Introduction: Navigating the Global Market for drive 5v led strip arduino

The integration of 5V LED strips driven by Arduino controllers has revolutionized lighting solutions across diverse sectors, from architectural installations to industrial automation. For international B2B buyers, especially in emerging and dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these components is crucial to achieving competitive advantage and innovation. These LED strips offer unparalleled flexibility with individually addressable LEDs, enabling sophisticated color and brightness control that can be tailored to complex project requirements.

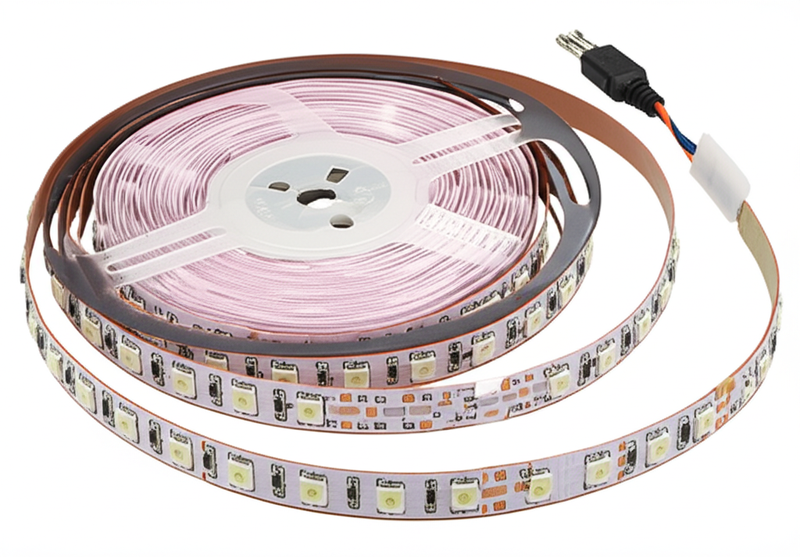

This comprehensive guide delves into the entire ecosystem surrounding drive 5V LED strip Arduino solutions. It covers the spectrum of product types—from standard WS2812B addressable strips to waterproof and customizable length variants—highlighting key technical specifications and compatibility considerations. Buyers will gain insights into critical materials and manufacturing standards that ensure durability and performance, along with stringent quality control measures adopted by reputable suppliers worldwide.

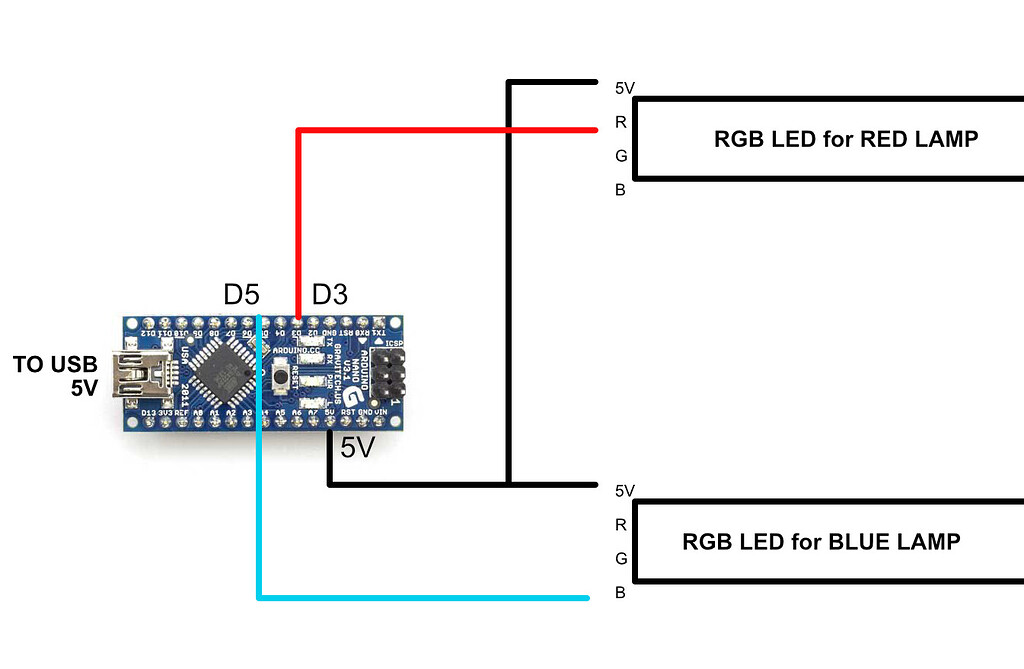

Additionally, the guide offers a detailed analysis of global supplier landscapes, including cost structures and procurement strategies tailored for regions like Nigeria, Indonesia, and beyond. Practical advice on navigating import regulations, ensuring supply chain reliability, and leveraging volume discounts is also provided. To empower informed decision-making, frequently asked questions address common challenges such as power management, wiring best practices, and integration with various Arduino models.

By equipping procurement professionals with this knowledge, the guide enables strategic sourcing decisions that optimize product quality, cost-efficiency, and delivery timelines—ultimately driving successful project outcomes in the competitive global marketplace.

