Guide to Cuttable Led Strip Lighting

- Introduction: Navigating the Global Market for cuttable led strip lighting

- Understanding cuttable led strip lighting Types and Variations

- Key Industrial Applications of cuttable led strip lighting

- Strategic Material Selection Guide for cuttable led strip lighting

- In-depth Look: Manufacturing Processes and Quality Assurance for cuttable led strip lighting

- Comprehensive Cost and Pricing Analysis for cuttable led strip lighting Sourcing

- Spotlight on Potential cuttable led strip lighting Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for cuttable led strip lighting

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cuttable led strip lighting Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cuttable led strip lighting

- Strategic Sourcing Conclusion and Outlook for cuttable led strip lighting

Introduction: Navigating the Global Market for cuttable led strip lighting

Cuttable LED strip lighting has emerged as a pivotal solution in modern commercial and architectural lighting, offering unparalleled flexibility and customization for diverse projects worldwide. For B2B buyers across Africa, South America, the Middle East, and Europe—including markets like Egypt and the UK—understanding the nuances of cuttable LED strips is essential to unlocking tailored lighting solutions that fit exact spatial and design requirements. These strips enable businesses to optimize installations by creating precise lengths, accommodating complex layouts, and integrating multiple lighting zones, all while minimizing waste and controlling costs.

This guide delivers an authoritative and comprehensive exploration of cuttable LED strip lighting, designed specifically to empower international buyers in making informed sourcing decisions. It covers critical topics including the variety of LED strip types (SMD, COB, waterproof, addressable), essential materials and manufacturing quality controls, and the impact of supplier selection on product reliability. Additionally, it addresses cost considerations and market dynamics to help buyers evaluate value beyond price alone.

By navigating this resource, procurement managers, distributors, and project planners will gain actionable insights into the technical and commercial aspects of cuttable LED strips. This enables the design and execution of efficient, high-quality lighting solutions tailored to local market demands and regulatory environments. Ultimately, this guide equips B2B buyers with the knowledge to confidently source LED strip lighting that aligns with their project specifications, budget constraints, and sustainability goals—ensuring competitive advantage in a rapidly evolving global lighting marketplace.

Understanding cuttable led strip lighting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| SMD LED Strip Lights | Surface-mounted LEDs (e.g., 3528, 5050) with marked cut points | Retail, hospitality, office lighting | Versatile and cost-effective; cutting intervals vary by density; can require careful handling to avoid damage |

| COB LED Strip Lights | Chip-on-board LEDs providing uniform light without visible diodes | High-end retail, architectural, display lighting | Superior light quality and smoothness; generally higher cost; cutting intervals less frequent than SMD |

| Addressable RGB Strips | Individually controllable LEDs with integrated chips | Entertainment, signage, dynamic displays | Highly customizable; cutting only at specific points; complexity in wiring and control increases installation cost |

| Waterproof LED Strips | Encased in silicone or epoxy with IP65 to IP68 ratings | Outdoor, marine, industrial applications | Durable and weather-resistant; requires resealing after cutting; slightly higher upfront investment |

| High Voltage LED Strips | Operate directly on mains voltage (110V/220V) | Large-scale architectural, commercial lighting | Reduced power supplies needed; cutting and installation require expertise; safety risks if mishandled |

SMD LED Strip Lights

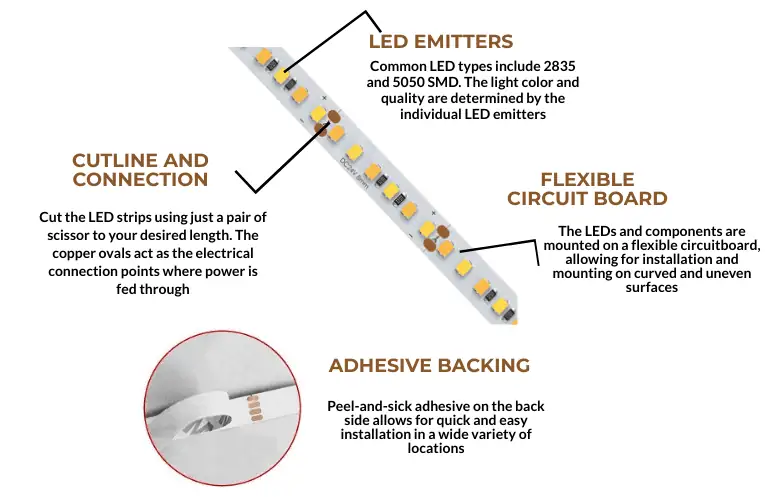

SMD (Surface Mounted Device) LED strips are the most common and widely used type of cuttable LED strip lighting. They feature individual LED chips mounted on a flexible circuit board, with cutting points clearly marked, typically every 5 to 10 cm depending on LED density. This type is highly versatile and suits a broad range of commercial applications such as retail displays, office ambient lighting, and hospitality venues. For B2B buyers, SMD strips offer a balance of affordability and flexibility. However, buyers should consider the density and cutting intervals to align with project specifications and minimize waste.

COB LED Strip Lights

COB (Chip on Board) LED strips provide a continuous, uniform light output with no visible individual LEDs, making them ideal for premium applications requiring high-quality illumination. These strips are cuttable but usually at longer intervals compared to SMD types, reflecting their denser LED packaging. COB strips are favored in high-end retail environments, architectural lighting, and display cases where visual appeal and light consistency are paramount. B2B buyers should weigh the higher upfront cost against the superior lighting effect and reduced need for diffusers or additional fixtures.

