Introduction: Navigating the Global Market for clips for led strip lights

The global demand for LED strip lighting continues to surge, driven by its versatility, energy efficiency, and aesthetic appeal across commercial, residential, and industrial applications. Central to the successful deployment and longevity of these lighting solutions are clips for LED strip lights—small yet indispensable components that secure strips in place, ensure proper alignment, and facilitate flexible installation on diverse surfaces.

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including emerging markets like Argentina and Thailand—understanding the nuances of these clips is crucial. Variations in clip types, materials, and mounting mechanisms can significantly impact installation quality, durability, and compatibility with different LED strip profiles. Additionally, sourcing from reliable manufacturers who adhere to stringent quality control processes ensures product performance and reduces costly installation failures.

This comprehensive guide delves into the full spectrum of clips for LED strip lights, covering:

– Types and designs including adjustable, fixed, and specialty clips

– Material considerations such as plastic, metal, and corrosion-resistant alloys

– Manufacturing and quality assurance standards vital for durability and safety

– Key global suppliers and their regional availability

– Cost factors influencing procurement strategies

– Market trends and emerging innovations shaping future demand

– An extensive FAQ section addressing common concerns and technical queries

Armed with this knowledge, B2B buyers can make informed sourcing decisions that optimize installation efficiency, product longevity, and cost-effectiveness—ultimately delivering superior value to their end customers and strengthening their competitive advantage in a dynamic global marketplace.

Understanding clips for led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Snap-On Clips | Simple plastic or metal clips that snap over LED strips | General indoor installations, retail displays | + Easy to install and cost-effective – Limited adjustability |

| Angle Adjustable Clips | Clips with pivot or hinge allowing angle adjustment | Architectural lighting, corners, uneven surfaces | + Versatile for angled mounting – Slightly higher cost |

| Magnetic Mount Clips | Clips integrated with magnets for metal surface mounting | Temporary setups, trade shows, metal fixtures | + Non-invasive, reusable – Requires ferromagnetic surface |

| Adhesive-Backed Clips | Clips combined with strong adhesive pads | Quick installations on smooth surfaces | + Fast application without drilling – Adhesive may weaken over time |

| Heavy-Duty Metal Clips | Robust metal clips for outdoor or industrial environments | Outdoor signage, industrial lighting, harsh climates | + Durable, withstands weather – Higher price, installation effort |

Standard Snap-On Clips

These clips are the most common and straightforward option, typically made from plastic or lightweight metal. They snap securely over LED strip lights, providing a reliable hold for most flat surface applications. Ideal for large-scale indoor projects such as retail lighting or office installations, they offer a budget-friendly mounting solution. B2B buyers should consider their ease of installation and compatibility with standard strip widths, but note that they lack flexibility for angled or irregular surfaces.

Angle Adjustable Clips

Designed with a pivot mechanism, these clips allow LED strips to be mounted at various angles, accommodating corners, curved surfaces, or architectural features. This flexibility makes them valuable for premium lighting projects in commercial buildings or hospitality venues where aesthetics and precise positioning matter. Buyers targeting sophisticated installations should evaluate these clips for their adaptability and slightly higher cost, balancing it against the enhanced installation options they provide.

Magnetic Mount Clips

Magnetic clips incorporate strong magnets, enabling LED strips to be mounted on ferromagnetic surfaces without drilling or adhesives. This type is especially useful for temporary setups, such as trade shows or exhibitions, and for mounting on metal fixtures. For B2B buyers in event management or metal fabrication sectors, magnetic clips offer convenience and reusability. However, their use is limited to magnetic surfaces, which buyers must verify beforehand.

Adhesive-Backed Clips

These clips come with integrated adhesive pads, often using high-strength tapes like 3M, allowing for rapid installation on smooth surfaces without mechanical fasteners. They are suitable for quick retrofit projects or locations where drilling is prohibited. Buyers in regions with varying climate conditions should assess adhesive longevity and surface compatibility to avoid future detachment issues, especially in humid or dusty environments common in parts of Africa and South America.

Heavy-Duty Metal Clips

Constructed from robust metals such as stainless steel or aluminum, these clips are designed for outdoor or industrial applications where durability against weather, vibration, and mechanical stress is critical. They are ideal for outdoor signage, industrial lighting, or harsh environments in Middle Eastern or European markets with demanding conditions. While offering superior longevity, these clips require more effort during installation and come at a premium price, factors that B2B buyers should weigh against the benefits of long-term reliability.

