Guide to Chip On Board Led Strip

- Introduction: Navigating the Global Market for chip on board led strip

- Understanding chip on board led strip Types and Variations

- Key Industrial Applications of chip on board led strip

- Strategic Material Selection Guide for chip on board led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for chip on board led strip

- Comprehensive Cost and Pricing Analysis for chip on board led strip Sourcing

- Spotlight on Potential chip on board led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for chip on board led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the chip on board led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of chip on board led strip

- Strategic Sourcing Conclusion and Outlook for chip on board led strip

Introduction: Navigating the Global Market for chip on board led strip

Chip on Board (COB) LED strips represent a transformative advancement in lighting technology, reshaping how businesses worldwide approach illumination solutions. For international B2B buyers—especially those operating across diverse markets such as Africa, South America, the Middle East, and Europe—understanding the nuances of COB LED strips is essential to making strategic procurement decisions that optimize performance, cost-efficiency, and application versatility.

COB LED strips stand out due to their superior light quality, uniformity, and energy efficiency. By mounting multiple LED chips directly on a substrate, these strips deliver continuous, high-density illumination without the common “hot spots” of traditional LED strips. This innovation not only enhances aesthetic appeal but also reduces operational costs through lower power consumption and extended lifespan—critical factors for businesses seeking sustainable and reliable lighting solutions in varying regulatory and environmental contexts.

This comprehensive guide covers every facet relevant to international buyers: from the types and materials used in manufacturing COB LED strips to quality control standards, supplier evaluation criteria, pricing structures, and emerging market trends. Additionally, it addresses frequently asked questions to clarify technical and logistical considerations.

By leveraging this guide, procurement professionals in regions such as Poland, Colombia, the UAE, or Nigeria will gain actionable insights to navigate supplier selection, assess product specifications, and negotiate terms effectively. Ultimately, this resource empowers you to source COB LED strips that align with your project goals, budget constraints, and market demands—ensuring a competitive edge in today’s dynamic global lighting marketplace.

Understanding chip on board led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard COB LED Strip | High LED chip density on flexible PCB, uniform continuous light | Architectural lighting, retail displays, ambient lighting | Pros: Smooth light output, flexible installation; Cons: Moderate color consistency challenges |

| High-Density COB Strip | Extremely dense LED chips (up to 480 chips/meter), enhanced brightness | High-end retail, museum lighting, precision task lighting | Pros: Superior brightness and color uniformity; Cons: Heat dissipation limits max wattage |

| Waterproof COB Strip | Encapsulated with silicone or epoxy for moisture resistance | Outdoor signage, landscape lighting, marine use | Pros: Durable in harsh environments; Cons: Slightly reduced heat dissipation, higher cost |

| Tunable White COB Strip | Incorporates dual or multiple LEDs for adjustable color temperature | Office lighting, healthcare, hospitality sectors | Pros: Adjustable lighting ambiance, improves occupant comfort; Cons: Higher initial investment, requires compatible drivers |

| RGB COB LED Strip | Integrates red, green, blue chips for dynamic color mixing | Entertainment venues, advertising displays, event lighting | Pros: Versatile color effects; Cons: Lower luminous efficacy, complexity in control systems |

Standard COB LED Strip

This is the most common variation, featuring a high density of LED chips mounted directly on a flexible PCB to produce a continuous, uniform light output. It is highly suitable for applications requiring aesthetic appeal and consistent illumination, such as retail environments and architectural accent lighting. When purchasing, B2B buyers should consider the moderate challenges in color consistency and ensure suppliers provide quality binning processes to meet brand standards.

High-Density COB Strip

These strips push the density of LED chips to an extreme, delivering exceptional brightness and color uniformity. Ideal for premium applications like museum exhibits or precision task lighting, they demand careful thermal management due to heat buildup risks at higher wattages. Buyers should evaluate the supplier’s thermal design and warranty terms to ensure longevity in demanding environments.

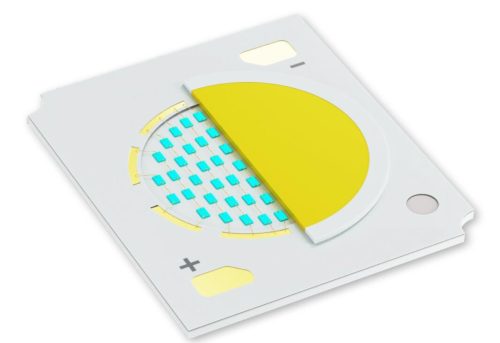

Illustrative Image (Source: Google Search)

Waterproof COB Strip

Encased in silicone or epoxy, waterproof COB strips are engineered for outdoor or moisture-prone environments. This makes them a preferred option for landscape lighting, marine applications, and outdoor signage in regions with variable climates such as parts of Africa and South America. Buyers need to balance the slightly increased cost against durability benefits and verify IP ratings for compliance with local standards.