Addressable RGB LED Strips

Addressable RGB strips contain integrated chips that allow individual control of each LED’s color and brightness, enabling complex lighting effects and patterns. Cutting these strips is more restrictive, as it can only be done at specific points between control chips, typically every 3-4 LEDs. These are well-suited for entertainment venues, dynamic signage, and installations requiring programmable lighting sequences. For international B2B buyers, understanding the intricacies of installation and control systems is critical to avoid costly errors and ensure optimal performance.

Waterproof LED Strips

Waterproof LED strips are designed with protective coatings or housed in sealed tubes to achieve IP65 to IP68 ratings, making them suitable for outdoor, marine, and industrial environments. They maintain cuttable features but require careful resealing after cutting to preserve waterproof integrity. This type is essential for projects in harsh climates or where exposure to moisture is unavoidable. B2B buyers from regions with variable weather conditions (e.g., Middle East, South America) should prioritize waterproof options to ensure durability and reduce maintenance costs.

High Voltage LED Strips

High voltage LED strips operate directly from mains power (110V or 220V), reducing the need for bulky power supplies and enabling longer runs without voltage drop. Cutting these strips requires specialized knowledge and equipment due to safety concerns and the need for proper connectors post-cut. They are ideal for large-scale architectural or commercial lighting projects where efficiency and installation simplicity are valued. Buyers must ensure compliance with local electrical standards and invest in skilled installation to mitigate risks and maintain warranty coverage.

Related Video: How to cut, connect & power LED Strip Lighting

Key Industrial Applications of cuttable led strip lighting

| Industry/Sector | Specific Application of cuttable led strip lighting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Custom display lighting and shelf illumination | Enhances product visibility, attracts customers, and increases sales | Flexible lengths, high CRI for true color rendering, waterproof options for durability |

| Hospitality & Leisure | Ambient and accent lighting in hotels, restaurants, and bars | Creates inviting atmospheres, improves guest experience, and supports brand identity | Dimmable features, color tunability, ease of installation and maintenance |

| Architecture & Interior Design | Cove lighting, wall washes, and feature highlights | Enables creative lighting designs, energy savings, and seamless integration | Cut intervals matching design specs, consistent light output, quality certifications |

| Automotive & Transportation | Interior cabin lighting and custom vehicle lighting | Improves safety and comfort, allows bespoke lighting solutions | Heat resistance, vibration durability, compliance with automotive standards |

| Industrial & Manufacturing | Machine status indicators and workspace illumination | Increases operational safety, improves productivity, and reduces downtime | Robustness, IP rating for dust/water resistance, long lifespan LEDs |

Cuttable LED strip lighting offers versatile solutions across multiple industries by allowing precise customization of lighting length and configuration. In the retail and commercial sector, these LED strips are widely used for illuminating product displays and shelves. The ability to cut strips to exact lengths ensures perfect fitment within showcases and shelving units, enhancing product appeal and customer engagement. For international buyers in regions like South America and Europe, sourcing strips with high color rendering index (CRI) and waterproof ratings is critical to withstand varied environmental conditions and maintain visual quality.

In the hospitality and leisure industry, cuttable LED strips serve to create dynamic ambient and accent lighting in hotels, restaurants, and bars. The flexibility to tailor lighting lengths supports complex architectural features and themed interiors. Businesses in the Middle East and Africa often prioritize dimmable and color-tunable options to adapt atmospheres for different times of day or events, enhancing guest satisfaction while optimizing energy consumption.

Within architecture and interior design, cuttable LED strips are essential for cove lighting, wall washes, and feature highlights. Designers benefit from the ability to customize strip lengths to fit unique spatial requirements, enabling seamless integration into ceilings and walls. Buyers from regions such as the UK and Egypt should focus on suppliers offering consistent light output and certifications ensuring safety and performance, especially for commercial building projects.

The automotive and transportation sector utilizes cuttable LED strips for interior cabin lighting and custom vehicle lighting solutions. These strips must endure heat, vibration, and comply with automotive standards to ensure reliability and safety. International manufacturers and fleet operators require durable products that maintain performance over time, with sourcing considerations emphasizing quality control and adherence to regional automotive regulations.

Finally, in industrial and manufacturing environments, cuttable LED strips are employed for machine status indicators and workspace illumination. These applications demand rugged, dust- and water-resistant lighting solutions with long operational lifespans to minimize maintenance and downtime. Buyers from diverse markets, including Africa and Europe, should prioritize IP-rated products and robust components to withstand harsh factory conditions while improving worker safety and productivity.

Strategic Material Selection Guide for cuttable led strip lighting

When selecting materials for cuttable LED strip lighting, international B2B buyers must consider factors such as durability, environmental resistance, cost, and compliance with regional standards. The choice of material directly impacts product longevity, installation flexibility, and suitability for specific applications, especially in diverse climates and regulatory environments found across Africa, South America, the Middle East, and Europe.

