Introduction: Navigating the Global Market for boat led strip lights

Boat LED strip lights have become indispensable in modern marine lighting solutions, blending functionality with aesthetic appeal to enhance safety and ambiance on vessels of all sizes. For international B2B buyers—especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe—understanding the nuances of these specialized lighting products is crucial for making strategic sourcing decisions. These regions demand durable, energy-efficient, and customizable lighting options that can withstand harsh marine environments while meeting regulatory and consumer expectations.

This guide offers a thorough exploration of boat LED strip lights, covering key aspects including the various types of LED strips—such as encased waterproof and neon-diffused options—manufacturing standards, and quality control processes. Buyers will gain insights into sourcing from reputable suppliers who provide competitive pricing, customization capabilities, and reliable after-sales support. Additionally, the guide delves into cost considerations, market trends, and essential installation best practices tailored to marine applications.

By navigating this comprehensive resource, B2B buyers can confidently evaluate product specifications, supplier credibility, and logistical factors critical to successful bulk procurement. Whether outfitting commercial fleets, recreational boats, or marina facilities, understanding these elements empowers buyers to optimize investment returns, ensure compliance, and deliver superior lighting solutions to their end customers. This actionable intelligence is especially valuable for enterprises in emerging and mature markets seeking to leverage the latest LED technologies and maintain a competitive edge in the global marine lighting industry.

Understanding boat led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Encased LED Strip Lights (Clear Sleeve) | Waterproof silicone sleeve, clear for direct LED visibility | Under-gunnel lighting, deck safety lighting | + High brightness and clarity – Requires careful placement to avoid glare |

| Neon LED Strip Lights (Opaque Sleeve) | Diffused light with soft glow, neon-like appearance | Ambient and decorative lighting, open mounting | + Soft, eye-friendly light – Slightly lower brightness than clear sleeve |

| Neon Mini LED Strip Lights | Ultra-thin profile, diffused neon effect | Tight spaces, subtle accent lighting | + Compact size for limited space – Limited light output for large areas |

| RGB LED Strip Lights | Multi-color control with RGB controller | Dynamic lighting effects, customizable ambiance | + Versatile color options – Requires compatible controllers and wiring |

| High-Lumen White LED Strips | High brightness, focused white light | Task lighting, navigation, and work areas | + Intense illumination for safety – Higher power consumption |

Encased LED Strip Lights (Clear Sleeve)

Encased LED strip lights with a clear silicone sleeve are designed to protect the LEDs from water and physical damage while allowing the light to shine brightly and clearly. This type is ideal for under-gunnel or recessed mounting where direct LED visibility is acceptable and glare can be controlled. For B2B buyers, these strips offer durability and high brightness, making them suitable for safety-critical applications on boats. When sourcing, ensure the sleeve material is marine-grade and UV-resistant to withstand harsh environments common in Africa and the Middle East.

Neon LED Strip Lights (Opaque Sleeve)

Neon LED strips feature an opaque silicone sleeve that diffuses light, creating a soft, even glow reminiscent of traditional neon lighting. This design is perfect for ambient and decorative lighting where harsh LED points are undesirable. B2B buyers targeting hospitality or luxury boat markets in Europe or South America will find these strips advantageous for enhancing aesthetic appeal. Buyers should verify the diffusion quality and waterproof rating to ensure consistent performance under marine conditions.

Neon Mini LED Strip Lights

The Neon Mini variant offers a compact, ultra-thin profile while maintaining the neon-style diffused light effect. Its small size enables installation in tight or inconspicuous areas, ideal for accent lighting or subtle illumination without compromising boat design. For international B2B buyers, especially those in markets with space constraints like smaller yachts or fishing boats common in Nigeria or Spain, Neon Mini strips provide a flexible solution. Consideration must be given to lower light output and ensuring compatibility with existing lighting systems.

RGB LED Strip Lights

RGB LED strips allow for full-color customization through an RGB controller, enabling dynamic lighting effects and mood setting on boats. These are highly sought after for entertainment and luxury vessels where ambiance is a priority. B2B buyers should focus on sourcing marine-grade controllers and cables to prevent corrosion and ensure reliable operation in saltwater environments. Additionally, planning for installation complexity and power requirements is essential for seamless integration.

High-Lumen White LED Strips

High-lumen white LED strips provide intense, focused illumination suitable for navigation, work areas, or safety lighting on boats. These strips are essential for commercial vessels or fishing boats where visibility is critical. Buyers from regions with high maritime activity, such as the Middle East or coastal Europe, will benefit from sourcing high-efficiency, durable strips that comply with local maritime safety standards. It is important to balance brightness with energy consumption and heat dissipation in procurement decisions.

