Introduction: Navigating the Global Market for diy led strip

The global demand for DIY LED strip lighting has surged dramatically, driven by their versatility, energy efficiency, and customizable design options. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of sourcing high-quality DIY LED strips is critical to maintaining competitive advantage and meeting diverse customer needs. These markets are characterized by varying regulatory environments, climate conditions, and consumer preferences, making informed procurement decisions essential.

This comprehensive guide addresses the full spectrum of considerations for successful engagement in the DIY LED strip market. Buyers will gain insights into the various types of LED strips available—from single-color to RGB and tunable white options—and the critical materials and components that define product durability and performance. The guide also covers manufacturing standards and quality control practices to ensure product reliability and compliance with international certifications.

Furthermore, it explores strategies for identifying reputable suppliers and manufacturers, optimizing cost structures, and navigating logistical challenges unique to each region. Market trends and consumer demand patterns in key regions such as France, Spain, Middle Eastern hubs, and emerging African and South American economies are analyzed to empower buyers with actionable intelligence.

By consolidating technical knowledge, sourcing best practices, and market insights, this guide equips B2B buyers to make strategic, well-informed decisions—maximizing value while mitigating risks in the rapidly evolving DIY LED strip industry. Whether upgrading existing product lines or entering new markets, this resource is designed to be an indispensable tool for procurement professionals seeking sustainable growth and innovation.

Understanding diy led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color LED Strips | Emit one consistent color, often white or warm white. | Ambient lighting, retail displays, architectural accents | Pros: Cost-effective, simple installation; Cons: Limited color flexibility |

| RGB LED Strips | Contain red, green, and blue LEDs enabling color mixing. | Dynamic lighting, event venues, signage, hospitality | Pros: Versatile color options; Cons: Requires controllers, higher cost |

| Waterproof LED Strips | Encased in silicone or epoxy for moisture resistance. | Outdoor installations, industrial environments, bathrooms | Pros: Durable in harsh conditions; Cons: Slightly higher price, reduced flexibility |

| High-Density COB LED Strips | Continuous line of light from closely packed LEDs (Chip-on-Board). | High-end retail, photography, automotive, display lighting | Pros: Even illumination, high brightness; Cons: Higher cost, requires heat management |

| Battery-Operated LED Strips | Portable, low voltage with integrated power source. | Pop-up events, temporary setups, mobile displays | Pros: Flexibility and portability; Cons: Limited runtime, lower brightness |

Single-Color LED Strips are the most straightforward option, delivering consistent illumination in a single hue, commonly used for accent lighting or general ambient purposes. For B2B buyers in retail or hospitality sectors across Africa, South America, and Europe, these strips offer a cost-efficient solution with easy integration. However, their limited color options may restrict applications requiring dynamic or mood lighting.

RGB LED Strips provide vibrant, customizable lighting through red, green, and blue LEDs, enabling millions of color combinations. This type is ideal for businesses in event management, signage, and hospitality industries seeking versatile lighting solutions. Buyers should consider additional costs for controllers and the technical complexity of installation, which may require skilled labor, especially in regions with emerging LED markets.

Waterproof LED Strips are designed with protective coatings that allow safe use in outdoor or moisture-prone environments such as industrial sites or bathrooms. For B2B buyers in the Middle East and coastal areas of Europe and Africa, these strips ensure durability and longevity under harsh conditions. The trade-off includes a higher upfront cost and slightly reduced flexibility in terms of cutting or bending.

High-Density COB LED Strips offer a seamless light output with densely packed LEDs, delivering superior brightness and uniformity. They suit premium retail installations, automotive lighting, and photography studios where quality illumination is critical. Buyers should prioritize suppliers with robust quality control and assess heat dissipation solutions due to the higher power consumption of these strips.

Battery-Operated LED Strips cater to temporary or mobile lighting needs without reliance on fixed power sources. They are perfect for pop-up shops, exhibitions, and mobile displays common in fast-growing urban centers in South America and Africa. While offering unmatched portability, buyers must evaluate battery life and brightness levels to ensure they meet operational demands.

