Introduction: Navigating the Global Market for cob led strip

In today’s rapidly evolving lighting industry, COB (Chip-on-Board) LED strips stand out as a transformative technology that offers unparalleled efficiency, brightness, and design flexibility. For international B2B buyers—especially those operating across Africa, South America, the Middle East, and Europe—understanding the nuances of COB LED strips is essential to sourcing high-quality, cost-effective lighting solutions that meet diverse market demands.

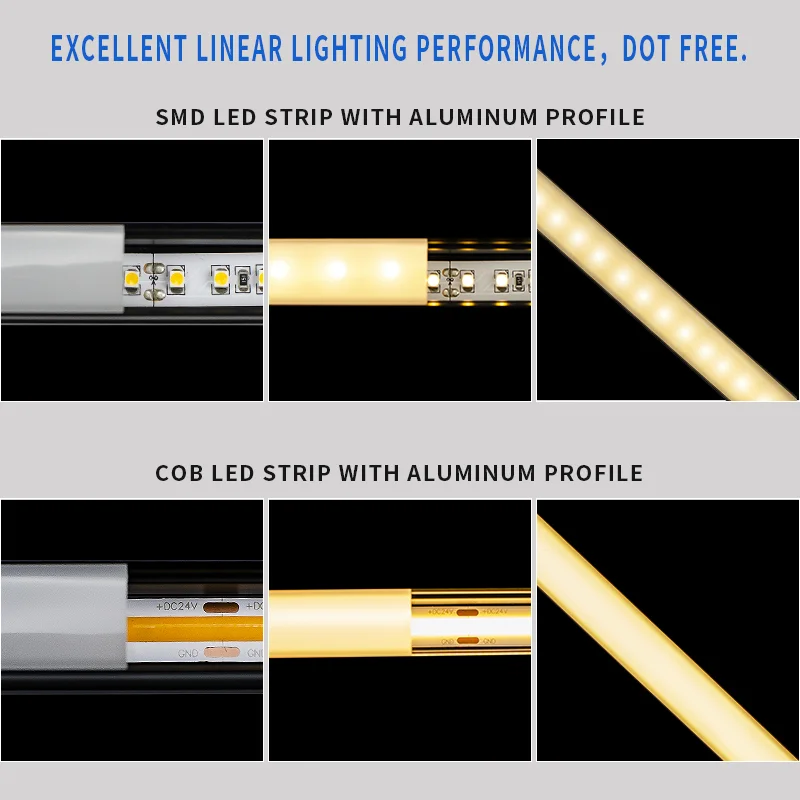

COB LED strips revolutionize traditional lighting by densely integrating multiple LED chips on a single substrate, delivering continuous, uniform illumination without the common hotspots seen in conventional LED strips. This innovation not only enhances light quality but also improves thermal management and energy efficiency, making COB LED strips ideal for a variety of applications, from commercial installations to architectural accent lighting.

This comprehensive guide is designed to equip buyers with critical insights into the types of COB LED strips, materials used, manufacturing processes, and quality control standards that define product reliability and performance. It also explores the global supplier landscape, pricing dynamics, and regional market trends, enabling buyers from emerging and established markets—such as South Africa and Brazil—to make informed decisions that balance quality, cost, and supply chain resilience.

By consolidating expert knowledge and practical advice, this guide empowers international procurement professionals to confidently navigate the complexities of the global COB LED strip market, optimize sourcing strategies, and secure lighting solutions that drive competitive advantage and sustainable growth.

Understanding cob led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard COB LED Strip | High LED chip density, continuous uniform light, flexible design | Retail displays, office lighting, residential ambient lighting | Pros: Excellent color uniformity, energy efficient; Cons: Moderate cost, limited customization on color temperature |

| High CRI COB LED Strip | Enhanced color rendering index (CRI > 90), natural light output | Museums, art galleries, high-end retail | Pros: Superior color accuracy, premium lighting quality; Cons: Higher price, specialized application niche |

| Waterproof COB LED Strip | IP65 to IP67 rated, silicone or epoxy encapsulated | Outdoor signage, architectural lighting, marine environments | Pros: Durable in harsh conditions, versatile outdoor use; Cons: Slightly reduced light output due to encapsulation |

| Tunable White COB LED Strip | Adjustable color temperature from warm to cool white | Healthcare, hospitality, smart buildings | Pros: Flexible lighting ambiance, supports circadian rhythms; Cons: Requires advanced control systems, higher upfront investment |

| High Brightness COB LED Strip | Elevated lumen output per meter, enhanced heat dissipation | Industrial lighting, warehouses, large commercial spaces | Pros: Intense illumination, long lifespan under heavy use; Cons: Higher power consumption, requires robust heat management |

Standard COB LED Strip

Standard COB LED strips are the most commonly used type, featuring a dense array of LED chips mounted on a flexible substrate to deliver smooth, continuous lighting without visible hotspots. This type suits general-purpose applications such as retail displays, office environments, and residential ambient lighting. For B2B buyers, these strips offer a balance of cost-effectiveness and performance, making them ideal for large-scale installations where uniform light quality and energy efficiency are priorities. Buyers should consider the desired color temperature and installation environment to optimize performance.