Related Video: How to Install LED Strip Lights to Connectors and a Power Supply

Key Industrial Applications of clips for led strip lights

| Industry/Sector | Specific Application of clips for led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Secure mounting of LED strips for accent and display lighting | Enhances visual merchandising, increases customer engagement | Durability, aesthetic compatibility, ease of installation, availability in bulk |

| Hospitality & Leisure | Installation in hotel lobbies, restaurants, and bars | Creates ambiance, supports brand image, enables flexible lighting layouts | Corrosion resistance (for humid climates), adjustable clips, compliance with safety standards |

| Industrial & Manufacturing | Fixed positioning of LED strips in machinery and workstations | Improves workspace illumination, enhances safety and productivity | Heat resistance, vibration tolerance, compatibility with industrial LED profiles |

| Architectural & Outdoor Lighting | Mounting LED strips on facades, signage, and landscape features | Weatherproof secure mounting, long-term reliability | Weatherproof materials, UV resistance, strong mechanical hold for outdoor use |

| Automotive & Transportation | Interior and exterior LED strip mounting for vehicles and public transport | Precise, secure fit for dynamic environments, vibration resistance | Lightweight materials, flexibility, high retention strength under motion |

Retail & Commercial Spaces

In retail environments, clips for LED strip lights are essential for securely affixing lighting to shelves, display cases, and signage. These clips ensure that LED strips remain precisely positioned to highlight products and create appealing visual effects that drive customer attention and sales. For B2B buyers in Africa, South America, and Europe, sourcing clips that blend durability with an attractive finish is critical, as installations often require both robustness and aesthetic appeal. Bulk availability and ease of installation reduce labor costs and downtime during fit-outs.

Hospitality & Leisure

Hotels, restaurants, and bars rely on LED strip lighting to create inviting atmospheres. Clips for LED strips in these settings must accommodate frequent changes and adjustments, often requiring angle-adjustable or flexible mounting solutions. For international buyers, especially in humid or coastal regions of the Middle East and South America, corrosion-resistant materials are vital to maintain longevity. Compliance with local electrical and fire safety standards is also a key sourcing consideration, ensuring that installations meet regulatory requirements while delivering ambiance-enhancing lighting.

Industrial & Manufacturing

In industrial settings, LED strip lights improve visibility in workshops, assembly lines, and machinery enclosures. Mounting clips here must withstand heat, vibration, and dust exposure without loosening or degrading. Buyers from regions with heavy manufacturing sectors, such as parts of Europe and South America, should prioritize clips made from heat-resistant and vibration-dampening materials. Compatibility with various LED strip profiles is important to accommodate different industrial lighting configurations, ensuring a secure fit that enhances worker safety and operational efficiency.

Architectural & Outdoor Lighting

For architectural facades, signage, and landscape lighting, clips must provide a secure, weatherproof hold on LED strips exposed to rain, wind, and UV radiation. This is particularly important for buyers in regions with harsh climates, such as the Middle East and parts of Africa. Clips made from UV-stabilized plastics or corrosion-resistant metals extend the lifespan of outdoor lighting installations. Additionally, the mechanical strength of clips ensures that LED strips remain firmly in place over time, reducing maintenance costs and protecting the investment in high-visibility lighting features.

Automotive & Transportation

LED strip lights in vehicles and public transportation require mounting clips that accommodate movement, vibration, and tight installation spaces. Clips must be lightweight yet strong enough to maintain a secure hold during vehicle operation. Buyers in Europe and South America, where automotive customization and public transit upgrades are prevalent, should focus on sourcing clips that offer flexibility and high retention strength. Materials that resist temperature fluctuations and comply with automotive safety standards are also critical to ensure durability and regulatory compliance.

Related Video: How to Install LED Strip Lights

Strategic Material Selection Guide for clips for led strip lights

When selecting materials for clips used in LED strip light installations, international B2B buyers must carefully weigh performance characteristics, cost-effectiveness, and regional compliance requirements. The choice of material directly influences the durability, ease of installation, and long-term reliability of the mounting solution, especially in diverse environments such as those found across Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties: Stainless steel clips offer excellent corrosion resistance, high tensile strength, and can withstand elevated temperatures typically up to 800°C. They maintain structural integrity under mechanical stress and resist oxidation, making them suitable for both indoor and outdoor applications.

Pros & Cons: Stainless steel is highly durable and resistant to environmental degradation, which reduces maintenance costs over time. However, it is relatively expensive and heavier compared to other materials, which can increase shipping costs and complicate installation in large-scale projects. Manufacturing complexity is moderate due to the need for precision stamping or forming.