Understanding drive 5v led strip arduino Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| WS2812B Individually Addressable Strip | Integrated driver IC per LED, one-wire data control, full RGB color control | Dynamic lighting displays, architectural lighting, digital signage | Pros: High flexibility and control, easy Arduino integration; Cons: Higher cost, requires precise power management |

| Non-Addressable 5V LED Strip | Simple parallel wiring, single color or RGB without individual LED control | Basic illumination, decorative lighting, retail displays | Pros: Lower cost, simpler wiring; Cons: Limited control, less dynamic effects |

| APA102 (DotStar) LED Strip | Separate clock and data lines, faster refresh rates, improved color accuracy | High-speed video walls, advanced lighting effects, industrial displays | Pros: Superior color fidelity, faster updates; Cons: More complex wiring, slightly higher cost |

| Waterproof IP65/IP67 Variants | Protective coating or encapsulation for moisture resistance | Outdoor signage, marine applications, harsh environment installations | Pros: Suitable for outdoor use, durable; Cons: Higher price, potential heat dissipation issues |

| Flexible & Cuttable Strips | Can be cut to custom lengths, flexible PCB substrate | Custom installations, curved surfaces, automotive lighting | Pros: Customizable length and shape; Cons: Requires careful handling, possible added cost for flexibility |

WS2812B Individually Addressable Strip

This type features an integrated driver IC per LED, enabling individual control of each LED’s color and brightness via a single data line. It is ideal for applications demanding dynamic, programmable lighting effects, such as architectural lighting or digital signage. For B2B buyers, the key considerations include ensuring compatibility with Arduino controllers and managing power supply carefully to avoid voltage drops in longer strips. While offering high flexibility, WS2812B strips come at a higher price point and require technical expertise for optimal deployment.

Non-Addressable 5V LED Strip

These strips have LEDs wired in parallel without individual control, typically available in single colors or simple RGB variants. They are suited for straightforward illumination needs like retail display lighting or decorative accents. B2B buyers benefit from their lower cost and simpler installation, making them attractive for large-scale projects with fixed lighting requirements. However, the lack of individual LED control limits creative lighting effects and adaptability.

APA102 (DotStar) LED Strip

Featuring separate clock and data lines, APA102 strips offer faster refresh rates and more precise color control than WS2812B. This makes them well-suited for high-speed video displays, industrial environments, and advanced lighting installations requiring smooth animations. Buyers should consider the increased wiring complexity and slightly higher cost, balanced against superior performance and reliability in demanding applications.

Waterproof IP65/IP67 Variants

Designed with silicon coatings or encapsulation, these LED strips withstand moisture and harsh environmental conditions. They are essential for outdoor signage, marine, or industrial projects where durability is critical. B2B buyers must factor in the increased cost and potential challenges in heat dissipation but gain the advantage of long-lasting, weather-resistant lighting solutions.

Flexible & Cuttable Strips

These strips feature flexible PCBs that can be cut to custom lengths and bent around curves, enabling bespoke installations in automotive lighting, custom architectural features, or product displays. Buyers should assess the flexibility requirements and installation environment to avoid damage during handling. While offering customization benefits, flexible strips may incur higher costs and require careful planning for effective integration.

Related Video: Getting Started With Arduino To Control An Addressable LED Strip In This Beginner Project Tutorial

Key Industrial Applications of drive 5v led strip arduino

| Industry/Sector | Specific Application of drive 5v led strip arduino | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Visual Merchandising | Dynamic in-store lighting and digital signage customization | Enhances customer engagement and brand experience with programmable lighting effects | Quality of LEDs for consistent brightness, flexible strip lengths, reliable Arduino compatibility |

| Automotive & Transportation | Interior ambient lighting and dashboard custom displays | Improves vehicle aesthetics and user interface customization, boosting customer appeal | Durability under vibration, low power consumption, and ease of integration with vehicle electronics |

| Smart Buildings & IoT | Automated architectural lighting and environmental status indicators | Energy-efficient, customizable lighting solutions that can be remotely controlled | Waterproofing (IP rating), compatibility with building automation protocols, and power supply stability |

| Entertainment & Events | Stage lighting effects and interactive installations | Creates immersive visual experiences that can be easily programmed and adapted | Scalability of LED strips, fast response times, and ease of programming with Arduino libraries |

| Agriculture & Horticulture | Controlled spectrum lighting for plant growth chambers | Enhances crop yield and quality through precise light spectrum and timing control | Spectrum accuracy, energy efficiency, and robustness in humid environments |

In the retail and visual merchandising sector, drive 5V LED strips controlled by Arduino enable businesses to create dynamic, eye-catching displays that attract and retain customer attention. These programmable LED strips allow for individually addressable colors and effects, providing a competitive edge in crowded marketplaces. For B2B buyers, especially in emerging markets such as Nigeria or Indonesia, sourcing LED strips with consistent brightness and flexible lengths is critical to adapt to diverse store layouts and lighting requirements.

Within the automotive and transportation industry, these LED strips are increasingly used for interior ambient lighting and customizable dashboard displays. They offer enhanced aesthetics and functionality, improving user experience and brand differentiation. International buyers must prioritize LED strips that withstand vibrations, operate efficiently on 5V power supplies, and integrate seamlessly with existing vehicle electronics, which is particularly relevant for markets in South America and the Middle East where vehicle customization is growing.