High CRI COB LED Strip

High CRI COB LED strips are designed to render colors more accurately and naturally, with a color rendering index typically above 90. This makes them indispensable in settings requiring precise color discrimination, such as museums, art galleries, and luxury retail outlets. For B2B buyers, investing in high CRI strips enhances product or artwork presentation, potentially increasing customer engagement. However, these strips come at a premium price and are best suited for projects where color fidelity is a critical factor.

Waterproof COB LED Strip

Waterproof COB LED strips are coated with protective silicone or epoxy encapsulation, providing IP65 to IP67 ratings for resistance against water, dust, and harsh environmental conditions. These strips are essential for outdoor signage, architectural lighting, and marine applications common in regions with humid or rainy climates like parts of South America and the Middle East. B2B buyers should assess the environmental exposure and ensure compatibility with their installation sites. The encapsulation slightly reduces light output but significantly extends durability and lifespan.

Tunable White COB LED Strip

Tunable white COB LED strips allow adjustment of color temperature from warm to cool white, supporting dynamic lighting schemes that enhance occupant comfort and productivity. They are increasingly popular in healthcare facilities, hospitality venues, and smart building projects where circadian rhythm lighting is valued. For B2B buyers, these strips offer flexibility and innovation but require compatible control systems, which may increase initial setup costs. The ability to customize lighting ambiance can be a strong selling point for clients focused on wellness and experience.

High Brightness COB LED Strip

High brightness COB LED strips deliver elevated luminous output with superior heat dissipation mechanisms, making them ideal for industrial environments, warehouses, and large commercial spaces where intense lighting is necessary. These strips support long operational hours and withstand demanding conditions. B2B buyers should consider power supply capacity and thermal management solutions when specifying these strips. Although power consumption is higher, the enhanced brightness and durability justify the investment for applications prioritizing visibility and safety.

Related Video: Choosing The Right COB LED Strip For Your LED Installation

Key Industrial Applications of cob led strip

| Industry/Sector | Specific Application of cob led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Display and accent lighting in stores | Enhances product visibility with uniform, high-quality lighting; attracts customers and increases sales | Ensure consistent color temperature and high CRI; flexible strip length; reliable supplier with quality certifications |

| Architecture & Interior Design | Cove and ambient lighting for premium spaces | Creates seamless, elegant lighting effects; improves aesthetic appeal and customer experience | High durability, heat dissipation, and flexible form factor; compliance with regional electrical standards |

| Automotive & Transportation | Interior and exterior vehicle lighting | Provides energy-efficient, compact, and uniform illumination; enhances safety and design innovation | Robustness against vibration and temperature extremes; long lifespan; compatibility with vehicle power systems |

| Hospitality & Entertainment | Mood and decorative lighting in hotels and venues | Enables customizable ambiance with smooth, continuous light; reduces maintenance costs | Waterproof or IP-rated options; dimmability and control system compatibility; adherence to local safety regulations |

| Industrial & Manufacturing | Task and machine lighting in production lines | Improves worker productivity and safety with bright, glare-free lighting; reduces energy consumption | High thermal management; resistance to dust and moisture; ease of installation and maintenance |

Retail & Commercial Lighting

In retail environments across Africa, South America, the Middle East, and Europe, COB LED strips are widely used to deliver uniform, high-intensity illumination for product displays and accent lighting. Their continuous light output eliminates hotspots, making merchandise more attractive and boosting customer engagement. Buyers must prioritize strips with consistent color temperature and high color rendering index (CRI) to ensure true product colors are visible. Flexible strip lengths and reliable suppliers with international quality certifications are critical for seamless integration into varied retail layouts.

Architecture & Interior Design

Architectural projects benefit from COB LED strips by utilizing their sleek, flexible design for cove and ambient lighting in luxury residential and commercial spaces. These strips provide smooth, continuous illumination that enhances spatial aesthetics and elevates the user experience. For international buyers, especially in regions like South Africa and Brazil, sourcing COB strips with excellent heat dissipation and mechanical flexibility is essential to maintain performance and longevity in diverse climates. Compliance with local electrical standards also ensures safe and efficient installations.

Automotive & Transportation

COB LED strips are increasingly adopted in the automotive sector for interior lighting, dashboard backlighting, and exterior decorative elements. Their compact size and high brightness make them ideal for enhancing vehicle design while improving safety through better visibility. Buyers from emerging automotive markets in the Middle East and South America should focus on products that withstand vibration, temperature fluctuations, and have long operational lifespans. Compatibility with automotive power systems and certifications for automotive use are vital sourcing criteria.

