. RFQs are critical for comparing offers, negotiating terms, and establishing cost-effective sourcing agreements. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Clarity on Incoterms reduces disputes and facilitates smoother cross-border transactions. -

Lead Time

The period between placing an order and receiving the goods. Lead time impacts project schedules and inventory planning. Buyers should negotiate realistic lead times and consider local logistics infrastructure when importing from international suppliers. -

RoHS Compliance (Restriction of Hazardous Substances)

Certification indicating that electronic components meet environmental and safety standards by limiting hazardous materials. RoHS compliance is increasingly required in European and other regulated markets, ensuring products are safe and environmentally friendly.

By focusing on these technical properties and mastering relevant trade terminology, international B2B buyers can make informed decisions, optimize procurement strategies, and establish reliable supply chains for drive LED strip matrix Arduino solutions tailored to diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drive led strip matrix arduino Sector

Market Overview & Key Trends

The global market for drive LED strip matrix Arduino solutions is rapidly expanding, driven by increasing demand for customizable, energy-efficient lighting and display systems in industrial automation, smart city infrastructure, and consumer electronics. For international B2B buyers, particularly those in emerging and developed regions such as Africa, South America, the Middle East, and Europe, understanding the evolving landscape is critical to securing competitive advantages and ensuring supply chain resilience.

Key market drivers include the proliferation of IoT and embedded systems, which leverage Arduino-compatible LED matrices for real-time visual feedback and interactive displays. The flexibility and open-source nature of Arduino platforms make them especially appealing for innovation-focused industries, including automotive, robotics, and signage. Buyers in regions like Egypt and Australia are witnessing growing adoption in education and prototyping sectors, further broadening market applications.

From a sourcing perspective, modular LED strip matrix units integrated with Arduino controllers are increasingly sourced through specialized electronics distributors and emerging regional suppliers, reducing lead times and import costs. The rise of WS2812B and similar addressable RGB LEDs has set new standards for pixel-level control, enabling intricate displays at competitive prices. Buyers should monitor supply chain shifts influenced by semiconductor availability and regional trade policies, particularly in light of geopolitical factors affecting component exports.

Emerging trends also highlight customizable firmware and software ecosystems that support advanced control of LED matrices. This is enabling manufacturers and system integrators to offer tailored solutions for clients across diverse markets. For B2B buyers, partnering with suppliers who provide comprehensive technical support, including tutorials and software libraries, is becoming a crucial differentiator.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly a decisive factor in procurement decisions within the drive LED strip matrix Arduino sector. The environmental impact of electronics manufacturing, including the production of LED components and PCBs, necessitates a focus on green materials and ethical supply chains. International buyers are prioritizing suppliers who adhere to regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), which limit toxic substances and ensure safer products.

Ethical sourcing extends beyond compliance. Buyers are encouraged to evaluate supplier transparency regarding labor practices and environmental stewardship, especially when sourcing from regions with evolving regulatory frameworks. Certifications like ISO 14001 (Environmental Management) and Fair Labor Association (FLA) membership provide assurance of sustainable operations and responsible labor conditions.

Illustrative Image (Source: Google Search)

On the materials front, the adoption of lead-free solder, halogen-free laminates, and recyclable PCB substrates is becoming common among reputable manufacturers. For LED strip matrices, energy efficiency remains a core sustainability metric; WS2812B and similar LED technologies offer low power consumption, reducing the overall carbon footprint of deployed systems. Moreover, modular designs supporting easy repair and component replacement help extend product lifecycles, aligning with circular economy principles.

Illustrative Image (Source: Google Search)

B2B buyers from Africa, South America, the Middle East, and Europe should actively engage with suppliers on sustainability initiatives, seeking partners who demonstrate commitment to eco-design, waste reduction, and carbon footprint transparency. This not only mitigates risk but also enhances brand value in increasingly eco-conscious markets.

Evolution and Historical Context

The drive LED strip matrix Arduino sector has evolved significantly since the advent of Arduino in 2005, which democratized embedded system development through accessible, open-source hardware and software. Early LED matrix projects were limited by monochromatic displays and complex wiring, but the introduction of addressable RGB LEDs like the WS2812B transformed the landscape by enabling vibrant, individually controllable pixels on compact strips.

This evolution has empowered manufacturers and system integrators to design sophisticated visual applications, from interactive games and signage to industrial status indicators, with minimal hardware complexity. The modular shield and expansion board designs compatible with Arduino Uno and Raspberry Pi Pico further simplified integration, accelerating adoption across educational, prototyping, and commercial markets worldwide.

For B2B buyers, understanding this trajectory highlights the importance of selecting suppliers who stay abreast of technological advancements, provide robust support for firmware development, and innovate in power management and form factor design. This ensures access to cutting-edge solutions that meet evolving market needs while maintaining cost efficiency and reliability.

Related Video: Ultimate Guide to Programming LED Strips with Arduino | Wiring, Powering & Code with FastLED

Frequently Asked Questions (FAQs) for B2B Buyers of drive led strip matrix arduino

-

How can I effectively vet suppliers of drive LED strip matrix Arduino modules for international B2B purchases?