Impact on Application: Ideal for outdoor or humid environments such as coastal regions in South America or the Middle East, where corrosion resistance is critical. Stainless steel clips are also preferred in industrial settings where mechanical robustness is required.

Regional Considerations: Buyers in Europe and Middle Eastern markets often require compliance with ASTM A240 or DIN EN 10088 standards for stainless steel, ensuring quality and traceability. In Africa and South America, availability and cost may vary, so sourcing from certified suppliers is advisable to meet local regulations and durability expectations.

2. Polycarbonate (PC) Plastic

Key Properties: Polycarbonate clips are lightweight, offer good impact resistance, and can tolerate temperatures up to approximately 135°C. They exhibit excellent electrical insulation properties and moderate UV resistance when treated with additives.

Pros & Cons: Polycarbonate is cost-effective and easy to mold into complex shapes, allowing for versatile clip designs with integrated features such as snap locks or adjustable angles. However, it is less resistant to prolonged UV exposure unless specially coated, which can lead to brittleness and discoloration over time.

Impact on Application: Best suited for indoor LED strip installations or covered outdoor areas where exposure to harsh weather is limited. Its electrical insulation makes it ideal for applications where clips may come into contact with wiring.

Regional Considerations: For buyers in regions with high solar exposure, such as parts of Africa and the Middle East, selecting UV-stabilized polycarbonate is crucial. Compliance with international standards like UL 94 for flammability and ISO 9001 for manufacturing quality is often required in Europe and South America.

3. Aluminum

Key Properties: Aluminum clips provide a good balance of strength, lightweight, and corrosion resistance, withstanding temperatures up to about 250°C. Aluminum’s natural oxide layer offers moderate protection against corrosion, which can be enhanced with anodizing.

Pros & Cons: Aluminum is more affordable than stainless steel and easier to machine or extrude, making it suitable for custom clip profiles. It is lighter, reducing shipping and handling costs. However, it is softer and can deform under high mechanical stress, limiting its use in heavy-duty applications.

Impact on Application: Aluminum clips are well-suited for indoor and semi-outdoor environments, particularly where weight savings are important, such as in large commercial lighting installations. Anodized finishes improve durability in humid climates common in South America and parts of Europe.

Regional Considerations: Buyers should ensure compliance with EN 755 or ASTM B221 standards for aluminum extrusion quality. In markets like Europe and South America, anodized aluminum is often preferred for aesthetic and durability reasons. In Africa and the Middle East, corrosion resistance should be verified based on local environmental conditions.

4. Nylon (Polyamide)

Key Properties: Nylon clips offer excellent flexibility, good mechanical strength, and resistance to chemicals and abrasion. They can tolerate temperatures up to around 120°C and provide natural electrical insulation.

Pros & Cons: Nylon is highly cost-effective and lightweight, with easy manufacturing via injection molding. It performs well in environments requiring vibration resistance. However, nylon can absorb moisture, which may affect dimensional stability and mechanical properties over time.

Impact on Application: Suitable for indoor LED strip installations or controlled environments where moisture exposure is minimal. Its chemical resistance makes it appropriate for industrial settings with exposure to oils or solvents.

Regional Considerations: In humid regions such as parts of South America and Southeast Asia, moisture absorption must be considered; buyers may require nylon grades with low moisture uptake. Compliance with standards like ISO 1874 for polyamide materials ensures consistent quality, especially for European buyers.

| Material | Typical Use Case for clips for led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor, industrial, high-corrosion environments | Superior corrosion resistance and strength | Higher cost and weight | High |

| Polycarbonate | Indoor, electrical insulation, complex clip designs | Lightweight, impact resistant, easy to mold | UV degradation without additives | Medium |

| Aluminum | Indoor and semi-outdoor, lightweight commercial installations | Lightweight with good corrosion resistance | Softer, less mechanical strength | Medium |

| Nylon | Indoor, chemical exposure, vibration-prone environments | Cost-effective, flexible, chemically resistant | Moisture absorption affects stability | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for clips for led strip lights

The manufacturing and quality assurance of clips for LED strip lights are critical factors that directly impact the reliability, durability, and overall performance of LED installations. For international B2B buyers—especially from regions such as Africa, South America, the Middle East, and Europe—understanding these processes ensures informed procurement decisions and helps establish robust supplier partnerships.

Manufacturing Process of Clips for LED Strip Lights

The production of clips for LED strip lights typically involves several key stages, each requiring precision and adherence to industry best practices:

1. Material Preparation

- Selection of Raw Materials: Clips are often made from metals (such as stainless steel or aluminum) or durable plastics (like polycarbonate or ABS). Material choice depends on the required strength, corrosion resistance, and environmental conditions of the installation.