Hospitality & Entertainment

Hotels, restaurants, and entertainment venues leverage COB LED strips to create immersive mood and decorative lighting. The strips’ ability to produce smooth, continuous light lines allows for dynamic ambiance customization, which is crucial for guest satisfaction and brand differentiation. International buyers should seek waterproof or IP-rated COB strips for durability in humid environments and ensure dimmability and compatibility with advanced lighting control systems. Adherence to safety regulations in target markets remains a top priority.

Industrial & Manufacturing

In industrial settings, COB LED strips provide bright, glare-free task lighting that enhances worker productivity and safety on production lines and assembly areas. Their energy efficiency helps reduce operational costs, a key consideration for large-scale manufacturing facilities in Europe and Africa. Buyers must prioritize COB LED strips with superior thermal management and resistance to dust and moisture. Easy installation and maintenance are also critical to minimize downtime and support continuous industrial operations.

Related Video: LED Flasher Circuit

Strategic Material Selection Guide for cob led strip

Aluminum Substrate

Key Properties: Aluminum substrates offer excellent thermal conductivity (typically around 2.0 W/cm·K), good mechanical strength, and moderate corrosion resistance. They can withstand operating temperatures up to approximately 120°C and are highly effective in dissipating heat generated by COB LED chips.

Pros & Cons: Aluminum substrates are cost-effective and widely available, making them a popular choice for mass production. Their superior heat dissipation enhances LED lifespan and performance. However, aluminum is prone to oxidation and corrosion if not properly coated or anodized, which can affect long-term reliability in humid or coastal environments.

Impact on Application: Aluminum substrates are ideal for general lighting applications requiring efficient thermal management, such as commercial and residential LED strips. They perform well in dry to moderately humid climates but may require protective coatings for harsh environments.

International B2B Considerations: Buyers in regions like South Africa and Brazil should ensure substrates meet ASTM B209 or equivalent standards for aluminum alloys to guarantee quality and durability. In the Middle East and Europe, anodized aluminum with compliance to DIN 17611 or EN 573 standards is preferred for enhanced corrosion resistance. Aluminum substrates are widely accepted and compatible with existing manufacturing processes globally.

Ceramic Substrate (Alumina)

Key Properties: Alumina ceramic substrates exhibit excellent thermal conductivity (~25-30 W/m·K), outstanding electrical insulation, and high resistance to thermal shock and corrosion. They maintain stability at elevated temperatures exceeding 200°C.

Pros & Cons: Ceramic substrates provide superior heat dissipation and electrical insulation, which enhances COB LED reliability and performance in high-power applications. They are more expensive and brittle compared to aluminum, increasing manufacturing complexity and risk of damage during assembly.

Impact on Application: Ceramic substrates are well-suited for high-performance, high-temperature applications such as industrial lighting and outdoor installations in harsh environments. Their chemical inertness makes them compatible with aggressive cleaning agents and corrosive atmospheres.

International B2B Considerations: European buyers often require compliance with EN 60601 for electrical safety and ISO 9001 manufacturing standards. Buyers in South America and Africa should verify suppliers’ adherence to ASTM C799 for ceramic materials. The higher cost and fragility necessitate careful logistics and handling, especially for long-distance shipping.

Flexible Polyimide (PI) Substrate

Key Properties: Polyimide substrates offer excellent flexibility, moderate thermal conductivity (~0.12 W/m·K), and high thermal stability up to 260°C. They resist chemical corrosion and have good dielectric properties.

Pros & Cons: PI substrates enable flexible COB LED strips that can be bent or shaped for curved or irregular surfaces, expanding design possibilities. However, their lower thermal conductivity compared to metals limits heat dissipation, potentially reducing LED lifespan under high power.

Impact on Application: Ideal for architectural lighting, automotive interiors, and wearable devices where flexibility and lightweight design are critical. Less suitable for high-heat or outdoor environments unless combined with additional heat sinking.

International B2B Considerations: Compliance with UL 94 V-0 flammability rating and IEC 60216 thermal aging standards is important for buyers in Europe and the Middle East. South American and African markets may prioritize cost-effective flexible substrates but should ensure suppliers meet RoHS and REACH regulations for environmental compliance.

Stainless Steel Substrate

Key Properties: Stainless steel substrates provide excellent mechanical strength, corrosion resistance, and moderate thermal conductivity (~15 W/m·K). They withstand high temperatures and harsh environmental conditions without degradation.

Pros & Cons: Stainless steel is highly durable and corrosion-resistant, suitable for rugged or outdoor applications. However, it is heavier and more expensive than aluminum and ceramic, and its thermal conductivity is lower than aluminum, which may affect heat dissipation efficiency.