Tunable White COB Strip

Featuring multiple LED chips capable of adjusting color temperature, tunable white COB strips enable dynamic lighting solutions that improve occupant comfort and productivity. They are increasingly popular in office spaces, healthcare facilities, and hospitality venues across Europe and the Middle East. B2B purchasers should ensure compatibility with dimming and control systems, as well as assess the total cost of ownership including driver technology.

RGB COB LED Strip

These strips combine red, green, and blue LED chips to offer a wide spectrum of colors and dynamic lighting effects. They are widely used in entertainment, advertising, and event lighting where visual impact is critical. Buyers must consider the trade-off between creative versatility and lower luminous efficacy, as well as the complexity and cost of control systems necessary for effective color management.

Related Video: COB (Chip On board) process. COB LED. About a black dot on PCB.

Key Industrial Applications of chip on board led strip

| Industry/Sector | Specific Application of chip on board led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Retail display and signage lighting | Uniform, bright illumination enhances product visibility and customer experience | High color rendering index (CRI), consistent color temperature, durability for long hours |

| Architectural & Interior Design | Cove and accent lighting in commercial and luxury spaces | Smooth, continuous lighting improves aesthetics and reduces maintenance | Flexibility of strips for curved surfaces, IP rating for indoor/outdoor use |

| Automotive & Transportation | Interior vehicle lighting and dashboard illumination | Energy-efficient, low-heat lighting enhances driver comfort and visibility | Compliance with automotive standards, vibration resistance, compact design |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage areas | Reliable, uniform lighting improves worker safety and productivity | High lumen output, robust build quality, ease of installation and maintenance |

| Hospitality & Entertainment | Ambient and decorative lighting in hotels, restaurants, and theaters | Creates inviting atmospheres, reduces energy costs, and offers design flexibility | Dimmability, color tunability, long lifespan to reduce replacement frequency |

Retail & Commercial Lighting

In retail environments across markets such as Poland, Colombia, and the Middle East, COB LED strips are extensively used for display and signage lighting. Their ability to provide uniform, shadow-free illumination highlights merchandise effectively, driving customer engagement and sales. Buyers prioritize strips with high CRI and consistent color temperature to maintain brand aesthetics. Durable designs that withstand prolonged operational hours are essential, especially in regions with fluctuating power quality, ensuring minimal maintenance and operational downtime.

Illustrative Image (Source: Google Search)

Architectural & Interior Design Applications

For architectural firms and interior designers in Europe and Africa, COB LED strips offer seamless accent and cove lighting solutions that enhance spatial perception and ambiance. Their flexibility allows installation on curved surfaces and intricate designs, critical for modern commercial and luxury spaces. International buyers should focus on strips with appropriate IP ratings to cater for both indoor and semi-outdoor applications, ensuring longevity and compliance with local building codes.

Automotive & Transportation Sector

Automotive manufacturers and aftermarket suppliers leverage COB LED strips for interior vehicle lighting and dashboard illumination due to their compact size and low heat emission. In regions like South America and the Middle East, where vehicle interiors are customized frequently, the strips’ energy efficiency and vibration resistance are highly valued. Buyers must verify compliance with automotive lighting standards and ensure consistent color output to meet safety and aesthetic requirements.

Manufacturing & Warehousing Lighting

COB LED strips are increasingly adopted in manufacturing plants and warehouses in Africa and Europe to provide task-specific and safety lighting. Their uniform light output reduces eye strain and improves visibility, enhancing workplace safety and productivity. B2B buyers should seek high lumen output strips with robust construction to endure industrial environments. Easy installation and maintenance are also critical to minimize operational disruptions.

Hospitality & Entertainment Lighting

Hotels, restaurants, and theaters in emerging and developed markets utilize COB LED strips to create dynamic ambient and decorative lighting. These strips support dimmability and color tunability, allowing tailored atmospheres that enhance guest experience while reducing energy consumption. Buyers from regions such as South America and Europe should ensure the products have long lifespans and reliable dimming compatibility to reduce replacement costs and maintain consistent performance over time.

Related Video: Arduino – Turn LED On and Off With Push Button

Strategic Material Selection Guide for chip on board led strip

Analysis of Common Materials for Chip on Board (COB) LED Strips

1. Flexible Printed Circuit Board (FPCB) – Polyimide or PET Substrate

Key Properties:

FPCBs used in COB LED strips typically feature polyimide or polyethylene terephthalate (PET) substrates. Polyimide offers excellent thermal stability (up to 260°C), good mechanical flexibility, and chemical resistance. PET is less heat-resistant (up to ~150°C) but more cost-effective and widely used for less demanding applications. Both materials provide good dielectric properties and flexibility, essential for conforming to curved or irregular surfaces.

Pros & Cons:

Polyimide-based FPCBs are highly durable, resistant to thermal degradation, and suitable for high-performance lighting applications. However, they come at a higher cost and more complex manufacturing processes. PET substrates reduce costs and simplify production but may suffer from lower thermal endurance and mechanical robustness over time.

