Guide to Dotless Led Strip Lights

- Introduction: Navigating the Global Market for dotless led strip lights

- Understanding dotless led strip lights Types and Variations

- Key Industrial Applications of dotless led strip lights

- Strategic Material Selection Guide for dotless led strip lights

- In-depth Look: Manufacturing Processes and Quality Assurance for dotless led strip lights

- Comprehensive Cost and Pricing Analysis for dotless led strip lights Sourcing

- Spotlight on Potential dotless led strip lights Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for dotless led strip lights

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dotless led strip lights Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dotless led strip lights

- Strategic Sourcing Conclusion and Outlook for dotless led strip lights

Introduction: Navigating the Global Market for dotless led strip lights

Dotless LED strip lights represent a transformative advancement in the lighting industry, delivering seamless, uniform illumination without visible hotspots. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding the unique advantages and sourcing strategies for dotless LED strips is essential to meeting evolving design, efficiency, and durability demands.

These innovative lighting solutions utilize high-density LED arrays encapsulated in advanced silicone diffusers, offering superior aesthetics and performance compared to traditional dotted strip lights. Their slim profiles, IP65-rated protection, and customizable color options make them ideal for a wide range of applications, from architectural accent lighting in Italy to robust outdoor installations in Kenya’s varied climates.

This comprehensive guide equips buyers with actionable insights across all critical dimensions:

– Types and configurations including single color, tunable white, RGB, and advanced multi-channel options

– Material quality and manufacturing processes that impact longevity and light consistency

– Quality control standards ensuring product reliability in demanding environments

– Supplier evaluation criteria to identify trustworthy manufacturers and streamline procurement

– Cost analysis and pricing strategies tailored for bulk international purchases

– Market trends and regional considerations for optimizing investment returns

– Answers to frequently asked questions addressing technical, logistical, and regulatory concerns

By leveraging this expertly curated knowledge, B2B buyers can confidently navigate the complexities of the global dotless LED strip light market, securing high-quality products that align with their project specifications and regional requirements—ultimately enhancing their competitive edge and operational efficiency.

Understanding dotless led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Color Dotless LED Strip | Uniform single-color output, slim profile, milky silicone diffuser for smooth light | Retail lighting, architectural accents, hospitality venues | + High reliability and uniformity; – Limited color flexibility |

| Tunable White Dotless LED Strip | Adjustable color temperature from warm to cool white, seamless diffusion | Office lighting, healthcare facilities, museums | + Versatile ambiance control; – Slightly higher cost than single color |

| RGB Dotless LED Strip | Multi-color LEDs with color mixing, dotless continuous light effect | Entertainment venues, advertising, dynamic retail displays | + Dynamic color effects; – Requires compatible controllers |

| RGBW Dotless LED Strip | Adds dedicated white LEDs to RGB for richer whites and mixed colors | High-end residential, luxury retail, event lighting | + Enhanced color accuracy and white tones; – More complex installation |

| RGBTW (RGB + Tunable White) Dotless LED Strip | Combines RGB and tunable white LEDs, offering full color range plus white tuning | Premium commercial projects, smart lighting systems | + Ultimate flexibility; – Higher investment and control complexity |

Single Color Dotless LED Strip

This type offers a consistent, single-color illumination with a slim, milky silicone diffuser that eliminates visible LED dots. Ideal for applications requiring clean, uniform lighting such as retail displays or architectural highlights, it provides excellent reliability and ease of installation. For B2B buyers, these strips are cost-effective and simple to integrate, making them suitable for large-scale bulk purchases where color variation is not critical.

Tunable White Dotless LED Strip

Tunable white strips enable adjustment of color temperature, shifting from warm to cool white to match different environments or moods. This versatility makes them well-suited for offices, healthcare, and cultural institutions where lighting quality impacts productivity and experience. Buyers should consider the need for compatible dimming controls and the slightly higher price point, balanced by enhanced user comfort and energy savings.

RGB Dotless LED Strip

RGB dotless strips deliver a continuous line of vibrant colors through integrated red, green, and blue LEDs. Perfect for dynamic environments like entertainment venues or advertising where color-changing effects attract attention. B2B buyers must evaluate compatibility with controllers and potential complexity in installation but gain the advantage of creating engaging, customizable lighting solutions.

RGBW Dotless LED Strip

Adding dedicated white LEDs to the RGB mix, RGBW strips offer richer white tones alongside full color capabilities. This type is favored in luxury retail and upscale residential projects requiring both vivid colors and quality white light. Buyers benefit from enhanced color rendering but should prepare for more sophisticated installation and higher upfront costs.

RGBTW (RGB + Tunable White) Dotless LED Strip

The most advanced variation, RGBTW combines RGB color mixing with tunable white LEDs, enabling full-spectrum color and adjustable white temperature in one strip. This flexibility suits premium commercial and smart lighting projects aiming for maximum customization and ambiance control. While offering unmatched versatility, B2B buyers must consider the increased investment in controllers and technical expertise for integration.