Impact on Application: Best suited for industrial, marine, or outdoor lighting where mechanical robustness and corrosion resistance are paramount. Not typically used for flexible COB LED strips due to rigidity.

International B2B Considerations: Buyers in the Middle East and coastal regions (e.g., South Africa) value stainless steel for its corrosion resistance against saltwater exposure. Compliance with ASTM A240 or EN 10088 standards is critical. European buyers may require certification for food-grade or medical-grade stainless steel depending on application.

| Material | Typical Use Case for cob led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General lighting, residential & commercial | Excellent thermal conductivity, cost-effective | Susceptible to corrosion without coating | Low |

| Ceramic (Alumina) | High-power industrial & outdoor lighting | Superior heat dissipation and electrical insulation | Brittle and higher manufacturing complexity | High |

| Polyimide (PI) | Flexible lighting, automotive, architectural | Flexibility and high thermal stability | Lower thermal conductivity limits heat dissipation | Medium |

| Stainless Steel | Industrial, marine, outdoor rugged lighting | High corrosion resistance and mechanical strength | Heavier, more expensive, lower thermal conductivity | High |

In-depth Look: Manufacturing Processes and Quality Assurance for cob led strip

Manufacturing Process of COB LED Strips

The production of COB LED strips is a sophisticated process that integrates precision engineering with advanced material science to achieve superior light quality and durability. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—it is essential to understand each manufacturing stage to evaluate suppliers effectively.

1. Material Preparation

- Substrate Selection and Treatment: The substrate, commonly aluminum or ceramic, is chosen for its excellent thermal conductivity and mechanical stability. This ensures efficient heat dissipation, critical for LED longevity. The substrate undergoes thorough cleaning and surface treatment to enhance adhesion for subsequent layers.

- LED Chips Sourcing: High-quality LED chips from reputable manufacturers are procured. The chips’ performance characteristics—such as brightness, color temperature, and power consumption—must align with the product specifications.

- Phosphor and Encapsulation Materials: For white light COB LED strips, phosphor coatings are prepared, typically using yttrium aluminum garnet (YAG). Encapsulation materials, often silicone or epoxy resins, are selected for their protective qualities and light-transmitting properties.

2. Forming and Chip Mounting

- High-Precision Pick-and-Place: Automated machines place multiple LED chips onto the prepared substrate with micron-level accuracy. This stage defines the LED density and layout, which directly influences light uniformity and intensity.

- Wire Bonding: Fine gold or aluminum wires connect the LED chips electrically. This bonding ensures consistent current flow across all chips and is critical for the stable operation of the strip.

- Encapsulation: The mounted chips and wire bonds are coated with a protective resin. This layer shields the LEDs from moisture, dust, and mechanical damage while enhancing light extraction efficiency.

3. Phosphor Coating (for White Light Strips)

- Uniform Application: A uniform phosphor layer is applied over the encapsulated chips to convert blue LED light to white light. Precise control during this stage ensures color consistency and prevents color shifts over time.

4. Singulation and Assembly

- Cutting to Size: The large substrate is singulated into strips of specified lengths, maintaining electrical connectivity and mechanical integrity.

- Attachment of Backing and Connectors: Adhesive backing is applied for easy installation. Connectors or solder pads are attached, enabling flexible integration into lighting systems.

- Optional Components: Depending on client requirements, additional elements such as heat sinks, lenses, or diffusers may be assembled to enhance performance or aesthetics.

5. Finishing and Packaging

- Visual Inspection: Each strip undergoes inspection for defects such as misaligned chips, poor encapsulation, or physical damage.

- Protective Packaging: Strips are packaged using anti-static, moisture-resistant materials to preserve product quality during transportation and storage.

Quality Assurance and Control in COB LED Strip Production

Robust quality assurance (QA) and quality control (QC) systems are paramount for maintaining product reliability and meeting international standards. B2B buyers should prioritize suppliers who implement comprehensive QC protocols and comply with relevant certifications.

Relevant International and Industry Standards

- ISO 9001: This is the foundational quality management system standard globally recognized across industries. Suppliers certified with ISO 9001 demonstrate consistent production quality and continuous improvement processes.

- CE Marking (Europe): Indicates compliance with EU safety, health, and environmental requirements, critical for European markets.

- RoHS Compliance: Restricts hazardous substances in electrical products, often mandatory for Europe and increasingly adopted worldwide.

- Other Regional Certifications: For example, INMETRO in Brazil and SASO in Saudi Arabia enforce product safety and quality, influencing acceptance in South America and the Middle East.

- Industry-Specific Standards: Depending on application, such as API standards for industrial lighting or IEC standards for electrical safety, may apply.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials and components like LED chips, substrates, and encapsulants are inspected for conformity to specifications before production begins. This includes dimensional checks, material certifications, and sample performance testing.