Impact on Application:

For markets with high ambient temperatures such as parts of Africa and the Middle East, polyimide substrates are preferred due to superior heat resistance, preventing premature failure. In Europe and South America, where cost sensitivity may be higher, PET substrates are common for indoor, low-heat applications. The flexibility of these substrates allows COB LED strips to be installed in various architectural and retail environments.

International B2B Considerations:

Buyers from regions with stringent safety and quality standards (e.g., Europe’s RoHS and REACH compliance) should prioritize polyimide FPCBs that meet these regulations. In emerging markets like Colombia or Poland, balancing cost and performance is critical; suppliers offering PET-based FPCBs with verified certifications can be attractive. Additionally, compatibility with ASTM and DIN standards for electrical insulation and thermal endurance enhances buyer confidence.

2. Epoxy Resin Encapsulation

Key Properties:

Epoxy resin is commonly used as an encapsulant or protective coating over the LED chips on COB strips. It provides good adhesion, electrical insulation, and moderate resistance to moisture and chemicals. Thermal conductivity is moderate, which helps in heat dissipation but is less efficient compared to silicones.

Pros & Cons:

Epoxy encapsulation is cost-effective and provides robust mechanical protection against dust and minor impacts. However, it tends to yellow and degrade under prolonged UV exposure, limiting outdoor or high-UV applications. Its lower flexibility compared to silicone can lead to cracking under repeated bending.

Impact on Application:

Epoxy encapsulation is suitable for indoor lighting solutions in controlled environments, such as retail displays or office ambient lighting common in European and South American markets. It is less ideal for outdoor or harsh environments prevalent in some African and Middle Eastern regions unless additional protective measures are applied.

International B2B Considerations:

Buyers should verify the epoxy resin’s compliance with international standards like UL 94 for flammability and IEC 60598 for electrical safety. For regions with high UV exposure, such as the Middle East, suppliers offering UV-stabilized epoxy or alternative encapsulants may be preferable. Cost-conscious buyers in emerging markets may favor epoxy for its affordability but must balance this with expected product lifespan.

3. Silicone Encapsulation

Key Properties:

Silicone encapsulants provide excellent thermal stability (up to 250°C), superior UV resistance, and high flexibility. Silicone’s high transparency ensures minimal light loss, and its hydrophobic nature improves moisture resistance.

Pros & Cons:

Silicone encapsulation significantly enhances COB LED strip durability, especially in outdoor or high-temperature environments. It resists yellowing and cracking, maintaining optical clarity over time. However, silicone materials are generally more expensive and require more precise manufacturing controls.

Impact on Application:

Ideal for outdoor architectural lighting, signage, and industrial applications found in diverse climates across Africa, South America, and the Middle East. European buyers focused on premium, long-lasting lighting solutions also prefer silicone-encapsulated COB strips. The flexibility and weather resistance make silicone a go-to for projects demanding longevity and consistent performance.

International B2B Considerations:

Silicone encapsulation meets many international certifications, including IEC standards for outdoor lighting and IP ratings for water and dust ingress. Buyers from regions with harsh environmental conditions should prioritize silicone-encapsulated products. The higher cost may be justified by reduced maintenance and replacement expenses, a key consideration for large-scale commercial projects.

4. Copper Clad Laminate (CCL) for PCB Base

Key Properties:

The PCB base of COB LED strips often uses copper clad laminates, typically FR4 or metal-core PCBs (MCPCB). FR4 is a fiberglass epoxy laminate with moderate thermal conductivity, while MCPCBs incorporate a metal base (usually aluminum) for enhanced heat dissipation.

Pros & Cons:

FR4 is cost-effective and suitable for low to medium power COB LED strips but has limited thermal management capabilities. MCPCBs offer superior heat dissipation, improving LED lifespan and performance but at a higher cost and manufacturing complexity.

Impact on Application:

For high-power COB LED strips used in industrial or architectural lighting, MCPCBs are preferred, especially in hot climates like parts of Africa and the Middle East. FR4-based PCBs are more common in low-power, indoor applications typical in Europe and South America.

International B2B Considerations:

Buyers should consider local standards such as DIN EN 60695 for PCB flammability and thermal performance. MCPCBs are favored in regions with high ambient temperatures or where long-term reliability is critical. Cost-sensitive buyers may opt for FR4 but must account for potential trade-offs in thermal performance and product lifespan.

Summary Table of Materials for Chip on Board LED Strips

| Material | Typical Use Case for chip on board led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide or PET Flexible PCB | Substrate for flexible COB LED strips in indoor/outdoor lighting | High flexibility and thermal stability (polyimide); cost-effective (PET) | PET lower heat resistance; polyimide higher cost | Polyimide: High; PET: Medium |

| Epoxy Resin Encapsulation | Protective coating for indoor COB LED strips | Cost-effective, good mechanical protection | Yellowing and UV degradation over time | Low |

| Silicone Encapsulation | Outdoor and high-temperature COB LED strip protection | Excellent UV resistance, flexibility, and durability | Higher cost, more complex manufacturing | High |

| Copper Clad Laminate (FR4/MCPCB) | PCB base |

In-depth Look: Manufacturing Processes and Quality Assurance for chip on board led strip

Manufacturing Processes for Chip on Board (COB) LED Strips

The manufacturing of Chip on Board LED strips involves a series of precise and technologically advanced steps, designed to ensure high performance, durability, and uniform light output. For international B2B buyers, understanding these stages and the associated techniques is critical to selecting reliable suppliers and ensuring product quality.

