Guide to Dimmable Strip Led

- Introduction: Navigating the Global Market for dimmable strip led

- Understanding dimmable strip led Types and Variations

- Key Industrial Applications of dimmable strip led

- Strategic Material Selection Guide for dimmable strip led

- In-depth Look: Manufacturing Processes and Quality Assurance for dimmable strip led

- Comprehensive Cost and Pricing Analysis for dimmable strip led Sourcing

- Spotlight on Potential dimmable strip led Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for dimmable strip led

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dimmable strip led Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dimmable strip led

- Strategic Sourcing Conclusion and Outlook for dimmable strip led

Introduction: Navigating the Global Market for dimmable strip led

Dimmable strip LED lighting has rapidly become a cornerstone technology for businesses seeking adaptable, energy-efficient illumination solutions. Its ability to finely control light intensity not only enhances ambiance and user experience but also enables significant energy savings and extended product lifespan—key factors driving demand across commercial, industrial, and architectural projects worldwide. For B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe (including advanced economies like Italy and Saudi Arabia), understanding the complexities of sourcing high-quality dimmable strip LEDs is essential to achieving optimal outcomes.

This comprehensive guide offers a strategic roadmap tailored to international buyers, addressing every critical aspect of the dimmable strip LED supply chain. It covers the full spectrum of product types and variations, from single-color dimmable strips to advanced multi-channel RGBW options. Detailed insights into material selection, manufacturing processes, and stringent quality control protocols provide the assurance needed to secure durable, high-performance lighting solutions.

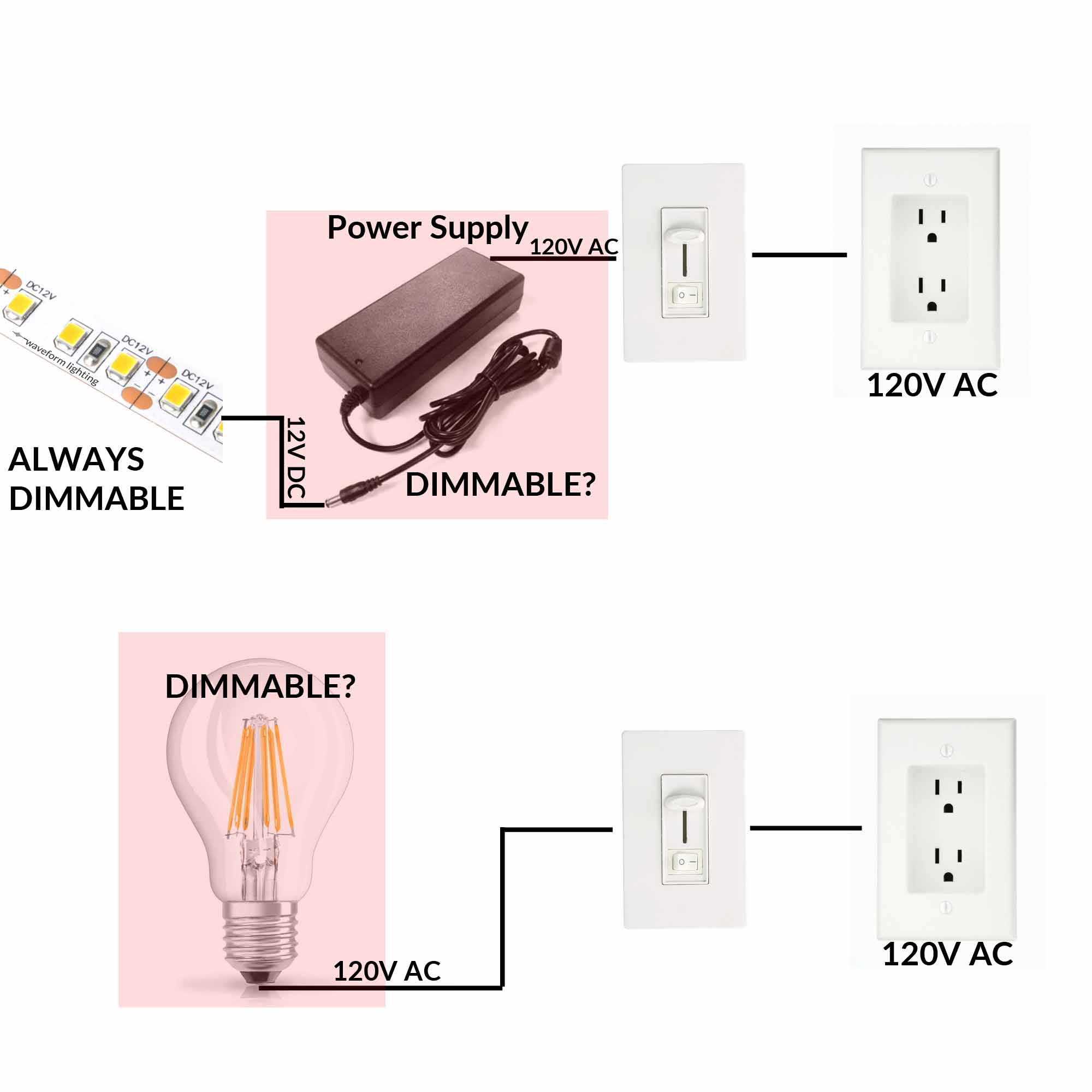

Illustrative Image (Source: Google Search)

Additionally, the guide evaluates supplier landscapes, pricing structures, and logistics considerations, empowering buyers to negotiate favorable terms and streamline procurement. Market dynamics and regional regulatory requirements are also examined to help navigate import/export challenges and ensure compliance.