Related Video: HowTo: Install LED Strip Lighting on your Boat

Key Industrial Applications of boat led strip lights

| Industry/Sector | Specific Application of Boat LED Strip Lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Transportation | Deck and walkway illumination on commercial vessels | Enhances safety by improving visibility, reduces accidents | Waterproof rating, durability against saltwater corrosion, compliance with maritime safety standards |

| Luxury Yacht & Charter | Ambient and accent lighting for aesthetic appeal | Elevates customer experience, supports brand differentiation | Customizable colors, flexibility in installation, high-quality diffusion for soft light effects |

| Fishing Industry | Functional lighting for night fishing boats | Improves operational efficiency and safety during night hours | High brightness, energy efficiency, ruggedness for harsh marine environments |

| Port and Harbor Services | Dock and mooring area lighting | Facilitates safer and more efficient loading/unloading processes | Long lifespan, easy installation and maintenance, compatibility with existing power systems |

| Recreational Boating | Interior cabin and under-gunnel lighting | Enhances user comfort and boat usability after dark | Compact size, low heat emission, ease of trimming and customization |

Boat LED strip lights are widely adopted in marine transportation to illuminate decks and walkways on commercial vessels. These strips provide consistent, energy-efficient lighting that significantly enhances crew safety by reducing trip hazards in low-light conditions. For B2B buyers in regions like Nigeria or Spain, sourcing LED strips with high waterproof ratings (IP67 or above) and corrosion-resistant materials is critical to withstand harsh saltwater environments and comply with international maritime regulations.

In the luxury yacht and charter sector, boat LED strip lights serve as ambient and accent lighting, transforming the onboard atmosphere to meet high aesthetic standards. This application is vital for businesses aiming to differentiate their offerings and attract premium clientele. Buyers should prioritize suppliers offering customizable RGB options with smooth light diffusion to create elegant, soft glows without glare. Flexibility in strip length and mounting options is essential to accommodate unique yacht designs typical in European and Middle Eastern markets.

The fishing industry relies on boat LED strip lights for functional illumination during night fishing operations. Bright, durable, and energy-efficient strips improve visibility for handling gear and navigating waters safely. Buyers from South America and Africa must focus on sourcing LED strips that deliver high lumen output while maintaining low power consumption to optimize battery life on fishing vessels. Rugged construction to endure rough marine conditions is a key requirement.

In port and harbor services, LED strip lights are used for dock and mooring area illumination, enhancing safety and operational efficiency during loading and unloading. Businesses benefit from the long lifespan and low maintenance needs of LED strips, which reduce downtime and operational costs. International buyers should seek products compatible with existing infrastructure and easy to install in outdoor, often exposed, environments.

For recreational boating, LED strip lights improve interior cabin lighting and under-gunnel illumination, enhancing comfort and usability after dark. The compact size and low heat emission of LED strips allow for discreet installation in tight spaces. Buyers, especially in markets like Spain and the Middle East, should consider options that allow trimming and customization to fit varied boat layouts while ensuring energy efficiency and durability.

Related Video: LED Strip Lights Installed on Boat

Strategic Material Selection Guide for boat led strip lights

When selecting materials for boat LED strip lights, international B2B buyers must consider factors such as marine environmental exposure, durability, compliance with regional standards, and cost-effectiveness. The materials used in the encapsulation, substrate, and wiring significantly influence the product’s performance and longevity in harsh marine conditions. Below is an analysis of four common materials used in boat LED strip lights, emphasizing their properties, advantages, limitations, and relevance to buyers from Africa, South America, the Middle East, and Europe.

Silicone Encapsulation

Key Properties:

Silicone is highly flexible and offers excellent resistance to UV radiation, saltwater corrosion, and extreme temperatures ranging from -60°C to 230°C. It provides superior waterproofing and electrical insulation, making it ideal for marine environments.

Pros & Cons:

Silicone encapsulation protects LED strips from moisture and physical damage while maintaining flexibility for installation in curved or tight spaces. However, it is generally more expensive and can be more challenging to manufacture compared to PVC alternatives.

Impact on Application:

Silicone-encased LED strips are particularly suited for exposed areas on boats where direct contact with water and sunlight occurs, such as under gunnels or deck lighting. Their resilience to saltwater makes them ideal for coastal regions with high salinity, common in parts of Africa and the Middle East.

Considerations for International Buyers:

Buyers in Europe and South America should verify compliance with regional standards such as the European CE marking and RoHS directives, which often include restrictions on material toxicity and environmental impact. Silicone’s durability aligns well with these regulations. For African and Middle Eastern markets, prioritizing silicone-encased strips can reduce maintenance costs due to harsh climatic conditions.

