Introduction: Navigating the Global Market for cob led strip connector u shape

In today’s rapidly evolving lighting industry, the U-shape COB LED strip connector stands out as a pivotal component that enables seamless, efficient, and flexible LED lighting installations. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—understanding this connector’s technical nuances and practical applications is critical for sourcing high-quality, cost-effective lighting solutions. Its unique design not only simplifies installation through solderless, quick-connect features but also ensures reliable power delivery and uninterrupted lighting performance across various LED strip types including single color, RGB, and CCT configurations.

This comprehensive guide is crafted to empower procurement professionals and technical buyers with actionable insights into the global marketplace for U-shape COB LED strip connectors. You will explore diverse connector types and materials, delve into manufacturing and quality control standards, and gain a clear understanding of leading suppliers and cost structures that influence your sourcing decisions. Additionally, market trends and frequently asked questions are addressed to equip you with a holistic perspective, enabling you to mitigate risks and optimize your supply chain management.

Whether your goal is to enhance commercial lighting projects, innovate smart lighting designs, or simply ensure compatibility and durability in your installations, this guide delivers the knowledge and tools to make informed purchasing decisions. By navigating this specialized segment with confidence, buyers from Indonesia to Spain and beyond can secure connectors that meet rigorous standards and drive competitive advantage in their respective markets.

Understanding cob led strip connector u shape Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U-Shape Connector | Compact U-shaped design, solderless connection, supports single-color COB strips | General lighting installations, retail displays, commercial lighting | Pros: Easy installation, cost-effective, versatile; Cons: Limited to simpler strip types |

| RGB-Compatible U-Shape Connector | Enhanced pin configuration for RGB COB strips, maintains color integrity | Dynamic lighting projects, event lighting, hospitality sector | Pros: Supports multi-color control, flexible design; Cons: Slightly higher cost, requires compatible strips |

| Waterproof U-Shape Connector | Sealed design with silicone or plastic casing for moisture protection | Outdoor lighting, industrial environments, architectural façade lighting | Pros: Durable in harsh environments, weather-resistant; Cons: Bulkier, higher price point |

| Adjustable Angle U-Shape Connector | Allows adjustable angles within U-shape for curved or irregular surfaces | Custom installations, automotive lighting, creative architectural projects | Pros: High flexibility, adaptable to varied layouts; Cons: More complex installation, premium pricing |

| High-Current U-Shape Connector | Designed for higher amperage, thicker pins, enhanced power handling | Large-scale commercial projects, high-power LED strips, industrial applications | Pros: Reliable for heavy-duty use, prevents voltage drop; Cons: More expensive, requires compatible power supplies |

Standard U-Shape Connector

This is the most widely used variant, featuring a straightforward U-shaped design optimized for solderless connection with single-color COB LED strips. Its simplicity makes it ideal for bulk procurement by businesses focused on general lighting solutions such as retail displays and office environments. Buyers should consider compatibility with their LED strip type and prioritize volume discounts. Its cost-effectiveness and ease of installation reduce labor costs, making it attractive for large-scale projects requiring fast deployment.

RGB-Compatible U-Shape Connector

Specifically engineered for RGB COB LED strips, this connector supports multiple pins to ensure precise color control and signal integrity. It is best suited for clients in event management, hospitality, and entertainment sectors where dynamic lighting effects are paramount. B2B buyers must assess the technical specifications of both the connector and LED strips to ensure seamless integration. Although it carries a higher unit cost, the enhanced functionality justifies the investment for applications demanding vibrant, customizable lighting.

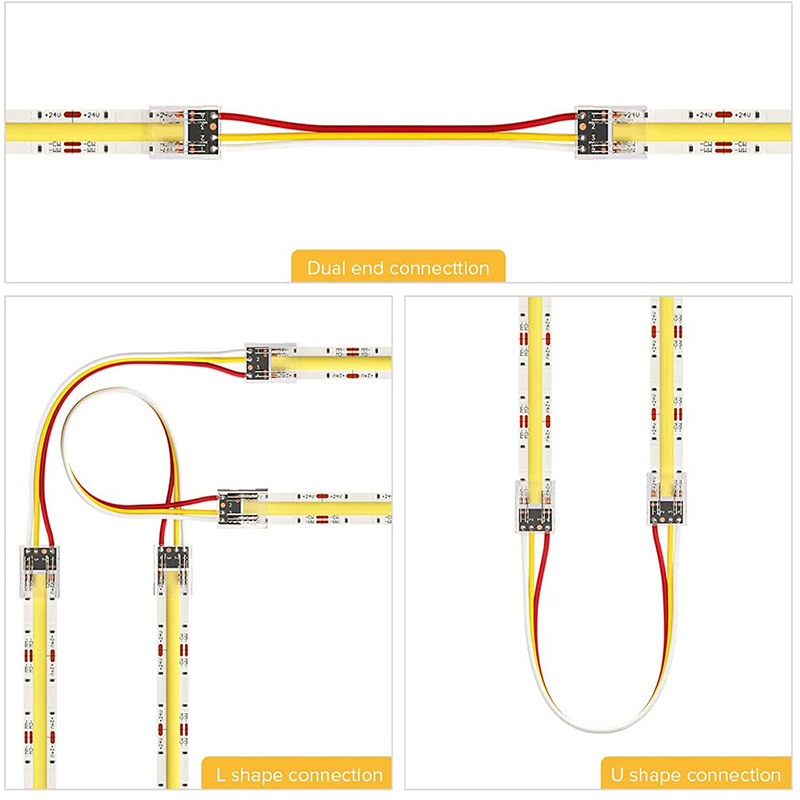

Illustrative Image (Source: Google Search)