- In-Process Quality Control (IPQC): During production, real-time monitoring ensures correct chip placement, wire bonding integrity, and encapsulation uniformity. Automated optical inspection (AOI) systems frequently verify chip alignment and solder joint quality.

- Final Quality Control (FQC): Completed strips undergo functional testing, including electrical performance, light output measurement, color consistency, and thermal resistance. Visual inspections detect cosmetic defects and packaging integrity is checked.

Common Testing Methods

- Electrical Testing: Verifies current-voltage characteristics, power consumption, and ensures no shorts or opens in circuits.

- Photometric Testing: Measures luminous flux (lumens), color temperature (Kelvin), and color rendering index (CRI) to confirm light quality.

- Thermal Testing: Assesses heat dissipation performance under operational conditions to predict lifespan and reliability.

- Environmental Testing: Includes humidity, temperature cycling, and vibration tests to simulate real-world conditions.

- Durability and Lifespan Testing: Accelerated aging tests estimate the operational lifetime and identify potential failure modes.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, particularly from regions with diverse regulatory environments such as Africa, South America, the Middle East, and Europe, verifying supplier QC practices is crucial to mitigate risks and ensure product consistency.

- Factory Audits: On-site audits or virtual factory inspections evaluate manufacturing capabilities, equipment, personnel expertise, and QC processes. Buyers should request detailed audit reports or conduct third-party audits through recognized agencies.

- Review of QC Documentation: Suppliers should provide comprehensive quality documentation, including process flow charts, inspection records, test reports, and certificates of compliance (ISO, CE, RoHS).

- Third-Party Testing and Certification: Independent laboratories can validate product performance and safety claims. Buyers may require third-party test certificates or arrange for product sampling and testing in their own labs.

- Sample Evaluation: Requesting product samples for in-house testing allows buyers to assess light quality, durability, and installation compatibility before committing to large orders.

- Supplier Quality Agreements: Formal agreements specifying QC requirements, inspection frequencies, and non-conformance handling protocols help align expectations and accountability.

Quality Assurance Nuances for Global B2B Buyers

- Regional Compliance Variations: Buyers in South America (e.g., Brazil) should ensure suppliers meet local standards such as INMETRO, while Middle Eastern buyers may require SASO certification. European buyers prioritize CE and RoHS compliance.

- Logistics and Environmental Conditions: Products shipped to regions with high humidity or temperature fluctuations require additional protective measures and environmental testing to ensure performance upon arrival.

- After-Sales Support: Robust warranty policies and responsive technical support are critical for markets with emerging LED infrastructure, such as parts of Africa and South America.

- Cultural and Communication Considerations: Clear communication regarding specifications, certifications, and QC expectations can prevent misunderstandings and ensure smoother procurement processes.

Summary for B2B Buyers

Understanding the detailed manufacturing processes and rigorous quality assurance protocols behind COB LED strips empowers international buyers to make informed sourcing decisions. Prioritizing suppliers with transparent, certified QC systems and proven manufacturing expertise ensures access to high-performance, reliable lighting products tailored to regional market demands. Engaging in factory audits, demanding thorough documentation, and leveraging third-party testing are key strategies to mitigate risk and secure quality in global B2B transactions.

Related Video: How COB Tape Light Is Made – LED Factory Production Line

Comprehensive Cost and Pricing Analysis for cob led strip Sourcing

Breakdown of Cost Components in COB LED Strip Sourcing

When sourcing COB LED strips, understanding the underlying cost structure is critical for making informed purchasing decisions. The primary cost components include:

- Materials: High-quality LED chips, substrates (often aluminum or ceramic for thermal performance), phosphor coatings, encapsulation resins, and flexible circuit materials constitute the bulk of material costs. Premium materials enhance light quality and durability but increase unit price.

- Labor: Precision assembly, including LED chip placement, wire bonding, and encapsulation, requires skilled labor. Labor costs vary significantly by manufacturing location and impact the final price.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, quality control processes, and operational management. Efficient production lines with automation can reduce overhead costs.

- Tooling and Setup: Initial tooling for custom COB LED strip designs, including substrate patterning and specialized fixtures, adds upfront costs. These are amortized over production volume.

- Quality Control (QC): Rigorous testing for light uniformity, color consistency, and electrical performance is essential, especially for high-spec applications. QC adds to cost but mitigates risks of defective batches.

- Logistics and Shipping: Freight, customs duties, and insurance vary by destination and shipment mode. International buyers must factor in these costs, especially when importing to regions like Africa, South America, the Middle East, and Europe.

- Margin: Suppliers add profit margins which reflect market positioning, brand reputation, and order size.