In smart buildings and IoT applications, 5V LED strips driven by Arduino serve as automated architectural lighting and environmental indicators, contributing to energy savings and smart facility management. Businesses benefit from customizable lighting that can be remotely controlled and scheduled. Buyers should focus on sourcing LED strips with appropriate IP ratings for indoor/outdoor use, compatibility with automation systems, and stable power supplies to ensure long-term reliability in European and African smart infrastructure projects.

For the entertainment and events sector, these LED strips provide vibrant stage lighting effects and interactive installations. Their programmability and scalability allow event organizers to create captivating experiences tailored to diverse audiences. Key sourcing factors for international buyers include fast LED response times, robust Arduino library support for programming, and the ability to scale installations economically, which is essential for event companies operating in regions with fluctuating demand.

In agriculture and horticulture, drive 5V LED strips are used for controlled spectrum lighting within plant growth chambers. Precise control over light color and duration helps optimize photosynthesis, improving crop yields and quality. Buyers from regions like Africa and South America must ensure the LED strips provide accurate spectral output, energy efficiency, and durability against humidity and temperature fluctuations, addressing the unique challenges of controlled-environment agriculture in these markets.

Related Video: How to use WS2812B RGB LED strip with Arduino | ws2811 ws2812 ws2813 ws2815 sk6812 sk9822 neopixel

Strategic Material Selection Guide for drive 5v led strip arduino

When selecting materials for components involved in driving 5V LED strips with Arduino, B2B buyers must consider electrical, thermal, mechanical, and environmental properties to ensure reliability and performance in diverse markets such as Africa, South America, the Middle East, and Europe. The following analysis covers four common material categories used in wiring, connectors, PCBs, and protective housings critical to these applications.

Copper (for Wiring and PCB Traces)

Key Properties: Copper offers excellent electrical conductivity (~5.8×10^7 S/m), good thermal conductivity, and moderate corrosion resistance when properly coated or plated. It withstands typical operating temperatures around 100°C in LED strip applications.

Pros & Cons: Copper wiring and PCB traces provide low resistance paths, ensuring efficient power delivery to the LED strip. It is widely available and cost-effective, with mature manufacturing processes globally. However, copper is prone to oxidation and corrosion if exposed to moisture or harsh environments without adequate protection, which can be a concern in humid or coastal regions.

Impact on Application: Copper’s high conductivity supports stable 5V power supply and signal integrity for addressable LED strips like WS2812B. For outdoor or high-humidity markets (e.g., Nigeria, Indonesia), copper wiring must be insulated or plated (e.g., tin or silver) to prevent degradation.

International B2B Considerations: Compliance with international standards such as ASTM B170 for copper wire and IPC-6012 for PCB copper thickness is crucial. Buyers in Europe and the Middle East often require RoHS compliance and certifications for halogen-free materials to meet environmental regulations.

Polyvinyl Chloride (PVC) Insulation for Wiring

Key Properties: PVC insulation offers good electrical insulation, flame retardancy, and chemical resistance. It can operate reliably between -20°C to 105°C, suitable for indoor LED strip installations.

Pros & Cons: PVC is inexpensive, flexible, and easy to process, making it a common choice for wire insulation. However, it can release harmful gases if burned and may degrade under prolonged UV exposure, limiting outdoor use without additional UV stabilizers.

Impact on Application: For indoor LED strip installations controlled by Arduino, PVC-insulated cables offer an economical and safe solution. In outdoor or high-UV environments (e.g., Middle East deserts), PVC insulation may require UV-resistant additives or replacement with more durable alternatives.

International B2B Considerations: Buyers from Africa and South America should verify compliance with IEC 60332 (fire resistance) and regional electrical safety standards. PVC materials compliant with REACH and RoHS are preferred in Europe to align with sustainability goals.

FR4 (Flame Retardant Epoxy Glass Laminate) for PCB Substrate

Key Properties: FR4 is a composite material with good mechanical strength, electrical insulation, and flame retardancy. It typically withstands temperatures up to 130°C (Tg) and offers dimensional stability.

Pros & Cons: FR4 is the industry standard for Arduino-compatible PCBs due to its reliability and cost-effectiveness. It supports fine copper trace etching needed for complex LED driver circuits. However, FR4 is not ideal for high-frequency or high-temperature applications beyond its Tg, and it is brittle under mechanical stress.

Impact on Application: FR4 ensures stable mounting and signal routing for Arduino boards driving 5V LED strips. For humid or corrosive environments, conformal coatings are recommended to protect the PCB. In markets like Indonesia and Nigeria, ensuring PCBs have protective coatings can extend product lifespan.

International B2B Considerations: Buyers should demand PCBs manufactured to IPC-4101 and UL94V-0 flame retardant standards. European and Middle Eastern buyers often require RoHS-compliant FR4 laminates to meet environmental regulations.