Waterproof U-Shape Connector

Featuring a sealed enclosure with silicone or plastic casing, this variation is designed to withstand moisture and dust, making it indispensable for outdoor and industrial lighting applications. Buyers from regions with humid or unpredictable climates—such as parts of Africa, the Middle East, and South America—will find these connectors essential for durability and longevity. While the upfront cost is higher, the reduction in maintenance and replacement expenses offers significant long-term savings.

Adjustable Angle U-Shape Connector

This type allows the connector to flexibly adjust angles within the U-shape, accommodating curved or irregular surfaces commonly found in architectural and automotive lighting projects. International buyers focusing on bespoke installations or creative design projects should consider these connectors for their adaptability. They require more careful handling during installation, and their premium price reflects their specialized function. However, they enable unique lighting configurations that standard connectors cannot support.

High-Current U-Shape Connector

Built to handle increased amperage with thicker pins and robust construction, this connector suits large-scale commercial or industrial lighting systems that demand stable power delivery. Buyers engaged in infrastructure projects or high-power LED strip deployments must prioritize these connectors to prevent voltage drops and ensure safety compliance. Although costlier, these connectors minimize operational risks and downtime, making them a strategic investment for high-demand environments.

Related Video: How to Cut, Connect & Power COB LED Strip Lighting | Solderless Connector Tutorial

Key Industrial Applications of cob led strip connector u shape

| Industry/Sector | Specific Application of cob led strip connector u shape | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and Commercial | Seamless lighting integration in display cases and store fixtures | Enhances product visibility and customer experience; reduces downtime during installation | Compatibility with various COB LED strip types; durability under frequent reconfiguration; ease of installation without specialized labor |

| Hospitality & Interior Design | Customizable ambient lighting in hotels, restaurants, and lounges | Enables flexible, elegant lighting designs that improve guest satisfaction and brand image | Quality and consistency of connectors for aesthetic uniformity; ability to support RGB and CCT strips for dynamic lighting effects |

| Automotive Manufacturing | Interior lighting assembly in vehicle cabins and dashboards | Improves assembly efficiency with solderless connectors; ensures reliable connectivity in compact spaces | Compliance with automotive standards; robustness against vibration and temperature variations; connector size fitting narrow installation areas |

| Architecture & Urban Planning | Architectural accent lighting in façades, walkways, and public spaces | Provides energy-efficient, low-maintenance lighting solutions that enhance urban aesthetics | Weather-resistant connectors; long-term reliability; ability to support continuous lighting in complex shapes and angles |

| Electronics & Consumer Goods | Integration in electronic devices and appliances for backlighting | Facilitates rapid assembly and repair; supports sleek product designs with minimal wiring clutter | Precision in connector sizing; electrical safety standards compliance; sourcing from suppliers with proven quality control |

Retail and Commercial Lighting

In retail environments across Africa, South America, the Middle East, and Europe, the U-shape COB LED strip connector plays a pivotal role in creating seamless lighting for display cases, shelves, and signage. Its solderless, easy-to-use design allows store owners and commercial fit-out companies to quickly install or reconfigure lighting setups without specialized labor. This reduces downtime and operational disruption. Buyers should prioritize connectors compatible with a variety of COB LED strip types and those capable of withstanding frequent reinstallation or adjustments, especially in markets where skilled technicians may be scarce or costly.

Hospitality and Interior Design

Hotels, restaurants, and lounges globally benefit from the flexibility offered by U-shape connectors when designing ambient lighting schemes. These connectors enable designers to link RGB or CCT COB LED strips in complex patterns that enhance atmosphere and guest experience. For international B2B buyers, particularly in regions like the Middle East and Europe, ensuring uniform connector quality is crucial to maintain consistent light output and color rendering. Additionally, sourcing connectors that facilitate quick installation without soldering minimizes labor costs and accelerates project timelines.

Automotive Manufacturing

The automotive sector relies on compact, reliable lighting solutions for vehicle interiors, including dashboards and ambient cabin lighting. U-shape COB LED strip connectors enable efficient assembly lines by providing solderless, stable connections that withstand vibrations and temperature fluctuations common in automotive environments. For buyers in emerging markets such as South America and Africa, sourcing connectors that meet automotive industry standards and are designed for tight spaces ensures product reliability and reduces warranty claims.