Key Pricing Influencers for COB LED Strips

Several factors influence the final price of COB LED strips in B2B transactions:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from economies of scale, reducing per-unit cost. Buyers from emerging markets should negotiate MOQs aligned with their inventory capacity and demand.

- Product Specifications and Customization: Custom lengths, color temperatures, beam angles, and IP ratings increase complexity and price. Standardized products are generally more cost-effective.

- Material Quality and Certifications: Certified components (e.g., RoHS, CE, UL) assure compliance and quality but add to costs. Buyers targeting regulated markets in Europe or the Middle East should prioritize certified products.

- Supplier Location and Reliability: Manufacturers in Asia often offer competitive pricing due to scale, but lead times and communication should be considered. Local or regional suppliers might provide faster turnaround at a premium.

- Incoterms and Payment Terms: FOB, CIF, or DDP shipping terms affect cost responsibility. Favorable payment terms (e.g., letters of credit, extended credit) can improve cash flow and reduce financial risks.

Strategic Tips for International B2B Buyers

- Leverage Volume Discounts: Consolidate purchases or collaborate with other buyers to meet MOQ thresholds and unlock better pricing.

- Evaluate Total Cost of Ownership (TCO): Consider not only unit price but also durability, energy efficiency, warranty, and after-sales support. Higher upfront costs can be offset by lower maintenance and replacement expenses.

- Negotiate for Value-Added Services: Request supplier support such as custom packaging, technical consultation, or extended warranties, which can enhance product value without significant price hikes.

- Understand Regional Pricing Nuances: Buyers in Africa, South America, and the Middle East should account for local import taxes, currency fluctuations, and infrastructure limitations that may impact landed cost.

- Verify Supplier Credentials: Conduct due diligence on supplier certifications, factory audits, and customer references to avoid quality and compliance risks.

- Plan for Logistics and Lead Times: Account for potential delays in shipping and customs clearance, especially in regions with complex import regulations, to prevent supply chain disruptions.

Indicative Pricing Disclaimer

COB LED strip prices vary widely based on specifications, order size, and supplier terms. As of mid-2024, typical FOB prices range from approximately $5 to $20 per meter for standard quality strips. Customized or certified products may command premiums. Buyers should obtain multiple quotes and conduct thorough cost comparisons to identify the best value.

By carefully analyzing cost drivers and leveraging negotiation strategies, international B2B buyers can optimize sourcing of COB LED strips to achieve competitive pricing while ensuring product quality and supply reliability tailored to their regional market needs.

Spotlight on Potential cob led strip Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cob led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cob led strip

Critical Technical Properties of COB LED Strips

When sourcing COB LED strips for international markets such as Africa, South America, the Middle East, and Europe, understanding key technical specifications is essential for ensuring product performance and compatibility with your application. Here are the most important properties to evaluate:

-

LED Chip Density (LEDs per Meter)

This indicates how many LED chips are mounted on each meter of the strip. Higher density means brighter, more uniform light output with fewer dark spots. For applications requiring seamless illumination—like retail displays or architectural accents—prioritize strips with a high LED chip density. -

Color Temperature (Kelvin, K)

Color temperature defines the hue of the light emitted, ranging from warm white (~2700K) to daylight (~6500K). Selecting the correct color temperature is vital for ambiance and visual comfort. For example, warm white is preferred in hospitality or residential settings, while cooler tones suit office or industrial environments. -

Luminous Flux (Lumens per Meter)

This measures the total light output per meter. Higher lumens indicate brighter light, critical for task lighting or outdoor applications. Comparing lumens helps buyers assess energy efficiency and ensure the lighting meets project brightness requirements. -

Power Consumption (Watts per Meter)

Power usage affects operational cost and compatibility with power supplies. COB LED strips typically consume between 10 to 30 watts per meter. Lower wattage with high lumens indicates better energy efficiency, a key consideration for cost-conscious buyers. -

Color Rendering Index (CRI)

CRI indicates how accurately the light source reveals colors compared to natural light. A CRI above 80 is good for most commercial uses; above 90 is preferred for retail or medical applications where color fidelity is crucial. -

IP Rating (Ingress Protection)

This rating defines protection against dust and water. For indoor use, IP20 or IP44 may suffice, but outdoor or industrial applications often require IP65 or higher for resistance to moisture and dust ingress.