Silicone (for LED Strip Encapsulation and Waterproofing)

Key Properties: Silicone offers excellent flexibility, UV resistance, thermal stability (-60°C to 200°C), and superior moisture and chemical resistance. It is widely used for encapsulating LED strips to provide IP65 or higher waterproof ratings.

Pros & Cons: Silicone encapsulation protects LED strips from environmental damage, extending product life in outdoor or harsh conditions. It is more expensive than PVC or epoxy but provides superior durability and flexibility. Its softness can complicate automated assembly processes.

Impact on Application: For outdoor LED strip installations in regions with heavy rainfall or dust (e.g., South America, Africa), silicone encapsulation ensures reliable operation. It also enhances thermal dissipation, preventing LED overheating.

International B2B Considerations: Buyers should verify silicone materials meet ISO 10993 for biocompatibility if used in public or commercial spaces. Certifications for UV stability and IP ratings (IP65, IP67) are important for Middle Eastern and European markets where stringent quality standards prevail.

Summary Table

| Material | Typical Use Case for drive 5v led strip arduino | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Wiring and PCB traces for power and signal transmission | Excellent electrical and thermal conductivity ensuring efficient power delivery | Susceptible to corrosion without protective coatings in humid or coastal environments | Medium |

| PVC | Insulation for wiring in indoor LED strip installations | Cost-effective, flexible, and flame retardant insulation | Degrades under UV exposure and releases harmful gases if burned | Low |

| FR4 | PCB substrate for Arduino and LED driver circuits | Reliable mechanical strength and flame retardancy with good electrical insulation | Brittle under mechanical stress and limited high-temp tolerance | Medium |

| Silicone | Encapsulation and waterproofing of LED strips | Superior moisture, UV, and thermal resistance for outdoor durability | Higher cost and potential assembly complexity | High |

This material selection guide equips international B2B buyers with actionable insights to choose optimal materials that balance performance, cost, and compliance for driving 5V LED strips with Arduino across diverse environmental and regulatory landscapes.

In-depth Look: Manufacturing Processes and Quality Assurance for drive 5v led strip arduino

Manufacturing Process of 5V LED Strips for Arduino Applications

The production of 5V LED strips, particularly those compatible with Arduino control such as WS2812B addressable strips, involves several critical stages designed to ensure functionality, durability, and visual quality. Understanding these stages helps B2B buyers evaluate supplier capabilities and product reliability.

1. Material Preparation

- LED Chips and ICs: The core components are RGB SMD LEDs (commonly 5050 size) integrated with driver ICs (e.g., WS2812B) that allow individual LED control. These components are sourced from specialized semiconductor manufacturers.

- Flexible Printed Circuit Boards (FPCBs): The base material is a flexible PCB, typically made from polyimide or polyester film, pre-coated with copper for circuitry.

- Electrical Components: Resistors, capacitors, and connectors are prepared to regulate voltage and signal integrity.

- Protective Materials: For waterproof or dustproof variants, silicone or epoxy coatings are prepared.

2. Forming and Circuit Fabrication

- PCB Etching and Patterning: Copper layers on the flexible substrate are etched to form precise circuit paths that connect the LEDs and ICs in series.

- Solder Mask Application: A solder mask is applied to protect circuitry and prevent accidental shorting.

- Component Placement: Using Surface Mount Technology (SMT), LEDs, ICs, resistors, and capacitors are accurately placed on the PCB. Automated pick-and-place machines ensure high precision and speed.

- Soldering: Reflow soldering is employed to secure components onto the PCB, ensuring robust electrical connections.

3. Assembly

- Segment Cutting: LED strips are cut into standardized lengths or customized sizes as per buyer requirements.

- Connector Attachment: Power and signal connectors are attached, often with soldering and sometimes crimping or welding, to enable easy integration with Arduino boards.

- Waterproofing (if applicable): Strips are coated with silicone or encased in protective tubing for IP65 or higher ratings.

- Packaging: Strips are rolled on spools or laid flat in antistatic packaging to prevent damage during shipment.

4. Finishing

- Visual Inspection: Automated optical inspection (AOI) systems check for placement accuracy and soldering defects.

- Functional Testing: Initial power-on tests verify LED illumination and addressable control functionality.

- Labeling and Documentation: Strips are labeled with batch numbers, voltage ratings, and certification marks. User manuals and wiring guides are often included.

Quality Assurance and Control (QA/QC) Framework

A rigorous QA/QC system is critical to guarantee that 5V LED strips meet performance specifications and regulatory requirements, especially for complex, addressable LED products aimed at international markets.

International Standards and Certifications

- ISO 9001: Many reputable manufacturers implement ISO 9001 quality management systems, ensuring standardized processes and continuous improvement.

- CE Marking: Required for products sold in Europe, it confirms compliance with safety, electromagnetic compatibility (EMC), and environmental directives.

- RoHS Compliance: Restricts hazardous substances, critical for European and increasingly global markets.

- FCC: Ensures electromagnetic interference (EMI) limits compliance, important for North American and some Middle Eastern markets.

- UL Certification: Safety certification commonly recognized in North America but also valued globally.

- Additional Regional Certifications: Some markets like the Middle East or South America may require local approvals or compliance with standards such as INMETRO (Brazil) or SASO (Saudi Arabia).