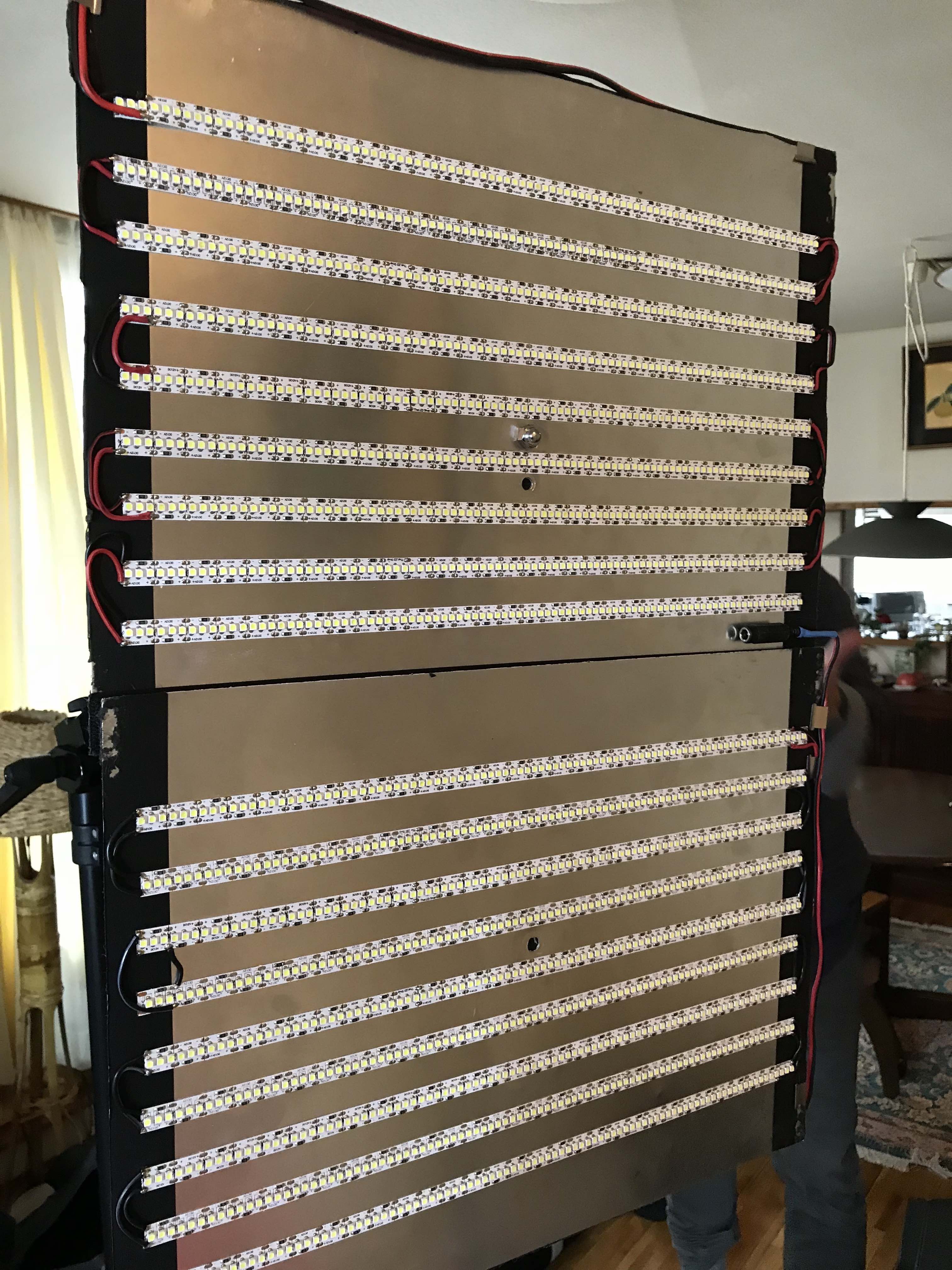

Related Video: Building DIY LED lights

Key Industrial Applications of diy led strip

| Industry/Sector | Specific Application of diy led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Ambient and accent lighting for product displays and signage | Enhances product visibility, attracts customers, and elevates brand image | Durability, color consistency, energy efficiency, and ease of installation |

| Hospitality & Tourism | Decorative lighting in hotels, restaurants, and event venues | Creates immersive atmospheres, improves guest experience, and reduces energy costs | Waterproof ratings (IP65+), flexible design, and compatibility with control systems |

| Automotive & Transport | Interior and exterior vehicle lighting customization | Improves aesthetic appeal and safety, offers customization options | Heat resistance, vibration durability, and compliance with regional vehicle standards |

| Manufacturing & Warehousing | Task lighting and safety indicators in production lines | Increases worker safety and productivity, reduces downtime | High brightness, long lifespan, and resistance to industrial contaminants |

| Smart Building & Architecture | Dynamic lighting for façades, pathways, and smart controls | Supports energy savings, enhances architectural features, and enables automation | Compatibility with smart systems, scalability, and energy consumption ratings |

Retail & Commercial Spaces

DIY LED strips are extensively used in retail environments for backlighting shelves, highlighting product displays, and illuminating signage. These strips help retailers create vibrant, attractive spaces that draw customer attention and enhance product appeal. For B2B buyers in Africa, South America, the Middle East, and Europe, sourcing LED strips with consistent color rendering and energy efficiency is critical to maintain brand standards and reduce operational costs. Flexible installation options and robust supply chains ensure timely project completion and scalability.

Hospitality & Tourism

Hotels, restaurants, and event venues leverage DIY LED strips to craft unique ambiances that elevate guest experiences. Waterproof and flexible LED strips are essential for applications in spas, pools, and outdoor terraces, where exposure to moisture is common. Businesses benefit from reduced energy consumption and lower maintenance costs. International buyers should prioritize IP-rated products and compatibility with popular lighting control systems to integrate seamlessly into existing infrastructures.