Related Video: L-Series Dotless™ Linear LED Strip Lights

Key Industrial Applications of dotless led strip lights

| Industry/Sector | Specific Application of dotless led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Hospitality | Ambient and accent lighting in high-end retail stores and luxury hotels | Enhances customer experience with seamless, elegant lighting; reduces energy costs and maintenance | Ensure IP65 rating for durability, color options for branding, consistent color temperature |

| Architecture & Interior Design | Cove lighting, wall washing, and feature illumination in commercial and residential projects | Provides uniform, shadow-free illumination enhancing aesthetic appeal; flexible installation | Custom length and color tuning options, compatibility with dimmers and smart controls |

| Automotive & Transportation | Interior lighting for vehicles, public transport, and showrooms | Creates premium look with continuous lighting effect; robust and dust-resistant for harsh environments | High durability, vibration resistance, and compliance with automotive safety standards |

| Outdoor & Landscape Lighting | Pathways, facade, and signage illumination in urban and commercial outdoor settings | Weather-resistant, anti-UV lighting solution with smooth light output improves visibility and safety | Confirm IP65 or higher rating, UV resistance, and ease of installation in varied climates |

| Exhibition & Event Management | Dynamic lighting for exhibitions, trade shows, and event stages | Enables creative, customizable lighting effects to attract attention and enhance visual displays | Availability of RGB/RGBW options, ease of integration with control systems, and rapid deployment |

Dotless LED strip lights are revolutionizing retail and hospitality environments by delivering smooth, continuous illumination that enhances the ambiance without visible light dots. For B2B buyers in regions like Italy and Kenya, sourcing IP65-rated strips with customizable color temperatures can ensure durability and brand alignment while reducing energy consumption and maintenance overheads in luxury stores and hotels.

In the architecture and interior design sector, dotless LED strips serve as ideal solutions for cove lighting and wall washing, providing shadow-free, uniform illumination that elevates the spatial experience. Buyers focused on commercial and residential projects across Europe and South America should prioritize suppliers offering tunable white and dimmable options, allowing precise control over lighting moods and compliance with local electrical standards.

The automotive and transportation industry benefits from dotless LED strips in vehicle interiors and showrooms, where continuous lighting enhances premium aesthetics and passenger comfort. For B2B clients in the Middle East and Africa, selecting products with robust vibration resistance and dust-proof coatings is critical, given the challenging operating environments and safety regulations in these markets.

For outdoor and landscape lighting, dotless LED strips provide weatherproof, UV-resistant illumination solutions suitable for pathways, building facades, and signage. Businesses in urban centers across South America and Africa should ensure that the LED strips meet IP65 or higher standards to withstand harsh environmental conditions while delivering consistent light quality for safety and visual appeal.

In exhibition and event management, dotless LED strips offer dynamic, customizable lighting that can transform trade show booths and event stages. International buyers should focus on suppliers providing RGB or RGBW options compatible with advanced control systems, enabling rapid installation and versatile lighting effects to capture audience attention and enhance brand presence at global events.

Related Video: Dotless™ LED Strip Lights. L-Series aspectLED

Strategic Material Selection Guide for dotless led strip lights

When selecting materials for dotless LED strip lights, international B2B buyers must consider factors such as durability, environmental resistance, manufacturing complexity, and compliance with regional standards. The material choice directly affects product longevity, installation flexibility, and suitability for specific applications, especially in diverse climates and regulatory environments found across Africa, South America, the Middle East, and Europe.

Silicone

Key Properties: Silicone is prized for its flexibility, excellent thermal stability (typically -60°C to +230°C), UV resistance, and inherent waterproofing capabilities. It is chemically inert and resistant to corrosion and dust, making it ideal for outdoor and harsh environments.

Pros & Cons: Silicone’s flexibility allows for slim, continuous extrusion processes that produce the seamless “dotless” effect. It provides excellent protection against moisture and UV degradation, which is critical for outdoor installations common in regions with intense sunlight such as the Middle East and parts of Africa. However, silicone can be more costly than other materials and requires specialized extrusion equipment, potentially increasing manufacturing lead times.

Impact on Application: Silicone is ideal for applications requiring IP65 or higher ingress protection, such as outdoor architectural lighting or signage in humid or dusty environments. Its resistance to UV and corrosion makes it suitable for coastal areas in South America and Europe where salt air is a concern.

B2B Considerations: Buyers in Italy and Europe should verify compliance with EU RoHS and REACH regulations, which silicone materials typically meet. In Africa and South America, suppliers should provide certifications for UV resistance and IP ratings. The higher cost is often justified by reduced maintenance and longer lifespan in demanding environments.

Polycarbonate (PC)

Key Properties: Polycarbonate offers high impact resistance, good thermal tolerance (up to around 135°C), and excellent optical clarity. It is less flexible than silicone but provides robust mechanical protection.

Pros & Cons: PC is more affordable than silicone and easier to mold, making it suitable for rigid or semi-rigid LED strip housings. However, it can yellow over time when exposed to UV light unless treated with anti-UV coatings. Its rigidity limits use in highly curved or flexible installations.

Impact on Application: PC is commonly used in indoor or semi-outdoor environments where impact resistance is prioritized over extreme flexibility. It suits commercial lighting in retail or office spaces prevalent in European and Middle Eastern markets.

B2B Considerations: Buyers should ensure that PC components have UV stabilization if intended for outdoor use, especially in regions with strong sunlight like South America or Africa. Compliance with ASTM D1003 for optical properties and DIN standards for mechanical strength is advantageous. PC’s cost-effectiveness makes it attractive for mid-range projects.