By consolidating technical expertise, market intelligence, and practical sourcing strategies, this resource equips B2B buyers with the clarity and confidence to make well-informed purchasing decisions. Whether managing large-scale installations or bespoke projects, businesses will find actionable insights to select reliable partners and secure dimmable strip LED products that align precisely with their operational goals and sustainability commitments.

Understanding dimmable strip led Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Color Dimmable LED | Offers adjustable brightness on a fixed color temperature | Retail, hospitality, office ambient lighting | Simple control, cost-effective, but limited in color flexibility |

| RGB Dimmable LED Strip | Allows dimming and color mixing across red, green, blue LEDs | Event venues, architectural accents, clubs | Versatile lighting effects, higher cost, requires compatible controllers |

| Tunable White Dimmable LED | Adjustable brightness and color temperature from warm to cool white | Healthcare, museums, corporate offices | Enhances mood and productivity, moderate complexity, slightly higher price |

| Waterproof Dimmable LED | Encapsulated with silicone or epoxy for outdoor use | Outdoor signage, landscape lighting, marine | Durable and weather-resistant, higher price, requires proper installation for longevity |

| Smart Dimmable LED Strip | Integrated with IoT-enabled controllers for app or voice control | Smart buildings, luxury retail, smart homes | Advanced control and automation, premium price, requires network infrastructure and technical support |

Single-Color Dimmable LED

This type offers a fixed color temperature with adjustable brightness levels, making it ideal for environments requiring consistent lighting ambiance such as retail stores or office spaces. For B2B buyers, these strips are cost-effective and straightforward to integrate with existing dimming systems. However, they lack the flexibility of color change, limiting their use in dynamic lighting projects. Bulk buyers should focus on verifying dimmer compatibility and supplier warranties to ensure long-term reliability.

RGB Dimmable LED Strip

RGB strips provide a wide spectrum of colors by mixing red, green, and blue LEDs, with dimming capabilities for each color channel. This versatility makes them perfect for event venues, clubs, and architectural features where dynamic lighting is crucial. Buyers must consider the need for compatible controllers and the potential complexity in installation. The slightly higher cost is offset by the ability to create customizable lighting scenes that attract end clients.

Tunable White Dimmable LED

Tunable white LED strips allow users to adjust both brightness and color temperature from warm to cool white, supporting circadian rhythms and enhancing productivity. This feature is highly valued in healthcare facilities, museums, and corporate offices. B2B buyers should evaluate the integration options with existing building management systems and ensure the supplier provides precise color temperature control and consistent quality across batches.

Waterproof Dimmable LED

Encased in protective coatings such as silicone or epoxy, these strips are designed for outdoor and harsh environment applications like landscape lighting, marine use, and outdoor signage. Their durability comes at a premium, and buyers need to confirm IP ratings and installation guidelines to avoid early failure. For international buyers, understanding local weather conditions and compliance with regional standards is essential.

Smart Dimmable LED Strip

Incorporating IoT technology, smart dimmable strips enable control via apps, voice assistants, or automation systems. They are suited for smart buildings, luxury retail, and smart home integrations where advanced lighting control enhances user experience. Buyers should assess network compatibility, cybersecurity features, and after-sales technical support. While the initial investment is higher, the long-term benefits include energy savings and scalable control options.

Key Industrial Applications of dimmable strip led

| Industry/Sector | Specific Application of dimmable strip led | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Hospitality | Ambient and accent lighting in stores, hotels, and restaurants | Enhances customer experience, increases dwell time, and reduces energy costs | Dimmability range, color rendering index (CRI), compatibility with control systems, and durability for high-traffic environments |

| Architecture & Interior Design | Dynamic architectural lighting and mood setting in commercial buildings | Enables flexible lighting schemes, supports branding, and improves space aesthetics | Custom length options, consistent light output, and compliance with regional safety standards |

| Manufacturing & Warehousing | Adjustable task lighting on assembly lines and inspection stations | Improves worker productivity, reduces eye strain, and adapts to varying operational needs | High lumen output, robust build quality, and ease of integration with existing lighting controls |

| Healthcare Facilities | Patient room lighting and circadian rhythm-supportive lighting | Enhances patient comfort, supports healing environments, and allows personalized lighting control | Non-flicker technology, medical-grade certifications, and ease of cleaning and maintenance |

| Event Management & Exhibition | Flexible, dimmable lighting for stages, exhibits, and trade shows | Provides customizable ambiance, quick installation, and energy-efficient operation | Portability, remote dimming capability, and fast setup compatibility |

Retail & Hospitality

Dimmable strip LED lighting is widely employed in retail stores, hotels, and restaurants to create inviting atmospheres that encourage longer customer visits and enhance brand perception. Adjustable brightness levels allow businesses to tailor lighting to different times of day or events, optimizing energy consumption without compromising ambiance. For international buyers, especially in regions like Europe and the Middle East, sourcing dimmable strips with high CRI and robust dimming capabilities ensures lighting quality meets sophisticated aesthetic demands and complies with local energy regulations.

Architecture & Interior Design

In commercial architecture and interior design projects, dimmable strip LEDs enable dynamic lighting schemes that can transform spaces according to mood or function. This flexibility supports branding efforts and elevates the visual appeal of offices, lobbies, and public areas. Buyers from markets such as Italy and Saudi Arabia prioritize suppliers offering custom lengths and consistent light output to achieve seamless installations that meet stringent European and Gulf safety standards. Integration with smart building controls is also a critical factor.

Manufacturing & Warehousing

Adjustable task lighting using dimmable strip LEDs enhances precision and comfort on production lines and inspection stations. The ability to modulate brightness helps reduce eye strain and adapt lighting to specific operational tasks, boosting worker efficiency and safety. For B2B buyers in South America and Africa, selecting products with high lumen efficacy and durable construction is essential to withstand industrial environments while maintaining long-term performance. Compatibility with existing control systems simplifies retrofits and expansions.