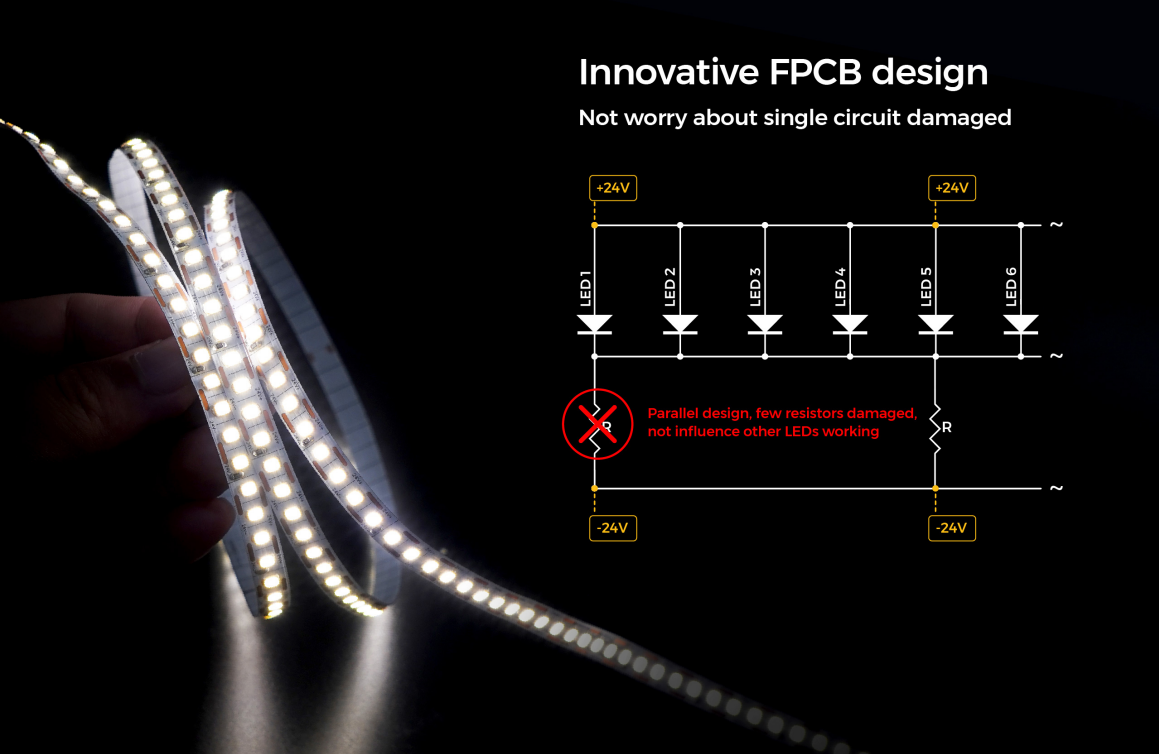

1. Flexible Printed Circuit Board (FPCB) Base Material

Key Properties:

FPCBs are typically made from polyimide or polyester substrates, offering excellent flexibility, high-temperature resistance (up to 200°C for polyimide), and good electrical insulation. They provide a stable platform for mounting SMD LEDs and conductive copper traces.

Pros & Cons:

– Pros: Highly flexible for curved or irregular surfaces, lightweight, and supports complex circuit designs. Polyimide-based FPCBs resist heat and chemicals well.

– Cons: Polyester variants have lower thermal stability and may degrade faster under harsh conditions. FPCBs require careful handling to avoid mechanical damage during cutting.

Impact on Application:

Ideal for installations requiring bending or shaping, such as architectural coves or vehicle interiors. Their flexibility suits dynamic environments but demands precision cutting to avoid circuit damage.

Considerations for Buyers:

Buyers in regions with high ambient temperatures (e.g., Middle East, parts of Africa) should prioritize polyimide-based FPCBs for heat resilience. Compliance with IPC standards and regional certifications (e.g., CE in Europe, SASO in Saudi Arabia) ensures quality. Suppliers offering FPCBs with RoHS compliance and flame retardancy are preferred in Europe and the UK.

2. Silicone Encapsulation (for Waterproof LED Strips)

Key Properties:

Silicone is used as a flexible, transparent encapsulant that provides IP65 to IP68 waterproof ratings. It exhibits excellent UV resistance, chemical inertness, and operates effectively across a wide temperature range (-40°C to +200°C).

Pros & Cons:

– Pros: Superior protection against moisture, dust, and mechanical abrasion; maintains flexibility after curing; safe for outdoor and humid environments.

– Cons: Higher material and manufacturing costs; requires precise cutting and resealing to maintain waterproof integrity; potential for silicone degradation under prolonged UV exposure if not UV-stabilized.

Impact on Application:

Essential for outdoor, marine, or industrial lighting projects where exposure to water or chemicals is frequent. Silicone encapsulation extends product life in harsh climates common in South America and coastal regions of Africa.

Considerations for Buyers:

International buyers should verify IP rating certifications and ensure suppliers provide proper end caps and sealing materials for cut strips. In Europe and the UK, compliance with EN 60598 for luminaires and environmental directives is critical. In Middle Eastern markets, UV-resistant silicone formulations are advantageous.

3. Copper Conductive Traces

Key Properties:

Copper is the standard conductive material in LED strips, prized for high electrical conductivity and thermal management. Thickness varies (commonly 1 oz to 2 oz copper per square foot), affecting current capacity and heat dissipation.

Pros & Cons:

– Pros: Excellent electrical performance, supports high current loads, and improves LED lifespan by reducing heat buildup.

– Cons: Copper is prone to oxidation and corrosion if not properly coated; adds to material cost compared to aluminum-based alternatives.