To vet suppliers, start by verifying their business credentials and certifications such as ISO 9001 for quality management. Request product samples to assess build quality and compatibility. Check references or client testimonials, especially from buyers in your region (Africa, South America, Middle East, Europe). Confirm their technical support capabilities and after-sales service. Additionally, evaluate their production capacity and compliance with international standards like RoHS and CE to ensure product reliability and regulatory adherence. -

Is customization of drive LED strip matrix Arduino solutions feasible for bulk orders, and how should I approach it?

Yes, many manufacturers offer customization including LED matrix size, color configurations, and firmware modifications. When negotiating, clearly define your technical requirements and application needs upfront. Request a prototype or sample with the custom specifications before full production to minimize risks. Ensure the supplier can support your customization in terms of tooling and technical expertise. Discuss intellectual property rights and confidentiality agreements to protect your design. -

What are typical minimum order quantities (MOQs) and lead times for drive LED strip matrix Arduino products in international trade?

MOQs can vary widely depending on the supplier and customization level, typically ranging from 100 to 1000 units. Standard lead times for off-the-shelf products are around 2-4 weeks, while custom orders may require 6-12 weeks due to design and tooling. To avoid delays, confirm production schedules early and maintain clear communication. Factor in additional time for international shipping and customs clearance, especially when importing to regions like Africa or the Middle East. -

Which payment terms are common for international B2B transactions involving drive LED strip matrix Arduino products?

Suppliers often require a deposit upfront (30-50%) with the balance paid before shipment or upon delivery. Letters of credit (LC) and escrow services can provide security for both parties. For trusted suppliers, net 30 or net 60 payment terms may be negotiated. Always clarify currency and payment method (e.g., wire transfer, PayPal, Alibaba Trade Assurance) to avoid surprises. Consider local regulations and banking infrastructure in your country to select the most efficient payment option. -

What quality assurance measures and certifications should I expect from suppliers of these LED matrix Arduino modules?

Suppliers should provide quality control documentation including incoming material inspection, in-process testing, and final product verification. Certifications such as CE, RoHS, and FCC demonstrate compliance with safety and environmental standards. Request test reports for LED brightness consistency, power consumption, and durability. For critical applications, ask about warranty terms and availability of batch traceability to quickly address any defects or recalls. -

How can I optimize logistics and shipping for importing drive LED strip matrix Arduino products to regions like Africa or South America?

Choose suppliers with experience in international shipping and customs regulations relevant to your destination. Consolidate shipments where possible to reduce freight costs. Use reliable freight forwarders familiar with your region’s import duties and clearance procedures. Consider Incoterms carefully (e.g., FOB, CIF) to define responsibility for shipping and insurance. Plan for potential delays caused by customs inspections or local infrastructure limitations and build buffer time into your supply chain. -

What steps should I take to manage disputes or quality issues with overseas suppliers?

Establish clear contractual terms including product specifications, delivery schedules, and penalties for non-compliance. Document all communications and maintain detailed records of orders, samples, and inspections. In case of disputes, attempt amicable resolution through negotiation or mediation. Leverage international trade bodies or chambers of commerce for support if needed. Utilizing third-party inspection services before shipment can preempt quality problems and provide evidence if claims arise. -

Are there specific considerations for sourcing drive LED strip matrix Arduino products from emerging markets or smaller manufacturers?

Emerging market suppliers may offer competitive pricing and flexibility but require thorough due diligence. Verify their manufacturing capabilities and quality management systems. Assess language barriers and time zone differences that could impact communication. Smaller manufacturers might have limited capacity or longer lead times, so plan orders accordingly. Building strong relationships through visits or local agents can improve reliability and responsiveness in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drive led strip matrix arduino

In the evolving landscape of embedded electronics, sourcing drive LED strip matrix Arduino solutions demands a strategic approach that balances quality, cost-efficiency, and supplier reliability. For international B2B buyers across Africa, South America, the Middle East, and Europe, understanding the intricacies of LED matrix technologies such as WS2812B and compatible Arduino driver boards is crucial to unlocking innovation and competitive advantage. Prioritizing suppliers with proven expertise in modular design, scalable manufacturing, and compliance with regional standards will mitigate risks and ensure seamless integration into your product lines.

Key takeaways for successful sourcing include:

- Supplier vetting: Focus on manufacturers offering technical support, customization options, and robust after-sales service.

- Component compatibility: Ensure LED strips and driver modules are fully compatible with your Arduino platforms to minimize development cycles.

- Cost optimization: Leverage bulk purchasing and regional partnerships to reduce logistics costs and tariffs.

- Sustainability and compliance: Consider suppliers adhering to environmental and safety certifications relevant to your markets.

Looking ahead, the demand for intelligent lighting and display solutions is set to accelerate, driven by smart city initiatives and IoT applications. Buyers who strategically source from agile, innovation-focused suppliers will be best positioned to capitalize on these trends. Engage early with trusted vendors to co-develop tailored LED matrix solutions that meet your specific operational and market requirements, ensuring sustained growth and technological leadership in your region.