Architecture and Urban Planning

Architectural lighting projects, including façade illumination and pathway lighting, demand connectors that support continuous, flexible COB LED strips shaped around curves and angles. U-shape connectors are ideal for these applications, allowing architects and urban planners to realize creative lighting designs that are energy-efficient and low maintenance. International buyers should focus on weather-resistant and durable connectors suited for outdoor use, especially in regions with harsh climates, ensuring long-term performance and reduced maintenance costs.

Electronics and Consumer Goods

In electronics manufacturing, U-shape COB LED strip connectors facilitate the integration of backlighting in devices such as monitors, appliances, and control panels. Their compact form factor supports sleek product designs while enabling rapid assembly and easy repairs. Buyers, especially from Europe and Indonesia, should verify that connectors comply with electrical safety standards and are sourced from manufacturers with rigorous quality control to prevent product failures and support after-sales service commitments.

Related Video: BTF-LIGHTING: COB LED Strip Light, How to Connect

Strategic Material Selection Guide for cob led strip connector u shape

When selecting materials for U-shape COB LED strip connectors, international B2B buyers must consider factors such as electrical conductivity, durability, environmental resistance, and cost-effectiveness. These connectors are critical for ensuring stable electrical connections and mechanical integrity in diverse lighting applications. Below is an analysis of four common materials used for these connectors, focusing on their performance attributes and suitability for markets in Africa, South America, the Middle East, and Europe.

1. Copper (with Tin or Nickel Plating)

Key Properties: Copper is renowned for its excellent electrical conductivity and thermal performance, essential for efficient power transfer in COB LED strip connectors. Tin or nickel plating is often applied to improve corrosion resistance and solderability.

Pros: Copper’s superior conductivity minimizes voltage drop and heat generation, enhancing LED strip longevity. Plating extends the lifespan by preventing oxidation, especially in humid or coastal environments common in many African and Middle Eastern regions. Copper connectors are relatively easy to manufacture and solder, facilitating quick assembly.

Cons: Copper connectors can be prone to mechanical wear and may require protective coatings to avoid tarnishing. The raw material cost is moderate to high, influenced by global copper prices.

Impact on Application: Ideal for high-current applications and environments where stable electrical performance is critical. Buyers in Europe and South America often prefer copper connectors due to stringent quality and safety standards (e.g., DIN and ASTM certifications).

B2B Considerations: Compliance with international standards such as IEC and RoHS is common for copper connectors. Buyers in regions with high humidity or salt exposure should prioritize connectors with high-quality plating to prevent corrosion. Copper’s recyclability also appeals to environmentally conscious markets like Spain and parts of Europe.

2. Phosphor Bronze

Key Properties: Phosphor bronze combines good electrical conductivity with superior mechanical strength and excellent corrosion resistance, especially against saltwater and acidic environments.

Pros: This alloy offers enhanced durability and springiness, which is beneficial for maintaining secure connections in flexible or vibration-prone installations. It resists fatigue better than pure copper, making it suitable for repeated assembly and disassembly.

Cons: Phosphor bronze is more expensive than standard copper and requires more complex manufacturing processes, which can impact lead times and cost.

Impact on Application: Well-suited for demanding industrial or outdoor lighting applications, including installations in coastal areas of Africa and the Middle East where corrosion resistance is critical.

B2B Considerations: Buyers should verify compliance with ASTM B139 or equivalent standards. The higher cost is often justified by longer service life and reliability, which is important for large-scale commercial projects in Europe and South America.

3. Stainless Steel (with Conductive Coating)

Key Properties: Stainless steel offers exceptional corrosion resistance and mechanical strength but has lower electrical conductivity compared to copper and its alloys. Conductive coatings (e.g., silver or gold plating) are applied to enhance electrical performance.

Pros: Stainless steel connectors are highly durable and resistant to environmental degradation, ideal for harsh climates such as desert regions in the Middle East or tropical zones in Africa and South America. They provide excellent mechanical protection to the LED strip connections.

Cons: The lower inherent conductivity requires conductive coatings, which add to manufacturing complexity and cost. Stainless steel connectors tend to be heavier and less flexible, potentially limiting their use in compact or highly flexible lighting designs.

Impact on Application: Best used in applications where environmental exposure and mechanical robustness outweigh the need for maximum electrical efficiency, such as outdoor signage or architectural lighting.

B2B Considerations: International buyers should ensure coatings meet standards like ASTM B488 for plating quality. The material’s robustness aligns well with infrastructure projects in emerging markets and regions with extreme weather conditions.

4. Polycarbonate (with Embedded Metal Contacts)

Key Properties: Polycarbonate is a durable, lightweight plastic often used for the housing of U-shape connectors, combined with embedded metal contacts for electrical conduction.

Pros: Offers excellent insulation, resistance to impact, and high-temperature tolerance (up to around 120°C). Polycarbonate housings reduce the risk of short circuits and enhance user safety. The material is cost-effective and easy to mold into complex shapes, enabling versatile connector designs.