- Material Quality Checks: Incoming raw materials undergo initial inspections to verify chemical composition, mechanical properties, and dimensional accuracy. This step prevents defects downstream.

2. Forming and Shaping

- Metal Clips: For metal clips, processes include stamping, punching, bending, and sometimes CNC machining. Stamping dies are designed to create precise clip profiles that securely hold LED strips without damage.

- Plastic Clips: Injection molding is commonly used for plastic clips. This involves melting plastic pellets and injecting them into molds shaped to exact specifications. Molds must be maintained to ensure consistent clip dimensions.

- Surface Treatments: Depending on the application, clips may receive surface finishes such as powder coating, anodizing (for aluminum), or plating (e.g., zinc or nickel) to enhance corrosion resistance and aesthetics.

3. Assembly

- Some clips may include additional components such as screws, rubber pads, or adhesive layers to improve mounting stability. Assembly can be manual or automated, depending on volume.

- For adjustable or angle clips, mechanical assembly ensures that moving parts operate smoothly and maintain position without loosening over time.

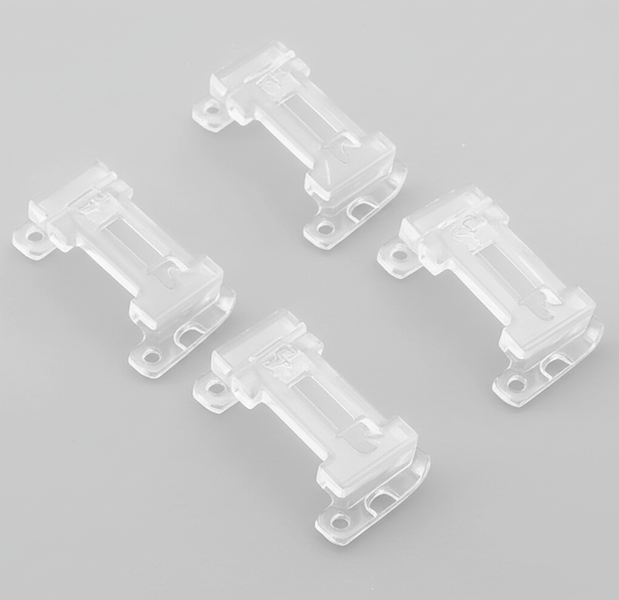

Illustrative Image (Source: Google Search)

4. Finishing and Packaging

- Final finishing processes remove sharp edges, burrs, and any surface imperfections.

- Clips are then cleaned, dried, and packaged in batches to protect them from damage during transport.

- Packaging often includes labeling with batch numbers, compliance certifications, and usage instructions, which are crucial for international shipping and customs clearance.

Quality Assurance and Control (QA/QC) in Clip Manufacturing

Robust quality assurance protocols are essential to guarantee that clips meet both functional requirements and international standards. The QA/QC framework typically includes:

Relevant International Standards

- ISO 9001: This is the global benchmark for quality management systems. Suppliers certified under ISO 9001 demonstrate consistent processes and continuous improvement.

- CE Marking: For clips sold within or exported to Europe, CE certification ensures compliance with EU safety, health, and environmental directives.

- RoHS Compliance: Restriction of hazardous substances is important for clips used in electronics to meet environmental regulations globally.

- Industry-Specific Certifications: Depending on the application, clips might require additional approvals such as API standards for industrial settings or UL listing for electrical safety.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw materials and components before manufacturing begins.

- In-Process Quality Control (IPQC): Ongoing inspections during forming, assembly, and finishing to detect defects early. This may include dimensional checks, visual inspections, and functional tests of clip adjustability or locking mechanisms.

- Final Quality Control (FQC): Comprehensive testing on finished clips, including batch sampling to verify mechanical strength, corrosion resistance, and surface finish quality.

Common Testing Methods

- Dimensional Inspection: Using calipers, micrometers, or coordinate measuring machines (CMM) to ensure clips meet specified tolerances.

- Mechanical Strength Testing: Clips undergo tensile and shear tests to confirm their ability to securely hold LED strips without deformation.

- Corrosion Resistance Tests: Salt spray or humidity chamber tests simulate harsh environmental conditions, particularly important for outdoor or humid climate applications common in Africa, the Middle East, and parts of South America.

- Adhesion and Fit Tests: For clips with adhesive layers or adjustable features, testing ensures secure attachment and reliable functionality over time.