Impact on Application:

Critical for high-power LED strips or long runs where voltage drop and heat are concerns. Proper copper thickness ensures stable performance in commercial installations like retail or hospitality lighting.

Considerations for Buyers:

Buyers in humid or corrosive environments (e.g., coastal South America, Middle East) should seek copper traces with protective coatings such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold). Compliance with ASTM B152 or equivalent international standards assures material quality.

4. Aluminum Backing (Heat Sink Layer)

Key Properties:

Aluminum backing provides a rigid substrate and acts as an effective heat sink, dissipating heat away from LEDs. It typically has anodized or painted finishes to enhance corrosion resistance.

Pros & Cons:

– Pros: Enhances thermal management, improves LED efficiency and lifespan, adds mechanical strength for installation.

– Cons: Less flexible than FPCB; increases weight and cost; cutting aluminum-backed strips requires specialized tools and techniques.

Impact on Application:

Best suited for fixed, flat installations where heat dissipation is critical, such as industrial or architectural lighting in Europe and the UK. Aluminum backing is less common in highly flexible applications but preferred where durability is paramount.

Considerations for Buyers:

International buyers must consider local standards for aluminum quality (e.g., EN AW-6063 in Europe) and ensure compatibility with installation environments. In hot climates like Egypt or the Middle East, aluminum backing mitigates thermal degradation risks. Handling and cutting protocols must be followed to maintain product integrity.

Summary Table

| Material | Typical Use Case for cuttable led strip lighting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Flexible Printed Circuit Board (FPCB) | Flexible installations requiring bending and shaping | High flexibility and heat resistance (polyimide) | Susceptible to mechanical damage if mishandled | Medium |

| Silicone Encapsulation | Outdoor, waterproof, and harsh environment applications | Excellent waterproofing and UV resistance | Higher cost and requires careful resealing | High |

| Copper Conductive Traces | High-power LED strips needing efficient electrical and thermal performance | Superior conductivity and heat dissipation | Prone to corrosion without protective coating | Medium |

| Aluminum Backing | Fixed, heat-sensitive installations requiring robust heat sinking | Effective heat dissipation and mechanical strength | Reduced flexibility; requires special cutting tools | Medium to High |

This material selection guide empowers B2B buyers to make informed decisions tailored to their regional requirements and application needs. Prioritizing materials based on environmental conditions, compliance standards, and project specifications ensures optimal performance and cost-efficiency in cuttable LED strip lighting solutions.

In-depth Look: Manufacturing Processes and Quality Assurance for cuttable led strip lighting

Manufacturing Processes for Cuttable LED Strip Lighting

Cuttable LED strip lighting manufacturing involves several precise stages to ensure flexibility, durability, and reliable performance. Understanding these processes helps B2B buyers from Africa, South America, the Middle East, and Europe evaluate suppliers critically and select products aligned with their project requirements.

1. Material Preparation

Manufacturing begins with sourcing high-quality raw materials:

– Flexible PCB (Printed Circuit Board): The base substrate typically uses flexible polyimide or PET films, chosen for their bendability and heat resistance.

– LED Chips: Commonly surface-mounted device (SMD) LEDs such as 3528, 5050, or 2835 types, selected based on brightness and power needs.

– Resistors and Conductors: Precision resistors regulate current, while copper conductors embedded in the PCB ensure electrical continuity.

– Encapsulation Materials: Silicone or epoxy coatings for waterproof strips, or protective films for non-waterproof variants.

Raw materials undergo inspection for electrical and mechanical properties before use, ensuring the foundation for quality products.

2. Forming and Circuit Assembly

This stage integrates LEDs and electronic components onto the flexible PCB:

– Surface Mount Technology (SMT): Automated pick-and-place machines position LEDs and resistors onto the PCB with micron-level accuracy.

– Reflow Soldering: Components are soldered using controlled temperature profiles to ensure strong joints without damaging sensitive LEDs.

– Cutting Mark Integration: The flexible PCB is printed with clearly marked cutting points (usually every 5–10 cm depending on LED density), facilitating easy segmentation without damaging circuits.

Illustrative Image (Source: Google Search)

This process requires precision to maintain uniform LED spacing and functional electrical connections, which directly impact light quality and cuttability.

3. Encapsulation and Finishing

The final assembly steps protect the strip and prepare it for handling:

– Coating: Depending on IP rating requirements, strips are coated with a thin silicone layer (IP65) or enclosed in silicone tubes (IP67/IP68) for waterproofing.

– Connector Attachment: End connectors or solder pads are applied for easy power and controller integration.

– Labeling and Packaging: Strips are labeled with product specifications, cutting guidelines, and batch numbers, then carefully rolled or boxed to prevent damage during shipment.

Proper finishing is critical for ensuring durability, especially in harsh environments common in many international markets.

Quality Assurance and Control in Cuttable LED Strip Lighting

Robust quality assurance (QA) and quality control (QC) frameworks are indispensable for delivering reliable LED strip lighting products. For international B2B buyers, understanding these frameworks and verifying supplier compliance safeguards investments and project success.

Key International and Industry Standards

- ISO 9001: This globally recognized quality management standard ensures manufacturers maintain consistent processes, documentation, and continuous improvement practices.

- CE Marking: Mandatory for products sold in the European Economic Area, this certifies compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical products, critical for buyers in Europe and increasingly relevant worldwide.

- UL Certification: Especially important for North American and some Middle Eastern buyers, verifying electrical safety.