1. Material Preparation

The process begins with sourcing high-quality raw materials. This includes:

- Flexible Printed Circuit Board (FPCB): The substrate onto which LED chips are mounted must have excellent thermal conductivity and flexibility.

- LED Chips: Selection of premium LED chips with consistent luminous efficacy and color uniformity is essential.

- Phosphor Coating Materials: Used to convert blue LED light into the desired white light spectrum.

- Encapsulation Materials: Silicone or epoxy resins protect the chips and ensure durability.

Material quality directly impacts the strip’s longevity and light consistency, so suppliers usually source from established chip manufacturers and material providers.

2. Forming and Mounting

The core of COB LED strip manufacturing involves mounting the LED chips directly onto the substrate:

- Chip Placement: LED chips are placed densely on the substrate using automated pick-and-place machines, ensuring precise positioning and uniform spacing.

- Flip-chip Technology: Commonly employed to reduce components and improve thermal management by mounting the LED chip face-down, directly on the substrate pads.

- Soldering and Wire Bonding: Chips are soldered or bonded to electrical contacts without traditional gold wires, reducing failure points.

This stage demands strict control of alignment and bonding quality to prevent hotspots and ensure consistent light output.

3. Assembly and Circuit Integration

After chip mounting:

- Phosphor Coating Application: A uniform phosphor layer is applied to achieve the desired light color and improve color consistency.

- Encapsulation: Protective layers are applied to shield the LEDs from moisture, dust, and mechanical stress.

- Electrical Circuit Integration: Parallel and series connections between chips are carefully designed for optimal current distribution and fault tolerance.

- Cutting and Shaping: The strips are cut into standard or customized lengths at designated points, often with pre-marked intervals for easy installation and maintenance.

Flexible design considerations are addressed here, allowing the strips to be bent or shaped to fit diverse applications.

4. Finishing and Packaging

Final steps include:

- Adhesive Backing Application: Enables easy installation on various surfaces.

- Protective Coatings: Additional silicone or waterproofing layers may be applied for outdoor or humid environments.

- Labeling and Packaging: Includes serial numbers, batch codes, and compliance markings to ensure traceability.

Packaging is designed to protect the strips during shipping and handling, especially important for long-distance international shipments.

Quality Assurance and Control (QA/QC) in COB LED Strip Manufacturing

Quality assurance is paramount in COB LED strip production due to the product’s complexity and the critical nature of lighting applications. B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must verify that suppliers adhere to stringent QC protocols and international standards.

Relevant International and Industry Standards

- ISO 9001: The foundational quality management system standard ensuring consistent manufacturing processes and continuous improvement.

- CE Marking: Mandatory for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, critical for environmental safety and regulatory compliance globally.

- UL Certification: Especially relevant for electrical safety and fire hazard prevention, valued in markets like Europe and the Middle East.

- API and IEC Standards: For electrical and lighting products, ensuring performance and safety benchmarks.

B2B buyers should request documentation proving compliance with these certifications as part of supplier evaluation.

QC Checkpoints Throughout Manufacturing

Quality control is integrated at multiple stages to catch defects early and maintain product integrity:

- Incoming Quality Control (IQC): Verification of raw materials and components before production begins, including LED chips and substrate testing.

- In-Process Quality Control (IPQC): Continuous monitoring during chip placement, soldering, coating, and assembly. This includes visual inspections, alignment checks, and thermal imaging to detect hotspots.

- Final Quality Control (FQC): Comprehensive testing of finished strips, including electrical performance, color consistency, brightness, and mechanical durability.

Each QC checkpoint uses specific testing protocols to ensure defects are minimized and products meet specifications.

Common Testing Methods

- Electrical Testing: Measures voltage, current, and power consumption to ensure efficiency and safety.

- Luminous Flux and Color Measurement: Using integrating spheres and spectrometers to verify brightness and color temperature consistency.

- Thermal Imaging: Detects heat distribution and potential hotspots that could reduce lifespan.

- Mechanical Flexibility Tests: Ensures strips can withstand bending and installation stresses without damage.

- Environmental Testing: Includes humidity, salt spray, and UV exposure tests for outdoor-rated products.

These tests are crucial for validating product claims and ensuring reliability under various operating conditions.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, particularly in emerging and diverse markets such as Africa, South America, the Middle East, and Europe, verifying supplier QC processes is essential to mitigate risks associated with product quality and regulatory compliance.

Recommended Verification Practices

- Factory Audits: Conduct on-site or third-party audits focusing on manufacturing processes, equipment, and QC protocols. Audits should assess compliance with ISO 9001 and industry certifications.

