Introduction: Navigating the Global Market for cuttable led strip lights

Cuttable LED strip lights represent a transformative solution in the global lighting market, enabling unparalleled customization and efficiency for diverse commercial and industrial applications. For international B2B buyers—particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuances of these flexible lighting systems is essential to meet specific project demands and optimize operational costs.

These versatile lighting strips allow precise length adjustments, facilitating tailored installations in sectors ranging from retail and hospitality to architectural and infrastructure projects. Their adaptability supports complex configurations, multi-zone controls, and energy-efficient designs, making them indispensable for modern lighting solutions worldwide.

This comprehensive guide delves into every critical aspect of cuttable LED strip lights, including:

- Types and technologies: From standard SMD to premium COB and addressable digital strips, understanding their cutting intervals and performance characteristics.

- Material quality and manufacturing standards: Ensuring durability and consistent light output through rigorous quality control.

- Supplier evaluation: How to identify reliable manufacturers and distributors who can deliver compliant and cost-effective products.

- Cost considerations: Balancing upfront investment with lifecycle value in different regional markets.

- Market trends and regional insights: Tailoring procurement strategies to meet local regulations and buyer preferences.

- Frequently asked questions: Addressing common challenges and technical concerns in cutting and installation.

Equipped with this knowledge, B2B buyers from emerging and established markets will be empowered to make informed sourcing decisions that minimize waste, enhance project outcomes, and secure competitive advantages in their respective industries.

Understanding cuttable led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMD LED Strips | Surface Mounted Device LEDs; common sizes: 3528, 5050, 2835; cuttable at marked intervals (5-10 cm) | General commercial lighting, retail displays, office spaces | Pros: Cost-effective, versatile, easy to cut and install. Cons: Visible LED dots may affect aesthetics in high-end settings. |

| COB LED Strips | Chip On Board LEDs providing uniform light without visible diodes; cuttable with specific intervals | High-end retail, architectural lighting, hospitality venues | Pros: Superior light quality and uniformity, sleek appearance. Cons: Higher cost, requires precise cutting and handling. |

| Addressable RGB LED Strips | Integrated control chips allow individual LED control; cutting limited to specific points (every 3-4 LEDs) | Dynamic lighting, event production, themed environments | Pros: High customization, dynamic effects. Cons: Complex installation, risk of damage if cut incorrectly. |

| Waterproof LED Strips | Coated or encased for water resistance (IP65-IP68); require resealing after cutting | Outdoor installations, wet environments, industrial settings | Pros: Durable, weatherproof. Cons: Additional sealing steps post-cutting, higher price. |

| High-Voltage LED Strips | Operate directly on mains voltage (110V/220V); special connectors needed after cutting | Large-scale architectural projects, outdoor signage | Pros: Longer runs without voltage drop, fewer power supplies. Cons: Safety risks, complex installation, requires trained personnel. |

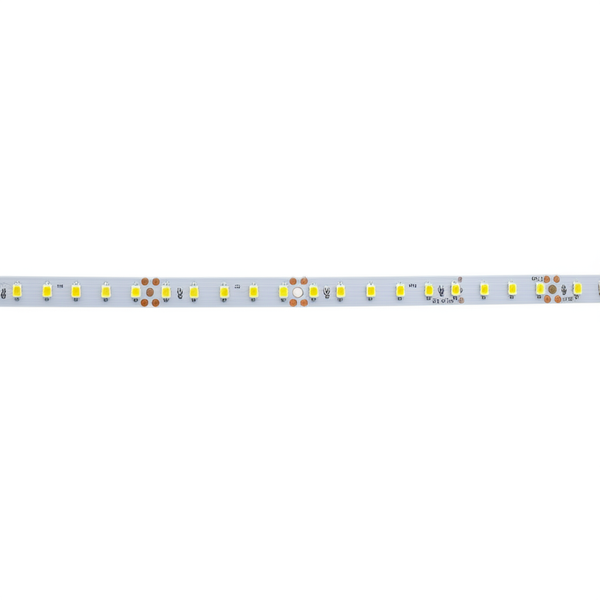

SMD LED Strips

SMD LED strips are the most widely used type in commercial projects due to their affordability and flexibility. They come in various LED densities and sizes, allowing buyers to select based on brightness and cutting precision needed. Their marked cutting points simplify customization for projects requiring exact lengths, ideal for retail shelving, offices, and hospitality interiors. B2B buyers should consider LED density and power requirements to optimize energy efficiency and lighting quality for their specific application.

COB LED Strips

COB LED strips offer a premium lighting solution with a smooth, continuous light output, eliminating the visible LED dots typical of SMD strips. This makes them highly suitable for upscale retail, galleries, and architectural lighting where aesthetics are critical. While more expensive, their enhanced light uniformity supports projects demanding visual elegance. Buyers should factor in the higher cost and ensure precise cutting and installation to maintain performance and warranty.

Addressable RGB LED Strips

These strips incorporate integrated chips allowing individual LED control, enabling complex color patterns and animations. They are perfect for entertainment venues, themed retail environments, and event productions where dynamic lighting effects are essential. However, cutting these strips requires strict adherence to designated points to avoid damaging the control circuits. B2B purchasers must ensure technical expertise in installation or partner with specialized contractors to leverage these advanced capabilities.