Polyvinyl Chloride (PVC) Sleeve

Key Properties:

PVC is a widely used thermoplastic with moderate flexibility and good resistance to abrasion and water. It typically withstands temperatures up to 60°C to 80°C but is less UV resistant than silicone.

Pros & Cons:

PVC sleeves are cost-effective and easier to manufacture, making them attractive for large-scale procurement. However, PVC can degrade under prolonged UV exposure and may become brittle in cold climates, reducing its lifespan on boats operating in variable temperature zones.

Impact on Application:

PVC-encased LED strips are suitable for indoor or sheltered marine applications where direct exposure to sunlight and salt spray is limited. They are often used in cabin lighting or under consoles.

Considerations for International Buyers:

Buyers from regions with intense sunlight, such as the Middle East and parts of Africa, should be cautious with PVC due to its UV sensitivity. European buyers must ensure PVC materials meet REACH and RoHS standards. In South America, where cost sensitivity is high, PVC may be preferred for budget-conscious projects with indoor or protected installations.

Aluminum Substrate

Key Properties:

Aluminum is commonly used as a substrate for LED strips due to its excellent thermal conductivity, which helps dissipate heat generated by LEDs, enhancing lifespan and performance.

Pros & Cons:

Aluminum substrates improve LED efficiency and reliability by reducing overheating risks. However, aluminum is heavier than flexible PCB alternatives and requires additional waterproofing layers to prevent corrosion in marine environments.

Impact on Application:

Ideal for high-performance boat LED strips where heat management is critical, such as high-lumen task lighting or extended runtime applications. Aluminum-based strips are preferred in temperate European waters and commercial vessels requiring robust lighting solutions.

Considerations for International Buyers:

Buyers should confirm that aluminum substrates are anodized or coated to meet ASTM B117 salt spray resistance standards, especially important for African and Middle Eastern buyers dealing with corrosive marine atmospheres. Aluminum’s higher cost and weight might be a limiting factor for smaller boats common in South America.

Marine-Grade Tinned Copper Wiring

Key Properties:

Marine-grade wiring features copper conductors coated with tin to prevent corrosion and maintain electrical conductivity in wet and salty environments. It typically complies with marine electrical standards such as ISO 10133.

Pros & Cons:

Tinned copper wiring offers superior corrosion resistance and flexibility, essential for wiring LED strips in boats. The downside is a slightly higher cost compared to standard copper wiring and the need for proper connectors and insulation.

Impact on Application:

Using marine-grade wiring ensures long-term reliability of electrical connections in boat LED strip installations, critical for safety and maintenance reduction. It is indispensable in all marine lighting applications, especially in Africa and the Middle East where humidity and salt exposure are high.

Considerations for International Buyers:

Buyers should insist on wiring that meets international marine standards (ISO, ASTM, or JIS) to ensure compatibility and safety. European buyers often require compliance with IEC standards. Proper certification reduces risks of electrical failures and enhances buyer confidence in product quality.

| Material | Typical Use Case for boat led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Encapsulation | Exposed marine areas, under gunnels, deck lighting | Superior waterproofing and UV resistance | Higher cost and manufacturing complexity | High |

| PVC Sleeve | Indoor or sheltered marine lighting | Cost-effective and easy to produce | UV degradation and limited temperature range | Low |

| Aluminum Substrate | High-performance, heat-sensitive lighting | Excellent heat dissipation | Requires additional waterproofing, heavier | Medium |

| Marine-Grade Tinned Copper Wiring | Electrical connections for all marine LED installations | Corrosion-resistant and reliable | Higher cost than standard wiring | Medium |

This guide equips international B2B buyers with critical insights to make informed decisions about material selection for boat LED strip lights, balancing performance, durability, compliance, and cost tailored to their regional needs and applications.

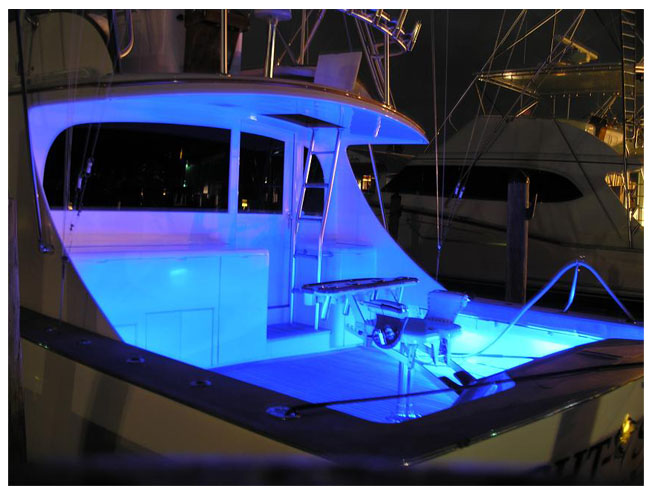

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for boat led strip lights

The manufacturing and quality assurance of boat LED strip lights involve meticulous processes designed to ensure durability, safety, and performance in harsh marine environments. For international B2B buyers—especially those operating in Africa, South America, the Middle East, and Europe—understanding these processes and quality checkpoints is crucial to selecting reliable suppliers and products that meet both local and international standards.