Healthcare Facilities

Healthcare environments benefit greatly from dimmable strip LEDs for patient rooms and treatment areas, where lighting can be adjusted to support circadian rhythms and improve patient well-being. Non-flickering, medically certified LED strips contribute to a calming atmosphere and facilitate personalized lighting settings for different care scenarios. Buyers from diverse regions must consider strict hygiene standards and certifications, ensuring products are easy to clean and meet local health regulations, particularly important in markets with evolving healthcare infrastructure.

Event Management & Exhibition

For event organizers and exhibition centers, dimmable strip LEDs offer versatile lighting solutions that can be rapidly installed and adjusted to suit various themes and display requirements. The ability to remotely control brightness and color temperature enhances the visitor experience while optimizing energy use. International buyers targeting event venues in Africa, Europe, and the Middle East should prioritize suppliers providing portable, user-friendly systems with reliable remote dimming functionality and quick setup to meet tight event schedules.

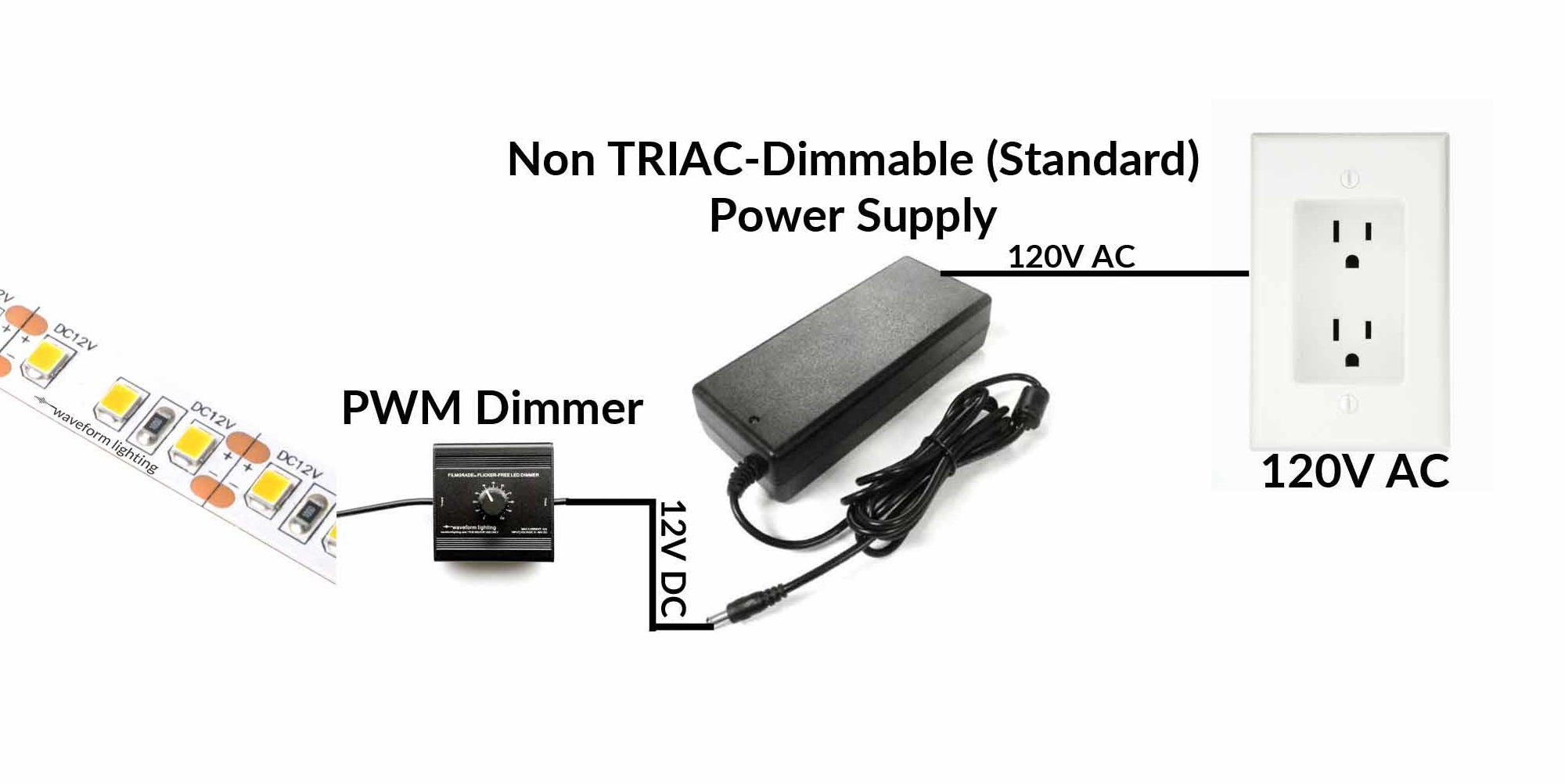

Related Video: All About 12V LED Dimmers

Strategic Material Selection Guide for dimmable strip led

When selecting materials for dimmable strip LED products, international B2B buyers must balance performance, durability, cost, and regional compliance requirements. The choice of materials directly affects product longevity, dimming reliability, thermal management, and installation flexibility. Below is an analysis of four common materials integral to dimmable strip LED construction, focusing on their technical merits and strategic implications for buyers from Africa, South America, the Middle East, and Europe.

1. Flexible Printed Circuit Board (FPCB) Substrate – Polyimide (PI)

Key Properties:

Polyimide-based FPCBs are renowned for their excellent thermal stability, withstanding temperatures up to 260°C, and superior mechanical flexibility. They offer good chemical resistance and electrical insulation, making them ideal for compact, bendable LED strips.