Acrylic (PMMA)

Key Properties: Acrylic provides excellent light transmission (up to 92%), good weather resistance, and moderate thermal stability (up to 80-90°C). It is more brittle than PC but offers superior clarity.

Pros & Cons: Acrylic is relatively inexpensive and easy to fabricate, making it suitable for decorative lighting applications where light quality is paramount. However, its brittleness and lower impact resistance limit its use in high-traffic or industrial environments.

Impact on Application: Acrylic is ideal for indoor decorative lighting in retail or hospitality sectors, especially in European and South American markets focused on aesthetics. It is less suitable for outdoor or rugged installations common in African or Middle Eastern industrial settings.

B2B Considerations: Buyers should verify compliance with JIS K 7105 or ASTM D4802 standards for weather resistance. Acrylic’s lower thermal tolerance means it should be paired with LED strips of moderate power to avoid deformation. Its lower cost appeals to budget-conscious projects emphasizing visual appeal.

Thermoplastic Polyurethane (TPU)

Key Properties: TPU is a highly flexible, abrasion-resistant material with good chemical resistance and moderate thermal stability (typically up to 120°C). It offers excellent elasticity and durability.

Pros & Cons: TPU’s flexibility supports complex shapes and tight installation spaces, making it suitable for custom or wearable lighting solutions. It is more abrasion-resistant than silicone but less UV resistant, requiring additives for outdoor use. TPU is moderately priced but less commonly used in large-scale LED strip manufacturing.

Impact on Application: TPU is suitable for indoor applications requiring flexibility and durability, such as automotive interiors or wearable tech lighting in Europe and South America. Its lower UV resistance limits outdoor use in harsh climates without protective coatings.

B2B Considerations: Buyers should request detailed material data sheets and certifications for chemical resistance and flexibility. TPU’s niche applications mean sourcing may be limited, so buyers in emerging markets like Kenya or Brazil should plan for longer lead times. Compliance with ASTM D412 for tensile properties is recommended.

Summary Table

| Material | Typical Use Case for dotless led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone | Outdoor, waterproof, UV-exposed installations | Excellent flexibility, UV and corrosion resistance | Higher cost, specialized manufacturing required | High |

| Polycarbonate (PC) | Indoor/semi-outdoor, impact-resistant housings | High impact resistance, good optical clarity | Less flexible, prone to yellowing without UV treatment | Medium |

| Acrylic (PMMA) | Indoor decorative lighting requiring high light transmission | Superior clarity, cost-effective | Brittle, lower impact and thermal resistance | Low |

| Thermoplastic Polyurethane (TPU) | Flexible, abrasion-resistant indoor applications | High elasticity and abrasion resistance | Lower UV resistance, less common in bulk supply | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for dotless led strip lights

The manufacturing of dotless LED strip lights involves a series of precise, controlled stages that ensure the final product delivers seamless illumination, durability, and compliance with international quality standards. For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding these processes and quality assurance measures is critical to making informed sourcing decisions.

Manufacturing Process Overview

1. Material Preparation

The process begins with sourcing high-grade raw materials, including:

- LED Chips and PCBs: Typically, LM80-certified LEDs are selected for their longevity and color consistency. Flexible printed circuit boards (PCBs) serve as the substrate, designed for optimal thermal management and flexibility.

- Silicone Extrusion Material: For dotless LED strips, a milky silicone diffuser is used, which is prepared for the extrusion process. This silicone must be UV-resistant, dust-proof, and corrosion-resistant to ensure outdoor durability.

- Connectors and Plug Components: Injection-molded plugs, matching the strip width, are prepared for assembly. These components ensure tight fitting and IP65-rated sealing.

Strict control over material quality at this stage is vital because it impacts the product’s performance and lifespan.

2. Forming and Extrusion

Dotless LED strips use an integrated silicone extrusion process:

- Silicone One-Piece Extrusion: The milky silicone diffuser is extruded in a continuous, uniform layer over the LED array, creating the signature “dotless” seamless light effect. This extrusion is carried out with high-precision machinery to maintain consistent thickness and diffusion.

- Injection Molding of Plugs: Plugs are molded directly onto the strip ends to maintain a slim profile and prevent water ingress without adding bulk.

- Cutting and Marking: The strip is cuttable at designated points visible through transparent windows, allowing customization to project-specific lengths without compromising sealing.

This stage demands precision to maintain uniform light diffusion and waterproofing integrity.

3. Assembly

After forming, the strips undergo assembly where:

- LED Chips are Mounted and Soldered: Automated pick-and-place machines position LEDs on PCBs, followed by soldering using reflow ovens to ensure strong electrical connections.

- Silicone Diffuser Attachment: The extruded silicone layer is bonded or co-extruded with the LED-embedded PCB.

- Endcaps and Connectors: Endcaps are fitted post-cutting to reseal cut sections and maintain IP65 protection.

- Mounting Accessories: 3M double-sided tapes or PC mounting clips are added for easy installation.

Automated assembly lines increase production efficiency while minimizing human error.

4. Finishing and Packaging

Final finishing includes:

- Surface Treatment: Application of dust-proof, anti-UV coatings to improve longevity and ease of cleaning.