Manufacturing Process Overview

1. Material Preparation

The foundation of high-quality boat LED strip lights lies in selecting robust materials capable of withstanding marine conditions such as moisture, saltwater corrosion, UV exposure, and vibration. Key materials include:

- Flexible PCB substrates (often polyimide or PET) that provide flexibility and electrical insulation.

- High-grade LEDs with marine-grade brightness and color consistency.

- Waterproof encapsulation materials, typically silicone or polyurethane, applied as sleeves or coatings to seal the strip.

- Marine-grade wiring and connectors, often tinned copper to resist corrosion.

Suppliers typically source raw materials from certified vendors, ensuring traceability and compliance with environmental and safety regulations.

2. Forming and Circuit Assembly

This stage involves:

- Mounting LEDs on flexible circuit boards via automated pick-and-place machines for precise positioning.

- Soldering components including resistors, capacitors, and controllers using reflow soldering to ensure strong, durable electrical connections.

- Applying waterproof coatings or encasing strips in silicone sleeves. Two main types exist: clear sleeves that allow direct LED visibility and diffused sleeves that soften light output (neon effect).

Precision in this step is critical as any defects can lead to failures in harsh marine environments.

3. Final Assembly and Integration

After LED assembly, strips are:

- Cut to standard or custom lengths, with marked cut points to preserve circuit integrity.

- Wired with marine-grade cables and connectors, often requiring manual soldering and heat-shrink tubing for insulation.

- Integrated with control systems such as RGB controllers or dimmers, depending on the product variant.

Manufacturers may also incorporate mounting channels or adhesive backing to facilitate installation on boats.

4. Finishing and Packaging

Final finishing includes:

- Visual inspection for defects such as soldering faults, scratches, or uneven coating.

- Cleaning and drying to remove flux residues and contaminants.

- Packaging in moisture-resistant and branded materials, often customized for B2B clients to enhance brand identity and protect product integrity during shipping.

Quality Assurance and Control (QA/QC)

For B2B buyers, the assurance of quality and compliance is paramount. Key elements include adherence to international standards, rigorous testing, and transparent supplier verification.

Relevant International and Industry Standards

- ISO 9001:2015 — A fundamental quality management system standard ensuring consistent manufacturing quality and continuous improvement.

- CE Marking — Indicates conformity with European safety, health, and environmental protection requirements; crucial for buyers in Europe and many other markets.

- RoHS Compliance — Restricts hazardous substances in electronic products, important for environmental and health regulations globally.

- IP Ratings (e.g., IP67, IP68) — Certify waterproof and dustproof capabilities, vital for marine applications.

- Marine Industry Standards — Depending on region, certifications such as ABS (American Bureau of Shipping), DNV GL, or API standards may apply for marine-grade lighting products.

QC Checkpoints in Manufacturing

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspections, LED placement accuracy, and waterproofing integrity.

- Final Quality Control (FQC): Comprehensive testing of finished products before packaging, focusing on functional performance, waterproofing, and physical defects.

Common Testing Methods

- Electrical Testing: Verifies voltage, current, and power consumption to ensure LEDs operate within specified parameters.

- Waterproof Testing: Submersion or spray tests to confirm IP ratings.

- Thermal Testing: Measures heat dissipation and operating temperature range to prevent premature failure.

- Durability and Vibration Testing: Simulates marine conditions to assess mechanical robustness.

- Color and Brightness Consistency: Using photometric equipment to ensure uniform light output.

How B2B Buyers Can Verify Supplier Quality

1. Supplier Audits

Conducting on-site or third-party factory audits is critical. Audits should evaluate:

- Manufacturing capabilities and equipment.

- Quality management system compliance (ISO 9001 certification).

- Worker training and safety practices.

- Traceability and documentation controls.

For buyers in regions with logistical challenges, partnering with local inspection agencies or global quality assurance firms can facilitate remote or scheduled audits.

2. Review of Quality Documentation

Requesting and reviewing:

- Test reports (e.g., electrical, waterproof, and thermal tests).

- Certificates of compliance (CE, RoHS, IP rating certificates).

- Material traceability documents.

- Warranty policies and defect rates.

Transparency here is a strong indicator of a reputable supplier.

3. Third-Party Inspection Services

Engaging independent inspection companies to perform pre-shipment inspections can mitigate risks. These inspections typically cover:

- Visual quality checks.

- Functional testing on random samples.