Common Trade Terms and Industry Jargon

Navigating international B2B transactions can be complex. Familiarity with these key terms will help buyers communicate clearly with suppliers and manage procurement efficiently:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce products or components that are purchased by another company and retailed under that purchasing company’s brand. For buyers, working with OEMs can mean access to customized COB LED strips tailored to specific project needs. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell. MOQs vary widely, especially for custom COB LED strips. Buyers should negotiate MOQs aligned with budget and project scale to avoid excess inventory or prohibitive upfront costs. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers asking for pricing and terms on specific products. Preparing detailed RFQs with clear technical specifications expedites accurate quotes and reduces misunderstandings. -

Incoterms (International Commercial Terms)

A set of globally recognized trade terms defining responsibilities for shipping, insurance, and tariffs between buyer and seller. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms helps buyers manage logistics and cost allocation effectively. -

Lead Time

The period from order confirmation to product delivery. For COB LED strips, lead times can vary based on customization and supplier location. Planning procurement around lead times prevents project delays. -

Binning

The process of sorting LED chips by brightness, color, and voltage characteristics. Consistent binning ensures uniform light quality and performance, which is critical for large-scale installations requiring color consistency.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions, streamline supplier communications, and optimize procurement strategies for COB LED strips tailored to diverse market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cob led strip Sector

Market Overview & Key Trends

The global COB (Chip-on-Board) LED strip market is experiencing rapid growth, driven by increasing demand for energy-efficient, high-quality lighting solutions across commercial, industrial, and residential sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are capitalizing on this momentum to modernize infrastructure, enhance retail and architectural lighting, and promote smart city projects. Countries like South Africa and Brazil are investing heavily in LED technology as part of broader energy conservation and urban development initiatives.

Illustrative Image (Source: Google Search)

Key market drivers include the superior light uniformity, high energy efficiency, and compact design of COB LED strips, which outperform traditional LED strips in both performance and lifespan. For B2B buyers, sourcing trends emphasize higher LED chip density and improved thermal management to ensure durability and consistent light output, crucial for demanding applications such as retail displays, hospitality, and automotive lighting. The flexibility of COB LED strips—allowing installation on curved or narrow surfaces—is also fueling adoption in innovative lighting designs.

Emerging trends for buyers focus on integrated smart lighting solutions that support IoT-enabled controls and adaptive lighting environments. Additionally, supply chain diversification is a priority, as businesses seek reliable suppliers that can offer scalable production, quality certifications, and competitive pricing. For regions with logistical challenges, partnering with manufacturers that provide local assembly or regional distribution hubs can reduce lead times and costs. Furthermore, the rise of customizable COB LED strips tailored to specific voltage, color temperature, and form factor requirements is helping buyers differentiate their offerings in competitive markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the procurement of COB LED strips, driven by global regulatory pressures and corporate social responsibility goals. The environmental impact of LED manufacturing—primarily energy consumption during production and the use of raw materials such as rare earth elements—necessitates a focus on green manufacturing practices. Buyers are increasingly prioritizing suppliers who demonstrate reduced carbon footprints through energy-efficient production methods and waste minimization.

Ethical sourcing of materials is equally important. This includes ensuring that components such as semiconductor chips and phosphors are procured from conflict-free zones and that labor practices meet international standards. Certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and Energy Star provide buyers with assurance on environmental compliance and product safety.

In addition, the shift towards eco-friendly encapsulation materials such as silicone-based resins over traditional epoxies enhances recyclability and reduces hazardous waste. For international buyers, especially in regions with stringent environmental regulations like the European Union, partnering with manufacturers who maintain transparent supply chains and offer traceability is essential. Leveraging sustainable COB LED strips not only aligns with global sustainability goals but also enhances brand reputation and meets the growing demand from environmentally conscious end-users.

Brief Evolution & Historical Context

COB LED technology emerged as a significant advancement over traditional LED packaging methods in the early 2010s. By mounting multiple LED chips directly onto a single substrate, manufacturers achieved higher LED density, superior thermal management, and more uniform light output. This innovation addressed many limitations of surface-mounted device (SMD) LEDs, such as visible hotspots and complex driver circuitry.

Over the past decade, COB LED strips have evolved from niche industrial applications to mainstream commercial and residential lighting solutions. Advances in substrate materials, such as aluminum and ceramic with enhanced thermal conductivity, and improvements in phosphor coatings have expanded their color rendering capabilities and efficiency. For B2B buyers, understanding this evolution highlights the technology’s maturity and reliability, reinforcing COB LED strips as a future-proof investment in lighting infrastructure.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of cob led strip

-

How can I effectively vet COB LED strip suppliers for international B2B sourcing?

To ensure reliability, conduct thorough due diligence by reviewing supplier certifications (ISO, RoHS, CE), requesting product samples, and verifying manufacturing capabilities. Check for experience exporting to your region (Africa, South America, Middle East, Europe) and ask for client references. Evaluate their quality control processes, including in-house testing and third-party inspections. Utilize platforms with verified supplier profiles and consider visiting factories or hiring local inspection agencies to validate production standards. Transparent communication and responsiveness are key indicators of a trustworthy supplier. -

What customization options are typically available for COB LED strips, and how can I ensure they meet my market’s needs?