Waterproof LED Strips

Designed for environments exposed to moisture, waterproof LED strips come with protective coatings or encasements rated IP65 to IP68. They are essential for outdoor signage, industrial facilities, and wet locations. Cutting these strips demands careful resealing with end caps or waterproof connectors to preserve ingress protection. Buyers should plan for additional installation steps and potential maintenance to sustain waterproof integrity, balancing durability with project complexity.

High-Voltage LED Strips

Operating directly on mains voltage, these strips allow for longer continuous runs without voltage drops, reducing the number of power supplies needed. This makes them cost-effective for large-scale architectural lighting and extensive outdoor installations. However, they pose higher safety risks and require specialized connectors and trained installers to handle cutting and wiring safely. B2B buyers must prioritize compliance with local electrical standards and invest in qualified installation teams.

Related Video: NEW Govee M1 with Govee Immersion Kit Review | The BEST cuttable LED STRIP LIGHT with RBGIC!

Key Industrial Applications of cuttable led strip lights

| Industry/Sector | Specific Application of cuttable led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Customized shelf and display case lighting | Enhances product visibility and customer engagement | Flexible cutting intervals, high CRI for color accuracy, IP rating for durability |

| Hospitality & Tourism | Ambient and accent lighting in hotels, restaurants, and bars | Creates mood and atmosphere, improves guest experience | Dimmable options, waterproofing for humid environments, ease of installation |

| Architectural & Interior Design | Cove lighting, wall accents, and ceiling features | Enables tailored lighting designs, energy-efficient illumination | Compatibility with control systems, cut precision, color temperature options |

| Automotive & Transportation | Interior vehicle lighting, dashboard and footwell illumination | Improves aesthetics and safety, customizable length for tight spaces | Low voltage options, vibration resistance, heat dissipation features |

| Manufacturing & Warehousing | Task lighting in workstations and safety lighting in aisles | Increases productivity and safety, adaptable to changing layouts | Robust build quality, ease of maintenance, scalability for large areas |

Cuttable LED strip lights serve as a versatile lighting solution across various industries, enabling businesses to tailor lighting precisely to their spatial and functional needs.

In the retail and commercial sector, these strips are widely used for illuminating shelves and display cases. Their cuttable nature allows lighting to be adapted to various product sizes and shelving configurations, enhancing product visibility and customer engagement. For buyers in regions like South America or the Middle East, selecting strips with high color rendering index (CRI) and appropriate IP ratings ensures durability in diverse climates and accurate product presentation.

Within hospitality and tourism, cuttable LED strips provide customizable ambient lighting in hotels, restaurants, and bars. Their flexibility supports creating unique atmospheres that elevate guest experiences. Buyers in humid or coastal areas, such as parts of Africa or Southeast Asia, should prioritize waterproof and dimmable models to ensure longevity and versatility under varying conditions.

Architectural and interior design applications benefit from cuttable LED strips for cove lighting and accent walls. The ability to cut strips to exact lengths facilitates seamless integration into intricate designs while maintaining energy efficiency. European buyers often demand compatibility with advanced control systems for smart building integrations, requiring attention to product specifications and cutting intervals.

In the automotive and transportation industry, cuttable LED strips are used for interior vehicle lighting, including dashboards and footwells. Their customizable length and low voltage operation make them ideal for tight, vibration-prone environments. International buyers should seek products with robust heat dissipation and vibration resistance to meet safety and durability standards.

Finally, in manufacturing and warehousing, cuttable LED strips provide focused task lighting and safety illumination along aisles. Their adaptability allows businesses to reconfigure lighting layouts as operational needs evolve. Buyers should focus on durable, easy-to-maintain products that can be scaled efficiently for large industrial spaces, especially in regions with variable power conditions.

Understanding these industry-specific applications and sourcing considerations empowers international B2B buyers to select cuttable LED strip lights that maximize operational efficiency, aesthetic appeal, and long-term value.

Related Video: Free Cut Neon LED Strip Lights | Super Lighting LED

Strategic Material Selection Guide for cuttable led strip lights

Flexible PCB Substrate (Polyimide and PET)

Flexible printed circuit boards (FPCBs) made from polyimide or polyethylene terephthalate (PET) are the core materials used in most cuttable LED strip lights. Polyimide offers excellent thermal stability, withstanding temperatures up to 260°C, and good chemical resistance, making it suitable for demanding environments. PET is more cost-effective but has a lower temperature tolerance (around 120°C) and less chemical resistance.

Pros: Polyimide substrates provide high durability, flexibility, and excellent electrical insulation, supporting long LED strip lifespans. PET substrates reduce manufacturing costs and are easier to process. Both materials enable precise cutting at designated intervals without damaging circuits.

Cons: Polyimide is more expensive and may increase product cost, while PET’s lower heat resistance limits use in high-temperature applications. Both require careful handling during cutting to avoid damaging conductive traces.

Application Impact: Polyimide-based strips are preferred for industrial, architectural, and outdoor lighting projects requiring heat resistance and durability. PET is common in residential and decorative lighting where cost sensitivity is higher.