Pros & Cons:

PI substrates enable high-density LED placement and reliable dimming control due to stable electrical properties. However, they are more expensive than standard materials like polyester and require precise manufacturing processes to avoid defects. Their flexibility supports complex installations but can be sensitive to prolonged UV exposure.

Impact on Application:

Ideal for indoor and semi-outdoor dimmable LED strips where heat dissipation and bending are critical. Their thermal endurance supports dimming circuits that may generate heat during operation.

B2B Considerations:

Buyers in regions with high ambient temperatures, such as the Middle East and parts of Africa, benefit from PI substrates’ thermal resilience. Compliance with international standards like IPC-2221 (for PCB design) and RoHS is common in European markets, including Italy and Germany. Buyers should verify supplier certification and UV resistance for outdoor applications.

2. Silicone Encapsulation / Coating

Key Properties:

Silicone encapsulants provide excellent waterproofing (IP65 to IP68 ratings) and UV resistance, with operational temperature ranges from -40°C to +200°C. Silicone’s elasticity protects LEDs from mechanical stress and environmental damage.

Pros & Cons:

Silicone coatings enhance durability and enable outdoor dimmable LED strips to function reliably in harsh climates. The material is chemically inert and non-yellowing, preserving light quality. However, silicone encapsulation adds to manufacturing complexity and cost, and can complicate recycling efforts.

Impact on Application:

Crucial for outdoor and industrial dimmable LED strips, especially in regions with high humidity or dust, such as tropical South America and coastal Africa. Silicone’s flexibility also supports installations on curved surfaces.

B2B Considerations:

Buyers in the Middle East and Europe should ensure silicone materials comply with REACH and EU environmental directives. For African and South American markets, durability against UV and moisture is paramount. Sourcing from suppliers with ISO 9001 and environmental certifications ensures quality and compliance.

3. Aluminum Backing / Heat Sink

Key Properties:

Aluminum provides excellent thermal conductivity (around 205 W/mK), facilitating heat dissipation from LEDs, which is essential for maintaining dimming performance and extending lifespan. It also offers structural rigidity and corrosion resistance when anodized.

Pros & Cons:

Aluminum-backed LED strips improve thermal management, enabling higher brightness and stable dimming without thermal throttling. It is cost-effective and widely available but adds weight and reduces flexibility compared to fully flexible substrates.

Impact on Application:

Best suited for commercial and industrial dimmable LED strips requiring robust heat dissipation, such as retail lighting in Europe or large-scale architectural projects in the Middle East. Less ideal for highly flexible or curved installations.

B2B Considerations:

European buyers often demand compliance with EN 485 (aluminum alloy standards) and environmental certifications. In regions with high corrosion risk (coastal Africa, South America), anodized aluminum or protective coatings are recommended. Aluminum sourcing should consider sustainability and supply chain transparency.

4. Copper Traces on PCB

Key Properties:

Copper is the standard conductive material for LED strip PCBs due to its excellent electrical conductivity and thermal performance. Typical copper thickness ranges from 1 oz/ft² to 3 oz/ft², influencing current capacity and heat dissipation.

Pros & Cons:

Copper traces ensure stable electrical flow critical for consistent dimming and brightness control. Thicker copper layers improve durability but increase cost and reduce flexibility. Copper is prone to oxidation if not properly coated, which can affect longevity.

Impact on Application:

Copper trace quality directly impacts dimmable LED strip reliability in all applications, from residential to industrial. Thicker copper is preferred for high-power strips used in demanding environments.

B2B Considerations:

Buyers should verify that copper used meets IPC standards and is coated with protective finishes (e.g., HASL, ENIG) to prevent corrosion, especially important in humid climates like South America or coastal regions in Africa. Compliance with international electrical safety standards (IEC, UL) is critical for European and Middle Eastern markets.

Summary Table

| Material | Typical Use Case for dimmable strip led | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide (PI) FPCB | Flexible indoor and semi-outdoor dimmable LED strips | High thermal stability and flexibility | Higher cost and sensitive to UV exposure | High |

| Silicone Encapsulation | Outdoor and industrial waterproof dimmable LED strips | Excellent waterproofing and UV resistance | Increased manufacturing complexity | Medium |

| Aluminum Backing / Heat Sink | Commercial/industrial strips requiring heat dissipation | Superior thermal management and rigidity | Adds weight, less flexible | Medium |

| Copper Traces on PCB | All dimmable LED strips requiring reliable conductivity | Excellent electrical and thermal conductance | Oxidation risk without proper coating | Low to Medium |

This material selection guide equips international B2B buyers with critical insights to optimize dimmable strip LED procurement. Considering regional climate, regulatory standards, and application-specific demands ensures sourcing decisions that enhance product performance, compliance, and cost-efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for dimmable strip led

Dimmable LED strip lights combine advanced lighting technology with flexibility and energy efficiency, making them highly sought after in global B2B markets. Understanding the manufacturing and quality assurance processes behind these products is essential for buyers across Africa, South America, the Middle East, and Europe to ensure they select reliable suppliers and secure products that meet both technical and regulatory standards.

Manufacturing Process of Dimmable LED Strip Lights

The production of dimmable LED strip lights involves several critical stages, each requiring precision and quality control to guarantee optimal performance and durability.

1. Material Preparation

At the outset, raw materials such as LED chips, flexible printed circuit boards (FPCBs), resistors, capacitors, and dimming control components are sourced and inspected. High-quality LED chips (typically SMD 2835, 3528, or 5050) are selected for consistent light output and longevity. The FPCBs are prepared with copper traces designed for flexibility and electrical conductivity. Material preparation also includes the procurement of silicone or epoxy for waterproofing and protective coatings.