Key QC Checkpoints

- Incoming Quality Control (IQC): Raw materials and components (LED chips, ICs, PCBs) undergo strict inspection for defects, dimensions, and electrical parameters before production.

- In-Process Quality Control (IPQC): Continuous monitoring during SMT placement, soldering, and assembly stages. This includes AOI for solder joints and component alignment, as well as in-line electrical testing.

- Final Quality Control (FQC): Complete LED strips are tested for:

- Electrical integrity (voltage, current, signal integrity)

- LED functionality and color accuracy

- Addressable control responsiveness with Arduino or equivalent controllers

- Waterproofing and mechanical durability (for IP65+ variants)

- Visual defects and packaging integrity

Common Testing Methods

- Electrical Testing: Power-on tests with load simulation to verify voltage and current consumption per LED segment.

- Color Calibration: Measurement of LED color temperature and brightness uniformity using spectrometers.

- Signal Integrity Testing: Ensures data transmission through the strip’s ICs is stable and error-free.

- Environmental Stress Testing: Thermal cycling and humidity exposure to assess durability.

- Mechanical Testing: Flexibility tests on the strip to confirm resistance to bending and handling.

How B2B Buyers Can Verify Supplier Quality Control

International buyers, especially from emerging markets in Africa, South America, the Middle East, and Europe, should adopt proactive strategies to validate supplier QA/QC capabilities:

1. Conduct Factory Audits

- On-site Inspections: Arrange visits or third-party audits to inspect production lines, equipment, and quality management systems.

- Process Verification: Confirm adherence to ISO 9001 and other relevant standards. Review supplier documentation such as process flow charts and QC manuals.

- Staff Qualification: Evaluate training and competency of production and QC personnel.

2. Request Quality Documentation

- Test Reports: Obtain batch-specific IQC, IPQC, and FQC reports including electrical and visual inspection results.

- Certificates: Verify authenticity of CE, RoHS, UL, or other certifications.

- Sample Testing: Request product samples for independent lab testing to verify performance claims.

3. Utilize Third-Party Inspection Services

- Pre-shipment Inspections: Engage third-party quality control firms to perform random inspections before shipment.

- Laboratory Analysis: Independent labs can conduct detailed electrical, chemical, and mechanical testing, providing unbiased assurance.

4. Understand Regional QC Nuances

- Voltage and Power Standards: Ensure compatibility with local power infrastructure (e.g., stable 5V DC supply) and safety norms.

- Environmental Requirements: For humid or dusty regions (e.g., Nigeria, Indonesia), prioritize suppliers offering IP65 or higher-rated waterproof LED strips.

- Regulatory Compliance: Confirm that products meet import regulations and certification requirements specific to the buyer’s country or trading bloc.

- After-Sales Support: Verify warranty terms and technical support availability, considering time zone and language differences.

Conclusion: Strategic Insights for International B2B Buyers

- Supplier Selection: Prioritize manufacturers with transparent, documented manufacturing processes and strong adherence to international QA/QC standards.

- Customization Capability: Look for suppliers able to tailor strip length, IP rating, and connector types to your market needs.

- Quality Verification: Implement a multi-tiered verification approach combining audits, documentation review, and third-party inspections to mitigate risks.

- Regulatory Alignment: Align product certifications with your regional import and safety standards to avoid customs issues and ensure market acceptance.

- Long-Term Partnership: Invest in building relationships with suppliers who demonstrate consistent quality and responsiveness, crucial for scaling LED strip applications in diverse environments.

By thoroughly understanding the manufacturing and quality assurance processes, international B2B buyers can confidently source 5V LED strips optimized for Arduino projects, ensuring reliable performance and compliance across global markets.

Comprehensive Cost and Pricing Analysis for drive 5v led strip arduino Sourcing

When sourcing 5V LED strips compatible with Arduino for B2B projects, understanding the detailed cost and pricing structure is essential to optimize procurement and ensure profitability. The pricing of these components is influenced by multiple factors spanning from raw materials to logistics, which vary significantly across regions such as Africa, South America, the Middle East, and Europe.

Key Cost Components

-

Materials: The primary cost driver is the LED strip itself, typically WS2812B or similar addressable RGB LEDs integrated with driver ICs. Quality of LEDs (e.g., brand, chip type), PCB materials, and protective coatings (IP30 vs. IP65 waterproofing) directly affect the price. Copper-clad substrates and quality silicone coatings add to costs but enhance durability.

-

Labor and Manufacturing Overhead: Labor costs fluctuate based on the manufacturing country. For example, sourcing from China or Southeast Asia usually offers lower labor costs compared to European manufacturers, affecting overall pricing. Overhead includes factory utilities, quality assurance processes, and equipment depreciation.

-

Tooling and Setup Costs: Initial setup for customized LED strip lengths, color calibration, or specialized connectors entails tooling expenses. These are amortized over order volume but can increase unit costs for small or highly customized runs.

-

Quality Control (QC): Rigorous testing of LEDs for color accuracy, brightness consistency, and electrical stability adds to cost but reduces returns and defects. Suppliers with certifications like ISO 9001 or CE marking may charge premiums reflecting their quality assurance standards.