International Buyer Considerations: Buyers in regions like Europe and the Middle East often prioritize compliance with international standards such as IPC-2223 for flexible circuits and RoHS directives for hazardous substances. African and South American buyers may focus on cost-efficiency and local environmental regulations, balancing performance with price. Understanding local standards like DIN (Germany) or ASTM (USA) helps ensure material compatibility and certification acceptance.

Silicone Encapsulation and Coating

Silicone is widely used as a protective encapsulant or coating for cuttable LED strips, especially waterproof versions (IP65-IP68). It offers excellent flexibility, UV resistance, and temperature tolerance (-60°C to 200°C), protecting the LEDs and circuitry from moisture, dust, and mechanical damage.

Pros: Silicone coatings enhance durability, enable outdoor and harsh environment applications, and maintain flexibility for bending and cutting. They also provide superior electrical insulation and chemical resistance.

Cons: Silicone encapsulation increases manufacturing complexity and cost. It can complicate cutting and resealing processes, requiring specialized tools and end caps to maintain waterproof ratings after cutting.

Application Impact: Ideal for outdoor signage, marine, and industrial lighting projects in humid or corrosive environments. Silicone-coated strips are essential for buyers targeting markets with heavy rainfall or high humidity, such as parts of South America and Southeast Asia.

International Buyer Considerations: Compliance with IP ratings and IEC standards is critical for international procurement. Buyers in Europe and the Middle East often require certified waterproof ratings and fire safety compliance (e.g., UL 94 V-0). For African markets, silicone-coated strips offer resilience against dust and heat but may require cost negotiation due to higher price points.

Copper Conductive Traces

Copper is the primary conductive material in cuttable LED strips, forming the electrical pathways. Its high electrical conductivity ensures efficient power delivery and minimal voltage drop along the strip length.

Pros: Copper’s excellent conductivity supports longer runs and higher LED densities. It is widely available and compatible with standard manufacturing processes, facilitating repair and customization.

Cons: Copper is prone to oxidation and corrosion if not properly protected, which can degrade performance over time. It also adds weight and cost compared to alternative conductive materials.

Application Impact: Copper traces are essential for commercial and industrial installations requiring reliable, high-performance lighting. For outdoor or humid environments, copper traces must be paired with protective coatings or encapsulations.

International Buyer Considerations: Buyers from Europe and the Middle East often require copper purity and plating to meet IEC or ASTM standards to ensure longevity and safety. African and South American buyers should verify supplier quality certifications to avoid substandard copper that could increase maintenance costs.

Adhesive Backing Materials (Acrylic vs. Silicone Adhesives)

The adhesive layer on the back of LED strips enables easy installation on various surfaces. Acrylic and silicone adhesives are the most common choices, each with distinct properties.

Pros: Acrylic adhesives offer strong initial tack and good temperature resistance (up to 80°C), suitable for indoor applications. Silicone adhesives provide superior heat resistance (up to 200°C) and flexibility, ideal for industrial or outdoor use.

Cons: Acrylic adhesives may fail in high-temperature or humid environments, leading to detachment. Silicone adhesives are more expensive and may have lower initial tack, requiring careful surface preparation.

Application Impact: Acrylic adhesives are cost-effective for retail, hospitality, and residential projects. Silicone adhesives suit automotive, aerospace, and outdoor architectural lighting where environmental exposure is severe.

International Buyer Considerations: Buyers in Europe and the Middle East often demand adhesives compliant with REACH and RoHS regulations. African and South American buyers should consider climate conditions; for example, high humidity and heat in Brazil necessitate silicone adhesives to ensure installation longevity.

Summary Table

| Material | Typical Use Case for cuttable led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible PCB Substrate (Polyimide/PET) | Core LED strip base for flexible, cuttable lighting solutions | High flexibility and thermal stability (Polyimide) | PET lower heat resistance; Polyimide higher cost | Medium |

| Silicone Encapsulation/Coating | Waterproof and outdoor LED strips requiring environmental protection | Excellent moisture and UV resistance | Increased manufacturing complexity and cost | High |

| Copper Conductive Traces | Electrical pathways in all LED strips requiring efficient power delivery | Superior electrical conductivity | Susceptible to corrosion without protection | Medium |

| Adhesive Backing (Acrylic/Silicone) | Mounting LED strips on various surfaces, indoor and outdoor applications | Acrylic: strong tack and cost-effective; Silicone: high heat resistance | Acrylic: poor in heat/humidity; Silicone: higher cost | Low (Acrylic) / High (Silicone) |

This material selection guide equips international B2B buyers with critical insights for sourcing cuttable LED strip lights tailored to diverse project requirements and regional standards. Prioritizing material properties aligned with application environments and compliance needs ensures optimal performance, durability, and cost-efficiency in global markets.

In-depth Look: Manufacturing Processes and Quality Assurance for cuttable led strip lights

Manufacturing Processes for Cuttable LED Strip Lights

The production of cuttable LED strip lights involves a series of meticulously controlled stages to ensure flexibility, durability, and consistent lighting quality. Understanding these processes enables B2B buyers to better evaluate supplier capabilities and product reliability.

1. Material Preparation

Manufacturing begins with sourcing high-quality base materials. Flexible Printed Circuit Boards (FPCBs) serve as the substrate, typically made from polyimide or PET, chosen for flexibility and heat resistance. Copper foil is laminated onto the substrate to create conductive pathways. The quality of raw materials affects longevity and electrical performance, so suppliers often source from certified vendors.