2. Forming and Circuit Assembly

The FPCBs are printed and etched to form the circuit pathways. Surface mount technology (SMT) machines place LED chips and electronic components onto the boards with high accuracy. Automated soldering processes, such as reflow soldering, ensure strong and reliable electrical connections. This stage also integrates dimming components—either analog (0-10V, PWM) or digital (DMX, DALI)—to enable brightness control.

3. Encapsulation and Protective Finishing

After assembly, the LED strips undergo encapsulation to protect against moisture, dust, and mechanical damage. Depending on the application, strips may be coated with a silicone or epoxy resin layer or sealed within waterproof PVC tubing. This finishing step is crucial for outdoor or industrial applications, ensuring long-term durability and consistent performance.

4. Cutting and Packaging

Strips are cut to standardized lengths or customized sizes based on buyer requirements. They are then tested for electrical continuity and packaged with necessary accessories such as connectors, controllers, and power supplies. Packaging often includes anti-static materials to prevent damage during shipping.

Quality Assurance Frameworks and Standards

Quality assurance (QA) is integral to the manufacturing process, ensuring that dimmable LED strip lights meet international performance and safety standards. Buyers should verify that suppliers comply with recognized certifications and maintain robust quality control systems.

Key International and Industry Standards

- ISO 9001: This is the global benchmark for quality management systems (QMS). Suppliers certified under ISO 9001 demonstrate systematic processes for consistent product quality and continuous improvement.

- CE Marking: Mandatory for products sold within the European Economic Area, CE certification confirms compliance with EU safety, health, and environmental protection requirements.

- RoHS Compliance: Restriction of hazardous substances ensures the LED strips do not contain harmful materials like lead or mercury, critical for environmental safety and import regulations.

- UL and ETL Certifications: Particularly relevant for North American and some Middle Eastern markets, these certifications verify electrical safety and product reliability.

- API and Regional Certifications: Certain markets, such as Saudi Arabia or South American countries, may require additional local certifications or approvals related to electrical standards or import regulations.

Quality Control (QC) Checkpoints and Testing Methods

Robust QC processes involve multiple inspection stages during and after manufacturing to detect defects early and ensure product consistency.

Incoming Quality Control (IQC)

This stage inspects raw materials and components before they enter production. IQC checks include:

– Verification of LED chip luminous efficacy and color temperature.

– Inspection of PCB quality and copper thickness.

– Testing of dimming control modules for responsiveness and compatibility.

In-Process Quality Control (IPQC)

During assembly, IPQC focuses on:

– Monitoring SMT placement accuracy and solder joint integrity.

– Verifying circuit continuity and electrical resistance.

– Checking for correct integration of dimming components and uniform LED spacing.

Final Quality Control (FQC)

Before shipment, FQC involves comprehensive testing:

– Electrical Testing: Ensures strips operate at specified voltage and current levels without failure.

– Dimming Functionality Test: Confirms smooth brightness adjustment across the entire dimming range without flicker or color shift.

– Environmental Stress Testing: Includes thermal cycling and humidity exposure to simulate real-world conditions.

– Visual Inspection: Checks for physical defects, uniformity of light output, and proper encapsulation.

How B2B Buyers Can Verify Supplier Quality Assurance

International buyers should adopt a proactive approach to verify the quality assurance capabilities of suppliers, minimizing risks associated with product defects or non-compliance.

- Factory Audits: Conduct on-site or third-party audits to assess manufacturing capabilities, process controls, and adherence to QMS standards such as ISO 9001.

- Review Quality Documentation: Request detailed QC reports, certifications, and test result logs for batches supplied.

- Third-Party Inspection: Engage independent inspection agencies to perform random sampling and testing before shipment, especially for large or critical orders.

- Sample Testing: Obtain product samples to conduct in-house or third-party laboratory testing on dimming performance, durability, and safety compliance.

- Supplier Track Record: Evaluate supplier reputation through references, customer feedback, and delivery reliability metrics.

QC and Certification Considerations for Regional Markets

B2B buyers from Africa, South America, the Middle East, and Europe must navigate diverse regulatory landscapes and market-specific requirements.

- Africa and South America: While some countries have evolving standards, buyers should prioritize suppliers with international certifications (CE, RoHS, UL) to ensure product acceptance and safety. Local import regulations may also require customs testing or certification.

- Middle East (e.g., Saudi Arabia): Compliance with GCC standards and SASO certification is often mandatory. Electrical safety and EMC (Electromagnetic Compatibility) testing are critical. Buyers should confirm that products have passed regional conformity assessments.

- Europe (e.g., Italy, Germany): Strict adherence to EU directives (CE marking, RoHS, REACH) is essential. Buyers should insist on documentation proving compliance and consider energy efficiency labels as part of product evaluation.

Conclusion

For international B2B buyers investing in dimmable LED strip lights, a thorough understanding of manufacturing processes and quality assurance protocols is vital. By scrutinizing supplier certifications, production workflows, and QC practices—coupled with targeted audits and testing—buyers can mitigate risks, ensure compliance with regional standards, and secure high-performance products tailored to their market needs. This strategic diligence ultimately translates into reliable supply chains, cost-effective procurement, and enhanced customer satisfaction across diverse industrial and commercial applications.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for dimmable strip led Sourcing

Understanding the cost and pricing dynamics for sourcing dimmable LED strips is essential for international B2B buyers aiming to optimize procurement budgets while ensuring product quality and compliance. This analysis breaks down key cost components, pricing influencers, and offers practical buyer strategies tailored to markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in Dimmable LED Strip Production

-

Materials: The primary cost driver includes high-quality LED chips (often SMD types), flexible PCBs, dimming control components (such as IC drivers compatible with PWM or analog dimming), and protective coatings like silicone or epoxy for waterproof variants. Premium materials significantly impact durability and dimming smoothness.