Automotive & Transport

In the automotive sector, DIY LED strips enable customization of vehicle interiors and exteriors, enhancing aesthetics and safety. Applications include dashboard lighting, underglow effects, and signal indicators. For B2B buyers targeting markets in Europe and the Middle East, compliance with regional vehicle safety standards and resistance to heat and vibration are paramount. Reliable suppliers offering high-quality, durable LED strips ensure longevity and customer satisfaction.

Manufacturing & Warehousing

Task lighting and safety indicator strips improve visibility and operational efficiency in manufacturing plants and warehouses. DIY LED strips provide bright, focused illumination that reduces accidents and supports quality control processes. Buyers must focus on durability against dust, chemicals, and mechanical wear, especially in demanding industrial environments. Long lifespan and energy efficiency are crucial to minimize replacement frequency and energy expenses.

Smart Building & Architecture

Dynamic LED strip lighting is integral to modern smart buildings, used for façade illumination, pathway lighting, and integration with automated control systems. These installations enhance architectural aesthetics while contributing to energy savings. B2B buyers should evaluate LED strips for compatibility with IoT devices, scalability for large projects, and certifications for energy consumption. This ensures seamless integration and future-proofing in technologically advanced markets such as Europe and the Middle East.

Related Video: How to cut, connect & power LED Strip Lighting

Strategic Material Selection Guide for diy led strip

When selecting materials for DIY LED strips, international B2B buyers must carefully evaluate the physical, chemical, and electrical properties of the substrate and encapsulation materials. These choices directly influence product durability, performance, and compliance with regional standards, which vary across Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in DIY LED strip manufacturing.

Flexible Printed Circuit Board (FPCB) – Polyimide and PET Substrates

Key Properties:

FPCBs typically use polyimide or polyethylene terephthalate (PET) as the flexible substrate. Polyimide offers excellent thermal stability (up to 260°C), chemical resistance, and mechanical flexibility. PET is more cost-effective but has lower heat resistance (around 120°C) and less chemical durability.

Pros & Cons:

Polyimide-based FPCBs provide superior heat dissipation and longevity, making them ideal for high-power LED strips. PET substrates reduce manufacturing costs but may degrade faster under high temperatures or UV exposure. Both materials allow for compact, flexible designs but require precise manufacturing processes, increasing complexity.

Impact on Application:

Polyimide FPCBs are preferred for industrial or outdoor applications where heat and environmental exposure are concerns. PET substrates suit indoor, low-heat environments. For buyers in regions with high ambient temperatures (e.g., Middle East, parts of Africa), polyimide substrates ensure longer product life.

Regional Considerations:

European buyers (France, Spain) often require compliance with RoHS and REACH regulations, favoring polyimide for its environmental stability. South American and African markets may prioritize cost-efficiency, making PET an attractive choice if usage conditions are controlled. ASTM and DIN standards for flexible circuits guide quality assurance globally.

Silicone Encapsulation

Key Properties:

Silicone is widely used as an encapsulant for LED strips due to its excellent UV resistance, flexibility, and high temperature tolerance (up to 200°C). It also offers superior waterproofing (IP65 to IP68 ratings) and chemical inertness.

Pros & Cons:

Silicone encapsulation enhances LED strip durability in harsh environments, including outdoor and humid conditions, but it is more expensive than alternatives like epoxy. Manufacturing with silicone requires specialized equipment and curing processes, raising production complexity.

Impact on Application:

Ideal for outdoor lighting, architectural installations, and regions with high humidity or UV exposure, such as coastal areas in South America and the Middle East. Silicone’s flexibility supports curved or irregular mounting surfaces, expanding design possibilities.

Regional Considerations:

Buyers in Europe demand compliance with stringent environmental and safety standards (e.g., CE marking), where silicone’s non-toxicity and durability are advantageous. African and South American markets benefit from silicone’s robustness in tropical climates, despite higher upfront costs.

Epoxy Resin Encapsulation

Key Properties:

Epoxy resin is a common encapsulant offering good mechanical protection and electrical insulation. It typically withstands temperatures up to 120°C but has limited UV resistance and flexibility compared to silicone.

Pros & Cons:

Epoxy is cost-effective and easy to apply, suitable for indoor LED strips. However, it tends to yellow and crack under prolonged UV exposure, reducing lifespan outdoors. Its brittleness can limit use in flexible or curved applications.

Impact on Application:

Best suited for indoor or controlled environments, such as office lighting or retail displays. Not recommended for outdoor or high-humidity regions without additional protective measures.

Regional Considerations:

In Europe, epoxy must meet fire safety and chemical standards, which can increase compliance costs. Buyers in Africa and South America may find epoxy suitable for indoor markets but should consider environmental conditions carefully.

Aluminum Channel Housing

Key Properties:

Aluminum channels serve as mounting and heat dissipation structures for LED strips. Aluminum offers excellent thermal conductivity, corrosion resistance (especially anodized variants), and mechanical strength.

Pros & Cons:

Using aluminum channels extends LED strip lifespan by preventing overheating and physical damage. The material is lightweight and recyclable but adds to overall product cost and requires additional assembly steps.