- Visual Inspection: Ensuring no defects such as bubbles, cracks, or uneven extrusion.

- Packaging Customization: Depending on buyer requirements, packaging may be customized for branding or shipping efficiency.

Quality Assurance & Control (QA/QC)

Quality assurance is embedded throughout manufacturing, segmented into critical checkpoints aligned with international standards.

Key International and Industry Standards

- ISO 9001: Most reputable manufacturers maintain ISO 9001 certification, which governs quality management systems ensuring consistent product quality and continual improvement.

- CE Marking: Essential for European markets, confirming compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, crucial for environmental and safety compliance worldwide.

- IP Rating (IP65 or higher): Validates dust and water resistance, particularly important for outdoor applications.

- LM80 and TM21: Standards for LED lumen maintenance and lifetime testing.

- EMC and Safety Standards: Such as IEC 60598 for luminaires, ensuring electrical safety and electromagnetic compatibility.

QC Checkpoints

- Incoming Quality Control (IQC): Raw materials such as LED chips, PCBs, silicone, and connectors are inspected for conformance with specifications and defects.

- In-Process Quality Control (IPQC): Conducted during assembly and extrusion to catch issues early — includes checking solder joints, extrusion uniformity, and plug fitting.

- Final Quality Control (FQC): The finished strips undergo comprehensive testing before packaging.

Common Testing Methods

- Visual and Optical Inspection: Ensures dotless effect uniformity and absence of physical defects.

- Electrical Testing: Verifies voltage, current, and power consumption per unit length.

- Waterproof Testing: IP65 rating tested via water spray or immersion methods.

- Thermal Testing: Confirms heat dissipation efficiency and LED operating temperature under load.

- Color Consistency and CRI Testing: Ensures accurate color rendering and uniform light output.

- Durability Testing: UV resistance, dust resistance, and mechanical stress testing simulate real-world conditions.

How B2B Buyers Can Verify Supplier Quality

For international buyers, particularly from regions with varying regulatory environments, verifying supplier quality is paramount:

- Factory Audits: Engage third-party inspection agencies to perform on-site audits evaluating manufacturing capabilities, quality control processes, and compliance certifications.

- Review of Quality Documentation: Request ISO 9001 certificates, test reports (LM80, IP rating), and compliance declarations (CE, RoHS).

- Sample Testing: Obtain product samples for independent lab testing to validate claims on light quality, durability, and safety.

- Production Monitoring: For large orders, buyers can negotiate periodic quality checks during production runs to catch defects early.

- Warranty and After-Sales Support: Verify supplier policies on warranties and replacement to mitigate risks.

QC and Certification Nuances for Diverse International Markets

- Africa & Middle East: While formal certification requirements may vary, buyers should prioritize suppliers with internationally recognized standards (ISO, CE) to ensure product safety and longevity under harsh climates (high UV, dust, heat).

- South America: Import regulations may require specific certifications; CE and RoHS compliance are often accepted, but buyers should confirm local standards. Robust IP ratings are vital for outdoor installations in tropical environments.

- Europe (e.g., Italy): Strict adherence to CE marking, RoHS, and eco-design directives is mandatory. European buyers often demand detailed test reports and prefer suppliers who can provide customized documentation.

- Cross-Regional Considerations: Shipping and customs may also require compliance documentation. Buyers should ensure traceability and certification authenticity to avoid import delays.

Final Recommendations for B2B Buyers

- Partner with manufacturers who integrate advanced extrusion and injection molding techniques to guarantee the dotless, seamless light effect without compromising durability.

- Insist on suppliers with transparent, documented QA/QC processes aligned with ISO 9001 and relevant international standards.

- Leverage third-party audits and independent testing laboratories to verify quality claims, especially when sourcing from new or overseas suppliers.

- Customize quality criteria based on your local climate and regulatory requirements, ensuring the dotless LED strips can withstand environmental stresses typical to your market.

- Negotiate clear warranty terms and after-sales support, crucial for maintaining long-term client satisfaction and minimizing operational risks.

By understanding the intricacies of manufacturing and quality assurance for dotless LED strip lights, international B2B buyers can make strategic sourcing decisions that balance cost, quality, and compliance—driving successful projects across diverse global markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for dotless led strip lights Sourcing

When evaluating the cost and pricing of dotless LED strip lights for international B2B procurement, understanding the intricate cost components and key pricing influencers is essential. This knowledge enables buyers, especially from regions such as Africa, South America, the Middle East, and Europe, to optimize sourcing strategies, negotiate effectively, and ensure the best value.

Core Cost Components in Dotless LED Strip Lights

- Materials

The primary cost driver is raw materials, including high-quality LEDs (often LM80 certified for longevity), silicone diffusers, flexible PCBs, and protective coatings. Dotless LED strips require milky silicone extrusion for seamless light diffusion, which is more costly than standard diffusers. Additionally, IP65-rated waterproofing and UV-resistant materials increase material expenses but enhance durability.