- IP Ratings (e.g., IP65, IP67): Confirm ingress protection levels, crucial for waterproof LED strip applications.

- Other Regional Certifications: Some countries in Africa and South America may require local certifications or adherence to additional safety and environmental regulations.

Illustrative Image (Source: Google Search)

Buyers should prioritize suppliers who demonstrate compliance with applicable standards relevant to their markets.

QC Checkpoints in Manufacturing

Quality control is typically structured in three key phases:

- Incoming Quality Control (IQC): Raw materials including LEDs, PCBs, and coatings are inspected for conformity to specifications using visual checks, electrical tests, and material certifications.

- In-Process Quality Control (IPQC): During assembly, continuous monitoring occurs. This includes verifying solder joint quality, LED placement accuracy, and cutting mark precision. Automated optical inspection (AOI) machines are often used.

- Final Quality Control (FQC): Completed LED strips undergo comprehensive testing before shipment. This includes:

- Electrical testing for continuity and shorts.

- Light output measurement to ensure uniform brightness and color temperature.

- Waterproof testing for sealed products.

- Visual inspection for defects or damage.

Each batch is typically sampled and tested to confirm consistent quality.

Common Testing Methods

- Electrical Tests: Checking voltage, current, and resistance to ensure operational stability.

- Photometric Testing: Using spectrometers and lux meters to verify luminous intensity, color rendering index (CRI), and correlated color temperature (CCT).

- Environmental Stress Testing: Temperature and humidity cycling to simulate real-world conditions, critical for buyers in regions with extreme climates.

- Mechanical Testing: Flexibility and cut-point durability tests ensure the strip withstands bending and cutting without performance loss.

How B2B Buyers Can Verify Supplier Quality Assurance

For buyers in Africa, South America, the Middle East, and Europe, supplier verification is a critical step to mitigate risk.

1. Factory Audits and Inspections

- On-site Audits: Visiting manufacturing facilities or engaging third-party audit firms can validate adherence to ISO 9001 processes and confirm production capabilities.

- Production Line Witnessing: Observing SMT assembly, soldering, and testing procedures ensures equipment and operator skill levels meet expectations.

2. Review of Quality Documentation

- Certificates and Test Reports: Request copies of ISO 9001 certificates, CE declarations, RoHS test reports, and UL certifications.

- Batch Test Data: Obtain sample batch inspection reports showing electrical, photometric, and waterproof testing results.

- Material Traceability: Ensure suppliers provide traceability records for critical components like LEDs and PCBs.

3. Third-Party Testing and Inspection

- Engage independent laboratories in your region or globally to perform random batch inspections or certification testing. This is especially valuable for new suppliers or large orders.

- Some international freight forwarders offer inspection services prior to shipment to verify quantity, quality, and packaging compliance.

Quality Control Nuances for International Buyers

- Climate Considerations: Buyers from regions like the Middle East or parts of Africa should prioritize suppliers who test products under high-temperature and dust exposure conditions.

- Electrical Standards: European buyers (e.g., UK) should verify CE and RoHS compliance rigorously, while South American buyers might focus on local electrical safety certifications.

- Waterproofing Standards: For outdoor or humid environments common in tropical Africa or coastal South America, confirm IP ratings and post-cut sealing procedures.

- Cutting Flexibility Documentation: Since cuttable LED strips vary in cutting intervals and handling, request detailed cutting guides and warranty terms related to modifications.

- After-Sales Support: Consider suppliers offering technical support, replacement policies, and training on correct cutting and installation methods to reduce project risks.

By thoroughly understanding manufacturing processes and establishing stringent quality assurance verification protocols, international B2B buyers can confidently source high-performance cuttable LED strip lighting tailored to their unique regional and project needs. This strategic approach not only mitigates risk but also enhances the reliability and longevity of lighting installations across diverse global markets.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for cuttable led strip lighting Sourcing

Understanding Cost Components in Cuttable LED Strip Lighting

When sourcing cuttable LED strip lighting for B2B projects, it’s crucial to dissect the cost structure to negotiate effectively and optimize procurement budgets. The primary cost components include:

- Materials: This is the largest cost driver. It involves the LED chips (SMD or COB), flexible PCB substrate, resistors, connectors, and protective coatings (e.g., waterproof silicone). Higher quality materials and certifications (RoHS, CE) typically increase costs but ensure reliability and compliance.

- Labor: Skilled labor is required for assembly, cutting precision, soldering, and quality checks. Labor costs vary significantly by manufacturing location, impacting final pricing.

- Manufacturing Overhead: Includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with modern automation may offer better cost control.

- Tooling: Custom tooling for cutting, stamping, or casing can add upfront costs, particularly for specialized or small-batch orders.

- Quality Control (QC): Rigorous testing for electrical performance, waterproofing, and durability affects cost but is essential for reducing returns and warranty claims.

- Logistics: Freight charges, import duties, and handling fees vary by region. For buyers in Africa, South America, the Middle East, and Europe, logistics can significantly influence landed cost.

- Supplier Margin: This reflects the supplier’s profit margin, which varies based on brand positioning, order volume, and market competition.

Key Price Influencers in Cuttable LED Strip Lighting

Several factors shape the final pricing that international B2B buyers should consider:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock volume discounts. However, MOQs can be a barrier for smaller businesses or projects. Negotiating flexible MOQs or phased deliveries may optimize cash flow.