Impact on Application:

Essential for high-power LED strips or installations demanding robust protection, such as commercial signage or architectural lighting in Europe and the Middle East. Aluminum channels also facilitate compliance with safety and fire resistance standards.

Regional Considerations:

European markets often prefer anodized aluminum for its aesthetic appeal and compliance with environmental directives. In Africa and South America, aluminum channels improve product durability in dusty or corrosive environments, justifying the higher investment.

| Material | Typical Use Case for diy led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide FPCB | High-power, flexible LED strips for indoor/outdoor use | Excellent heat resistance and durability | Higher manufacturing complexity and cost | High |

| PET FPCB | Low-cost, indoor LED strips | Cost-effective and flexible | Lower heat resistance and chemical durability | Low |

| Silicone Encapsulation | Outdoor, waterproof, and flexible LED strips | Superior UV resistance and waterproofing | Higher material and processing costs | High |

| Epoxy Resin Encapsulation | Indoor, rigid LED strips | Cost-effective and easy to apply | Poor UV resistance and brittleness | Low |

| Aluminum Channel Housing | Mounting and heat dissipation for high-power strips | Excellent thermal management and mechanical protection | Adds cost and assembly complexity | Medium |

This guide equips international B2B buyers with a nuanced understanding of material options for DIY LED strips, enabling informed decisions tailored to regional market demands, regulatory compliance, and application-specific performance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for diy led strip

Overview of Manufacturing Processes for DIY LED Strips

The manufacturing of DIY LED strips involves a series of meticulously controlled stages, each critical to producing high-quality, reliable lighting products suitable for diverse international markets. Understanding these processes empowers B2B buyers—especially from Africa, South America, the Middle East, and Europe—to assess supplier capabilities accurately.

1. Material Preparation

The initial phase focuses on sourcing and preparing raw materials, including:

- Flexible PCB substrates: Typically made from polyimide or polyester materials, chosen for flexibility and thermal stability.

- LED chips and components: High-quality LEDs (e.g., 2835, 5050 SMD types) are procured from reputable manufacturers to ensure brightness and longevity.

- Solder paste and adhesives: Specialized materials facilitate component attachment and waterproofing (if applicable).

Material traceability and certification (RoHS compliance, for instance) should be verified at this stage to prevent future regulatory issues.

2. Forming and PCB Fabrication

This stage involves:

- PCB patterning: Using photolithography to etch conductive copper tracks onto flexible substrates.

- Cutting and shaping: The PCB is cut into strips of standard or custom lengths, with precision cutting techniques ensuring clean edges and accurate hole placements for connectors or mounting.

Advanced machinery ensures minimal defects such as short circuits or open circuits on the PCB.

3. Component Assembly

Critical for product functionality, assembly includes:

- Surface-Mount Technology (SMT): Automated pick-and-place machines position LEDs and resistors onto the PCB with high accuracy.

- Reflow soldering: The assembly passes through a reflow oven to melt solder paste, securing components firmly.

- Encapsulation: For waterproof or durable strips, silicone or epoxy coatings are applied, often using robotic dispensers for uniform coverage.

Automation in this stage reduces human error, enhancing repeatability and scalability.

4. Finishing and Packaging

Final steps include:

- Cutting and segmenting: Strips are cut into user-friendly lengths, often with designated cut points.

- Adhesive backing application: 3M or equivalent tapes are applied for easy installation.

- Labeling and packaging: Customized packaging with clear usage instructions and safety warnings is prepared, meeting import requirements for target regions.

Quality packaging also protects strips during international transit, a key concern for buyers shipping to remote or challenging destinations.

Quality Assurance Framework for DIY LED Strips

Robust quality assurance (QA) practices underpin supplier reliability and product compliance, especially crucial for international B2B transactions involving multiple regulatory regimes.

Relevant International and Industry Standards

- ISO 9001: The globally recognized quality management system standard ensures consistent manufacturing processes and continuous improvement.

- CE Marking: Mandatory for products entering the European Economic Area, indicating compliance with safety, health, and environmental protection directives.

- RoHS (Restriction of Hazardous Substances): Ensures materials are free from harmful substances, critical for European and some Middle Eastern markets.

- UL and ETL Certifications: Often required for electrical safety in North American and global markets; some European buyers also value these marks.

- IP Ratings (e.g., IP65, IP68): Verify waterproofing and dustproofing levels, vital for outdoor or humid environment applications common in Africa and South America.

Buyers should confirm that suppliers maintain up-to-date certifications and can provide relevant documentation.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Inspection of raw materials and components (LED chips, PCBs, solder paste).

– Verification against purchase specifications and certification documents.

– Use of statistical sampling to detect batch inconsistencies early. -

In-Process Quality Control (IPQC)

– Monitoring solder paste application thickness and placement accuracy.

– Visual and automated optical inspection (AOI) of SMT assembly to detect misaligned or missing LEDs.

– Temperature profiling during reflow soldering to avoid thermal damage. -

Final Quality Control (FQC)

– Electrical testing: Measuring voltage, current, and luminous intensity to ensure performance consistency.

– Functional tests: Checking for flicker, color uniformity, and dimming capabilities.