-

Labor: Skilled labor costs vary by manufacturing region. Asian hubs, notably China, typically offer lower labor expenses, but rising wages are shifting some production to Southeast Asia or Eastern Europe. Labor intensity increases with customization and quality assurance processes.

-

Manufacturing Overhead: This covers utilities, equipment depreciation, and factory overhead. Automated assembly lines lower per-unit costs but require high volumes to justify capital investment.

-

Tooling and Setup: Initial tooling for custom lengths, connectors, or packaging can add upfront costs. For repeat orders, these costs amortize over volume but are critical for projects requiring specific form factors or branding.

-

Quality Control (QC): Rigorous QC, including photometric testing, electrical safety checks, and dimming performance validation, ensures compliance with international standards (e.g., CE, RoHS, UL). Enhanced QC raises costs but mitigates risks of returns or failures.

-

Logistics and Import Duties: Shipping costs fluctuate based on order size, weight, and delivery mode (air freight vs. sea freight). Import tariffs and taxes vary by destination country, with some regions applying preferential trade agreements that buyers should leverage.

-

Supplier Margin: Suppliers build in profit margins reflecting market conditions, product complexity, and brand positioning. Margins may be negotiable, especially for large or repeat orders.

Influencing Factors on Pricing

-

Order Volume and Minimum Order Quantity (MOQ): Larger volumes generally secure lower unit prices due to economies of scale and amortized fixed costs. MOQs vary widely; buyers in emerging markets should negotiate flexible terms to avoid overstocking.

-

Product Specifications and Customization: Dimmable strips with advanced features (e.g., addressable LEDs, compatibility with smart home systems) command premium pricing. Custom colors, packaging, or connectors also elevate costs.

-

Material Quality and Certifications: Higher-grade LEDs and certified dimming drivers ensure better performance and longevity but increase price. Certifications like CE for Europe or SASO for Saudi Arabia add compliance costs but ease market entry.

-

Supplier Reliability and Location: Established suppliers with proven track records may price higher but reduce risks. Proximity to buyers, such as suppliers in Europe for Italian buyers, can lower shipping time and costs.

-

Incoterms and Payment Terms: Terms such as FOB, CIF, or DDP significantly affect landed cost. For example, FOB places shipping responsibility on buyers, while DDP includes duties and taxes in the price, simplifying budgeting for buyers unfamiliar with import procedures.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Volume Discounts and Flexible MOQs: Engage suppliers early to explore tiered pricing models and MOQ adjustments, especially critical for buyers in markets with limited storage capacity or fluctuating demand.

-

Evaluate Total Cost of Ownership (TCO): Look beyond unit price to include warranty support, energy savings from efficient dimming, and potential downtime costs. High-quality dimmable strips may reduce long-term expenses despite a higher upfront price.

-

Leverage Regional Trade Agreements: African buyers can benefit from the African Continental Free Trade Area (AfCFTA), while European buyers should consider EU trade policies. Middle Eastern buyers may access preferential tariffs through GCC agreements.

-

Plan for Logistics and Compliance: Factor in shipping lead times, customs clearance, and certification requirements early. Using suppliers who assist with documentation and provide compliant products minimizes delays and unexpected costs.

-

Request Samples and Conduct Pilot Testing: Before committing to large orders, test product dimming functionality and durability in real-world conditions. This is particularly important for environments with extreme temperatures or humidity, common in many African and Middle Eastern markets.

Pricing Disclaimer

All pricing insights are indicative and subject to fluctuations based on global raw material markets, currency exchange rates, geopolitical factors, and evolving manufacturing capabilities. Buyers should conduct due diligence, obtain multiple quotes, and consider total landed cost when making sourcing decisions.

By comprehensively understanding cost drivers and market variables, international B2B buyers can strategically source dimmable LED strips that balance quality, price, and operational efficiency, ensuring competitive advantages across diverse regional markets.

Spotlight on Potential dimmable strip led Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘dimmable strip led’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dimmable strip led

Critical Technical Properties of Dimmable Strip LED

1. LED Chip Quality and Type

The LED chip is the core light-emitting component. High-quality chips (commonly SMD 2835 or 5050) ensure brighter, more consistent illumination with lower energy consumption. For B2B buyers, selecting premium chip types guarantees longer lifespan and reduces maintenance costs, which is vital for large-scale or commercial projects.

2. Dimmability Compatibility and Control Method

Dimmable LED strips must be compatible with specific dimming technologies such as PWM (Pulse Width Modulation) or analog dimming. Understanding the control method is essential to ensure seamless integration with existing lighting control systems or remote dimmers. This compatibility impacts installation flexibility and user experience.

3. Color Temperature and Color Rendering Index (CRI)

Color temperature (measured in Kelvins) defines the light’s warmth or coolness, ranging typically from 2700K (warm white) to 6500K (daylight). CRI indicates how accurately colors appear under the LED light, with 80+ being standard for commercial use and 90+ preferred for high-quality applications. Buyers must specify these to meet aesthetic and functional lighting requirements.

4. Power Consumption and Voltage

Dimmable strips usually operate on 12V or 24V DC power supplies. Power consumption (watts per meter) affects energy costs and heat generation. Selecting the right voltage and wattage is crucial for system efficiency, safety, and ensuring the power supply can support the entire installation without voltage drop issues.