-

Logistics and Import Duties: Shipping costs depend on order size, mode (air vs. sea freight), and destination. African and South American buyers often face higher freight and customs duties compared to European buyers, impacting landed costs significantly.

-

Margin: Suppliers typically embed margins ranging from 10% to 30%, depending on exclusivity, brand reputation, and buyer relationships.

Price Influencers for International Buyers

-

Order Volume and Minimum Order Quantities (MOQs): Larger orders usually secure better unit pricing. However, buyers from emerging markets like Nigeria or Indonesia should balance MOQ with storage and capital constraints.

-

Product Specifications and Customization: Custom LED densities, waterproofing levels, or integrated control features increase costs. Tailoring firmware or Arduino compatibility can also affect pricing.

-

Material Quality and Certifications: Certified components command higher prices but assure performance and regulatory compliance, critical for European markets with strict standards.

-

Supplier Reliability and Location: Established suppliers with proven track records may price higher but reduce risk. Proximity to ports or trade hubs can lower logistics costs.

-

Incoterms and Payment Terms: Incoterms (e.g., FOB, CIF, DDP) affect who bears shipping and insurance risks, influencing total landed cost. Negotiating favorable payment terms (e.g., letters of credit) can improve cash flow.

Actionable Buyer Tips

-

Negotiate Beyond Price: Engage suppliers on payment terms, lead times, and after-sales support. Volume discounts and bundled orders (including Arduino boards and accessories) can improve cost-efficiency.

-

Calculate Total Cost of Ownership (TCO): Consider warranty, defect rates, shipping delays, and customs clearance complexity. Sometimes a higher upfront price reduces long-term costs.

-

Leverage Regional Sourcing Hubs: For African buyers, sourcing from Middle Eastern or European suppliers might reduce transit times and import duties. Similarly, South American buyers may benefit from regional distributors.

-

Request Samples and Certifications: Before large orders, verify product quality and compliance with local standards to avoid costly rejections.

-

Understand Pricing Nuances: Prices for 5V LED strips fluctuate with global supply chain shifts, raw material costs (e.g., copper, silicon), and seasonal demand. Stay informed to time purchases advantageously.

Indicative Pricing Disclaimer

Prices for 5V WS2812B LED strips typically range from $10 to $25 per 5-meter roll depending on quality, customization, and supplier location. Additional components such as Arduino boards, resistors, and capacitors add to project cost. These figures are indicative and vary based on current market conditions, supplier negotiations, and logistics.

By dissecting these cost elements and price influencers, international B2B buyers can develop a strategic sourcing approach tailored to their regional and project needs, optimizing both upfront investment and long-term value.

Spotlight on Potential drive 5v led strip arduino Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘drive 5v led strip arduino’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for drive 5v led strip arduino

Critical Technical Properties for Driving 5V LED Strips with Arduino

When sourcing 5V LED strips controlled by Arduino for international B2B projects, understanding key technical specifications is essential to ensure compatibility, performance, and cost-effectiveness.

-

Input Voltage and Power Consumption

The LED strips operate typically at 5 volts DC, making them compatible with Arduino’s 5V logic. Power consumption is often specified per LED (e.g., 0.3W/LED) or per meter (e.g., 18W/m for 60 LEDs). Accurate knowledge of power requirements helps buyers plan appropriate power supplies and avoid overloading circuits, which is critical in large-scale installations across diverse markets. -

LED Type and Chip Integration

Most 5V strips use SMD 5050 RGB LEDs integrated with driver ICs like the WS2812B. Each LED contains an embedded controller allowing individual addressability. This integration reduces wiring complexity and enhances effects customization, a key selling point for clients requiring advanced lighting solutions. -

LED Density and Flexibility

LED density is typically expressed as LEDs per meter (e.g., 60 LEDs/m). Higher density increases brightness and detail but impacts cost and power needs. The strip’s physical flexibility and cuttable segments enable custom lengths, accommodating varied project scales and installation environments in different regions. -

Ingress Protection Rating (IP Rating)

IP ratings, such as IP30 (non-waterproof) or IP65 (silicone-coated waterproof), indicate environmental resistance. Buyers in humid or outdoor markets (Middle East, Africa, South America) must prioritize waterproof variants to ensure durability and reduce maintenance costs. -

Signal Control and Communication Protocol

The strips use a one-wire serial communication protocol, controlled via a single digital pin on the Arduino. Understanding this ensures proper integration with control systems and software, reducing development time and technical support costs. -

Tolerance and Quality Assurance

Tolerance in voltage, current, and color consistency affects product reliability. Sourcing from manufacturers with stringent quality controls and clear tolerance specifications mitigates risks of early failures and warranty claims, especially critical for large-volume orders.

Key Trade Terminology for International B2B LED Strip Procurement

Navigating global procurement of Arduino-driven 5V LED strips requires familiarity with common trade and industry terms that influence pricing, delivery, and contractual obligations.