Most manufacturers offer customization in LED density, strip length, color temperature, CRI, waterproof rating (IP65, IP67), and flexible substrate materials. Discuss your specific application requirements, such as brightness levels or beam angles, upfront to align expectations. Request prototype samples to validate performance before mass production. Custom packaging and labeling are often available for branding purposes. Tailoring COB LED strips to local regulations and consumer preferences enhances market acceptance and competitive advantage. -

What are the common minimum order quantities (MOQs), lead times, and payment terms when importing COB LED strips?

MOQs vary widely, typically ranging from 500 to 5,000 meters per order depending on customization and supplier scale. Lead times average 3 to 6 weeks, factoring in production and shipping. For new buyers, expect stricter payment terms such as 30-50% upfront deposits with balance on shipment. Established buyers may negotiate net 30 or 60-day terms. To optimize cash flow, clarify payment methods accepted (T/T, L/C, PayPal) and confirm incoterms (FOB, CIF) before placing orders.

Illustrative Image (Source: Google Search)

-

Which quality assurance certifications should I require from COB LED strip suppliers?

Demand suppliers provide internationally recognized certifications like CE (European market), RoHS (hazardous substances compliance), UL or ETL (safety standards), and ISO 9001 (quality management systems). For specific markets, check local regulatory requirements such as SABS in South Africa or INMETRO in Brazil. Request detailed test reports on lumen output, color consistency, and lifespan. Third-party lab testing and factory audits reinforce product reliability and reduce risks of non-compliance or product failure in your target market. -

What logistics considerations are important when importing COB LED strips internationally?

Plan for shipping modes (sea freight is cost-effective but slower; air freight is faster but pricier), customs clearance procedures, and import duties specific to your country. Ensure suppliers provide complete commercial invoices, packing lists, and certificates of origin to avoid delays. Understand hazardous material regulations if applicable and confirm packaging protects against moisture and mechanical damage during transit. Partnering with experienced freight forwarders familiar with your region’s import rules expedites delivery and reduces unexpected costs. -

How can I manage disputes or quality issues with COB LED strip suppliers after order placement?

Establish clear contractual terms covering quality standards, inspection rights, and remedies for defects before ordering. Use third-party quality inspections either pre-shipment or upon arrival to identify issues early. Document all communications and discrepancies with photos and reports. Negotiate resolution options such as partial refunds, replacements, or rework. Having an arbitration clause or involving trade chambers can facilitate dispute resolution. Building long-term supplier relationships with transparent feedback loops minimizes recurring problems. -

Are there specific challenges for B2B buyers in Africa, South America, or the Middle East when sourcing COB LED strips?

Buyers in these regions often face longer lead times due to less frequent shipping routes and customs complexities. Currency fluctuations and payment restrictions may impact transaction ease. Language barriers and time zone differences require proactive communication strategies. Additionally, infrastructure limitations can affect delivery reliability. To mitigate risks, work with suppliers experienced in your region, use local agents for coordination, and plan inventory buffers to avoid stockouts. -

What are best practices for ensuring COB LED strips comply with environmental and safety regulations in Europe?

European markets require strict adherence to directives like RoHS (restricting hazardous substances) and REACH (chemical safety). Ensure your supplier provides compliant certificates and test reports. Verify that products meet CE marking requirements for electrical safety. Stay informed about evolving EU regulations and eco-design standards that may affect product eligibility. Partner with suppliers who prioritize sustainability and can support eco-labeling, which is increasingly valued by European B2B customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cob led strip

COB LED strips represent a transformative advancement in lighting technology, offering unmatched brightness, energy efficiency, and uniform illumination. For international B2B buyers, particularly in emerging and diverse markets across Africa, South America, the Middle East, and Europe, understanding these benefits is crucial for making informed procurement decisions that enhance product offerings and customer satisfaction. Strategic sourcing of COB LED strips involves evaluating suppliers not only on cost but also on quality certifications, thermal management capabilities, and customization options to meet specific regional and application needs.

Key sourcing considerations include:

- Supplier reliability and manufacturing expertise to ensure consistent product performance and compliance with international standards.

- Customization flexibility to adapt COB LED strips to varied installation environments—from architectural to industrial lighting.

- Supply chain resilience to mitigate risks associated with geopolitical or logistical challenges common in cross-continental trade.

Looking ahead, the demand for sustainable, high-performance lighting solutions is set to grow sharply, driven by urbanization and energy efficiency mandates worldwide. B2B buyers who adopt a forward-thinking sourcing strategy today will position themselves as leaders in innovation and value delivery. It is imperative to engage proactively with trusted manufacturers and leverage emerging technologies to unlock new market opportunities. Embrace COB LED technology as a cornerstone of your lighting portfolio to future-proof your business and meet evolving customer expectations globally.