Verifying Supplier Quality: Practical Steps for B2B Buyers

For buyers sourcing clips internationally, especially from diverse markets such as Argentina, Thailand, or European countries, verifying supplier quality is crucial:

- Factory Audits: Conduct on-site or third-party audits to assess manufacturing capabilities, process controls, and compliance with ISO 9001 and other certifications.

- Review of Quality Documentation: Request quality manuals, process flowcharts, inspection reports, and certificates of conformity.

- Third-Party Inspections: Engage independent inspection agencies to perform random sampling and testing before shipment. This adds an unbiased layer of assurance.

- Sample Testing: Obtain physical samples for in-house or local lab testing to validate performance claims, particularly for mechanical strength and corrosion resistance.

- Supplier Transparency: Work with suppliers who openly share QC data, support traceability via batch numbers, and demonstrate responsiveness to quality concerns.

QC and Certification Nuances for International Markets

Understanding regional nuances in quality requirements is vital:

- Africa and Middle East: Environmental conditions such as high temperatures, dust, and humidity demand clips with superior corrosion resistance and durable finishes. Compliance with RoHS and CE is increasingly expected in these growing markets.

- South America (e.g., Argentina): Local regulations may vary, but international certifications like ISO 9001 and CE provide a common quality baseline. Importers often require additional customs documentation and compliance verification.

- Europe: The strict regulatory environment means CE marking and RoHS compliance are mandatory. Buyers should also consider REACH regulations related to chemical safety in plastics and coatings.

- Southeast Asia (e.g., Thailand): Rapid industrial growth encourages suppliers to meet international standards to remain competitive. Buyers should verify supplier certifications and demand transparent QC practices.

In summary, B2B buyers should prioritize clips for LED strip lights manufactured through rigorous processes incorporating quality raw materials, precise forming, thorough assembly, and robust finishing. Equally important is the supplier’s adherence to international standards and comprehensive quality control checkpoints throughout production. By leveraging factory audits, third-party inspections, and detailed quality documentation, buyers in Africa, South America, the Middle East, and Europe can secure reliable, high-quality clips that meet both functional needs and regulatory requirements—ensuring smooth project execution and customer satisfaction.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for clips for led strip lights Sourcing

Understanding the cost structure and pricing dynamics of clips for LED strip lights is essential for international B2B buyers aiming to optimize procurement strategies. This analysis highlights key cost components, pricing influencers, and practical tips tailored to buyers from diverse regions such as Africa, South America, the Middle East, and Europe.

Key Cost Components in Clips for LED Strip Lights

- Materials: Clips are typically made from plastics (e.g., polycarbonate, ABS) or metals (aluminum, stainless steel). Material choice significantly impacts raw material costs, durability, and price. Metal clips generally cost more but offer higher strength and longevity.

- Labor: Labor costs vary by manufacturing location. Countries with lower wage levels can offer more competitive pricing, though quality assurance must be factored in.

- Manufacturing Overhead: This includes factory utilities, equipment depreciation, and indirect labor. Efficient factories with modern automation tend to have lower overhead per unit.

- Tooling: Injection molding or stamping requires upfront tooling investment. High tooling costs are amortized over production volume, influencing per-unit cost especially at low order quantities.

- Quality Control (QC): Rigorous QC ensures product consistency and compliance with international standards (e.g., RoHS, CE). QC costs are embedded in the price but critical for reducing defects and returns.

- Logistics: Shipping, customs, and import duties vary widely by destination. Freight costs can constitute a notable portion of landed cost, especially for bulky or heavy packaging.

- Supplier Margin: Suppliers add margins to cover profit and risk. Margins differ based on supplier size, market positioning, and buyer relationship.

Primary Price Influencers

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically secure lower unit prices due to economies of scale and tooling amortization. Buyers from markets with smaller project scopes should negotiate MOQ flexibility or consolidated shipments.

- Specifications and Customization: Customized clips (e.g., adjustable angles, branded logos, color matching) incur higher costs due to design complexity, tooling changes, and additional QC.

- Material Quality and Certifications: Clips meeting stringent certifications or using premium materials command premium prices. Buyers targeting European or Middle Eastern markets often require certified products, impacting cost.

- Supplier Location and Reliability: Established suppliers with proven quality and reliable delivery may price higher but reduce risks and hidden costs.

- Incoterms and Payment Terms: The choice of Incoterms (FOB, CIF, DDP) affects who bears shipping, insurance, and customs costs. Favorable payment terms (e.g., LC, net 30) can improve cash flow and reduce financial burden.

Practical Buyer Tips for International Sourcing

- Negotiate on MOQ and Pricing Tiers: Especially for buyers in emerging markets like Argentina or Thailand, negotiating smaller MOQs with tiered pricing can improve cash flow and inventory management.