2. Circuit Forming and Component Placement

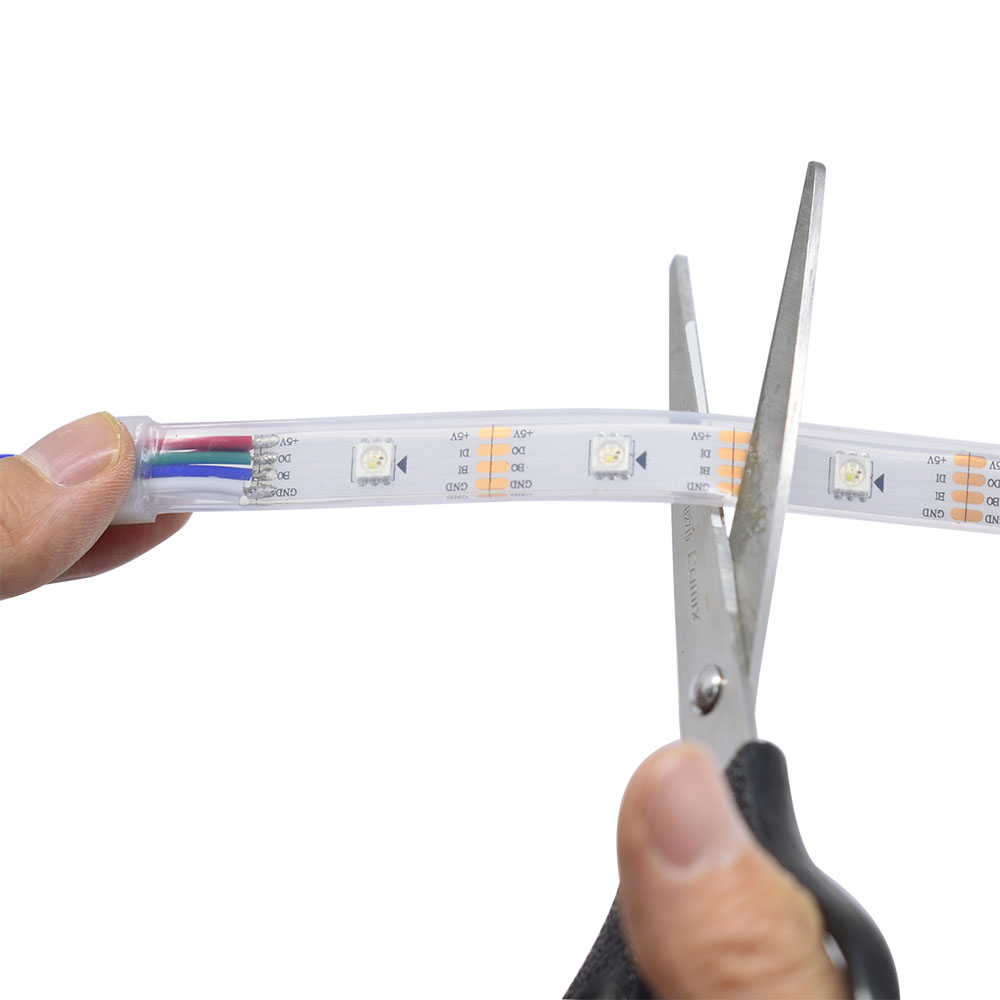

Using automated Surface Mount Technology (SMT), LEDs and resistors are precisely placed onto the FPCB. The LED types (e.g., SMD 3528, 5050, or COB LEDs) determine the strip’s brightness and color quality. Cutting intervals are predefined during circuit layout, marked by copper pads or scissors symbols, facilitating safe and clean cutting without damaging circuits.

3. Soldering and Connection

After component placement, soldering is performed using reflow ovens, ensuring secure electrical connections. For strips with connectors or integrated chips (e.g., addressable RGB strips), additional assembly steps include embedding control ICs and testing signal integrity.

4. Protective Coating and Finishing

Depending on the product specification, strips are coated with protective layers to enhance durability and water resistance. Options include:

- Silicone or epoxy coatings for IP65 protection.

- Encapsulation in waterproof tubes for IP67/IP68 ratings.

- Application of adhesive backing for easy installation.

Finishing also involves printing product codes and cutting guides on the strip, critical for installation and traceability.

Quality Assurance and Control (QA/QC) in LED Strip Manufacturing

Robust QA/QC frameworks ensure that cuttable LED strip lights meet international standards and perform reliably in diverse environments. B2B buyers should focus on suppliers adhering to recognized certifications and comprehensive testing protocols.

Relevant International Standards and Certifications

- ISO 9001: A fundamental quality management system standard ensuring consistent manufacturing and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, crucial for environmental safety and market acceptance.

- UL Certification: Important for electrical safety, especially in North American and some Middle Eastern markets.

- IP Ratings (IP65, IP67, IP68): Define water and dust resistance levels, essential for outdoor or industrial applications.

- Other regional certifications: For example, INMETRO for Brazil, SASO for Saudi Arabia, and SIRIM for Malaysia/Thailand.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials such as FPCBs, LEDs, and solder pastes to verify compliance with specifications before production.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including placement accuracy, solder joint quality, and correct application of coatings.