- Verification of packaging and labeling compliance.

This is especially beneficial for buyers importing from distant manufacturing hubs.

QC and Certification Nuances for International Buyers

-

Africa & South America: Import regulations may vary, and customs clearance often requires CE or equivalent certifications. Buyers should verify local approval requirements and ensure suppliers provide compliant documentation to avoid shipment delays.

-

Middle East: Some countries enforce strict electrical safety standards and may require certification from local authorities (e.g., SASO in Saudi Arabia). Buyers should clarify these requirements upfront and confirm supplier compliance.

-

Europe (e.g., Spain): Compliance with EU directives is mandatory. Buyers must ensure that suppliers provide CE marking and RoHS certificates, and that products meet IP ratings suitable for marine use.

-

Nigeria and other African markets: Power quality and stability can vary, so buyers should consider products with robust voltage regulation and surge protection. Additionally, due to import duties and taxes, consolidated bulk shipments with proper certifications can reduce costs and facilitate smoother customs processes.

Strategic Recommendations for B2B Buyers

- Prioritize suppliers with ISO 9001 certification and verifiable marine-grade product certifications.

- Insist on sample testing before large orders to evaluate real-world performance.

- Use written quality agreements detailing inspection criteria, defect rates, and remedies.

- Consider long-term partnerships with manufacturers offering customization, after-sales support, and flexible MOQ (minimum order quantities).

- Stay informed of regional certification requirements and ensure suppliers can support compliance documentation.

By thoroughly understanding the manufacturing stages and quality assurance measures for boat LED strip lights, international B2B buyers can make informed procurement decisions. This knowledge helps mitigate risks, ensures product longevity in challenging marine environments, and aligns purchases with regional compliance standards—key factors for successful international trade and end-user satisfaction.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for boat led strip lights Sourcing

Understanding the cost and pricing dynamics of boat LED strip lights is crucial for international B2B buyers aiming to maximize value while ensuring product quality and reliability. This analysis breaks down the main cost components, key pricing influencers, and strategic buyer tips to help businesses from Africa, South America, the Middle East, and Europe navigate this market effectively.

Key Cost Components in Boat LED Strip Lights

-

Materials

The core materials include high-quality LEDs, flexible PCB substrates, waterproof silicone sleeves (clear or diffused), and marine-grade wiring. Premium materials, especially marine-certified components resistant to corrosion and moisture, increase costs but ensure durability in harsh marine environments. -

Labor and Manufacturing Overhead

Skilled labor is needed for assembling, soldering, and quality checks. Overhead includes factory utilities, equipment depreciation, and administrative costs. Manufacturers with advanced automation may offer competitive pricing due to efficiency gains. -

Tooling and Customization

Custom lengths, colors, and packaging require specialized tooling and setup, impacting unit costs. Buyers requesting bespoke RGB configurations, specific waterproof ratings, or branded packaging should expect higher prices reflecting these additional processes. -

Quality Control (QC)

Rigorous QC ensures reliability and compliance with safety standards. Testing waterproofing, LED brightness, and electrical integrity adds to production costs but reduces defect rates, which is critical for marine applications. -

Logistics and Shipping

Shipping costs vary widely depending on order volume, destination, and shipping method (air vs. sea freight). Marine-grade packaging to prevent damage during transit also factors into logistics expenses. -

Supplier Margin

Margins depend on supplier scale, brand positioning, and market conditions. Established suppliers offering warranties and after-sales support may command higher margins but provide added value.

Influencing Factors on Price

-

Order Volume and Minimum Order Quantity (MOQ)

Bulk purchases significantly lower the per-unit price. Buyers from regions with higher import duties or shipping costs, such as Nigeria or South America, benefit from consolidating orders to reduce freight and customs overhead. -

Product Specifications and Customization

Higher IP ratings (e.g., IP68), RGB capabilities, and advanced features like dimming or app control increase unit costs. Custom colors or packaging tailored for branding also add to pricing. -

Material Quality and Certifications

Marine-grade certifications, CE, RoHS compliance, and other quality assurances influence pricing. Buyers prioritizing longevity and safety should factor these into their cost assessments. -

Supplier Reputation and Location

Suppliers closer to major shipping hubs (e.g., Europe or Middle East ports) may offer reduced lead times and freight costs. Established manufacturers with proven track records often price higher but mitigate risks of defects or delays. -

Incoterms and Payment Terms

Pricing varies with delivery terms such as FOB, CIF, or DDP. Buyers should understand these terms to anticipate additional costs like import duties, insurance, and local handling fees.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Based on Volume and Long-Term Partnership

Leverage order size and repeat business prospects to negotiate price breaks and favorable payment terms. Suppliers value steady relationships, especially in emerging markets like Africa and South America. -