5. IP Rating (Ingress Protection)

The IP rating defines the strip’s resistance to dust and water. For indoor applications, IP20 is common, while outdoor or humid environments require IP65 or higher. B2B buyers must match IP ratings to installation environments to avoid product failure and warranty issues.

6. PCB Material and Flexibility

The strip’s circuit board material (typically flexible polyimide or rigid FR4) affects durability and ease of installation. Flexible PCBs allow bending around corners or curved surfaces, essential for architectural lighting. Material grade impacts thermal management, directly influencing LED lifespan.

Common Trade Terminology for B2B Buyers

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce LED strips that can be rebranded and customized by buyers. OEM partnerships allow businesses to offer unique products with their branding, often with tailored specifications or packaging, ideal for market differentiation.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept per order. MOQs vary widely depending on manufacturer capacity and product complexity. Understanding MOQ helps buyers plan budgets and inventory, especially critical for startups or businesses with limited storage.

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers asking for pricing, lead times, and terms based on detailed product specifications. RFQs enable buyers to compare offers transparently and negotiate better deals, facilitating informed procurement decisions.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities and costs between buyers and sellers during shipping (e.g., FOB, CIF, DDP). Knowing Incoterms is crucial for managing logistics, customs clearance, and total landed costs, especially for cross-border transactions in regions like Africa or Europe.

Lumen Output

A measurement of the total visible light emitted by the LED strip. Higher lumens mean brighter light. Buyers must specify lumen requirements to ensure adequate illumination for their application, balancing brightness with energy efficiency.

Bin Sorting

A quality control process where LEDs are sorted by brightness and color consistency to minimize variation within a batch. For B2B buyers, insisting on bin-sorted LEDs ensures uniform lighting appearance across large installations, enhancing customer satisfaction.

By understanding these technical properties and trade terms, international buyers can confidently evaluate suppliers, optimize product selection, and streamline procurement processes, ensuring their dimmable LED strip projects meet both performance and commercial objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dimmable strip led Sector

Market Overview & Key Trends

The global market for dimmable LED strip lights is experiencing robust growth, driven by rising demand for energy-efficient, customizable lighting solutions across commercial, industrial, and residential sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including mature markets like Italy and emerging hubs like Saudi Arabia—are increasingly prioritizing dimmable LED strips for their ability to offer precise lighting control, reduce energy consumption, and enhance user experience.

Key market drivers include urbanization, smart building initiatives, and government incentives promoting energy-saving technologies. In Europe, stringent energy regulations and green building certifications are accelerating adoption, while in the Middle East and Africa, infrastructure development and growing retail and hospitality sectors fuel demand for versatile lighting. South American markets are witnessing growth due to expanding commercial construction and retrofitting projects.

From a sourcing perspective, B2B buyers are gravitating towards suppliers offering advanced dimming technologies such as PWM (Pulse Width Modulation) and TRIAC compatibility, ensuring seamless integration with existing control systems. The rise of smart dimmable LED strips with IoT-enabled remote controls and app-based customization is another notable trend, catering to tech-savvy markets. Buyers are also focusing on scalability and supply chain reliability, seeking suppliers capable of fulfilling large-volume orders with consistent quality.

Furthermore, regional trade dynamics influence sourcing strategies. For instance, buyers in Africa and South America often leverage Asian manufacturing hubs for cost-effective procurement, while European buyers emphasize compliance with EU directives like RoHS and CE certification. Import tariffs, shipping logistics, and after-sales support are critical considerations shaping supplier selection and contract negotiations.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer optional in the dimmable LED strip sector; it is a decisive factor influencing procurement and partnership decisions. The environmental impact of LED manufacturing, including raw material extraction, energy consumption, and electronic waste, requires B2B buyers to engage with suppliers committed to eco-friendly production practices.

Ethical sourcing of components such as LED chips, flexible PCBs, and solder materials is paramount. Buyers are increasingly scrutinizing supply chains to avoid conflict minerals and ensure fair labor practices. Suppliers demonstrating transparency through third-party audits and certifications like ISO 14001 (Environmental Management), UL GREENGUARD, and Energy Star provide greater assurance of sustainable manufacturing.

Material innovation also plays a role: dimmable LED strips incorporating lead-free solder, recyclable substrates, and low-VOC (volatile organic compounds) adhesives align with green building standards and corporate social responsibility goals. Additionally, energy efficiency gains achieved through dimmability directly contribute to reduced carbon footprints over product lifecycles.

B2B buyers should incorporate sustainability criteria into supplier evaluations, balancing cost with long-term value and regulatory compliance. Embracing circular economy principles—such as product take-back programs and modular designs facilitating repair or upgrade—can further enhance sustainability profiles. For businesses in regions with emerging environmental regulations, proactive sourcing of certified dimmable LED strips positions them competitively while meeting growing stakeholder expectations.

Evolution of Dimmable LED Strip Technology

The evolution of dimmable LED strip lighting reflects broader advancements in semiconductor and control technologies. Early LED strips offered fixed brightness levels, limiting their flexibility and application scope. Over the past decade, integration of dimming drivers and improved LED chip efficiency has transformed these products into highly adaptable lighting solutions.

Initially, dimming was achieved through simple analog methods prone to flicker and inconsistent output. The advent of digital dimming protocols, such as PWM and DALI (Digital Addressable Lighting Interface), enabled precise brightness control and compatibility with building automation systems. This progression allowed dimmable LED strips to penetrate professional lighting markets, including retail, hospitality, and architectural sectors.

Recent innovations include smart dimmable strips with wireless control, scene-setting capabilities, and integration with IoT platforms, reflecting a shift towards intelligent lighting ecosystems. For B2B buyers, understanding this technological trajectory is crucial to selecting products that not only meet current project specifications but also provide future-proof adaptability and integration potential.