- Final Quality Control (FQC): Comprehensive testing of finished products, including visual inspection, electrical testing, and packaging verification.

Common Testing Methods

- Visual and Microscopic Inspection: Detects soldering defects, LED misalignment, or substrate damage.

- Electrical Testing: Verifies circuit continuity, LED functionality, and correct voltage/current characteristics.

- Light Output Measurement: Assesses brightness uniformity, color temperature, and color rendering index (CRI).

- Environmental Stress Testing: Includes thermal cycling, humidity exposure, and waterproof testing to simulate real-world conditions.

- Cutting Reliability Tests: Ensures that cutting at marked intervals does not impair electrical performance or waterproofing.

How B2B Buyers Can Verify Supplier Quality Assurance

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying supplier QC is crucial to mitigate risks and ensure product reliability.

1. Factory Audits and Certifications Review

Request documentation of ISO 9001 and relevant product certifications. Conduct on-site or virtual factory audits to observe manufacturing processes and QC practices firsthand. Audits should confirm adherence to process controls, worker training, and equipment maintenance.

2. Quality Control Reports and Sample Testing

Demand detailed QC reports covering IQC, IPQC, and FQC results. Independent third-party laboratory testing of samples can verify claims regarding brightness, IP ratings, and safety standards. For large orders, consider batch testing post-delivery to ensure consistency.

3. Third-Party Inspection Services

Engage trusted third-party inspection firms specializing in electronics and lighting. These inspectors perform random sampling inspections, functional testing, and compliance verification at the supplier’s premises or upon shipment.

QC and Certification Nuances for International Buyers by Region

-

Africa: Many African markets emphasize CE, RoHS, and IEC safety standards. Import regulations may require local conformity certificates or approvals from bodies like ARSO (African Organisation for Standardisation). Buyers should verify if suppliers provide documentation recognized by regional authorities.

-

South America (e.g., Brazil): Compliance with INMETRO certification is often mandatory for electrical products. Buyers should ensure suppliers understand local certification requirements and can provide INMETRO-approved products or assist with local testing.

-

Middle East: Countries such as Saudi Arabia and UAE require SASO certification and adherence to Gulf Standards (GSO). Due to high temperatures and dust, buyers should prioritize suppliers that conduct rigorous environmental testing and provide IP68-rated products for outdoor use.

-

Europe: The EU market demands strict compliance with CE, RoHS, and WEEE directives. Buyers should expect detailed technical files and Declaration of Conformity (DoC) documents. High emphasis is placed on sustainability and recyclability, influencing supplier selection.

-

Southeast Asia (e.g., Thailand): While not the main target, buyers sourcing from or operating in this region should consider SIRIM certification and local electrical safety standards. The tropical climate necessitates robust waterproofing and heat resistance.

Summary for B2B Buyers

- Evaluate suppliers based on transparent manufacturing processes that include precise SMT assembly, reliable soldering, and durable protective coatings.

- Prioritize suppliers with internationally recognized certifications and strong QA/QC systems incorporating IQC, IPQC, and FQC checkpoints.

- Leverage third-party inspections and sample testing to confirm product quality and compliance, reducing the risk of costly project failures.

- Understand regional certification nuances to ensure smooth importation and market acceptance in Africa, South America, the Middle East, and Europe.

- Request detailed documentation and technical support to facilitate installation and after-sales service, especially for complex cuttable LED strip configurations.

By focusing on these manufacturing and quality assurance aspects, international B2B buyers can secure high-quality cuttable LED strip lights that meet project specifications, regulatory requirements, and long-term performance expectations.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for cuttable led strip lights Sourcing

When sourcing cuttable LED strip lights for international B2B projects, understanding the full cost structure and pricing dynamics is essential for informed procurement decisions. This section breaks down the key cost components, factors influencing price, and practical tips tailored for buyers from Africa, South America, the Middle East, and Europe.

Key Cost Components in Cuttable LED Strip Lights

-

Materials: The primary cost driver includes the quality and type of LEDs (e.g., SMD 3528, 5050, COB), flexible PCB substrates, resistors, connectors, and waterproofing materials. Premium components, such as high CRI LEDs or waterproof coatings (IP65-IP68), raise material costs but enhance durability and performance.

-

Labor: Skilled labor is required for assembly, soldering, and quality control processes. Labor costs vary significantly depending on the manufacturing country, impacting the final product price. Factories in Asia typically offer lower labor costs compared to European or Middle Eastern manufacturers.

-

Manufacturing Overhead: Includes factory utilities, equipment depreciation, and administrative expenses. Efficient factories with automated assembly lines can reduce overhead per unit.

-

Tooling and Setup: Initial tooling for custom lengths, cutting intervals, and connector integration can add upfront costs. Custom tooling amortized over large volumes reduces per-unit cost.

-

Quality Control (QC): Rigorous QC testing (electrical, waterproofing, longevity) adds cost but ensures reliability, which is critical for professional installations and warranty compliance.

-

Logistics and Shipping: International freight, customs duties, and inland transportation contribute substantially, especially for buyers in Africa and South America where port handling and inland delivery can increase costs.