- Review of QC Documentation: Request detailed QC reports, test certificates, and batch traceability documents for each shipment.

- Third-Party Inspections: Employ independent inspection agencies to perform random sample testing and verify compliance with specifications before shipment.

- Sample Testing: Order product samples for in-house or third-party lab testing to confirm electrical performance, light quality, and durability.

- Supplier Capability Assessment: Evaluate the supplier’s R&D capabilities and technological investments, especially in automated assembly and advanced testing equipment.

These steps help buyers ensure that suppliers maintain consistent quality and adhere to international standards.

QC and Certification Nuances for International B2B Buyers

Understanding regional certification requirements and quality expectations is vital for global transactions involving COB LED strips.

- Africa and South America: Regulatory frameworks vary widely; buyers should prioritize suppliers with ISO 9001, RoHS compliance, and, where applicable, local certification marks. Import regulations may require additional testing or approvals.

- Middle East: Safety certifications like UL and IEC are highly valued, especially for commercial and industrial applications. Buyers should ensure that products meet stringent fire safety and electrical standards.

- Europe (e.g., Poland): CE marking and strict adherence to RoHS and REACH regulations are mandatory. Color consistency and energy efficiency standards (e.g., EU energy labels) are increasingly important.

- Customs and Import Compliance: Buyers must verify that all documentation accompanies shipments to avoid customs delays, including Certificates of Conformity and test reports.

Collaborating closely with suppliers on certification and QC documentation helps streamline import processes and ensures compliance with local regulations.

Summary

For international B2B buyers targeting COB LED strips, a thorough understanding of the manufacturing process and quality assurance measures is crucial. The key manufacturing stages—from material preparation to final packaging—require precision and advanced technology. Equally important is the supplier’s adherence to international standards such as ISO 9001, CE, and RoHS, supported by rigorous QC checkpoints including IQC, IPQC, and FQC.

Buyers should actively verify supplier quality through audits, documentation reviews, third-party inspections, and sample testing. Additionally, awareness of regional certification nuances ensures smooth market entry and compliance across Africa, South America, the Middle East, and Europe.

By prioritizing these aspects, B2B buyers can secure high-quality COB LED strips that deliver reliable, uniform lighting performance tailored to diverse applications and regulatory environments.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for chip on board led strip Sourcing

Cost Components in COB LED Strip Sourcing

Understanding the detailed cost structure behind Chip-on-Board (COB) LED strips is crucial for international B2B buyers aiming to optimize procurement budgets. The primary cost components typically include:

- Materials: The core expense involves high-quality LED chips, phosphor coatings, flexible printed circuit boards (FPCBs), adhesives, and protective encapsulants. The density of LED chips per meter and the quality of phosphor directly impact price.

- Labor: Skilled labor is required for precise mounting of LED chips directly onto substrates, ensuring uniformity and reliability. Labor costs vary significantly based on the manufacturing country and automation levels.

- Manufacturing Overhead: This covers factory utilities, machinery depreciation, and indirect costs related to maintaining production lines tailored for COB technology.

- Tooling: Initial investment in specialized tooling and equipment for COB assembly is higher than traditional SMD LED strips due to the precision needed.

- Quality Control (QC): Rigorous testing is essential to ensure color consistency, brightness uniformity, and durability, adding to operational expenses.

- Logistics: International shipping, customs duties, and handling fees influence the final landed cost. Fragile packaging and temperature-controlled shipping may be necessary to preserve product integrity.

- Margin: Supplier profit margins vary depending on brand positioning, exclusivity, and after-sales services.

Key Price Influencers for COB LED Strips

Several factors influence the pricing landscape for COB LED strips, which buyers must carefully evaluate:

- Order Volume and Minimum Order Quantity (MOQ): Larger orders typically unlock better per-unit pricing. However, some manufacturers impose MOQs that may challenge smaller buyers in emerging markets.

- Product Specifications and Customization: Custom lengths, color temperatures, IP ratings (waterproofing), and special features like dimmability or specific color binning increase cost.

- Material Quality: Premium LED chips, high-grade phosphors, and robust FPCBs result in higher prices but better performance and longevity.

- Certifications and Compliance: Products certified for CE, RoHS, UL, or other regional standards carry additional testing and documentation costs.

- Supplier Reputation and Location: Established manufacturers from China, Taiwan, or South Korea might charge more but offer reliability and warranty support. Local distributors in Europe or the Middle East may have markup but reduce lead times.

- Incoterms and Payment Terms: Terms like FOB, CIF, or DDP affect who bears shipping and customs costs, impacting the total procurement price.

Actionable Buyer Tips for International B2B Procurement

For buyers from Africa, South America, the Middle East, and Europe, navigating the cost and pricing dynamics of COB LED strips requires strategic approaches:

- Leverage Volume Negotiations: Pooling orders with other regional buyers or consolidating multiple projects can help meet MOQs and negotiate better pricing tiers.

- Prioritize Total Cost of Ownership (TCO): Evaluate not just upfront price but also energy savings, product lifespan, and maintenance costs. COB LED strips’ superior efficiency and durability often justify a premium.