Cons: The electrical performance depends heavily on the quality of embedded contacts, which may vary. Plastic components may degrade under prolonged UV exposure unless treated, limiting outdoor use without additional protection.

Impact on Application: Ideal for indoor lighting installations, especially in commercial and residential projects across Europe and South America where safety and design flexibility are priorities.

B2B Considerations: Buyers should check for compliance with UL94 (flammability) and IEC 60695 standards. Polycarbonate connectors are favored in markets with strict electrical safety regulations, such as the EU, and are increasingly popular in Africa and the Middle East for cost-sensitive projects.

| Material | Typical Use Case for cob led strip connector u shape | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper (Plated) | High-current indoor/outdoor lighting requiring excellent conductivity | Superior electrical and thermal conductivity | Prone to oxidation without plating; moderate cost fluctuations | Medium |

| Phosphor Bronze | Industrial and coastal outdoor lighting with vibration exposure | High mechanical strength and corrosion resistance | Higher cost and complex manufacturing | High |

| Stainless Steel | Harsh environment applications needing mechanical durability | Exceptional corrosion resistance and strength | Lower conductivity requiring costly coatings | High |

| Polycarbonate | Indoor lighting with safety and design flexibility requirements | Lightweight, impact-resistant, excellent insulation | Limited outdoor UV resistance; dependent on metal contacts | Low |

This material selection guide equips international B2B buyers with a clear understanding of how each material influences the performance, durability, and cost of U-shape COB LED strip connectors. By aligning material choice with specific environmental conditions and regulatory requirements, buyers from Africa, South America, the Middle East, and Europe can optimize their procurement strategies for reliable and cost-effective lighting solutions.

In-depth Look: Manufacturing Processes and Quality Assurance for cob led strip connector u shape

Manufacturing Processes for U-Shape COB LED Strip Connectors

The production of U-shape COB LED strip connectors involves several critical stages designed to ensure functional integrity, durability, and ease of installation. Each stage employs precise techniques tailored to the specific requirements of the connector’s role in smart lighting systems.

1. Material Preparation

Material selection is foundational. Typically, high-quality copper alloys are chosen for the conductive pins due to their excellent electrical conductivity and corrosion resistance. The connector housing is often made from durable, heat-resistant plastics such as polycarbonate (PC) or polybutylene terephthalate (PBT), which provide insulation and mechanical protection.

During preparation, raw materials undergo cleaning and surface treatment processes to remove impurities and enhance bonding. For copper parts, electroplating with tin or nickel is common to improve solderability and prevent oxidation, a key consideration for long-term reliability.

2. Forming and Component Fabrication

The metallic pins and contacts are formed using precision stamping or progressive die-cutting techniques. These processes allow for high-volume production with tight tolerances, ensuring consistent pin alignment and fit within the connector housing.

Plastic components are typically produced via injection molding. This method allows for complex shapes, including the U-shape profile, to be created with repeatability and precision. Mold design is critical to prevent defects such as warping or incomplete filling, which can compromise connector performance.

3. Assembly

Assembly integrates the metal contacts into the plastic housing. Automated or semi-automated insertion machines are often employed to maintain accuracy and speed. The U-shape design requires careful alignment to ensure that the connector securely grips the LED strip without damaging the delicate COB surface.

Some manufacturers incorporate ultrasonic welding or snap-fit mechanisms to join housing parts without additional adhesives, enhancing durability and facilitating repair or replacement.

4. Finishing and Surface Treatment

Final finishing steps include cleaning to remove any residual manufacturing debris and applying protective coatings if needed. For connectors, this may include conformal coatings on metal parts or surface texturing on plastics to improve grip during installation.

Illustrative Image (Source: Google Search)

Packaging is also part of finishing, with anti-static and moisture-resistant materials used to protect connectors during transit, especially important for international shipments to regions with varying climates.

Quality Assurance and Control Protocols

High-quality manufacturing is supported by rigorous quality assurance (QA) and quality control (QC) frameworks, critical for maintaining product reliability in demanding B2B lighting applications.

Relevant International and Industry Standards

- ISO 9001: This global standard for quality management systems ensures manufacturers have consistent processes for product quality and continual improvement.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical equipment, essential for markets in Europe and increasingly in other regions.

- UL Certification: Recognized in North America, often referenced by international buyers for electrical safety.

- IEC Standards (e.g., IEC 60598): Relevant for lighting equipment, covering electrical safety and performance.

- Industry-specific certifications: Some markets may require additional certifications, such as API standards for connectors used in industrial lighting applications.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Raw materials and components are inspected for compliance with specifications. This includes verifying metal purity, plastic grade, and dimensional accuracy.

- In-Process Quality Control (IPQC): During assembly, continuous monitoring ensures proper alignment, insertion force, and absence of defects like cracks or incomplete welds.

- Final Quality Control (FQC): Completed connectors undergo thorough inspections including visual checks, dimensional measurement, and functional tests.