Related Video: Trade and tariffs | APⓇ Microeconomics | Khan Academy

Frequently Asked Questions (FAQs) for B2B Buyers of dimmable strip led

-

How can I effectively vet suppliers of dimmable strip LED products for international B2B purchasing?

To vet suppliers, start by verifying their business credentials and certifications such as ISO, CE, or RoHS compliance relevant to your region (e.g., EU’s CE marking or Middle East’s SASO). Request detailed product datasheets and test reports to confirm quality standards. Check references or customer reviews, especially from buyers in your continent. Engage in direct communication to assess responsiveness and technical support capabilities. If possible, arrange for product samples to test dimming functionality and durability under your expected conditions before committing to large orders. -

What customization options are typically available for dimmable strip LED products, and how should I approach them?

Customization can include LED strip length, color temperature, brightness levels, IP rating (waterproofing), and control interfaces compatible with regional dimmers or smart systems. Many suppliers offer bespoke packaging and branding options as well. Clearly define your project requirements upfront and discuss them with suppliers to understand feasibility, additional costs, and lead times. Customization is especially valuable for projects in diverse markets like Africa or Europe where installation environments and customer preferences vary significantly. -

What are common Minimum Order Quantities (MOQs), lead times, and payment terms I should expect when sourcing dimmable strip LEDs internationally?

MOQs vary widely depending on supplier scale and customization but typically range from 500 to 2,000 meters for standard products. Lead times average 3 to 8 weeks, influenced by order complexity and supplier location. Payment terms often include 30% upfront deposit with balance before shipment; however, established buyers may negotiate net 30 or letters of credit. For buyers in South America or the Middle East, factor in additional time for customs clearance and possible banking delays when planning procurement schedules. -

Which quality assurance certifications and testing standards should I verify for dimmable strip LED products?

Ensure products comply with international standards such as CE (Europe), UL or ETL (North America), and IEC standards for electrical safety. IP ratings indicate water and dust resistance levels, crucial for outdoor or industrial installations. Look for certifications related to dimming compatibility like TRIAC or PWM dimming compliance. Confirm that suppliers perform in-house aging tests and luminous flux measurements to guarantee product lifespan and dimming stability, reducing risks of early failures in your projects. -

What logistics considerations should B2B buyers keep in mind when importing dimmable strip LEDs from Asia or Europe?

Plan for freight modes (air vs. sea) based on urgency and cost; sea freight is economical for bulk but slower. Check supplier’s shipping terms (Incoterms) to clarify responsibility for customs clearance and duties. For markets like Italy or Saudi Arabia, ensure compliance with local import regulations and documentation requirements to avoid delays. Consolidating shipments can reduce freight costs. Engage experienced freight forwarders familiar with your destination to navigate logistical challenges and ensure timely delivery. -

How can I mitigate risks related to product disputes or defects with international dimmable strip LED suppliers?

Incorporate clear terms in your purchase agreement covering warranty periods, defect resolution, and return policies. Specify acceptable tolerance levels for product performance and appearance. Request pre-shipment inspection reports or third-party quality audits. Maintain open communication channels for prompt issue resolution. In case of disputes, use documented evidence such as test results and inspection photos. Consider working with suppliers offering escrow payment or trade assurance services to protect your investment. -

Are there regional differences in dimmable strip LED standards or technologies that international buyers should be aware of?

Yes, regional differences affect voltage standards (e.g., 220-240V in Europe vs. 110-120V in some African countries), dimmer compatibility, and certification requirements. Some markets prioritize energy efficiency labels or hazardous substance restrictions. For instance, Europe mandates strict RoHS compliance and CE marking, while Middle East countries may require SASO certification. Understanding these nuances helps avoid regulatory issues and ensures seamless integration with local electrical systems.

Illustrative Image (Source: Google Search)

- What are best practices for managing ongoing supplier relationships for repeat dimmable strip LED orders?

Establish regular performance reviews focusing on quality consistency, delivery punctuality, and responsiveness. Share forecasts and project timelines early to help suppliers plan production. Negotiate flexible MOQs or priority production slots as your order volume grows. Collaborate on product improvements based on end-customer feedback to enhance competitiveness. Building trust through transparent communication and timely payments fosters long-term partnerships critical for sustained supply chain stability across diverse international markets.

Strategic Sourcing Conclusion and Outlook for dimmable strip led

Dimmable LED strip lights represent a pivotal advancement in energy-efficient, customizable lighting solutions tailored for diverse commercial and industrial applications. For international B2B buyers—especially those operating within Africa, South America, the Middle East, and Europe—strategic sourcing is essential to unlock cost efficiencies, ensure product quality, and access the latest innovations such as enhanced dimming controls and smart integration capabilities.

Key considerations include partnering with reliable suppliers who offer comprehensive warranties, customization options, and compliance with regional standards. Bulk purchasing not only reduces unit costs but also guarantees consistency across large-scale projects, enabling seamless installation and maintenance. Moreover, leveraging supplier expertise to align product specifications with unique project requirements can significantly enhance operational outcomes.

Looking ahead, the dimmable LED strip market is poised for continued growth driven by rising demand for sustainable and adaptive lighting solutions. Buyers who proactively engage with forward-thinking manufacturers and stay informed on emerging technologies will secure competitive advantages in their respective markets. To capitalize on these opportunities, B2B buyers are encouraged to conduct thorough supplier evaluations, request product samples, and prioritize partnerships that emphasize innovation, reliability, and scalability.

Embracing strategic sourcing today will empower your business to deliver superior lighting solutions tomorrow—illuminating pathways to efficiency, flexibility, and long-term success.