- Specifications and Customization: LED density (e.g., 30, 60, 120 LEDs/m), waterproof rating (IP20, IP65, IP67), color temperature options, and addressable features all impact costs. Customized lengths and special connectors add complexity and price.

- Material Quality and Certifications: Certified materials and compliance with international safety and environmental standards (CE, RoHS, UL) increase costs but are often mandatory for European and Middle Eastern markets.

- Supplier Location and Reliability: Suppliers in China, Southeast Asia, or Eastern Europe may offer competitive pricing but vary in quality and lead times. Partnering with reputable suppliers with proven track records reduces risk.

- Incoterms: The choice of Incoterms (FOB, CIF, DDP) affects logistics and customs costs. Buyers should clarify responsibilities and costs upfront to avoid unexpected expenses.

Strategic Buyer Tips for International B2B Procurement

- Negotiate Beyond Unit Price: Focus on total cost of ownership (TCO), including warranty terms, shipping, customs clearance, and after-sales support. A slightly higher unit price with better service can be more cost-effective.

- Leverage Volume Flexibility: If your project allows, consolidate orders or partner with other buyers to increase volume and negotiate better pricing or payment terms.

- Assess Quality vs. Price: For markets like the UK and the EU with stringent regulations, prioritize certified products even if they cost more upfront. For emerging markets in Africa and South America, balance quality with budget constraints to avoid costly replacements.

- Understand Pricing Nuances for Customization: Custom lengths and cutting intervals may require additional tooling or manual labor, increasing price. Request detailed quotations specifying customization charges.

- Factor in Logistics and Duties: For buyers in Egypt, Middle East, and South America, import duties and shipping times can be significant. Engage freight forwarders familiar with your region and consider consolidated shipments to reduce costs.

- Request Samples and Prototypes: Before bulk purchasing, testing samples ensures product meets your specifications, avoiding costly mistakes.

- Clarify Payment Terms: Favor suppliers offering trade assurance, letters of credit, or escrow services to mitigate payment risks in international transactions.

Indicative Pricing Disclaimer

Pricing for cuttable LED strip lighting varies widely based on specifications, order size, and supplier. As a rough benchmark, standard non-waterproof LED strips may start from $1–$3 per meter at bulk volumes, while high-density, waterproof, or addressable strips can range from $5 to $15+ per meter. These figures are indicative; buyers should obtain tailored quotations reflecting current market conditions and specific requirements.

By understanding the detailed cost components and price influencers, international B2B buyers can make informed decisions, negotiate effectively, and optimize procurement strategies for cuttable LED strip lighting across diverse markets such as Africa, South America, the Middle East, and Europe.

Spotlight on Potential cuttable led strip lighting Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘cuttable led strip lighting’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cuttable led strip lighting

Critical Technical Properties of Cuttable LED Strip Lighting

1. Cutting Interval

This defines the specific length segments at which an LED strip can be safely cut without damaging the circuit. Typical intervals range from 2.5cm to 10cm depending on LED density (e.g., 30, 60, 120 LEDs/meter). For B2B buyers, understanding cutting intervals is crucial to ensure the strips fit precise installation dimensions and to minimize waste. Misjudging this can lead to unusable leftover pieces or installation failures.

2. LED Chip Type and Density

Common chip types include SMD (Surface Mounted Device) variants like 3528, 5050, and 5630, while premium options use COB (Chip On Board) technology for uniform light output. LED density (number of LEDs per meter) affects brightness and cutting granularity. Buyers should select chip types based on application needs—higher density for brighter, more continuous lighting or standard for cost-effective ambient illumination.

3. Material Grade and Flexibility

LED strips are typically mounted on flexible printed circuit boards (FPC) made from materials like polyimide or polyester. The material grade impacts durability, heat dissipation, and bending radius. High-quality materials ensure longer lifespan and reliability, especially in curved or irregular installations. B2B buyers should verify material certifications and suitability for their environmental conditions.

4. Waterproof Rating (IP Code)

Waterproof cuttable LED strips range from IP20 (non-waterproof) to IP68 (fully submersible). Waterproofing involves silicone coatings or encapsulation tubes, which must be properly resealed after cutting. For buyers in regions with humid or outdoor applications (e.g., Middle East, coastal Africa), selecting the correct IP rating is vital for product longevity and warranty compliance.

5. Voltage and Power Specifications

Most cuttable LED strips operate at low voltage (12V or 24V DC) for safety and ease of installation. Power consumption per meter (watts/meter) informs energy costs and power supply requirements. B2B purchasers should match voltage and power specs with their existing infrastructure and ensure compatibility with drivers and dimming controls.

6. Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvins) ranges from warm white (~2700K) to daylight (~6500K), affecting ambiance and visual comfort. CRI measures color accuracy; values above 80 are preferred for retail and hospitality to enhance product appearance. Buyers must specify these parameters to meet client expectations and project requirements.

Key Trade Terminology for International B2B Buyers

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing LED strips that other brands re-label and sell. OEM partnerships allow buyers to customize product features, packaging, and branding, enabling tailored solutions for local markets like Egypt or the UK.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ helps buyers plan inventory and cash flow, especially important for smaller distributors or regional installers in South America and Africa who may have budget constraints.

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain pricing, lead times, and terms for specific LED strip products. RFQs streamline procurement processes and enable buyers to compare competitive offers efficiently.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers (e.g., FOB, CIF, DDP). Familiarity with Incoterms ensures smooth logistics, cost transparency, and risk management across diverse regions like Europe and the Middle East.