- Understand Pricing Nuances: Be aware that cheaper per-meter prices may omit critical certifications or use lower-quality materials, leading to higher replacement costs. Request detailed product datasheets and warranty terms.

- Clarify Incoterms Early: Negotiate Incoterms that minimize your risk and cost exposure. For example, DDP (Delivered Duty Paid) can simplify customs but may increase supplier pricing.

- Assess Supplier Capability: Verify supplier’s QC processes, production capacity, and after-sales support, especially important for buyers in regions with logistical challenges.

- Consider Local Regulations: Compliance with local electrical and safety standards in Europe (e.g., CE marking) or Middle Eastern countries can influence product selection and cost.

- Plan for Logistics and Import Duties: Factor in shipping time, customs clearance complexity, and import tariffs which can significantly affect the landed cost, particularly for buyers in Africa and South America.

Indicative Pricing Disclaimer

Prices for COB LED strips vary widely based on specifications, volumes, supplier location, and market conditions. As of mid-2024, typical FOB prices range from approximately $8 to $20 per meter for standard quality strips, with premium or customized versions commanding higher prices. Buyers should request formal quotations and consider all cost components before finalizing orders.

By thoroughly analyzing these cost drivers and price influencers, international B2B buyers can negotiate effectively, optimize procurement strategies, and ensure cost-efficient, high-quality sourcing of COB LED strips tailored to their regional market needs.

Spotlight on Potential chip on board led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘chip on board led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for chip on board led strip

Critical Technical Properties of Chip on Board (COB) LED Strips

1. LED Chip Density

COB LED strips feature a high density of LED chips mounted directly on the substrate, typically ranging from 240 to over 480 chips per meter. This density ensures uniform, continuous light output without visible hotspots, which is crucial for applications requiring smooth illumination like retail displays or architectural lighting. For B2B buyers, higher chip density translates to premium lighting quality and enhanced aesthetic appeal, especially in markets valuing design sophistication such as Europe and the Middle East.

2. Power Consumption (Wattage per Meter)

Power rating usually falls between 6W to 15W per meter, with 15W being the practical upper limit due to heat dissipation constraints. Efficient power consumption means lower operating costs and less heat buildup, extending product lifespan. Buyers should balance wattage with lighting needs and ensure compatible power supplies to optimize energy efficiency, particularly important in regions with high electricity costs like South America and Africa.

3. Color Temperature and Color Rendering Index (CRI)

COB LED strips come in various color temperatures (measured in Kelvins), typically ranging from warm white (2700K) to daylight (6500K). The CRI value, often above 80, indicates how accurately the light renders colors. High CRI is essential for retail and hospitality sectors where true color perception affects customer experience. B2B buyers must specify exact color temperature and CRI requirements to meet project specifications and local market preferences.

4. Flexibility and Cut-Ability

COB LED strips are designed to be highly flexible and can be cut at predefined intervals (commonly every 25mm or 50mm). This flexibility allows installation on curved or irregular surfaces, expanding design possibilities. For international buyers, understanding cut points and the ability to splice or join strips ensures customization and reduces waste, facilitating installations in diverse architectural environments from Colombian commercial spaces to Polish offices.

5. Lifespan and Thermal Management

Typical COB LED strips offer lifespans exceeding 30,000 hours, supported by improved thermal management due to direct chip mounting and reduced heat generation. Effective heat dissipation is critical to maintaining consistent brightness and longevity. B2B buyers should confirm thermal specs and consider ambient installation conditions to maximize return on investment, especially in hot climates like the Middle East or tropical Africa.

6. Voltage and Dimming Compatibility

Most COB LED strips operate on 12V or 24V DC power supplies and support various dimming protocols such as PWM, Triac, or DALI. Dimming capability is important for energy savings and mood-setting in commercial or residential environments. Buyers must verify voltage compatibility and dimming options early in procurement to ensure system integration and control flexibility.

Key Industry and Trade Terms for International B2B Buyers

OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products which are branded and sold by another company. For B2B buyers, OEM partnerships often allow customization of COB LED strips, including branding, packaging, and technical specifications, enabling differentiation in local markets.

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. Understanding MOQ is essential for budgeting and inventory management, especially for buyers in emerging markets like Africa or South America where upfront capital may be limited. Negotiating MOQ can help tailor orders to project scale and reduce storage costs.

RFQ (Request for Quotation)

A formal process where buyers solicit detailed price and specification proposals from suppliers. Issuing an RFQ ensures transparent pricing and technical compliance, enabling buyers to compare offers from multiple vendors across regions such as Europe and the Middle East efficiently.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities, risks, and costs between buyers and sellers during international shipping. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, Freight). Understanding Incoterms is vital for managing logistics, customs clearance, and cost allocation in cross-border transactions.

Bin or Binning

A quality control process where LEDs are sorted based on color consistency and brightness. For COB LED strips, binning affects color uniformity and overall product quality. Buyers should inquire about binning standards to ensure color accuracy, especially for projects requiring strict visual consistency.