- Evaluate Total Cost of Ownership (TCO): Consider not just unit price but also shipping costs, customs duties, potential delays, and after-sales support. Cheaper clips with poor durability or inconsistent quality can increase replacement and labor costs.

- Leverage Supplier Relationships: Building strong partnerships can unlock volume discounts, priority production slots, and technical support. For buyers in Africa or South America, partnering with suppliers familiar with local import challenges is beneficial.

- Account for Regional Logistics Nuances: Shipping to remote or landlocked countries may increase costs and delivery times. Consolidated shipments or regional distribution hubs can optimize logistics.

- Request Samples and Certifications: Before large orders, obtaining samples and verifying certifications (e.g., CE for Europe, RoHS compliance) helps avoid costly compliance issues.

- Be Mindful of Currency Fluctuations: Currency volatility can impact landed costs. Buyers should consider hedging strategies or pricing in stable currencies to mitigate risks.

Indicative Pricing Disclaimer

Prices for clips for LED strip lights vary widely depending on material, design complexity, order volume, and supplier location. As a rough benchmark, basic plastic clips may range from $0.05 to $0.15 per unit at scale, while metal or adjustable clips can range from $0.20 to $0.50 or more. These figures are indicative and should be validated through direct supplier quotations tailored to specific project requirements.

By understanding these cost drivers and pricing factors, international B2B buyers can make informed sourcing decisions that balance cost-efficiency, quality, and supply chain reliability across diverse regional markets.

Spotlight on Potential clips for led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘clips for led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for clips for led strip lights

Key Technical Properties of Clips for LED Strip Lights

When sourcing clips for LED strip lights, understanding critical technical properties ensures compatibility, durability, and ease of installation. Here are the essential specs to consider:

-

Material Grade and Finish

Clips are commonly made from high-quality plastics (e.g., polycarbonate, ABS) or metals (e.g., stainless steel, aluminum). Material grade affects strength, corrosion resistance, and heat tolerance. For outdoor or humid environments common in Africa and the Middle East, corrosion-resistant metals or UV-stabilized plastics are vital to ensure longevity. -

Size and Profile Compatibility

Clips must match the LED strip’s width and profile height precisely to secure the strip without damage. Typical LED strips range from 8mm to 24mm wide, so clips are designed to fit these dimensions with minimal tolerance (±0.1mm). Proper fit prevents strip displacement and maintains neat installations, critical for commercial projects in Europe and South America. -

Tolerance and Dimensional Accuracy

Tight manufacturing tolerances (e.g., ±0.05mm) guarantee consistent clip dimensions for uniform mounting. In large-scale procurement, uniformity reduces installation errors and time, lowering labor costs and ensuring professional finishes. -

Angle Adjustability

Some clips feature adjustable angles, allowing LED strips to be mounted on uneven or angled surfaces. This flexibility is essential for architectural lighting applications, where lighting must conform to curved or sloped surfaces, enhancing design versatility. -

Load and Temperature Ratings

Clips should withstand the weight of the LED strip and any additional housing or diffuser without deforming. They must also tolerate operating temperatures typically ranging from -20°C to 60°C or higher, depending on the environment. This is particularly important for installations in hot climates such as parts of the Middle East and Africa. -

Mounting Method and Hardware Compatibility

Clips come with various mounting options—screw mounts, adhesive bases, or snap-in designs. Knowing the preferred mounting method helps streamline installation and ensures compatibility with existing infrastructure or tools.

Common Trade Terminology for B2B Buyers

Navigating international LED lighting procurement involves familiarity with key industry terms. Understanding these can help buyers communicate clearly and negotiate effectively.

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce clips or components to be branded and sold by another company. OEM partnerships allow buyers to customize product specifications and branding, which is crucial for businesses seeking private label products. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell per order. MOQs vary widely and impact pricing and inventory management. For buyers in emerging markets such as South America or Africa, negotiating flexible MOQs can reduce upfront costs and stock risks. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers requesting detailed pricing, delivery, and specification information. RFQs are essential for comparing vendors and securing competitive bids, especially in multi-supplier sourcing strategies common in Europe. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, customs clearance, and risk transfer. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps buyers manage logistics costs and risks across borders. -

Lead Time

The time interval between placing an order and receiving the goods. Lead time affects project scheduling and inventory planning. Buyers targeting fast project turnarounds must confirm realistic lead times with suppliers. -

Quality Certifications

Certifications such as ISO 9001 (quality management), RoHS (restriction of hazardous substances), and CE marking (European conformity) indicate compliance with international standards. These are critical for regulatory approval and market acceptance, particularly in Europe and the Middle East.