Illustrative Image (Source: Google Search)

-

Labor and Manufacturing Overhead

Skilled labor is involved in precision extrusion, injection molding of plugs, assembly, and quality control. Overhead costs include factory utilities, equipment depreciation, and indirect labor. Manufacturers with automated extrusion processes often achieve better economies of scale, reducing overhead per unit. -

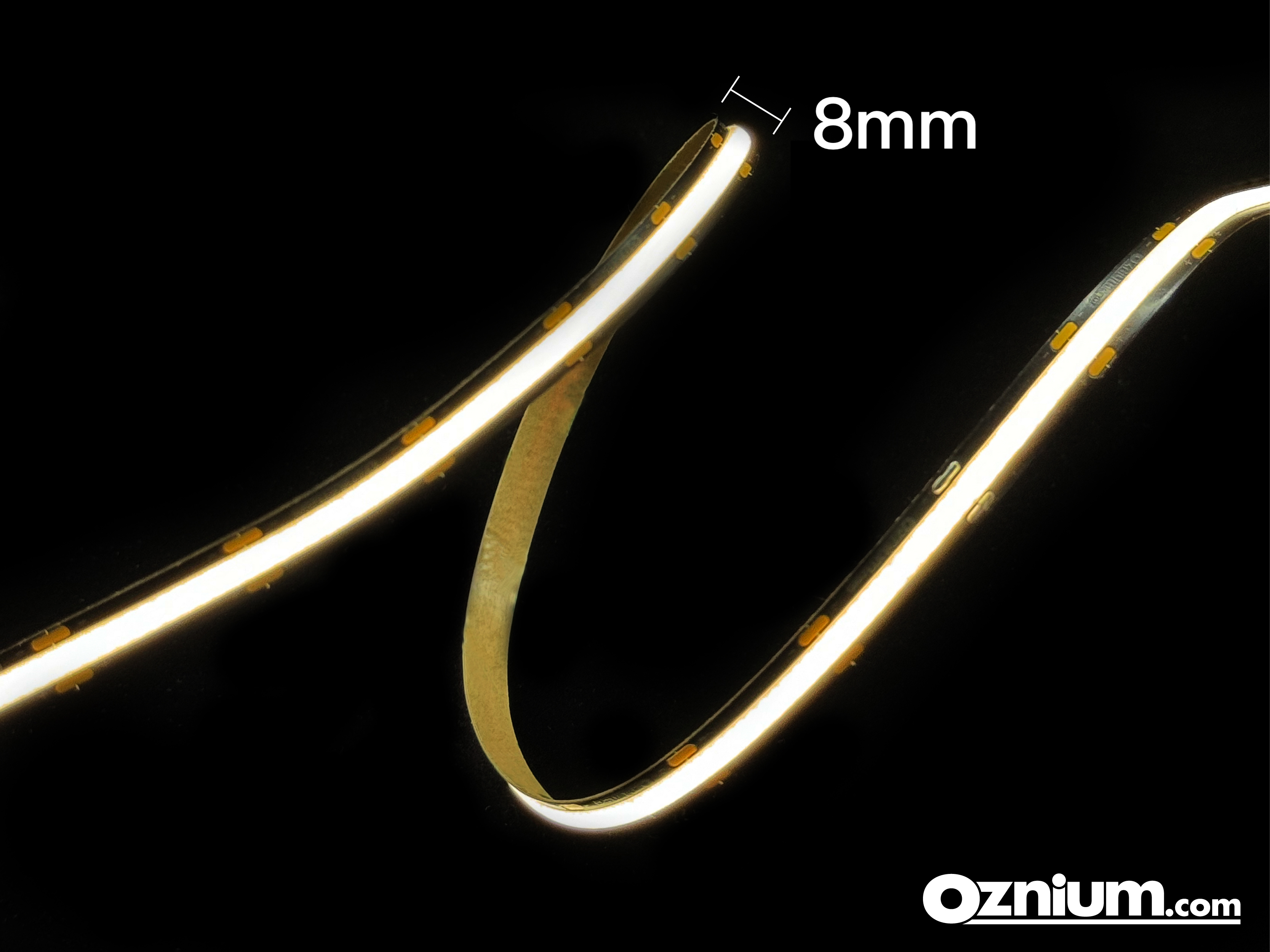

Tooling and Setup Costs

Initial tooling for extrusion dies and injection molds represents a significant upfront investment. Custom designs or sizes (e.g., 8mm to 14mm width variants) may require bespoke tooling, impacting unit costs, especially for low to medium order quantities. -

Quality Control and Testing

Rigorous testing for color consistency, waterproof rating, and electrical safety adds to costs but ensures reliability, a critical factor for professional buyers. Certifications such as CE, RoHS, and UL influence QC expenses and the ultimate price. -

Logistics and Shipping

Given the bulky yet lightweight nature of silicone-encased strips, shipping costs can vary widely depending on the destination. Buyers in Africa, South America, and the Middle East should factor in longer transit times and potential customs duties. Consolidated shipping and choosing suppliers with local warehouses can mitigate these costs. -

Supplier Margin and Distribution Markup

Margins depend on supplier scale, exclusivity of technology, and service levels. Direct manufacturer purchases tend to have lower margins compared to distributors or wholesalers.