Common Testing Methods

- Electrical Continuity and Resistance Testing: Verifies that connectors provide low-resistance, stable electrical paths to prevent voltage drops.

- Mechanical Durability Tests: Simulate repeated insertion/removal cycles to assess connector lifespan.

- Environmental Testing: Includes thermal cycling, humidity exposure, and salt spray tests to ensure performance under varying climatic conditions.

- Insulation Resistance Testing: Confirms that the plastic housing effectively isolates electrical contacts.

- Visual Inspection with Microscopy: Detects micro-cracks or surface defects that could affect performance.

Verification Strategies for B2B Buyers

For international B2B buyers—especially from Africa, South America, the Middle East, and Europe—due diligence in supplier QC verification is crucial to mitigate risks related to quality, compliance, and delivery.

Supplier Audits

Conducting on-site or remote audits helps verify that manufacturers adhere to documented processes and maintain certified quality systems. Audits should cover:

- Factory production lines and equipment

- Quality management documentation

- Staff training and certification

- Calibration records for measurement instruments

Review of QC Documentation

Request comprehensive QC reports including:

- Material certificates (e.g., RoHS compliance)

- Inspection and test records for each production batch

- Non-conformance and corrective action reports

- Third-party laboratory test results, if applicable

Third-Party Inspection and Certification

Engaging independent inspection agencies can provide unbiased verification. This may include:

- Pre-shipment inspections to check conformity and packaging

- Sample testing at accredited labs for electrical and mechanical properties

- Verification of certifications authenticity

QC and Certification Nuances for Different Regions

- Africa and South America: Buyers should ensure suppliers comply with international standards due to varying local regulatory environments. Emphasis on durability testing is important given environmental challenges like humidity and dust.

- Middle East: High ambient temperatures require connectors with robust thermal resistance; confirm environmental testing is part of QC.

- Europe (e.g., Spain): Strict adherence to CE and RoHS directives is mandatory. Buyers should verify up-to-date certifications and compliance statements.

- Southeast Asia (e.g., Indonesia): Import regulations may require specific certifications or testing; local standards can differ, so international certifications like ISO 9001 and CE are often preferred.

Conclusion

Understanding the manufacturing and quality assurance processes behind U-shape COB LED strip connectors empowers B2B buyers to make informed procurement decisions. Prioritizing suppliers with transparent, certified QC systems and robust manufacturing capabilities ensures reliable, high-performance connectors that meet diverse international market requirements. Rigorous verification through audits, documentation review, and third-party inspections mitigates risk and supports long-term partnerships across Africa, South America, the Middle East, and Europe.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for cob led strip connector u shape Sourcing

Understanding the cost and pricing dynamics of U-shape COB LED strip connectors is crucial for international B2B buyers aiming to optimize procurement strategies while ensuring product quality and supply reliability. This analysis breaks down key cost components, price influencers, and strategic buyer tips tailored to markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in U-Shape COB LED Strip Connector Manufacturing

-

Materials

The primary cost driver is the raw materials, including high-grade plastics for the connector housing, copper or other conductive metals for pins, and insulating materials. Material quality directly influences connector durability and electrical performance, impacting buyer satisfaction and warranty claims. -

Labor

Labor costs vary widely by manufacturing location. Countries with skilled yet cost-effective labor pools (e.g., Southeast Asia) can offer competitive pricing. Labor also covers assembly, quality checks, and packaging. -

Manufacturing Overhead

Overhead includes factory utilities, equipment depreciation, and administrative expenses. Efficient factories with modern automated assembly lines tend to have lower overhead per unit. -

Tooling and Setup Costs

Initial tooling for producing U-shape connectors, such as molds and stamping dies, can be significant but amortized over large production runs. Custom designs or specifications increase tooling expenses. -

Quality Control (QC)

QC ensures connectors meet electrical safety standards and performance benchmarks. This includes inspection, testing, and certification processes, which add to unit costs but reduce defective returns. -

Logistics and Shipping

Shipping costs depend on distance, weight, packaging size, and chosen Incoterms. For international buyers, especially in Africa and South America, logistics can be a substantial part of the total cost due to longer transit times and customs duties. -

Supplier Margin

Supplier pricing includes a profit margin that reflects market positioning, brand reputation, and after-sales service.

Influential Factors Affecting Price Variability

-

Volume and Minimum Order Quantity (MOQ)

Larger orders typically benefit from lower per-unit costs due to economies of scale. Buyers from emerging markets should negotiate MOQ to balance inventory risks with cost savings. -

Specification and Customization

Custom U-shape connectors with special dimensions, pin configurations, or certifications (e.g., RoHS, CE) increase costs. Standardized products tend to be more affordable and readily available. -

Material Grade and Certification

Higher-grade materials and compliance with international standards add to cost but improve longevity and reduce operational risks. -

Supplier Reliability and Location

Suppliers closer to the buyer’s region (e.g., Europe for Spanish buyers) may offer faster delivery and easier communication but might carry higher unit prices compared to Asian manufacturers. -

Incoterms and Payment Terms

Pricing can vary significantly depending on whether terms are FOB, CIF, DDP, etc. Understanding these terms helps buyers anticipate and manage additional costs like import duties and inland transport.