By carefully evaluating these technical properties and trade terms, international B2B buyers can make informed decisions that optimize product performance, procurement efficiency, and cost-effectiveness when sourcing clips for LED strip lights.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the clips for led strip lights Sector

Market Overview & Key Trends

The global market for clips used in LED strip light installations is expanding rapidly, driven by increasing demand for energy-efficient lighting solutions across commercial, residential, and industrial sectors. Key growth regions include Africa, South America, the Middle East, and Europe, where urbanization and infrastructure development are accelerating. Countries such as Argentina, Brazil, South Africa, UAE, and Germany are witnessing heightened investments in smart lighting and architectural illumination, boosting the need for reliable mounting accessories like clips.

Market drivers include the rising adoption of LED strip lights due to their flexibility, low power consumption, and long lifespan. Clips play a critical role in secure, durable installation, especially in diverse climatic conditions found across these regions. As LED strip technology evolves—with features like tunable whites, RGB color-changing, and waterproof profiles—mounting clips are also innovating to accommodate various strip widths, profiles, and installation angles. Adjustable and angle-specific clips are gaining popularity, offering enhanced versatility to installers.

Sourcing trends emphasize customization and modularity. International B2B buyers increasingly seek suppliers who can provide clips tailored to specific LED strip profiles and environmental requirements. For example, in humid or outdoor applications common in parts of South America and Africa, clips made from UV-resistant and corrosion-proof materials are preferred. Meanwhile, European buyers often prioritize precision-engineered clips compatible with standardized extrusions and channels.

Technological integration is emerging as a key market dynamic. Clips that facilitate easy installation and maintenance—such as snap-fit or tool-free designs—are favored to reduce labor costs and downtime. Additionally, suppliers offering bundled solutions (clips combined with channels, diffusers, or connectors) present a competitive advantage by simplifying procurement for buyers.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are becoming paramount for B2B buyers in the clips for LED strip lights sector, reflecting a broader global shift towards green procurement. The environmental impact of clip production centers on the choice of materials, manufacturing processes, and end-of-life recyclability. Clips traditionally made from plastics or metals pose challenges if sourced or disposed of irresponsibly.

Environmentally conscious buyers—especially in Europe and the Middle East—demand clips manufactured from recycled or bio-based plastics and non-toxic, RoHS-compliant metals. Suppliers that can demonstrate a reduction in carbon footprint through energy-efficient production and waste minimization are increasingly preferred. Certifications such as ISO 14001 (Environmental Management) and compliance with REACH regulations add credibility and facilitate smoother customs clearance in stringent markets.

Ethical sourcing is equally critical. Buyers from Africa and South America are particularly attentive to supply chain transparency to avoid products linked to unethical labor practices or conflict minerals. Partnering with manufacturers who uphold fair labor standards and provide traceability throughout their supply chain can mitigate reputational risks.

Green certifications and eco-labels related to LED accessories are gaining traction. Clips that integrate seamlessly with sustainable LED lighting systems—such as those designed for easy disassembly and reuse—align with circular economy principles. This approach not only supports environmental goals but also appeals to end customers increasingly aware of sustainability.

Brief Evolution & Historical Context

The evolution of clips for LED strip lights parallels the rapid adoption of LED lighting technology itself. Initially, LED strips were mounted using generic adhesives or simple plastic clips, which often failed to provide long-term stability or protection. As the LED strip market matured, the need for specialized mounting solutions became evident to ensure secure installation, especially in commercial and outdoor environments.

Over the past decade, mounting clips have evolved into highly engineered components. Innovations include angle-adjustable clips, corrosion-resistant materials, and compatibility with aluminum extrusions and diffusers, addressing the growing demand for customizable and durable lighting installations. This progression reflects the broader trend toward modular, efficient, and sustainable lighting systems, making clips an essential element in the LED strip ecosystem for B2B buyers worldwide.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of clips for led strip lights

-

How can I effectively vet suppliers of clips for LED strip lights in international markets?

When sourcing clips internationally, especially from regions like Africa, South America, the Middle East, and Europe, prioritize suppliers with verifiable business licenses and certifications such as ISO 9001. Request product samples to assess build quality and compatibility with your LED strips. Utilize third-party inspection services to audit manufacturing facilities and verify compliance with quality standards. Establish clear communication channels and review buyer feedback on platforms or trade references to confirm reliability and delivery consistency. -

Are customization options available for clips to fit different LED strip profiles?