– Environmental simulations: Thermal cycling and humidity resistance tests to simulate real-world usage.

– Visual inspection for cosmetic defects such as discoloration or surface blemishes.

Testing Methods and Tools Commonly Used

- Automated Optical Inspection (AOI): Detects solder joint defects and component placement errors.

- Electrical Testing Equipment: Multi-channel testers verify LED functionality, brightness, and color temperature.

- Environmental Chambers: Simulate heat, moisture, and UV exposure to assess durability.

- Spectroradiometers: Measure precise color output, ensuring adherence to customer specifications.

- Tensile Testing: Assesses PCB flexibility and adhesive strength, critical for installation reliability.

How B2B Buyers Can Verify Supplier Quality Assurance

To mitigate risks in international sourcing, buyers should adopt a multi-pronged verification approach:

- Factory Audits: Conduct or commission on-site inspections focusing on manufacturing practices, equipment, and worker training. For buyers from Africa, South America, and the Middle East, partnering with local third-party auditors or agencies with regional expertise can be cost-effective.

- Review of QC Documentation: Request detailed inspection reports, certificates of conformity, and batch test results. Scrutinize for consistency and traceability.

- Third-Party Testing: Utilize independent labs for random sample testing to validate supplier claims, especially for compliance with CE, RoHS, and IP standards.

- Sample Evaluation: Order pre-production samples and conduct in-house tests or pilot installations to verify performance under local environmental conditions.

- Quality Agreements: Establish clear contractual obligations on quality standards, inspection frequencies, and penalties for non-compliance.

QC and Certification Nuances for International Markets

- Africa and South America: Buyers often face challenges with customs inspections and variable enforcement of standards. Opt for suppliers with internationally recognized certifications (ISO, CE) and those willing to provide comprehensive test reports to facilitate smooth customs clearance.

- Middle East: Some countries have stringent import regulations requiring GCC conformity marks or local certification. Suppliers familiar with these regional requirements and able to adapt packaging and documentation accordingly are preferable.

- Europe (France, Spain, etc.): Compliance with EU directives is non-negotiable. Buyers should prioritize suppliers with CE marking, RoHS compliance, and adherence to the EU’s Eco-design and WEEE directives. Sustainability and environmental impact are increasingly critical selection criteria.

- Language and Documentation: Ensure all certificates, datasheets, and manuals are available in the buyer’s preferred language or in English with professional translations. This reduces misunderstandings and compliance risks.

Key Takeaways for B2B Buyers

- Prioritize suppliers with transparent, documented manufacturing processes and international certifications.

- Insist on comprehensive QC at every manufacturing stage, backed by reports and third-party validations.

- Understand regional regulatory nuances and verify supplier capability to meet these specific demands.

- Use factory audits and sample testing as essential tools to minimize risk and ensure product quality.

- Leverage partnerships with local inspection agencies or consultants familiar with regional market requirements.

By thoroughly evaluating manufacturing and quality assurance processes, international B2B buyers can confidently source DIY LED strips that meet both performance expectations and regulatory mandates, ensuring successful market entry and customer satisfaction.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for diy led strip Sourcing

Understanding the Cost Structure in DIY LED Strip Sourcing

When sourcing DIY LED strips, it is crucial for international B2B buyers to grasp the underlying cost components that determine the final pricing. These costs can be broadly categorized as follows:

- Materials: The core raw materials include LED chips (e.g., 2835, 5050 SMD), flexible PCBs, resistors, adhesives, and encapsulation materials. Higher-grade LEDs or specialty materials (like waterproof coatings or UV-resistant films) significantly increase costs.

- Labor: Labor expenses vary by manufacturing country and complexity of assembly. Manual soldering, quality inspections, and packaging contribute to labor costs.

- Manufacturing Overhead: Includes factory utilities, machinery depreciation, and indirect labor. Efficient factories with advanced automation can reduce overhead per unit.

- Tooling and Setup: Initial costs for creating molds, assembly jigs, and testing fixtures are amortized over production volumes. Custom designs or short runs elevate tooling expenses.

- Quality Control (QC): Rigorous testing for brightness, color consistency, waterproofing, and safety certifications adds to costs but ensures product reliability.

- Logistics and Shipping: Freight charges, customs duties, insurance, and last-mile delivery must be factored in. These vary significantly across regions and chosen Incoterms.

- Profit Margin: Suppliers incorporate margins based on market competition, order size, and buyer relationship.

Key Price Influencers for International Buyers

Several factors influence the final unit price of DIY LED strips, which B2B buyers should carefully evaluate:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically command lower per-unit prices due to economies of scale. MOQ requirements also affect pricing flexibility.

- Technical Specifications and Customization: Custom lengths, color temperatures, IP ratings (e.g., IP20 vs. IP65 waterproof), and smart control integrations increase costs. Buyers must balance feature needs with budget constraints.

- Material Quality and Certifications: LED strips with recognized certifications (CE, RoHS, UL) and premium LEDs from brands like Nichia or Cree will be priced higher but offer better longevity and performance.