Key Price Influencers for B2B Buyers

-

Order Volume and Minimum Order Quantities (MOQ)

Larger orders significantly reduce unit costs due to economies of scale. For dotless LED strips, MOQs typically start at several hundred meters. Buyers should balance demand forecasts with MOQ requirements to optimize pricing. -

Product Specifications and Customization

Customized lengths, colors (e.g., single color, tunable white, RGB variants), power ratings (5W to 15W per meter), and additional features like addressable SPI strips impact pricing. More complex configurations incur higher costs due to specialized components and assembly. -

Material Quality and Certification Levels

Premium LEDs with longer lifespans, high CRI (Color Rendering Index), and compliance with international safety standards command higher prices but reduce total cost of ownership (TCO) through durability and performance. -

Supplier Reputation and Service

Established manufacturers with proven quality and reliable delivery often price at a premium but reduce risks of defective shipments and delays. -

Incoterms and Payment Terms

Incoterms (e.g., FOB, CIF, DDP) influence the buyer’s responsibility for shipping, insurance, and customs clearance, affecting landed cost. Favorable payment terms can improve cash flow and negotiating leverage.

Strategic Buyer Tips for International Procurement

-

Negotiate Beyond Unit Price

Focus on total landed cost, including shipping, customs, and local taxes. Request volume discounts, bundled shipping, or extended payment terms. For buyers in Kenya or Italy, local import regulations and tariffs can notably affect final costs. -

Evaluate Total Cost of Ownership (TCO)

Consider product lifespan, energy efficiency, warranty, and after-sales support. Investing in certified, high-quality dotless LED strips can lower maintenance and replacement expenses, justifying a higher upfront price. -

Request Samples and Quality Documentation

Before committing to large orders, obtain samples to verify color uniformity, brightness, and build quality. Confirm supplier certifications to avoid compliance issues in regulated markets. -

Leverage Regional Trade Agreements and Logistics Hubs

Use free trade zones or regional warehouses to reduce customs duties and shorten delivery times. For example, European buyers might benefit from EU-based suppliers, while African buyers could explore suppliers with distribution centers in Dubai or South Africa. -

Monitor Currency Fluctuations and Hedging Options

Currency volatility can impact final pricing in international transactions. Negotiate contracts in stable currencies or use hedging strategies where possible.

Indicative Pricing Disclaimer

Due to the variability in specifications, order volumes, supplier capabilities, and shipping logistics, pricing for dotless LED strip lights can vary widely. Typical FOB prices may range from USD 3 to 10 per meter depending on features and order size. Buyers should treat these figures as indicative and conduct direct supplier consultations for precise quotations.

Illustrative Image (Source: Google Search)

By thoroughly analyzing these cost elements and price influencers, international B2B buyers can strategically source dotless LED strip lights that balance quality, cost-efficiency, and project requirements, ensuring successful and sustainable lighting investments.

Spotlight on Potential dotless led strip lights Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘dotless led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dotless led strip lights

Key Technical Properties of Dotless LED Strip Lights

Understanding the technical specifications of dotless LED strip lights is crucial for B2B buyers aiming to make informed procurement decisions. Below are some of the most critical properties and their business implications:

-

Material Grade (Silicone Diffuser & PCB Quality)

Dotless LED strips typically use a high-grade silicone diffuser with integrated extrusion, offering durability, flexibility, and a smooth light output without visible LED dots. The quality of the printed circuit board (PCB) also affects heat dissipation and longevity. For buyers, premium materials mean longer lifespan, reduced maintenance costs, and consistent lighting performance, which is especially important for commercial and outdoor projects. -

Ingress Protection Rating (e.g., IP65)

The IP rating defines the product’s resistance to dust and water. An IP65 rating indicates the strip is dust-tight and protected against water jets, making it suitable for outdoor or humid environments. B2B buyers in regions with variable climates (like parts of Africa and the Middle East) should prioritize higher IP ratings to ensure reliability and compliance with local standards. -

Power Consumption and Output (Wattage and Lumens per Meter)

Power ratings (commonly 5W, 10W, 15W per meter) indicate energy consumption, while lumens measure brightness. Efficient strips with high lumen output per watt offer better energy savings and performance. For large-scale installations, such as retail or hospitality venues, balancing brightness with power efficiency directly impacts operational costs. -

Cuttable and Customizable Lengths

Dotless LED strips often feature designated cut points visible through the diffuser, allowing precise length adjustments on-site. This flexibility minimizes waste and simplifies installation in irregular spaces, a major advantage for architectural projects and bespoke lighting designs. -

Color Options and Control (Single Color, Tunable White, RGB, RGBW, SPI Addressable)

Variety in color modes enables different lighting effects and ambiance control. Tunable white and RGB options allow dynamic color temperature and multi-color settings, essential for hospitality or event spaces. Addressable SPI strips offer pixel-level control, enabling complex lighting patterns for high-end applications. -

Dimensions and Profile (Width and Thickness)

Widths typically range from 8mm to 14mm, with slim profiles designed for seamless integration into channels or slots. Buyers must consider these dimensions for compatibility with existing fixtures and aesthetic requirements, especially in markets emphasizing sleek, modern design like Europe.