Strategic Buyer Tips for Cost-Efficient Sourcing

-

Negotiate on Volume and Payment Terms

Secure discounts through volume commitments or flexible payment schedules. Consider consignment or staged payments to improve cash flow. -

Evaluate Total Cost of Ownership (TCO)

Look beyond unit price to include installation time savings (e.g., solderless U-shape connectors reduce labor), warranty support, and potential rework costs. A slightly higher upfront cost may yield long-term savings. -

Leverage Local and Regional Suppliers

For African, Middle Eastern, and South American buyers, sourcing from regional hubs can reduce lead times and logistics complexities, mitigating risks related to customs delays or shipping disruptions. -

Request Samples and Certifications Early

Testing samples ensures compatibility and quality before large-scale purchase. Certifications are crucial for compliance with local electrical safety regulations and can prevent costly market entry issues. -

Understand Pricing Nuances by Region

Currency fluctuations, import tariffs, and local taxes can influence final costs. Buyers in Europe or South America should factor in VAT or import duties, while African buyers might face varied customs regimes depending on their country.

Indicative Pricing Disclaimer

Prices for U-shape COB LED strip connectors can vary widely based on specifications, order volume, and supplier location. As a guideline, unit prices may range from $0.10 to $0.50 USD per connector at scale, excluding shipping and taxes. Buyers should engage directly with suppliers for tailored quotations reflecting current market conditions.

By carefully analyzing these cost elements and price influencers, international B2B buyers can strategically source U-shape COB LED strip connectors that balance affordability, quality, and supply chain efficiency, enabling successful lighting projects across diverse global markets.

Spotlight on Potential cob led strip connector u shape Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cob led strip connector u shape’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cob led strip connector u shape

Critical Technical Properties of U-Shape COB LED Strip Connectors

Understanding the key technical properties of U-shape COB LED strip connectors is vital for international B2B buyers aiming to source reliable and compatible components for lighting projects. These properties impact installation efficiency, durability, and overall system performance.

-

Material Grade and Durability

High-quality connectors are typically made from robust plastics such as polycarbonate or ABS combined with corrosion-resistant metals like copper or tin-plated contacts. This ensures longevity and stable electrical conductivity. For buyers in humid or harsh environments (e.g., coastal Africa or Middle Eastern markets), selecting connectors with superior material grades prevents premature failure and reduces maintenance costs. -

Tolerance and Fit Precision

The connectors must maintain tight manufacturing tolerances to ensure a secure fit with COB LED strips. Precision in dimensions guarantees proper alignment of pins and contacts, which is crucial to avoid electrical shorts or intermittent connections. Buyers should verify supplier quality control standards to minimize installation issues and returns. -

Current and Voltage Ratings

U-shape connectors are designed to handle specific maximum current and voltage thresholds, often ranging from 12V to 24V DC systems common in LED applications. Exceeding these limits can cause overheating or connector damage. Buyers must match connectors to the power requirements of their COB LED strips to ensure safe and reliable operation. -

Solderless Connection Capability

One of the standout features is the solderless design, enabling quick and tool-free installation. This reduces labor costs and technical skill requirements, especially beneficial for markets with limited access to specialized electricians. Confirming the connector’s compatibility with solderless installation methods can accelerate project timelines. -

Pin Configuration and Compatibility

U-shape connectors come with varying pin counts (e.g., 2-pin for single color, 4-pin for RGB) tailored to different COB LED strip types. Accurate matching prevents wiring errors and functionality issues. Buyers should request detailed pinout specifications to ensure seamless integration with their lighting systems. -

Environmental Resistance

Depending on the application, connectors may need to be rated for water resistance (IP65 or higher) or UV resistance for outdoor installations. International buyers should consider these ratings when sourcing connectors for exterior or industrial use to guarantee performance under diverse climatic conditions.

Common Trade Terminology for International Buyers

Navigating global B2B transactions involves familiarity with key trade terms that influence procurement, pricing, and logistics. Below are essential terms for buyers of U-shape COB LED strip connectors:

-

OEM (Original Equipment Manufacturer)

Refers to products manufactured by a company that may be rebranded or customized by another company for resale. Buyers seeking private-label solutions or specific branding should clarify OEM capabilities with suppliers to align with their market strategies. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. Understanding MOQ is critical for budgeting and inventory planning, especially for small or emerging businesses in regions like South America or Africa where cash flow and storage space might be limited. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for detailed pricing, lead times, and terms based on specified product requirements. Precise RFQs enable buyers to compare offers transparently and negotiate better deals. -

Incoterms (International Commercial Terms)

Standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free On Board), CIF (Cost, Insurance, Freight), and EXW (Ex Works). Clear understanding prevents misunderstandings in cost allocation and delivery obligations. -

Lead Time

The period from order placement to product delivery. In global sourcing, lead times can vary widely due to manufacturing schedules and shipping logistics. Buyers should factor lead times into project timelines to avoid costly delays. -

Certification and Compliance

Certifications such as CE, RoHS, or UL indicate adherence to safety and environmental standards. For buyers in Europe and other regulated markets, verifying certifications is essential to ensure product acceptance and legal compliance.