-

Margin: Supplier markups vary by region and supplier type (wholesaler, direct manufacturer, distributor). Direct sourcing from manufacturers often yields better pricing than through intermediaries.

Factors Influencing Pricing

-

Order Volume / Minimum Order Quantity (MOQ): Larger orders typically unlock volume discounts. However, some suppliers impose high MOQs which may not suit smaller buyers or pilot projects. Negotiating flexible MOQs can improve cost efficiency.

-

Product Specifications and Customization: Customized cutting intervals, LED density (e.g., 30, 60, or 120 LEDs/meter), color temperature, waterproofing level, and added features (e.g., addressable LEDs) increase complexity and cost.

-

Material Quality and Certifications: Compliance with CE, RoHS, UL, or regional certifications affects both price and market acceptance. Certified products command higher prices but reduce risks related to import restrictions and safety liabilities.

-

Supplier Location and Reliability: Proximity to manufacturing hubs (China, Taiwan, South Korea) often means lower base prices but consider supplier reputation, lead times, and after-sales support. European or Middle Eastern suppliers may offer higher prices but better local support and warranty services.

-

Incoterms and Payment Terms: The choice of Incoterms (FOB, CIF, DDP) impacts who bears shipping and customs costs, affecting the landed cost. Favor terms that align with your import capabilities and risk appetite.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Total Cost of Ownership (TCO), Not Just Unit Price: Include shipping, customs, installation, and warranty support in cost calculations. Cheaper upfront prices can lead to higher hidden costs if product quality or supplier reliability is poor.

-

Leverage Volume Consolidation: Buyers from regions like Africa or South America can collaborate or consolidate orders to meet MOQs and secure better pricing.

-

Request Samples and Certifications Early: Testing samples before bulk purchase reduces the risk of costly returns or project delays. Verify product certifications to ensure compliance with local regulations.

-

Understand Regional Import Duties and VAT: Factor these into your pricing model to avoid unexpected expenses, particularly in Brazil and Middle Eastern countries with complex import rules.

-

Consider Local Assembly or Final Cutting: Some buyers reduce costs by importing bulk reels and performing cutting or assembly locally, benefiting from lower labor costs and avoiding excessive shipping fees on finished lengths.

-

Build Long-Term Supplier Relationships: Establishing trust with reliable manufacturers or distributors enables better negotiation leverage, customized service, and priority production slots during high demand.

Indicative Pricing Disclaimer

Prices for cuttable LED strip lights vary widely depending on specifications, volume, and sourcing region. Indicative price ranges (per meter) can start as low as $1.50 for basic non-waterproof strips to $10 or more for high-density, waterproof, and certified options. Always obtain multiple quotations and perform total cost analysis tailored to your project needs.

By carefully evaluating these cost and pricing factors, international B2B buyers can optimize procurement strategies, ensuring competitive pricing without compromising quality or project requirements. This approach is especially crucial for buyers in emerging markets and regions with logistical challenges, where cost efficiency and supplier reliability directly impact business success.

Spotlight on Potential cuttable led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cuttable led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cuttable led strip lights

Critical Technical Properties of Cuttable LED Strip Lights

-

Cutting Interval

This refers to the precise points along the LED strip where it can be safely cut without damaging the circuit. Common intervals range from 2.5 cm to 10 cm depending on LED density and strip design. For B2B buyers, understanding cutting intervals is essential to ensure custom length requirements are met accurately while maintaining electrical integrity and warranty compliance. -

LED Density (LEDs per Meter)

LED density indicates how many LEDs are mounted per meter of the strip (e.g., 30, 60, 120 LEDs/m). Higher density yields brighter, more uniform light but may increase power consumption and cost. Buyers should match LED density with project needs—higher density for premium displays or architectural lighting, lower density for ambient or decorative applications. -

Material Grade and Flexibility

Quality of the flexible PCB substrate and protective coatings (e.g., silicone or epoxy) impacts durability and ease of installation. High-grade materials resist heat, moisture, and mechanical stress, which is vital for installations in humid or outdoor environments common in Africa, South America, and the Middle East. Flexibility also determines the strip’s ability to conform to curves and corners, important for customized applications. -

Power Supply Voltage and Current Requirements

Most cuttable LED strips operate on low-voltage DC (typically 12V or 24V), but some high-voltage variants run directly on mains power (110V/220V). Understanding voltage and current specs is crucial for selecting compatible power supplies and ensuring safety, especially in regions with varying electrical standards.

-

Ingress Protection (IP) Rating

The IP rating classifies the strip’s resistance to dust and water. For example, IP20 indicates indoor use with no water protection, IP65 offers water resistance with silicone coating, and IP67/IP68 provides full waterproofing with sealed tubes. International buyers must consider IP ratings carefully to match environmental conditions and regulatory requirements. -

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvins) ranges from warm white (~2700K) to cool white (~6500K), affecting ambiance and visual comfort. CRI indicates how accurately the light reveals colors compared to natural light. For retail or hospitality projects, higher CRI values (80+) ensure product colors appear true and appealing.