Common Trade Terminology in Dotless LED Strip Light Procurement

Familiarity with industry jargon streamlines communication and negotiation with suppliers. Below are essential terms every B2B buyer should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing products that other companies brand and sell. Buyers looking to customize LED strips (e.g., branding, packaging, specific features) often engage OEM suppliers. This can reduce costs and create unique product offerings tailored to local markets. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory and budget, especially important for smaller businesses or those testing new products. Negotiating MOQs can be key for markets with limited storage or fluctuating demand. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing, availability, and terms based on specific product requirements. Preparing a detailed RFQ ensures accurate, comparable quotes and speeds up the sourcing process. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities between buyers and sellers during shipping, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight). Knowing Incoterms helps buyers estimate total landed costs, manage logistics, and reduce import risks. -

Cut Mark

A visible indicator on the LED strip where it can be safely cut without damaging functionality. Crucial for installers and buyers to ensure proper customization and avoid warranty issues. -

IP Rating (Ingress Protection)

A standardized measure of protection against solids and liquids. Higher IP ratings mean better durability in harsh environments, affecting product suitability and compliance in different regions.

For B2B buyers across Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms is vital. It ensures procurement of dotless LED strip lights that meet operational requirements, comply with regional standards, and support successful, scalable lighting projects.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dotless led strip lights Sector

Market Overview & Key Trends

The global market for dotless LED strip lights is experiencing robust growth, driven by increasing demand for seamless, energy-efficient lighting solutions across commercial, residential, and architectural sectors. Dotless LED strips—characterized by their continuous, smooth light output without visible dots—are gaining traction due to their aesthetic appeal and versatility. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, this presents significant opportunities to integrate advanced lighting technology that enhances design while optimizing operational costs.

Key Drivers:

- Energy Efficiency and Cost Savings: Dotless LED strips consume significantly less power than traditional lighting, aligning with global efforts to reduce energy consumption. This is particularly relevant for emerging markets in Africa and South America, where energy costs and grid reliability are critical considerations.

- Urbanization and Infrastructure Development: Rapid urban growth in the Middle East and parts of Africa is fueling demand for innovative lighting solutions in public spaces, retail, hospitality, and commercial real estate.

- Technological Innovation: Advances such as integrated silicone extrusion processes and high-density LED arrays improve durability and light uniformity. Features like tunable white and RGB/RGBW configurations enable customizable lighting schemes, appealing to European markets like Italy where design aesthetics are paramount.

- Supply Chain Evolution: International buyers are increasingly favoring suppliers who can provide flexible customization (lengths, colors, power levels) and faster lead times. The adoption of injection molded plugs and IP65-rated dust and water resistance facilitates installation versatility.

Emerging Sourcing Trends:

- Direct-from-Manufacturer Procurement: Buyers seek to minimize intermediaries to reduce costs and improve quality control, often leveraging digital platforms to connect with manufacturers offering dotless LED strips.

- Sample Testing and Quality Assurance: Especially for large-scale projects, requesting samples before bulk purchases has become a standard practice to verify color accuracy, durability, and compatibility.

- Integrated Smart Lighting: There is growing interest in addressable SPI and app-controllable dotless LED strips, enabling IoT integration for enhanced lighting management, favored by technologically advanced markets in Europe.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly a decisive factor for B2B buyers of dotless LED strip lights, reflecting broader environmental commitments and regulatory pressures across continents. These lighting products inherently offer environmental benefits by reducing energy consumption and extending lifespan compared to conventional lighting. However, responsible sourcing and manufacturing practices are essential to fully realize their green potential.

Environmental Impact Considerations:

- Material Selection: The use of non-toxic, recyclable materials such as silicone diffusers and lead-free soldering components reduces environmental hazards during production and disposal.

- Energy Efficiency Certifications: Buyers should prioritize products compliant with internationally recognized standards such as LM80 for LED longevity and certifications like Energy Star or equivalent regional marks that guarantee reduced energy consumption.

- Waste Reduction: Dotless LED strips with modular, cuttable designs help minimize material waste by allowing precise installation lengths without excess.

Ethical Supply Chains:

- Transparency in the supply chain ensures compliance with labor laws and environmental regulations. B2B buyers from Europe and the Middle East increasingly demand documentation verifying ethical manufacturing practices.

- Green certifications from suppliers—covering carbon footprint reduction, responsible sourcing of raw materials, and eco-friendly packaging—are becoming prerequisites in procurement processes.

Actionable Insights for Buyers:

- Engage with suppliers offering comprehensive sustainability reports and third-party certifications.

- Incorporate sustainability criteria into supplier selection and contract negotiations.

- Explore partnerships with manufacturers implementing circular economy principles, such as LED strip recycling programs.

Brief Evolution and Historical Context

The evolution of dotless LED strip lights reflects a broader trajectory in LED technology toward higher density, improved diffusion, and aesthetic refinement. Traditional LED strips initially suffered from visible “dots” caused by spaced individual LEDs, which limited their appeal for seamless lighting applications. The introduction of continuous silicone diffusers and integrated extrusion processes marked a pivotal shift, enabling the production of dotless LED strips with uniform light output.

Historically, the transition from COB (Chip on Board) LEDs to dotless strips represents a move toward more flexible, durable, and design-friendly products. This innovation has unlocked new applications in architectural lighting, retail displays, and outdoor environments, particularly appealing to international B2B markets seeking cutting-edge yet reliable lighting solutions. For buyers in emerging markets, dotless LED strips offer an opportunity to leapfrog older lighting technologies, while in established markets, they provide a premium option for sophisticated lighting designs.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of dotless led strip lights

-

How can I verify the reliability and quality of dotless LED strip light suppliers internationally?