-

OEM (Original Equipment Manufacturer)

OEM refers to suppliers who produce LED strips that can be branded or customized by the buyer. Engaging with OEMs enables buyers to differentiate products, control quality, and potentially reduce costs by bypassing intermediaries. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier is willing to sell per order. Understanding MOQ is crucial for budgeting and inventory management, especially for startups or distributors in emerging markets like Nigeria or Indonesia, where storage capacity and capital may be limited. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting detailed pricing, lead times, and technical specs. Well-prepared RFQs enable buyers to compare offers objectively and negotiate better terms, a key practice for buyers managing cross-border transactions. -

Incoterms (International Commercial Terms)

These standardized terms define responsibilities for shipping, insurance, and customs between buyer and seller. Common terms include FOB (Free On Board) and CIF (Cost, Insurance, Freight). Clear understanding prevents costly misunderstandings and helps buyers optimize logistics and total landed costs. -

Lead Time

Lead time is the period between placing an order and receiving goods. For LED strips, lead times can vary significantly by supplier location and production capacity. Accurate lead time estimation is vital for project scheduling and avoiding costly delays. -

Batch Number / Lot Traceability

Batch numbers allow tracking of production lots for quality control and warranty claims. Buyers should insist on traceability to maintain supply chain integrity, especially when sourcing from multiple factories or regions.

By mastering these technical specifications and trade terms, international B2B buyers can make informed purchasing decisions, streamline supply chains, and ensure product quality and compliance across diverse markets. This knowledge empowers buyers to negotiate effectively, reduce risks, and tailor solutions that meet both technical and commercial requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the drive 5v led strip arduino Sector

Market Overview & Key Trends

The drive 5V LED strip Arduino sector has witnessed significant growth globally, fueled by rising demand for customizable, energy-efficient lighting solutions in commercial, industrial, and creative applications. For international B2B buyers, especially from emerging markets in Africa, South America, the Middle East, and Europe, this sector offers ample opportunities driven by the convergence of IoT, smart automation, and flexible electronics.

Key market drivers include the increasing adoption of individually addressable LED strips like WS2812B, which allow precise control over color and brightness via Arduino or similar microcontrollers. This technology supports innovative use cases such as architectural lighting, digital signage, and interactive installations. Buyers in regions like Nigeria, Indonesia, and Brazil benefit from the flexibility of these strips, enabling tailored solutions that meet local infrastructure and aesthetic requirements.

Sourcing trends reveal a shift towards modular, plug-and-play LED strip kits that integrate power management, resistors, and capacitors to simplify installation and reduce technical barriers. Suppliers are increasingly offering customizable lengths, IP-rated waterproofing (IP30 to IP65), and improved chipsets to enhance reliability and application scope. For B2B buyers, this means prioritizing suppliers who can provide scalable volumes with consistent quality and technical support.

Additionally, the rise of open-source communities and Arduino-compatible ecosystems has democratized access to advanced lighting control, enabling companies across continents to innovate without heavy R&D investment. However, buyers must navigate supply chain complexities, including lead times, tariffs, and certification requirements, particularly when importing into regulated markets in Europe and the Middle East.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are becoming paramount in the procurement of drive 5V LED strip Arduino components. The environmental impact of electronic waste, energy consumption, and hazardous materials in LED manufacturing has prompted buyers to seek eco-friendly alternatives and ethical supply chains.

For international buyers, sourcing LED strips with RoHS compliance (Restriction of Hazardous Substances) ensures that products are free from harmful chemicals like lead, mercury, and cadmium. Certifications such as CE marking and ISO 14001 environmental management standards provide additional assurance of responsible manufacturing practices.

Illustrative Image (Source: Google Search)

Material selection is critical; LED strips utilizing low-power, high-efficiency WS2812B chips reduce energy consumption, aligning with corporate sustainability goals and reducing operational costs. Buyers should also assess suppliers’ policies on recycling, waste reduction, and carbon footprint, favoring those that offer transparent reporting and adhere to international labor standards.

In regions like Africa and South America, where electronic waste management infrastructure may be limited, the importance of durability and repairability of LED strips cannot be overstated. B2B buyers should prioritize products designed for longevity and modular replacement to minimize environmental impact.

Illustrative Image (Source: Google Search)

Moreover, ethical sourcing extends to fair labor practices and conflict-free sourcing of raw materials. Engaging with suppliers who demonstrate commitment to social responsibility not only mitigates reputational risks but also fosters sustainable partnerships across the supply chain.

Brief Evolution & Historical Context

The development of the drive 5V LED strip Arduino sector parallels advancements in microcontroller technology and LED innovations. Initially, LED strips offered static colors with limited control, primarily used for basic backlighting. The introduction of individually addressable LEDs like the WS2812B in the early 2010s revolutionized the market by integrating driver ICs directly into each LED package.

This innovation enabled precise color and brightness control through simple serial communication protocols compatible with Arduino platforms. The synergy between Arduino’s open-source hardware and WS2812B’s intelligent LED design catalyzed rapid adoption across diverse industries, from entertainment to industrial automation.

Over time, improvements in power efficiency, waterproofing, and manufacturing scalability have expanded applications and facilitated international trade. Today, the sector is characterized by a dynamic ecosystem of manufacturers, distributors, and developers collaborating to meet the evolving demands of global B2B buyers seeking customizable, sustainable lighting solutions.