By focusing on these technical properties and trade terms, international B2B buyers can make informed purchasing decisions, optimize supply chain efficiency, and secure high-quality U-shape COB LED strip connectors tailored to their specific market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cob led strip connector u shape Sector

Market Overview & Key Trends

The global market for COB LED strip connectors, particularly U-shape variants, is experiencing significant growth driven by the expanding adoption of smart lighting solutions across commercial, residential, and industrial sectors. Key market drivers include the increasing demand for energy-efficient lighting, rapid urbanization, and the rise of IoT-enabled smart infrastructure, which is especially prominent in regions such as Europe, the Middle East, Africa, and South America. For international B2B buyers, understanding regional nuances is critical: African markets often prioritize cost-effective, durable components suitable for harsh environments; South American buyers seek versatile connectors that support diverse lighting designs amid growing infrastructure projects; meanwhile, European and Middle Eastern buyers emphasize high-quality, compliant products that integrate with advanced smart lighting systems.

Emerging sourcing trends highlight the shift towards solderless U-shape COB LED connectors, which facilitate faster installation and reduce dependency on specialized labor, a critical factor in markets with limited technical expertise. The flexibility of these connectors to accommodate various LED types—RGB, single color, and CCT COB strips—makes them appealing for custom lighting configurations, from hospitality to retail environments. Additionally, the rise of modular lighting systems encourages suppliers to innovate connectors that support scalability and easy maintenance, aligning with the demand for adaptable, upgradeable lighting infrastructures.

For B2B buyers, leveraging regional manufacturing hubs—such as Southeast Asia for competitive pricing and Europe for cutting-edge technology—can optimize procurement strategies. Strategic partnerships with suppliers offering quick-turnaround and localized support further enhance supply chain resilience, especially in light of recent global disruptions. Moreover, buyers increasingly seek connectors that comply with international standards, ensuring interoperability and safety across diverse markets.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration in the procurement of COB LED strip connectors, with international buyers placing growing emphasis on environmental impact and ethical sourcing practices. The production of LED connectors involves raw materials such as metals and plastics, whose extraction and manufacturing can contribute to pollution and resource depletion. Therefore, B2B buyers from Africa, South America, the Middle East, and Europe are prioritizing suppliers who adopt eco-friendly materials—such as recycled plastics and lead-free metals—and who implement energy-efficient manufacturing processes.

Ethical supply chain management is equally critical. Buyers are increasingly scrutinizing suppliers for compliance with labor standards, transparency, and responsible sourcing of conflict-free minerals. Certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and ISO 14001 environmental management standards are becoming baseline requirements. These certifications assure buyers that the products meet stringent environmental and safety regulations, which is especially important for European and Middle Eastern markets with rigorous compliance frameworks.

Incorporating sustainability into procurement not only addresses regulatory and reputational risks but also aligns with global corporate social responsibility (CSR) goals. Green COB LED strip connectors, designed to minimize energy consumption and reduce waste through modularity and durability, appeal to buyers focused on long-term cost savings and environmental stewardship. For B2B buyers, partnering with suppliers who demonstrate transparent sustainability reporting and who actively pursue innovations in biodegradable or recyclable connector components can create a competitive advantage in increasingly eco-conscious markets.

Evolution and Industry Context

The evolution of COB LED strip connectors, particularly the U-shape design, reflects broader advancements in lighting technology and installation methodology. Initially, LED strip connections relied heavily on soldering, which was time-consuming and required skilled labor. The introduction of solderless U-shape connectors revolutionized the sector by enabling quick, secure, and tool-free assembly, significantly reducing installation time and costs. This innovation has been pivotal in accelerating the adoption of LED strip lighting in commercial and residential projects globally.

Over time, the U-shape COB LED strip connector has evolved to support a wide range of LED technologies—from single-color to RGB and CCT COB strips—offering greater versatility to designers and installers. This adaptability has made them indispensable in smart lighting ecosystems, where customization and seamless integration are paramount. For international B2B buyers, understanding this evolution highlights the importance of selecting connectors that not only meet current technical requirements but also offer scalability for future lighting innovations.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of cob led strip connector u shape

-

How can I effectively vet suppliers of U-shape COB LED strip connectors for international B2B purchases?

To vet suppliers thoroughly, start by verifying their business licenses and certifications related to electronics and lighting components. Request detailed product specifications, including compliance with international standards (e.g., CE, RoHS). Ask for samples to test quality and compatibility with your LED strips. Check customer reviews and ask for references, especially from buyers in your region such as Africa or Europe. Evaluate their production capacity and after-sales support. Using platforms that offer trade assurance and escrow payment options also adds security to your transaction. -

Is customization available for U-shape COB LED strip connectors, and what should I consider when requesting custom designs?