IP Rating (Ingress Protection Rating)

A classification indicating the level of protection against solids and liquids. For example, IP65 means dust-tight and protected against water jets. Knowing IP ratings helps buyers specify LED strips suitable for indoor or outdoor environments.

Dimmable vs. Non-Dimmable

Indicates whether LED strips support brightness adjustment. Dimmable strips require compatible drivers and controllers, offering flexibility in lighting design. Buyers should verify this feature for projects demanding mood or energy-saving controls.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and ensure successful deployment of cuttable LED strip lighting tailored to their specific market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cuttable led strip lighting Sector

Market Overview & Key Trends

The global cuttable LED strip lighting market is experiencing robust growth driven by rising demand for energy-efficient, customizable lighting solutions across diverse sectors such as retail, hospitality, architecture, and smart buildings. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, key market dynamics include increasing urbanization, infrastructure development, and a shift toward smart lighting systems that allow tailored illumination through modular, cuttable strips.

Key trends shaping the market include:

-

Customization and Flexibility: Cuttable LED strips offer unparalleled adaptability, enabling buyers to tailor lengths precisely to project requirements. This is crucial for complex installations in retail displays, commercial interiors, and outdoor architectural lighting across varied geographies.

-

Technological Advancements: Innovations such as COB (Chip On Board) LED strips, addressable RGB digital strips, and improved waterproofing options are expanding product applications. These advancements cater to sophisticated lighting designs favored in European and Middle Eastern markets while providing durable solutions suited to challenging environments in Africa and South America.

-

Supply Chain Localization: Regional sourcing hubs in Europe and the Middle East are growing to reduce lead times and logistics costs. African and South American buyers increasingly seek suppliers offering flexible MOQ (minimum order quantities) and reliable technical support tailored to local market conditions.

-

Integration with Smart Controls: The rise of IoT-enabled lighting solutions integrates seamlessly with cuttable LED strips, enabling energy management and dynamic lighting scenes. This is especially relevant for markets like the UK and UAE, where smart building initiatives are accelerating.

-

Cost Optimization & Waste Reduction: Efficient cutting techniques and modular designs help businesses minimize material waste, crucial for cost-sensitive markets in Africa and South America. Suppliers offering clear guidance on cutting intervals and compatibility with connectors enhance project efficiency and reduce installation errors.

For B2B buyers, understanding these trends enables more strategic procurement decisions, balancing innovation, cost-efficiency, and local market demands.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the cuttable LED strip lighting sector, with international buyers increasingly prioritizing eco-friendly products and ethical supply chains. LED technology inherently offers energy savings—consuming up to 80% less power than traditional lighting—contributing significantly to reducing carbon footprints in commercial projects.

Environmental impact considerations include:

-

Material Selection: Preference for LED strips manufactured using low-toxicity, recyclable materials such as lead-free solder and halogen-free substrates reduces hazardous waste. Buyers should inquire about compliance with RoHS (Restriction of Hazardous Substances) and REACH regulations, which are particularly stringent in European markets.

-

Energy Efficiency Certifications: Certifications like ENERGY STAR and DLC (DesignLights Consortium) validate product performance and energy savings, helping buyers justify investments in sustainable lighting solutions to clients and stakeholders.

-

Waterproofing and Longevity: High-quality waterproof coatings (IP65-IP68 ratings) extend product lifespan, reducing replacement frequency and associated waste. This durability is especially critical for outdoor installations in harsh climates typical in parts of Africa and the Middle East.

-

Ethical Supply Chain Transparency: Buyers should seek suppliers committed to fair labor practices and responsible sourcing of components. Transparent supply chains aligned with standards such as ISO 14001 (Environmental Management) and SA8000 (Social Accountability) mitigate risks related to unethical practices and enhance corporate social responsibility profiles.

-

End-of-Life Management: Some manufacturers now offer take-back or recycling programs for used LED strips, supporting circular economy initiatives and reducing landfill impact.

For B2B buyers across emerging and developed markets, partnering with suppliers who demonstrate strong environmental stewardship and ethical sourcing not only aligns with global sustainability goals but also meets increasing regulatory and consumer expectations.

Evolution of Cuttable LED Strip Lighting

Cuttable LED strip lighting has evolved significantly since its inception in the early 2000s. Initially designed as fixed-length, single-color strips, early products offered limited flexibility and required bulky fixtures. The introduction of flexible PCB technology allowed strips to bend and conform to surfaces, expanding applications dramatically.

The ability to cut LED strips at precise intervals transformed lighting design, enabling custom lengths and complex configurations tailored to unique project needs. Innovations such as multi-color RGB strips, addressable digital LEDs, and COB technology have further enhanced light quality and control options.

Today, cuttable LED strips form an integral part of modern lighting ecosystems, combining modularity with smart controls and sustainable materials. This evolution empowers B2B buyers to implement highly customized, energy-efficient lighting solutions that meet diverse architectural and commercial requirements globally.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of cuttable led strip lighting

-

How can I effectively vet suppliers of cuttable LED strip lighting for international B2B purchases?