To ensure supplier reliability, start by reviewing their business credentials, certifications (like ISO 9001), and customer testimonials. Request product samples to assess quality firsthand. Verify their production capabilities and quality control processes, particularly for dotless LED technology. For buyers in Africa, South America, the Middle East, and Europe, consider suppliers with experience exporting to your region to minimize customs or compliance issues. Using platforms with verified supplier ratings and conducting factory audits (virtual or in-person) can also help mitigate risks. -

What customization options are typically available for dotless LED strip lights in bulk orders?

Many manufacturers offer customization including strip width (8mm to 14mm), color temperature (single color, tunable white, RGB, RGBW), power wattage, and packaging. You can also request specific cut lengths, IP ratings (e.g., IP65 for outdoor use), and branding on packaging. Custom connectors or plug types compatible with local electrical standards can be arranged. When negotiating customization, clearly specify your technical requirements early to avoid delays and confirm minimum order quantities (MOQs) for custom runs. -

What are common minimum order quantities (MOQs) and lead times for dotless LED strip lights?

MOQs vary by supplier but typically range from 100 to 500 meters per model, depending on customization. Lead times usually span 3 to 6 weeks, influenced by order size, customization complexity, and current factory workload. For international buyers, factor in additional shipping and customs clearance time. To optimize supply chain efficiency, plan orders well ahead of project deadlines and consider consolidating orders to reduce costs and lead times. -

Which payment terms and methods are most secure and practical for international B2B purchases of dotless LED strip lights?

Common payment methods include bank wire transfers (T/T), letters of credit (L/C), and trade assurance platforms. T/T with partial upfront deposit (e.g., 30%) and balance on shipment is standard. Letters of credit offer more security but involve more paperwork. For buyers in regions with currency volatility, negotiating payment in stable currencies (USD, EUR) is advisable. Always confirm payment terms in contracts and avoid full upfront payments unless dealing with highly trusted suppliers. -

What quality assurance certifications should I expect from dotless LED strip light suppliers?

Look for certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), UL or ETL (safety standards), and LM80 (LED lumen maintenance). These ensure compliance with safety, environmental, and performance standards. Suppliers should provide test reports or certificates on request. For buyers in Europe and the Middle East, CE and RoHS are critical for regulatory compliance. Insist on warranty terms covering defects and product lifespan to safeguard your investment. -

How can I manage logistics and shipping challenges when importing dotless LED strip lights internationally?

Choose suppliers offering FOB or CIF shipping terms to clarify responsibility for freight costs and risks. Engage freight forwarders familiar with your destination country’s customs regulations to avoid delays. Consolidate shipments when possible to reduce costs and customs clearance complexity. For sensitive products like LED strips, opt for secure packaging and insurance. Be aware of import duties and taxes specific to your country, such as VAT in Europe or import tariffs in Africa and South America, and factor these into your total cost. -

What steps should I take if there is a dispute or product quality issue after receiving dotless LED strip lights?

Immediately document the issue with photos and detailed descriptions. Notify the supplier formally, referencing your contract and warranty terms. Request replacement units or refunds according to agreed policies. Use trade dispute resolution mechanisms such as mediation through the supplier’s country chamber of commerce or international arbitration if necessary. For buyers, maintaining clear communication records and understanding your legal rights under international trade law can expedite resolution. -

Are dotless LED strip lights suitable for outdoor applications in diverse climates like those in Kenya, Italy, or the Middle East?

Yes, dotless LED strips with IP65 or higher ratings are designed for outdoor use, offering dust and water resistance. Their silicone extrusion and anti-UV coatings make them durable under harsh sunlight, humidity, and temperature fluctuations typical in these regions. When sourcing, specify environmental conditions to ensure the product meets local climate requirements. Proper installation with compatible channels and sealing accessories also enhances longevity and performance outdoors.

Strategic Sourcing Conclusion and Outlook for dotless led strip lights

The sourcing of dotless LED strip lights presents a compelling opportunity for international B2B buyers to enhance their product offerings with cutting-edge, energy-efficient lighting solutions. These seamless, high-density strips deliver superior light diffusion and durability, making them ideal for a broad range of applications from architectural projects to retail and hospitality environments. For buyers in Africa, South America, the Middle East, and Europe, strategic sourcing is crucial to unlocking competitive pricing, ensuring product quality, and accessing the latest innovations such as tunable white and RGBTW options.

Key takeaways for B2B buyers include:

- Prioritize suppliers with proven reliability, IP65-rated products, and customizable options that align with regional market demands.

- Leverage bulk purchasing to reduce costs and streamline supply chains, particularly for large-scale or repeat projects.

- Request samples to validate performance and compatibility before committing to large orders.

- Consider suppliers offering flexible logistics and strong after-sales support to mitigate risks associated with international trade.

Looking ahead, the demand for dotless LED strip lights is poised to grow alongside global trends favoring smart, sustainable, and visually appealing lighting solutions. Buyers who adopt a proactive sourcing strategy—emphasizing quality, innovation, and supplier partnerships—will position themselves as leaders in their markets. We encourage businesses across all target regions to explore these advanced lighting technologies and capitalize on the evolving opportunities within the dotless LED segment.