Yes, many manufacturers offer custom clip designs to accommodate various LED strip widths, profiles, and mounting requirements. Customizations may include adjustable angles, materials (plastic, metal), and finishes to suit environmental conditions. When negotiating, clarify your specifications upfront and request technical drawings or prototypes. Custom orders typically involve MOQ commitments and longer lead times, so plan accordingly to align with your project timelines and budget constraints. -

What are typical minimum order quantities (MOQs) and lead times for bulk orders of LED strip light clips?

MOQs vary widely depending on the supplier and the complexity of the clip design. Standard clips often have MOQs starting from 500 to 1,000 units, while customized clips may require higher minimums. Lead times generally range from 3 to 8 weeks, factoring in production, quality checks, and international shipping. For buyers in regions like Argentina or Thailand, consider potential customs clearance delays and coordinate with suppliers to ensure realistic delivery schedules. -

Which payment terms are common and secure for international B2B transactions involving clips for LED strip lights?

Common payment methods include Letters of Credit (LC), Telegraphic Transfers (T/T), and Escrow services. For first-time international transactions, a 30% deposit upfront with balance paid upon delivery or inspection is advisable to mitigate risk. Use payment platforms that offer buyer protection and ensure contracts clearly define payment milestones, penalties for delays, and dispute resolution mechanisms. Engaging a trade finance expert can help tailor terms suitable for your region and supplier. -

What quality assurance certifications should I look for when buying clips for LED strip lights?

Seek suppliers with ISO 9001 certification to ensure a robust quality management system. Additionally, certifications such as RoHS (Restriction of Hazardous Substances) and REACH compliance are crucial for environmental safety and regulatory adherence, especially when importing into Europe or the Middle East. Request test reports verifying material durability, UV resistance, and mechanical strength to guarantee clips withstand installation conditions and product lifespan requirements.

Illustrative Image (Source: Google Search)

-

How can I optimize logistics for importing clips from international suppliers to Africa, South America, or the Middle East?

Leverage consolidated shipping to reduce freight costs and negotiate Incoterms (e.g., FOB, CIF) that balance cost and risk. Use freight forwarders experienced in your destination markets who can navigate customs efficiently. Plan shipments ahead of peak seasons to avoid delays. Packaging should be robust to prevent damage during transit, and suppliers should provide full shipping documentation, including commercial invoices, packing lists, and certificates of origin to expedite clearance. -

What strategies help resolve disputes or quality issues with overseas clip suppliers?

Establish clear contractual terms covering quality standards, inspection procedures, and remedies for non-compliance. Employ third-party inspection agencies pre-shipment to catch defects early. In disputes, maintain detailed documentation including purchase orders, communications, and inspection reports. Negotiate amicably with suppliers first; if unresolved, consider mediation or arbitration under agreed jurisdictions. Building long-term relationships based on transparency reduces conflict risks. -

How do regional differences impact the selection of clips for LED strip lights in international projects?

Environmental factors such as humidity, temperature, and UV exposure vary by region and affect clip material choice—plastic clips may degrade faster in tropical climates like Thailand, while metal clips might be preferred in dry, dusty environments like parts of the Middle East. Electrical standards and LED strip profiles may differ, so ensure clips are compatible with local LED models. Understanding local installation practices and regulatory requirements ensures product suitability and compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for clips for led strip lights

Effective procurement of clips for LED strip lights demands a strategic approach grounded in understanding product compatibility, quality standards, and supplier reliability. For international B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing suppliers who offer a diverse range of mounting solutions—including adjustable and profile-specific clips—ensures adaptability to varied installation environments and LED strip profiles. Emphasizing quality certifications and durability can significantly reduce installation failures and maintenance costs, enhancing overall project ROI.

Moreover, leveraging suppliers with robust customization capabilities allows buyers to tailor clips to unique project requirements, a critical advantage in competitive markets. Transparent communication and comprehensive after-sales support are equally vital to mitigate supply chain risks and secure timely delivery. Buyers should also consider environmental and regulatory compliance, especially when sourcing across different regions, to align with local standards and sustainability goals.

Looking ahead, the evolving LED lighting market presents opportunities to adopt innovative mounting technologies that improve installation efficiency and product lifespan. Buyers are encouraged to cultivate strong partnerships with manufacturers that invest in R&D and quality assurance. By doing so, businesses in emerging and established markets alike can enhance their competitive edge, drive operational excellence, and meet the growing demand for sophisticated LED lighting solutions worldwide. Act now to explore strategic sourcing options that align with your specific market dynamics and project ambitions.