Consider Total Cost of Ownership (TCO)

Beyond unit price, factor in installation costs, warranty coverage, replacement frequency, and energy efficiency. High-quality LED strips may cost more upfront but save on maintenance and power consumption. -

Request Samples and Verify Certifications

Always test samples for waterproofing, brightness, and durability before committing to large orders. Confirm supplier certifications to ensure compliance with local regulations and maritime safety standards. -

Account for Regional Logistics Nuances

In regions with complex customs processes or higher import taxes, plan for extended lead times and additional clearance costs. Consolidate shipments where possible to optimize freight charges. -

Understand Pricing Fluctuations

Global supply chain disruptions, raw material price shifts, and currency fluctuations can impact costs. Maintain flexible budgets and build buffer timeframes into procurement schedules.

Disclaimer: Prices for boat LED strip lights vary significantly depending on specifications, order size, and supplier location. The insights provided here are indicative and meant to guide strategic sourcing decisions rather than serve as fixed pricing references.

By closely analyzing these cost elements and pricing drivers, B2B buyers can make informed decisions that balance cost-efficiency with product quality and supplier reliability, ensuring successful sourcing of boat LED strip lights tailored to their unique market needs.

Spotlight on Potential boat led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘boat led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for boat led strip lights

Key Technical Properties of Boat LED Strip Lights

1. Waterproof Rating (IP Code)

Boat LED strip lights must have a high waterproof rating, typically IP65, IP67, or IP68. This rating indicates the product’s resistance to water ingress, crucial for marine environments where exposure to splashes, rain, and submersion is common. For B2B buyers, selecting the correct IP rating ensures durability and reduces warranty claims from water damage.

2. Marine-Grade Materials

Materials such as marine-grade silicone sleeves and tin-coated copper wiring are standard to prevent corrosion from saltwater and humidity. Using these materials extends the lifespan of LED strips and reduces maintenance costs, which is vital for commercial buyers in coastal regions like Nigeria or Spain where salt exposure is high.

3. LED Chip Density and Brightness (Lumens per Meter)

LED chip density refers to the number of LEDs per meter, often ranging from 30 to 120 LEDs/m. Higher density means brighter, more uniform light, essential for both aesthetic and safety lighting on boats. Buyers should assess their project needs carefully, balancing brightness with power consumption to optimize energy efficiency.

4. Voltage and Power Consumption

Most boat LED strip lights operate on 12V or 24V DC systems compatible with marine electrical setups. Understanding voltage requirements and power consumption (watts per meter) helps buyers ensure compatibility with onboard power systems and avoid electrical failures or excessive battery drain.

5. Flexibility and Cutability

Flexibility allows strips to conform to curved or irregular surfaces typical on boats. Cutability at designated marks enables customization of length for precise installation, reducing waste and installation time. This feature is critical for large-scale projects or OEM customization.

6. Color Options and Control Compatibility

Boat LED strips come in single color (e.g., white or blue) or RGB variants for dynamic lighting effects. Compatibility with marine-grade RGB controllers and wiring ensures seamless integration into advanced lighting systems. Buyers should verify controller compatibility to enable features like dimming or color changing.

Common Trade Terminology for International B2B Buyers

OEM (Original Equipment Manufacturer)

Refers to suppliers who produce products that can be branded and sold by another company. For boat LED strips, OEM arrangements allow buyers to customize packaging, colors, or specifications to match their brand identity, crucial for businesses in competitive markets like Europe or the Middle East.

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in one order. Understanding MOQ helps buyers from emerging markets like Africa and South America plan budgets and inventory effectively, avoiding excess stock or high upfront costs.

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain price quotes and terms for specific product quantities and specifications. RFQs are essential for B2B buyers to compare offers transparently and negotiate better prices or terms.

Incoterms (International Commercial Terms)

Standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) impact total landed cost and delivery timelines, critical for importers in regions with complex logistics.

Lead Time

The time between placing an order and receiving the goods. Accurate lead time estimates help buyers plan projects and inventory, minimizing delays especially for seasonal or event-driven marine lighting projects.

IP Rating (Ingress Protection Rating)

A standardized code indicating protection levels against solids and liquids. For marine buyers, prioritizing high IP ratings guarantees that lighting products withstand harsh environmental conditions, reducing returns and replacements.

Selecting boat LED strip lights with these technical properties and understanding key trade terms enables international B2B buyers to make informed purchasing decisions. This ensures product reliability, cost efficiency, and smoother supply chain management tailored to the marine industry’s demanding environment.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the boat led strip lights Sector

Market Overview & Key Trends

The global boat LED strip lights market is experiencing robust growth driven by increasing demand for energy-efficient, customizable, and durable lighting solutions in marine applications. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are capitalizing on this trend to enhance vessel aesthetics, safety, and functionality. In particular, countries with expanding marine tourism and commercial boating sectors—such as Nigeria and Spain—are notable markets with rising procurement volumes.