Related Video: Simple POV Display using APA102 RGB LED STRIP and Arduino NANO

Frequently Asked Questions (FAQs) for B2B Buyers of drive 5v led strip arduino

-

How can I effectively vet suppliers of 5V LED strips compatible with Arduino for international B2B purchases?

To vet suppliers, prioritize those with verifiable business licenses, ISO or relevant certifications, and positive trade references. Request product samples to evaluate quality and compatibility with Arduino systems. Check if suppliers provide detailed technical datasheets and support documentation. Use platforms with secure payment options and buyer protection policies. For buyers in Africa, South America, the Middle East, and Europe, consider suppliers with experience in cross-border logistics and compliance to avoid customs delays. -

What customization options are typically available for 5V LED strips driven by Arduino in bulk orders?

Most manufacturers offer customization in strip length, LED density (e.g., 30, 60 LEDs per meter), waterproofing levels (IP30, IP65, IP67), and color configurations (RGB, addressable WS2812B). Custom firmware or pre-programmed Arduino code can sometimes be provided. Packaging and labeling can also be customized for branding purposes. Discuss your exact technical and aesthetic needs upfront to ensure the supplier can accommodate your requirements, especially when scaling for large orders. -

What are common MOQ (Minimum Order Quantity) and lead times for 5V Arduino-compatible LED strips in international B2B transactions?

MOQ varies by supplier but typically ranges from 100 to 500 meters per order, depending on customization. Lead times generally span 2 to 6 weeks, factoring in production, quality checks, and international shipping. Buyers should negotiate MOQs early and confirm if samples are available with lower minimums. For faster market entry, consider suppliers with regional warehouses or those offering expedited production lines. -

Which payment terms and methods are advisable for international purchases of Arduino-driven 5V LED strips?

Secure payment methods like Letters of Credit (LC), PayPal, or escrow services protect buyers against fraud. Initial deposits (30%-50%) are common, with balances paid upon shipment or after inspection. Negotiate clear payment milestones tied to production stages. For buyers in emerging markets such as Nigeria or Indonesia, verify currency exchange policies and bank charges to avoid hidden costs. Transparent communication about payment terms reduces disputes. -

What quality assurance and certifications should international buyers expect for 5V LED strips used with Arduino?

Look for CE, RoHS, and FCC certifications to ensure compliance with safety, environmental, and electromagnetic standards. Quality assurance processes should include in-line testing for LED functionality, color consistency, and durability under various conditions. Request test reports or certification documents from suppliers. For demanding markets like Europe, certifications are often mandatory for import clearance and resale. -

How can logistics be optimized when importing 5V LED strips from overseas suppliers?

Choose suppliers offering consolidated shipments or FOB (Free On Board) terms to control freight costs. Work with freight forwarders experienced in handling electronics, ensuring proper packaging to prevent damage. Understand import duties and taxes applicable in your country to budget accurately. For regions with complex customs like the Middle East or South America, consider using bonded warehouses or local distribution partners to speed delivery.

-

What steps should be taken to resolve disputes related to quality or delivery delays in international B2B deals for LED strips?

Establish clear contracts detailing product specifications, delivery timelines, and penalties for non-compliance. Use inspection agencies or third-party quality auditors before shipment to catch defects early. Communicate promptly and document all correspondence in disputes. Leverage arbitration clauses or trade mediation platforms if direct negotiation fails. Maintaining a professional and cooperative relationship with suppliers often facilitates quicker resolutions. -

How do international buyers handle technical support and after-sales service for Arduino-driven 5V LED strips?

Prioritize suppliers offering comprehensive technical documentation, example Arduino code libraries, and responsive support teams. For complex projects, request training materials or remote assistance. Confirm warranty terms covering defective LEDs or driver ICs. Given time zone differences, establish clear communication channels (e.g., email, video calls) and response SLAs. Strong after-sales support minimizes downtime and enhances long-term partnership value.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for drive 5v led strip arduino

In navigating the procurement of 5V LED strips driven by Arduino, international B2B buyers must prioritize strategic sourcing to optimize cost, quality, and supply chain reliability. Understanding the technical intricacies—such as the WS2812B’s integrated driver ICs, power requirements, and data control protocols—enables more informed supplier evaluations and customization to end-use cases. For markets in Africa, South America, the Middle East, and Europe, sourcing from manufacturers who provide robust technical support, certifications, and scalable production is critical to meet diverse application demands ranging from industrial automation to smart lighting.

Key sourcing considerations include:

- Supplier expertise in addressable LED technology and Arduino compatibility

- Quality assurance with consistent electrical and mechanical specifications

- Customization capabilities for length, IP rating, and color configurations

- Logistics and lead times aligned with regional infrastructure and import regulations

Looking ahead, the increasing adoption of smart lighting and IoT-driven solutions across emerging and established markets presents a compelling growth opportunity. Buyers are encouraged to engage with innovative manufacturers and distributors who embrace transparency, flexible MOQ terms, and localized support. By leveraging strategic partnerships and investing in supplier relationships, businesses can secure competitive advantages in deploying advanced 5V LED strip solutions tailored to their specific operational environments.