- Supplier Location and Reputation: Established suppliers with proven track records may price higher but reduce risks of defects and delays.

- Incoterms Selection: Terms like FOB, CIF, or DDP impact who bears shipping and customs risks and costs. Buyers in Africa, South America, the Middle East, and Europe should select terms aligned with their import infrastructure and cost control strategies.

Practical Tips for Cost-Efficient Sourcing and Negotiation

For B2B buyers aiming to optimize procurement costs while maintaining quality, consider the following actionable strategies:

- Request Detailed Cost Breakdowns: Insist on transparent pricing that separates material, labor, and overhead costs. This insight helps identify negotiation levers.

- Leverage Volume Commitments: Negotiate better prices or payment terms by committing to multi-phase or bulk purchases, especially when working with new suppliers.

- Evaluate Total Cost of Ownership (TCO): Beyond unit price, factor in warranty, potential returns, energy efficiency, and lifespan. Cheaper strips may incur higher replacement or energy costs.

- Consider Regional Logistics Hubs: For buyers in Africa or South America, sourcing from suppliers with warehouses or distributors in nearby regions can reduce shipping time and costs.

- Account for Currency Fluctuations: Use forward contracts or multi-currency payment options to mitigate exchange rate risks, particularly relevant for buyers in volatile currency markets.

- Clarify Incoterms and Customs Procedures: Work closely with freight forwarders and customs brokers to avoid unexpected fees or delays at ports, notably in the Middle East and Africa.

- Sample Before Bulk Orders: Always test samples to verify quality and compliance with local regulations, preventing costly disputes or rejections.

Pricing Outlook and Disclaimer

Pricing for DIY LED strips can vary widely based on specifications and sourcing geography. Indicative FOB prices for basic 12V 5050 SMD LED strips range roughly from $1.00 to $3.00 per meter in bulk quantities, with customized or certified products priced higher. Buyers should treat these figures as general guidance and conduct supplier-specific due diligence.

By carefully analyzing cost drivers and leveraging negotiation tactics tailored to their regional context, B2B buyers across Africa, South America, the Middle East, and Europe can secure competitive pricing while ensuring product quality and supply chain reliability.

Spotlight on Potential diy led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘diy led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for diy led strip

Critical Technical Properties of DIY LED Strips

When sourcing DIY LED strips internationally, understanding core technical specifications is essential to ensure product quality, compatibility, and long-term reliability. Below are the key properties that influence purchasing decisions and supply chain efficiency:

-

LED Chip Quality and Type

The LED chip is the heart of the strip, commonly from manufacturers like Cree, Nichia, or Samsung. Key parameters include brightness (lumens), color temperature (Kelvin), and efficiency (lumens per watt). High-quality chips ensure consistent light output and durability, critical for professional installations and resale markets in Europe, the Middle East, Africa, and South America. -

Voltage and Power Consumption

Most DIY LED strips operate on 12V or 24V DC systems. Voltage impacts wiring complexity and power supply requirements, while wattage per meter affects energy efficiency and heat generation. Buyers must match strip voltage with their existing infrastructure or project specifications to avoid performance issues. -

IP Rating (Ingress Protection)

The IP rating indicates the strip’s resistance to dust and water. For indoor use, IP20 (non-waterproof) is common, while IP65 or higher is necessary for outdoor or humid environments. This property is especially important in regions with variable climates, such as parts of Africa or coastal areas in Europe and South America. -

LED Density (LEDs per Meter)

LED density affects light uniformity and brightness. Common densities range from 30 to 120 LEDs per meter. Higher density strips provide smoother illumination but may consume more power and require better heat dissipation solutions. Selecting the right density depends on the application—from accent lighting to task illumination. -

PCB Material and Flexibility

The strip’s base material (usually flexible PCB) must meet standards for heat resistance and mechanical durability. High-grade materials prevent warping or delamination during installation. Flexible PCBs allow bending around corners, a key factor for creative DIY projects and complex architectural designs. -

Color Rendering Index (CRI)

CRI measures how accurately the LED light renders colors compared to natural light. A CRI above 80 is generally preferred for retail, hospitality, and residential applications to enhance visual appeal and comfort.

Common Trade Terminology for B2B LED Strip Buyers

Understanding industry jargon streamlines communication with suppliers and ensures clarity in contract terms. Here are essential trade terms international B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce LED strips which buyers can brand as their own. OEM partnerships allow customization of product specifications, packaging, and logos, enabling businesses to differentiate in competitive markets like the EU or Middle East. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. MOQs vary widely depending on manufacturer capabilities and product complexity. Buyers from emerging markets should negotiate MOQs carefully to balance inventory costs with demand forecasts. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to multiple suppliers requesting price, delivery time, and terms for specific LED strip configurations. Effective RFQs include detailed technical specs to receive accurate, comparable quotes, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Choosing appropriate Incoterms is crucial for managing logistics and cost allocation across regions like South America or Africa. -

Binning

The process by which LED chips are sorted based on color and brightness consistency. High-quality bins ensure uniform lighting in a strip, which is vital for professional applications and satisfying end customers. -

Dimmable / PWM Control

Indicates whether the LED strip supports dimming through Pulse Width Modulation (PWM) or other control methods. Compatibility with dimmers and controllers affects installation flexibility and user experience, especially in modern smart lighting projects.