Key market drivers include:

- Energy Efficiency and Longevity: LED technology offers significant reductions in power consumption and longer lifespans compared to traditional lighting, which is crucial for marine environments where power resources may be limited.

- Customization and Versatility: Flexible strip designs, including RGB color options and waterproof encasements, allow buyers to meet diverse lighting needs—from underwater illumination to deck ambience.

- Technological Innovation: Advances such as smart LED controllers and app-enabled color tuning are becoming standard features, enabling sophisticated lighting effects and integration with vessel automation systems.

Emerging sourcing trends for B2B buyers:

- Preference for Marine-Grade Materials: Suppliers increasingly offer corrosion-resistant, waterproof, and UV-stabilized LED strips designed specifically for harsh saltwater environments.

- Bulk Purchasing and Custom Orders: Large-scale projects benefit from wholesale sourcing that provides cost efficiencies and tailored product specifications, such as custom lengths and packaging.

- Direct Manufacturer Partnerships: Buyers are seeking suppliers with transparent supply chains and direct factory relationships to ensure product quality, reduce lead times, and optimize logistics.

Regional market dynamics:

- Africa & South America: Growing recreational boating and commercial fishing industries are fueling demand, with buyers focusing on rugged, cost-effective lighting solutions.

- Middle East: High-end luxury yachts and commercial vessels drive demand for premium, customizable LED strips with advanced features.

- Europe (e.g., Spain): Stringent marine safety regulations and sustainability mandates encourage adoption of certified, eco-friendly LED lighting products.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly critical in the procurement of boat LED strip lights, reflecting broader corporate social responsibility (CSR) goals and regulatory pressures. Buyers prioritize suppliers who demonstrate commitment to environmentally sound manufacturing processes and ethical supply chains.

Environmental considerations include:

- Energy Conservation: LEDs inherently consume less power than incandescent or halogen alternatives, reducing carbon footprints associated with vessel operation.

- Material Selection: The use of recyclable and non-toxic materials in LED strips—such as lead-free solder and halogen-free plastics—helps minimize environmental impact.

- Packaging: Eco-friendly packaging solutions, including biodegradable or recycled materials, are preferred by buyers aiming to reduce waste.

Ethical sourcing practices are vital to mitigate risks related to labor rights and supply chain transparency. Verified certifications like ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and REACH compliance provide assurance that products meet international environmental and safety standards.

For B2B buyers from regions with emerging environmental regulations (e.g., the European Union) or growing consumer awareness (e.g., South Africa, Brazil), sourcing from certified, green manufacturers is not only a compliance issue but also a competitive differentiator. Building relationships with suppliers who invest in sustainable innovation and ethical labor practices supports long-term supply chain resilience and brand reputation.

Evolution of Boat LED Strip Lights: A Brief History

The evolution of boat LED strip lights mirrors broader advances in LED technology and marine lighting requirements. Initially, marine lighting relied heavily on incandescent bulbs, which were energy-intensive and had limited durability in wet, corrosive environments.

With the advent of flexible LED strip technology in the early 2000s, marine lighting underwent a transformation. Early LED strips were basic, often lacking waterproofing and marine-grade materials, limiting their use to interior or sheltered areas. Over the last decade, innovations such as waterproof silicone encasements, marine-grade wiring, and integrated RGB controllers have made LED strips suitable for exterior and underwater applications.

Today, boat LED strip lights are highly specialized products designed to withstand saltwater corrosion, UV exposure, and mechanical vibration. Their flexibility, energy efficiency, and aesthetic appeal have made them indispensable for modern commercial vessels, luxury yachts, and recreational boats worldwide. This evolution offers B2B buyers access to reliable, customizable lighting solutions that meet stringent marine standards and diverse operational needs.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of boat led strip lights

-

How can I effectively vet suppliers of boat LED strip lights for international B2B purchases?

To vet suppliers, prioritize those with established reputations and verifiable business licenses. Check for positive reviews from other international buyers, especially from regions similar to yours (e.g., Africa or South America). Request product samples to assess quality firsthand. Confirm they provide clear warranty terms and after-sales support. Additionally, verify their compliance with international quality standards and certifications relevant to marine products. Engaging with suppliers who participate in trade shows or have transparent communication channels helps build trust and reduces procurement risks. -

What customization options are typically available for boat LED strip lights in wholesale orders?