Lumen Output

A measurement of total visible light emitted by the LED strip, expressed in lumens (lm). Higher lumen output indicates brighter light. Buyers must specify required lumen levels to meet lighting standards and customer expectations in their target markets.

By understanding these essential technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they procure COB LED strips that align with their project requirements, budget constraints, and market demands. This knowledge supports smoother negotiations, optimized supply chain management, and successful lighting installations across diverse global regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the chip on board led strip Sector

Market Overview & Key Trends

The global chip on board (COB) LED strip market is experiencing robust growth driven by rising demand for efficient, high-quality lighting solutions across residential, commercial, and industrial sectors. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly adopting COB LED strips due to their superior brightness, uniform illumination, and energy efficiency compared to traditional LED strips. Key growth drivers include urbanization, infrastructure development, and rising environmental regulations encouraging energy-saving technologies.

Emerging sourcing trends reflect a shift toward flexible and customizable lighting products. Buyers are prioritizing suppliers who offer adaptable COB LED strips capable of fitting curved surfaces and tight spaces, allowing for innovative architectural and retail lighting designs. Additionally, with the rise of smart lighting, integration of COB LED strips with IoT and dimmable controls is becoming a vital feature, enabling remote management and energy optimization.

From a market dynamics perspective, price sensitivity remains a critical factor in regions like Africa and South America, where budget constraints push buyers to balance cost with performance. Meanwhile, European buyers, including those in Poland, emphasize product quality, longevity, and strict compliance with international standards. The Middle East market is characterized by demand for high-performance, durable solutions suitable for harsh environments, such as extreme heat.

Global supply chains are adapting to these regional nuances, with manufacturers increasingly offering tailored solutions and local warehousing to reduce lead times. Partnerships with logistics providers and adherence to international certifications also improve buyer confidence, especially for bulk procurement.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the procurement decisions of B2B buyers worldwide, including those in emerging and mature markets. COB LED strips inherently support environmental goals due to their energy efficiency, which reduces power consumption and carbon footprint. However, buyers should also evaluate the sustainability practices of their suppliers, encompassing raw material sourcing, manufacturing processes, and end-of-life product management.

Ethical sourcing is gaining prominence, with an emphasis on conflict-free materials, responsible labor practices, and transparency in the supply chain. Buyers from Europe and the Middle East particularly prioritize suppliers who demonstrate compliance with environmental and social governance (ESG) criteria. Certifications such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and Energy Star are increasingly required to ensure products meet stringent safety and environmental standards.

Materials innovation is another sustainability trend in the COB LED strip sector. Use of recyclable substrates, low-toxicity phosphors, and halogen-free components reduces environmental impact. Additionally, manufacturers focusing on heat dissipation technologies extend product lifespan, minimizing waste and lowering replacement frequency.

For international buyers, partnering with suppliers who offer transparent lifecycle assessments and provide take-back or recycling programs can significantly enhance sustainability credentials. This approach aligns with growing regulatory pressure and corporate responsibility commitments in regions like Europe and South America, while also appealing to environmentally conscious consumers.

Brief Evolution & Historical Context

COB LED technology emerged as a significant advancement in LED lighting over the past decade, evolving from traditional surface-mounted device (SMD) LEDs. Unlike SMD LEDs that house individual chips separately, COB LEDs mount multiple chips directly onto a single substrate, allowing higher LED density and improved light uniformity.

Initially developed to address issues such as visible hotspots and uneven illumination common in older LED strips, COB LED strips have progressively gained traction due to their enhanced brightness, energy efficiency, and compact form factor. This evolution has opened new applications in architectural, retail, and ambient lighting where seamless light lines are critical.

For B2B buyers, understanding this progression highlights why COB LED strips represent a strategic upgrade from conventional LED technologies, offering superior performance and cost-effectiveness in long-term lighting projects across diverse markets.

Related Video: LED Revolution – Ep 08 – What is COB (Chip on Board) LED display technology (in depth)

Frequently Asked Questions (FAQs) for B2B Buyers of chip on board led strip

-

How can I effectively vet suppliers of chip on board (COB) LED strips for international B2B purchases?

To vet suppliers, prioritize those with verifiable certifications such as ISO 9001 for quality management and CE or RoHS for safety and environmental compliance. Request detailed product datasheets and samples to evaluate performance and build quality. Check references or case studies from similar markets (Africa, South America, Middle East, Europe). Verify manufacturing capabilities, production capacity, and export experience. Utilize third-party inspection services or audits to ensure factory standards meet your requirements. Finally, assess communication responsiveness and after-sales support to ensure smooth long-term partnership. -

What customization options are typically available for COB LED strips, and how can I negotiate them?

COB LED strip customization often includes length, color temperature, brightness levels, PCB thickness, adhesive backing type, and waterproof ratings (IP65, IP67). Some suppliers also offer private labeling and packaging tailored to your market. When negotiating, clearly specify your technical requirements and intended applications. Request prototypes to verify customization feasibility. Bulk orders usually unlock better pricing for custom specs. Establish minimum order quantities (MOQs) for custom products early, and confirm lead times to align with your project deadlines, especially for international shipments. -

What are common MOQ and lead times for international B2B orders of COB LED strips, and how can these affect my supply chain?