Yes, many manufacturers offer customization such as different pin configurations, connector sizes, or materials to suit specific COB LED strip types (RGB, single color, or CCT). When requesting customization, clearly communicate your technical requirements, including voltage, current ratings, and strip width. Confirm minimum order quantities (MOQs) and lead times for custom orders. Also, ensure that customized connectors comply with safety and quality standards relevant to your market, especially if you intend to sell in regions with strict regulations like the EU. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international orders of U-shape COB LED strip connectors?

MOQs vary widely depending on the supplier, often ranging from 500 to 5,000 units for standard connectors, with higher quantities for custom orders. Lead times typically range from 2 to 6 weeks, depending on customization and production backlog. Payment terms commonly include 30% upfront deposit and 70% balance before shipment, but some suppliers offer flexible terms like letter of credit or escrow services, which provide additional security for international buyers. Always clarify these terms upfront to align with your procurement schedule and cash flow. -

What quality assurance (QA) measures and certifications should I demand to ensure reliable U-shape COB LED strip connectors?

Insist on suppliers providing quality assurance documents such as ISO 9001 certification and product-specific certificates like CE (Europe), RoHS (hazardous substances compliance), and UL (safety standards). Request batch testing reports for electrical performance, durability, and connectivity reliability. QA inspections before shipment, including visual and functional tests, help minimize defective units. For B2B buyers in regions like Africa and the Middle East, confirming compliance with local import regulations and certifications is essential to avoid customs delays or product rejections. -

How can I optimize logistics and shipping for U-shape COB LED strip connectors when importing from Asia to regions like South America or Europe?

Choose suppliers experienced with international shipping and familiar with Incoterms like FOB or CIF to clearly define delivery responsibilities. Opt for consolidated shipments to reduce freight costs, especially for smaller orders. Consider transit times and customs clearance procedures specific to your destination country; partnering with freight forwarders who specialize in electronics can streamline this process. Ensure packaging protects connectors from moisture and mechanical damage during transit. Tracking shipments and purchasing insurance are advisable to mitigate risks of loss or damage. -

What strategies can help resolve disputes with suppliers over quality or delivery issues in international B2B transactions?

Maintain clear communication with documented agreements covering product specifications, delivery schedules, and quality standards. In case of disputes, promptly provide evidence such as photos, test reports, and inspection records. Engage suppliers in constructive dialogue to negotiate remedies like replacements or refunds. Utilize third-party inspection services for objective assessments. If needed, leverage dispute resolution mechanisms provided by trade platforms or international arbitration bodies. Building long-term relationships with reliable suppliers reduces dispute risks and facilitates smoother conflict resolution. -

Are there specific considerations for sourcing U-shape COB LED strip connectors in terms of compatibility with regional electrical standards?

Yes, ensure connectors support the voltage and current ratings typical for your target market’s electrical infrastructure (e.g., 220-240V in Europe, 110-120V in parts of South America). Confirm that connectors are compatible with the types of COB LED strips prevalent in your region, whether for residential, commercial, or industrial applications. Additionally, check if connectors meet local safety standards and certifications, as these vary globally and can impact product acceptance and warranty claims. -

How can I assess the total cost of ownership when purchasing U-shape COB LED strip connectors for large-scale projects?

Beyond unit price, consider factors such as installation time savings due to solderless design, reduced labor costs, and lower risk of installation errors. Evaluate warranty terms and supplier support to minimize downtime and maintenance expenses. Factor in shipping costs, customs duties, and potential import taxes relevant to your region. Also, assess the impact of connector quality on LED strip lifespan and energy efficiency, as inferior connectors may cause power losses or early failures, increasing overall project costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cob led strip connector u shape

The U-shape COB LED strip connector represents a pivotal advancement in LED lighting technology, offering international B2B buyers a blend of simplicity, flexibility, and cost-efficiency. For businesses in Africa, South America, the Middle East, and Europe, leveraging these connectors can accelerate project timelines, reduce installation complexities, and enhance the overall quality of lighting solutions. Their solderless design and compatibility with various LED strip types—including RGB and CCT COB—enable tailored lighting configurations that meet diverse commercial and industrial demands.

Strategic sourcing of U-shape connectors should focus on suppliers who guarantee product reliability, compliance with regional electrical standards, and scalable supply chains to support growing market needs. Prioritizing partners with expertise in smart lighting components can also provide valuable technical support and innovation insights, fostering long-term collaboration and competitive advantage.

Looking ahead, the rising adoption of smart lighting and energy-efficient solutions across emerging and mature markets signals increasing demand for versatile connectors like the U-shape COB LED strip connector. International buyers are encouraged to engage proactively with manufacturers and distributors who invest in quality assurance and customization capabilities. By doing so, they position themselves to capitalize on evolving lighting trends and deliver superior lighting experiences that resonate across global markets.