Wholesale suppliers often offer customization in length, color temperature, waterproofing level, and packaging. Some also allow branding on packaging or tailored LED colors to match corporate identity. For boats, options like encased strips with clear or diffused sleeves (neon-style) can be selected based on aesthetic and functional needs. It’s critical to discuss project-specific requirements upfront to ensure the supplier can accommodate custom voltage ratings, connectors, or control systems, especially for RGB or smart LED variants, which enhances integration with existing boat systems. -

What are common minimum order quantities (MOQs), lead times, and payment terms I should expect?

MOQs vary widely but typically range from 100 to 500 meters of LED strip lights per order. Lead times depend on customization and stock availability, generally between 2 to 6 weeks for standard products and longer for custom orders. Payment terms often include a 30% deposit with the balance due before shipment or upon delivery. International buyers should negotiate clear terms regarding currency, payment methods (e.g., letter of credit, wire transfer), and any escrow services to secure transactions. Early communication on these points helps prevent delays and financial disputes. -

Which quality assurance certifications should I look for when sourcing boat LED strip lights?

Look for certifications that ensure product safety and durability in marine environments, such as IP67 or IP68 waterproof ratings, CE marking (for Europe), RoHS compliance (restricting hazardous substances), and UL or ETL listings for electrical safety. Additionally, ISO 9001 certification indicates consistent manufacturing quality. Suppliers should provide test reports for salt spray resistance and UV stability, critical for marine applications. Requesting these documents upfront ensures the products will meet your region’s regulatory standards and perform reliably in harsh conditions. -

How can I optimize logistics and shipping for bulk orders of boat LED strip lights across continents?

Choose suppliers who offer consolidated shipping options to reduce freight costs and customs complexities. Sea freight is cost-effective for large volumes but plan for longer transit times; air freight suits urgent orders but is pricier. Verify the supplier’s experience with export documentation, including certificates of origin, and ensure compliance with import regulations in your country. Partnering with freight forwarders familiar with your region (e.g., West Africa or the Middle East) can expedite customs clearance. Always factor in buffer time for potential delays caused by inspections or paperwork. -

What strategies can help resolve disputes related to quality or delivery issues in international B2B transactions?

First, establish clear contract terms covering product specifications, delivery schedules, and acceptance criteria. Use third-party inspection services before shipment to verify product quality. If disputes arise, engage in direct communication with the supplier, providing detailed evidence like photos or test reports. Arbitration clauses or mediation through trade bodies can facilitate resolution without litigation. Maintaining a professional relationship and documenting all communications helps in negotiating amicable solutions, preserving long-term supplier partnerships. -

Are there regional considerations for sourcing boat LED strip lights in Africa, South America, the Middle East, and Europe?

Yes, regional considerations include climate factors affecting product choice—high humidity or saline environments demand higher IP ratings. Import regulations and tariffs differ widely; for example, the EU has strict REACH and CE requirements, while some African countries have variable customs procedures. Power standards vary, so confirm voltage compatibility. Language and cultural differences can affect communication; working with suppliers familiar with your region’s business practices enhances efficiency. Also, consider local demand trends to select LED styles and colors popular in your target market. -

How important is it to source marine-grade wiring and accessories with boat LED strip lights?

Marine-grade wiring and accessories are essential for durability and safety in the harsh marine environment. Such wiring is tin-coated to resist corrosion, withstands saltwater exposure, and maintains electrical integrity under vibration and moisture. Using standard wiring risks failures and safety hazards, leading to costly repairs or replacements. Always verify that connectors, controllers, and mounting channels are designed for marine use and compliant with relevant certifications. Investing in marine-grade components ensures system longevity and reduces maintenance costs for your B2B customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for boat led strip lights

Strategic sourcing of boat LED strip lights unlocks substantial value for international B2B buyers by combining cost efficiency, product innovation, and customization. Prioritizing suppliers with proven quality, comprehensive warranties, and marine-grade specifications ensures durability and safety in demanding aquatic environments. Bulk purchasing not only reduces unit costs but also streamlines procurement, enabling seamless project scalability across commercial and recreational marine applications.

For buyers in Africa, South America, the Middle East, and Europe—regions with growing marine industries and leisure boating markets—leveraging the latest LED technologies such as waterproof, RGB, and diffused neon-style strips can differentiate offerings and meet diverse customer preferences. Emphasizing supplier partnerships that provide flexible order volumes, local compliance support, and reliable shipping enhances supply chain resilience in these dynamic markets.

Illustrative Image (Source: Google Search)

Looking ahead, the boat LED strip light sector is poised for continued innovation, driven by advancements in smart lighting controls and energy-efficient designs. B2B buyers are encouraged to adopt a strategic sourcing mindset that balances price, quality, and technological edge to future-proof their inventory and service capabilities. Engaging proactively with trusted manufacturers and exploring customizable solutions will position businesses to capitalize on expanding marine lighting demand worldwide.