MOQs for COB LED strips vary widely, typically ranging from 500 meters to several thousand meters depending on the supplier and customization level. Lead times generally span 3 to 8 weeks, influenced by order size, customization complexity, and production backlog. International shipping adds additional time, often 2-4 weeks depending on logistics. Plan orders well in advance and communicate with suppliers to align production and delivery schedules. Consider buffer stock to mitigate delays, especially when serving geographically distant markets such as Africa or South America. -

Which quality assurance standards and certifications should I require from COB LED strip suppliers?

Demand suppliers provide certifications like ISO 9001 for quality management systems, CE marking for European market compliance, RoHS for hazardous substances restriction, and UL or ETL certifications if targeting North American or global markets. Verify warranty policies and product test reports, including lumen output, color consistency (MacAdam steps), and lifespan testing. Request batch traceability to manage quality control during production. These certifications and standards assure product reliability and compliance with international regulations, reducing risks in cross-border transactions. -

What are the best practices for managing logistics and shipping of COB LED strips to regions like Africa, South America, the Middle East, and Europe?

Choose reliable freight forwarders with experience in your target regions to optimize shipping routes and reduce transit times. Consider shipping methods: air freight for urgent orders or sea freight for cost efficiency on bulk shipments. Ensure proper packaging to protect COB strips from moisture, static, and mechanical damage during transit. Clarify Incoterms (e.g., FOB, CIF) with suppliers to define responsibilities. Factor in customs clearance, import duties, and local regulations. Maintaining clear documentation and tracking systems helps avoid delays and facilitates smooth delivery. -

How can I mitigate risks related to disputes or product quality issues in international COB LED strip transactions?

Establish detailed contracts specifying product specifications, delivery terms, payment conditions, and quality standards. Include clauses for dispute resolution, such as arbitration or mediation, preferably under international trade laws (e.g., ICC rules). Insist on third-party pre-shipment inspections and quality control checkpoints. Maintain transparent communication and keep records of all correspondence. Use secure payment methods like letters of credit or escrow services to protect financial interests. Promptly address issues with suppliers and seek expert legal advice if necessary to resolve conflicts efficiently. -

What payment terms are standard for international B2B buyers of COB LED strips, and how can I negotiate favorable conditions?

Common payment terms include 30% upfront deposit with 70% balance before shipment, or letter of credit (L/C) to guarantee payment upon compliance with contract terms. For established relationships, net 30 or net 60 days post-delivery may be negotiated. To improve terms, demonstrate consistent order volume, timely payments, and strong business credibility. Consider using escrow or trade finance services to reduce risk. Always clarify currency and bank charges upfront to avoid surprises. Negotiating flexible terms improves cash flow management, especially in emerging markets with fluctuating currencies. -

Are there specific considerations for COB LED strip buyers in emerging markets like Africa or South America regarding product performance and support?

Buyers in emerging markets should prioritize suppliers offering COB strips with robust durability features such as high IP ratings for dust and moisture resistance, given challenging environmental conditions. Ensure product compatibility with local voltage and power standards. Evaluate supplier capacity to provide localized technical support, warranty services, and spare parts availability. Consider lead times carefully to avoid stockouts due to longer shipping durations. Also, assess supplier experience in similar markets to ensure understanding of regional logistics, regulations, and commercial practices for smoother transactions.

Strategic Sourcing Conclusion and Outlook for chip on board led strip

Key Insights for Strategic Sourcing of COB LED Strips

For international B2B buyers in Africa, South America, the Middle East, and Europe, sourcing Chip on Board (COB) LED strips presents a compelling opportunity to enhance lighting solutions with superior uniformity, energy efficiency, and design flexibility. The high LED density and smooth light output make COB strips ideal for premium architectural, retail, and residential projects, while their durability ensures long-term value. However, buyers should carefully evaluate suppliers’ capabilities in maintaining consistent color quality and thermal management to avoid performance issues.

Prioritize Strategic Sourcing to Unlock Value

- Supplier Expertise: Partner with manufacturers who demonstrate rigorous quality control, especially in color binning and heat dissipation.

- Customization and Compliance: Seek suppliers able to provide tailored solutions that comply with regional standards and installation requirements.

- Cost Efficiency: Consider total cost of ownership, balancing upfront pricing with energy savings and longevity.

- Logistics and Support: Opt for vendors offering reliable delivery channels and technical support tailored to your region’s market dynamics.

Looking Ahead

As COB LED technology continues to evolve, buyers who strategically source from innovative and dependable partners will gain a competitive edge in delivering cutting-edge lighting experiences. Embrace this technology to future-proof your projects and meet rising demand for high-quality, sustainable lighting across diverse markets. Begin your sourcing journey today to leverage the full potential of COB LED strips in your international ventures.