Common Industry and Trade Terms for LED Strip Lighting

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing LED strips that other brands re-label and sell. OEM partnerships allow buyers to customize product specifications, packaging, and branding—key for businesses aiming to differentiate their offerings in competitive markets. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell per order. Understanding MOQ helps buyers plan inventory, manage cash flow, and negotiate better pricing, especially important for small to medium enterprises in emerging markets. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for price, lead time, and terms based on specified product requirements. Mastering RFQ preparation ensures buyers receive competitive, accurate bids and facilitates transparent supplier comparisons. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyer and seller (e.g., FOB, CIF, DDP). Knowledge of Incoterms is critical for managing logistics, cost allocation, and risk in cross-border transactions. -

Cutting Tolerance

The permissible deviation in cutting length or position without compromising strip functionality. Suppliers may specify cutting tolerance to ensure consistent electrical performance and ease of installation, a key quality metric for professional projects. -

SMD (Surface Mounted Device)

Refers to the type of LED chips mounted directly on the strip’s surface. Common SMD sizes include 3528, 5050, and 2835, each with different brightness and power characteristics. Familiarity with SMD types helps buyers select strips aligned with their application and budget.

Understanding these technical properties and trade terms empowers international B2B buyers to make informed decisions, negotiate effectively, and ensure the right LED strip lighting solutions for diverse applications across Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cuttable led strip lights Sector

Market Overview & Key Trends

The global market for cuttable LED strip lights is experiencing robust growth driven by increasing demand for flexible, energy-efficient lighting solutions across commercial, industrial, and architectural sectors. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, this sector presents significant opportunities due to rising urbanization, infrastructure development, and a shift toward smart building technologies.

Key market drivers include the need for customizable lighting that can be precisely tailored to diverse applications—from retail displays in Brazil to hospitality projects in the Middle East and smart home installations in Europe. Cuttable LED strips enable buyers to optimize installation spaces with minimal waste, offering cost efficiency and design flexibility. Emerging trends highlight the integration of addressable RGB and COB LED technologies that provide enhanced lighting effects and uniform illumination, appealing to high-end commercial projects.

Sourcing strategies are evolving as buyers seek suppliers capable of delivering high-quality products with consistent cutting precision and reliable connectors. The rise of waterproof and IP-rated LED strips addresses demand in humid and outdoor environments prevalent in tropical regions like Thailand and coastal African markets. Additionally, B2B buyers increasingly prioritize suppliers offering customizable lengths, varied LED densities, and compatibility with smart control systems to future-proof their lighting infrastructure.

Market dynamics emphasize the importance of supplier agility, with manufacturers in Asia dominating production but facing growing competition from emerging regional suppliers in Europe and the Middle East. Buyers benefit from leveraging digital procurement platforms and forging strategic partnerships to ensure supply chain resilience amid fluctuating raw material prices and logistics challenges.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor for B2B buyers in the cuttable LED strip lights sector. The environmental impact of LED manufacturing, including energy consumption, raw material sourcing, and waste generation, necessitates stringent evaluation. Buyers from Europe and South America, in particular, face increasing regulatory pressure to source eco-friendly lighting products that align with corporate social responsibility (CSR) objectives.

Ethical sourcing involves ensuring transparency across the supply chain, avoiding conflict minerals, and partnering with manufacturers committed to fair labor practices. Certifications such as RoHS (Restriction of Hazardous Substances), REACH compliance, and Energy Star ratings are essential indicators of a supplier’s environmental stewardship and product safety standards. Additionally, eco-conscious buyers seek LED strips manufactured with recyclable materials, low-volatility organic compounds (VOCs), and lead-free solder.

Waterproof and flexible LED strips with durable silicone coatings not only extend product lifespan but also reduce waste from frequent replacements, aligning with sustainability goals. Buyers should also consider suppliers that offer take-back or recycling programs and demonstrate carbon footprint reduction initiatives.

By prioritizing green certifications and ethical supply chains, B2B buyers in emerging markets like Africa and the Middle East can enhance brand reputation, meet evolving customer expectations, and capitalize on incentives tied to sustainable procurement.

Illustrative Image (Source: Google Search)

Brief Evolution and Industry Context

The cuttable LED strip light market has evolved significantly over the past decade, transitioning from simple single-color strips to sophisticated, digitally addressable lighting systems. Early LED strips were limited in cutting flexibility and light uniformity, restricting their application scope. Advances in Surface Mounted Device (SMD) and Chip on Board (COB) technologies have improved cutting intervals, brightness, and color rendering, making these products viable for large-scale commercial projects.

The ability to cut LED strips precisely at designated intervals emerged as a game-changer, enabling tailored installations that reduce waste and simplify logistics. As demand for integrated smart lighting solutions grows, the sector continues to innovate with enhanced waterproofing, higher LED densities, and compatibility with IoT controls.

For international B2B buyers, understanding this evolution is crucial to selecting products that align with modern project specifications and sustainability requirements, ensuring competitive advantages in diverse regional markets.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of cuttable led strip lights

-

How can I effectively vet suppliers of cuttable LED strip lights for international B2B purchases?

Begin by verifying the supplier’s certifications such as ISO 9001 for quality management and CE or RoHS compliance for product safety and environmental standards. Request detailed product datasheets and samples to assess quality firsthand. Check references or reviews from other international buyers, especially from regions similar to yours. Evaluate their production capacity, export experience, and after-sales support responsiveness. For buyers in Africa, South America, the Middle East, and Europe, ensure the supplier understands regional electrical standards and customs regulations to avoid compliance issues. -

What customization options are typically available for cuttable LED strip lights in B2B orders?