Thorough supplier vetting is crucial for reliable sourcing. Start by requesting detailed company profiles, certifications (ISO, CE, RoHS), and client references. Verify factory audits or third-party inspection reports to assess manufacturing capabilities and quality control. For regions like Africa, the Middle East, and South America, prioritize suppliers with proven export experience and compliance with local import regulations. Request product samples to evaluate LED quality, cut points, and durability. Also, check their after-sales support and communication responsiveness to ensure smooth collaboration. -

What customization options should I expect when ordering cuttable LED strip lighting for commercial projects?

Most professional suppliers offer a range of customization services including cutting intervals, LED density (e.g., 30, 60, 120 LEDs/m), color temperature tuning, waterproof ratings (IP65-IP68), and connector types. For complex projects, you can request custom lengths, flexible circuit designs, and specific adhesive backing suitable for your installation environment. Addressable RGB or COB LED strips may require special customization regarding control chips or light uniformity. Confirm lead times and minimum order quantities (MOQs) for these tailored products to plan your procurement efficiently. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for cuttable LED strips in B2B international trade?

MOQs vary widely depending on supplier scale and product type, typically ranging from 100 meters for standard strips to higher volumes for customized orders. Lead times usually span 2 to 6 weeks, influenced by order complexity, certification processes, and shipping logistics. Payment terms commonly include 30% deposit upfront with balance before shipment or upon delivery, though negotiated terms such as letters of credit or escrow services may be available for new buyers. Clarify these terms early to avoid delays, especially when dealing with suppliers across continents. -

How can I ensure the quality and safety certifications of cuttable LED strip lighting meet international standards?

Demand copies of relevant certifications such as CE, RoHS, UL, and FCC, which indicate compliance with safety, environmental, and electromagnetic standards. For markets in Europe and the Middle East, CE and RoHS are often mandatory. Verify the authenticity of certificates through official registries or direct communication with certifying bodies. Additionally, request test reports for electrical safety, waterproofing (IP rating), and luminous efficacy. Insist on factory quality audits and batch testing to minimize defective products and ensure consistent performance. -

What logistical considerations are important when importing cuttable LED strip lighting from suppliers in Asia or Europe?

Plan for shipping methods that balance cost, speed, and product safety—air freight is faster but costly, while sea freight suits larger volumes. Confirm packaging protects strips from moisture and physical damage. Understand customs clearance requirements in your country, including import duties, taxes, and certification documentation. Coordinate with freight forwarders experienced in handling electronic lighting goods. Consider local regulations on electrical equipment and ensure all paperwork (commercial invoice, packing list, certificate of origin) is accurate to avoid clearance delays. -

How can I handle disputes or quality issues with overseas suppliers of cuttable LED strips effectively?

Establish clear contractual terms covering product specifications, inspection rights, and remedies for defects before ordering. Use third-party inspection services to verify quality pre-shipment. If issues arise, document them thoroughly with photos and test reports. Communicate promptly and professionally with the supplier to seek resolution, such as replacement shipments or refunds. For persistent disputes, leverage trade mediation services or arbitration clauses specified in contracts. Maintaining transparent communication and documented agreements reduces risks in cross-border transactions. -

Are there specific product features I should consider for cuttable LED strips used in harsh environments like the Middle East or coastal Africa?

Yes, focus on LED strips with high IP ratings (IP67 or IP68) for water and dust resistance, and UV-resistant coatings to withstand intense sunlight. Opt for robust silicone or epoxy encapsulation to protect circuitry from humidity and corrosion. Check operating temperature ranges to ensure performance in extreme heat. Suppliers offering custom adhesives suitable for rough or uneven surfaces improve installation durability. Confirm warranty terms cover environmental damage to safeguard your investment in challenging climates. -

What are the best practices for inventory management and stock optimization when sourcing cuttable LED strip lighting internationally?

Leverage accurate demand forecasting based on project timelines and market trends to avoid overstocking or shortages. Negotiate flexible MOQs or staggered shipments with suppliers to align inventory with consumption. Utilize supplier-managed inventory (SMI) or just-in-time (JIT) delivery models where possible to reduce holding costs. Keep buffer stock of common strip types and accessories like connectors and power supplies. Regularly review supplier lead times and logistics to adjust orders proactively, especially considering potential delays from customs or transport disruptions in your target regions.

Strategic Sourcing Conclusion and Outlook for cuttable led strip lighting

Cuttable LED strip lighting presents a compelling solution for diverse commercial and architectural lighting needs, offering unparalleled flexibility through precise customization and efficient material utilization. For B2B buyers across Africa, South America, the Middle East, and Europe, mastering the nuances of cutting intervals, strip types, and waterproofing standards is essential to maximizing product performance and minimizing installation risks. Strategic sourcing—focusing on suppliers who provide technical clarity, reliable quality certifications, and after-sales support—ensures that your procurement aligns with project specifications and regional regulatory requirements.

Key takeaways for international buyers include:

– Prioritize LED strips with clearly defined cutting points and compatibility with your installation environment.

– Opt for suppliers offering tailored solutions, including waterproof resealing accessories and specialized connectors for high-voltage or addressable strips.

– Leverage bulk purchasing and inventory optimization strategies to reduce waste and improve cost efficiency.

Looking ahead, the growing demand for energy-efficient, adaptable lighting solutions worldwide underscores the importance of partnering with innovative manufacturers who stay ahead of evolving technologies. Buyers who proactively engage with expert suppliers and integrate cutting-edge LED strip lighting into their projects will unlock competitive advantages in their markets. Embrace strategic sourcing today to illuminate your business success tomorrow.