For B2B buyers across Africa, South America, the Middle East, and Europe, mastering these technical properties and trade terms empowers effective supplier evaluation, negotiation, and product specification. This knowledge reduces risks, optimizes costs, and enhances end-product quality in the dynamic DIY LED strip market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the diy led strip Sector

Market Overview & Key Trends

The global DIY LED strip market is witnessing robust growth driven by increasing demand for customizable, energy-efficient lighting solutions across residential, commercial, and industrial sectors. For international B2B buyers, particularly from emerging and diverse markets such as Africa, South America, the Middle East, and Europe, the sector offers unique opportunities fueled by urbanization, smart building initiatives, and a growing preference for personalized lighting aesthetics.

Key market drivers include advancements in LED technology—such as improved chip efficiency, tunable white lighting, and integration with IoT smart home systems—that enable greater flexibility and enhanced user control. Buyers from regions like France and Spain are capitalizing on these trends by sourcing high-quality, tunable LED strips that support dynamic lighting environments in hospitality and retail. Similarly, Middle Eastern buyers focus on robust, waterproof LED strips suited for outdoor and architectural applications, while African and South American markets are exploring cost-effective solutions that balance performance with affordability.

In sourcing, there is a noticeable shift towards modular LED strip kits and standardized components, allowing easy customization and faster project turnaround. Supply chains are evolving with increased emphasis on direct manufacturer partnerships, reducing intermediaries to improve cost competitiveness and lead times. Additionally, digital platforms and online wholesale marketplaces have become essential channels for B2B procurement, providing transparent pricing, certifications, and bulk order capabilities.

Market dynamics also reflect a growing demand for flexible voltage options (12V, 24V) and varying IP ratings (IP20 to IP68), accommodating diverse installation environments. Buyers should monitor regional regulatory standards and certifications, such as CE in Europe or local electrical compliance in Middle Eastern countries, to ensure product acceptance and safety.

Sustainability & Ethical Sourcing in B2B

Sustainability is rapidly becoming a pivotal factor in the DIY LED strip sector, driven by global environmental commitments and increasing regulatory pressures across Europe, the Middle East, and emerging economies. International B2B buyers are prioritizing suppliers who demonstrate transparent, ethical sourcing practices and adherence to environmental standards.

Illustrative Image (Source: Google Search)

The environmental impact of LED strip production largely centers on raw material extraction, energy consumption during manufacturing, and end-of-life disposal. To mitigate these effects, buyers should look for suppliers offering products with RoHS compliance, which restricts hazardous substances, and certifications like Energy Star or TÜV Rheinland that verify energy efficiency and safety standards.

Materials innovation is also key; sourcing LED strips that utilize recyclable substrates, lead-free solder, and low-impact phosphors can significantly reduce ecological footprints. Additionally, buyers increasingly demand supply chains that uphold labor rights and responsible manufacturing conditions, aligning with ESG (Environmental, Social, Governance) criteria.

Illustrative Image (Source: Google Search)

For B2B buyers from Africa and South America, integrating sustainability can be a differentiator in markets where green building initiatives are emerging. European buyers, especially in France and Spain, are subject to stringent environmental laws, making certified sustainable products a necessity. Middle Eastern buyers are beginning to incorporate sustainability in public tenders and large-scale infrastructure projects.

Establishing long-term partnerships with manufacturers who invest in renewable energy, waste reduction, and circular economy practices ensures alignment with global sustainability goals and enhances brand reputation.

Evolution and Historical Context

The DIY LED strip market has evolved significantly over the past two decades, transitioning from basic, single-color strips primarily used for accent lighting to sophisticated, multi-color, tunable white, and smart-controlled systems. Early LED strips were limited by low brightness and fixed configurations, restricting their application scope.

The introduction of flexible circuit boards, surface-mount LED technology, and integrated controllers enabled broader adoption in both commercial and residential DIY projects. This evolution has empowered B2B buyers to offer tailored lighting solutions that combine aesthetics with functionality, reducing dependency on traditional lighting fixtures.

The rise of e-commerce and global supply chains further democratized access to diverse LED strip products, fostering innovation and competition. Today’s market reflects a mature ecosystem where quality, customization, sustainability, and smart integration define sourcing decisions for international buyers seeking to meet the nuanced demands of diverse regional markets.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of diy led strip

-

How can I effectively vet LED strip suppliers for international B2B purchases?

To ensure reliability, start by verifying the supplier’s business licenses and certifications such as ISO or CE compliance relevant to LED products. Request references or case studies from previous international buyers, particularly those in your region (Africa, South America, Middle East, or Europe). Conduct factory audits or use third-party inspection services to confirm manufacturing capabilities and quality control processes. Evaluate communication responsiveness and transparency regarding product specifications, lead times, and after-sales support before committing to large orders. -

What customization options are typically available for DIY LED strips, and how should I approach them?