Suppliers often provide customization in strip length, LED density, color temperature, waterproof ratings (IP65, IP67, IP68), adhesive backing types, and connector options. Some manufacturers also offer custom PCB widths or flexible substrates to fit unique installation requirements. For international buyers, it’s crucial to communicate your project’s precise technical needs and environmental conditions upfront. Custom firmware or addressable LED options may be available for advanced lighting control. Confirm minimum order quantities (MOQs) and lead times for custom specifications as these can vary widely. -

What are typical MOQ and lead times for cuttable LED strip light orders from overseas suppliers?

MOQs can range from a few hundred meters to several thousand depending on customization and supplier scale. Standard products usually have lower MOQs, while customized strips require higher minimums due to tooling and material costs. Lead times typically range from 2 to 6 weeks, influenced by order complexity, production schedules, and shipping logistics. For buyers in regions like Africa or South America, factor in additional time for customs clearance and inland transportation. Early communication with suppliers about order forecasts can help secure priority production slots. -

Which payment terms and methods are common and secure for international B2B transactions of LED strip lights?

Common payment terms include 30% upfront deposit with balance paid before shipment or upon delivery. Letters of Credit (LC) provide added security but involve higher administrative costs. Wire transfers (T/T) are widely accepted but require trusted suppliers. Platforms like Alibaba offer trade assurance for smaller buyers. For buyers in emerging markets, negotiating payment via escrow services or partial payments upon inspection can mitigate risk. Always confirm supplier banking details independently to avoid fraud and request proforma invoices for clear transaction records. -

What quality assurance measures should I insist on when sourcing cuttable LED strips internationally?

Require suppliers to provide batch-specific test reports including lumen output, color consistency, voltage tolerance, and waterproof integrity if applicable. Certifications like UL, CE, RoHS, and LM80 for LED lifespan are essential to ensure compliance with international standards. Request sample testing or third-party lab verification before large orders. Implementing on-site inspections or using inspection agencies at the factory can preempt defects. For large-scale projects in Europe or the Middle East, compliance with local electrical safety directives is mandatory and should be documented.

Illustrative Image (Source: Google Search)

-

How do I navigate logistics and customs challenges when importing cuttable LED strip lights from Asia or other manufacturing hubs?

Choose suppliers experienced with exporting to your region to ensure proper documentation (commercial invoices, packing lists, certificates of origin). Opt for Incoterms like FOB or CIF depending on your logistics control preference. For Africa and South America, be aware of import tariffs, VAT, and potential delays due to customs inspections. Partnering with a reliable freight forwarder familiar with local regulations can streamline clearance. Consolidate shipments when possible to reduce costs, and verify packaging is robust to prevent damage during transit. -

What steps should I take if I encounter product quality disputes with overseas LED strip suppliers?

First, document all discrepancies with photos, videos, and test results. Review your contract and quality agreements to confirm compliance terms. Communicate promptly and professionally with the supplier, providing evidence and requesting corrective action such as replacement or refund. If the supplier is unresponsive, escalate through trade dispute resolution platforms or your payment provider’s dispute mechanisms. For recurring issues, consider third-party mediation or legal advice. Building strong relationships and clear contracts upfront reduces the likelihood of disputes. -

Are there regional considerations for electrical standards and installation practices I should be aware of when buying cuttable LED strips internationally?

Yes, electrical voltage and frequency vary by region (e.g., 110V/60Hz in the Americas vs. 220-240V/50Hz in Europe and parts of Africa). Ensure the LED strips and power supplies are compatible with your local grid to avoid performance issues or hazards. Waterproof ratings and adhesive types should suit your climate—higher IP ratings may be necessary in humid or outdoor environments common in the Middle East or South America. Additionally, local regulations may mandate specific certifications or safety marks, so confirm compliance before purchase to facilitate smooth installation and inspection.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cuttable led strip lights

Cuttable LED strip lights represent a versatile and essential component for modern lighting solutions across diverse industries. For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, understanding the nuances of cutting intervals, strip types (SMD, COB, addressable RGB), and waterproofing requirements is crucial to ensure precision, durability, and safety in installations. Strategic sourcing of these products not only optimizes cost-efficiency by reducing waste and inventory surplus but also enhances project customization capabilities, enabling tailored lighting solutions that meet complex client demands.

Key takeaways for B2B buyers include:

- Prioritize suppliers offering detailed technical specifications and cutting guidelines to minimize installation errors.

- Evaluate product certifications and warranties to ensure quality and compliance with regional standards.

- Consider logistical factors such as lead times, shipping reliability, and after-sales support for seamless project execution.

- Leverage cutting flexibility to maximize material utilization and adapt lighting designs dynamically.

Looking ahead, the demand for energy-efficient, customizable lighting continues to grow globally. Buyers who invest in strategic partnerships with innovative manufacturers and distributors will gain competitive advantages through enhanced product quality, supply chain resilience, and technological innovation. Now is the time to deepen market insights, explore emerging suppliers, and align procurement strategies with evolving lighting trends to capture new business opportunities worldwide.