Most suppliers offer customization in length, color temperature, LED density, waterproof rating (IP levels), and control options (e.g., RGB, tunable white). For B2B buyers, clearly define your technical requirements and end-use applications upfront. Request samples with your custom specs to verify quality and performance. Negotiate minimum order quantities (MOQs) for custom runs, as they may differ from standard products. Ensure that the supplier can provide detailed technical documentation and support for integrating customized strips into your product lines. -

What are the common MOQ and lead time expectations for international bulk orders of DIY LED strips?

MOQ varies widely depending on supplier scale and customization level, typically ranging from 500 to several thousand meters. Lead times can range from 2 to 8 weeks, factoring in production, quality testing, and shipping. For buyers in Africa, South America, the Middle East, or Europe, consider additional customs clearance and shipping delays. Engage suppliers early to confirm current capacity and negotiate flexible MOQs or phased deliveries to balance inventory risk. Always build lead time buffers into your supply chain planning to avoid stockouts. -

Which payment terms and methods are most secure and practical for international B2B LED strip transactions?

Common payment methods include wire transfers (T/T), letters of credit (L/C), and trade assurance platforms. For first-time suppliers, L/Cs offer greater security by involving banks to guarantee payment upon meeting shipment terms. Established relationships may allow partial upfront payments with balance on delivery. Negotiate payment terms that align with your cash flow cycles, but always prioritize secure, traceable methods. Verify supplier bank details independently to avoid fraud and consider escrow services for large or custom orders. -

What quality assurance processes and certifications should I require from my LED strip supplier?

Demand certifications like CE, RoHS, UL, or IEC to ensure compliance with international safety and environmental standards. Quality assurance should include in-line production inspections, end-of-line testing for electrical safety, light output consistency, and waterproof integrity if applicable. Request sample test reports and third-party lab certifications. Implement incoming quality control (IQC) upon receipt to catch defects early. A supplier with documented quality management systems (e.g., ISO 9001) typically maintains consistent product standards vital for repeat B2B orders. -

How can I optimize logistics and shipping for importing DIY LED strips to diverse regions such as Africa or South America?

Choose suppliers experienced with international freight forwarding and customs procedures for your target markets. Opt for consolidated shipping to reduce costs when ordering multiple SKUs or smaller volumes. Use Incoterms like FOB or CIF to clearly define responsibility for shipping, insurance, and customs clearance. Consider port infrastructure and inland transportation challenges in your region when selecting shipping routes. Collaborate with freight forwarders who offer door-to-door tracking and customs brokerage to minimize delays and unexpected fees. -

What steps should I take to handle disputes or quality issues after receiving international shipments?

Establish clear contractual terms detailing quality standards, inspection rights, and dispute resolution mechanisms before purchase. Upon receipt, conduct thorough inspections and document any defects with photos and test results. Notify the supplier promptly with evidence and refer to agreed warranty or return policies. Use mediation or arbitration clauses in contracts to resolve disputes amicably. Maintaining open communication can often lead to partial refunds, replacements, or future credit. Avoid escalating conflicts prematurely to preserve long-term supplier relationships. -

Are there specific considerations for sourcing DIY LED strips from suppliers in China or Southeast Asia for buyers in Europe, Middle East, or Africa?

Suppliers in these regions often offer competitive pricing and customization but may require additional diligence on compliance with regional regulations (e.g., CE marking for Europe). Language barriers and time zone differences necessitate clear, documented communication and possibly local agent support. Factor in longer shipping times and potential tariffs or import duties. Verify that suppliers understand your market’s electrical standards (voltage, certifications) to avoid compatibility issues. Establish pilot orders to test supplier reliability and product performance before scaling purchases.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for diy led strip

Strategic sourcing of DIY LED strips demands a nuanced understanding of product specifications, supplier reliability, and regional market dynamics. For international B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing suppliers who offer consistent quality, energy-efficient options, and scalable customization is essential. Leveraging strategic partnerships with manufacturers that embrace innovation—such as tunable white, waterproof, and high-density LED strips—can significantly enhance product offerings and end-user satisfaction.

Key takeaways for buyers include:

- Thorough supplier vetting: Assess manufacturing capabilities, certifications, and after-sales support to mitigate supply chain risks.

- Focus on energy efficiency and compliance: Align product choices with regional regulations and sustainability goals to future-proof investments.

- Customization and flexibility: Opt for suppliers that provide modular and adaptable solutions catering to diverse project requirements.

- Logistics optimization: Factor in shipping routes, lead times, and local import regulations to maintain steady inventory flow and cost control.

Looking ahead, the DIY LED strip market is poised for continued growth driven by rising demand for smart, eco-friendly lighting solutions. Buyers who strategically source with a forward-thinking mindset will unlock competitive advantages and capitalize on emerging trends. To stay ahead, international B2B purchasers should actively engage with innovation-focused suppliers and embrace digital sourcing platforms that streamline procurement and foster transparency.

Take action now: Evaluate your current sourcing strategy, deepen supplier relationships, and invest in sustainable LED technologies to power your business into the next phase of growth.