Introduction: Navigating the Global Market for bed led lights

In today’s fast-evolving global lighting landscape, bed LED lights have become an essential component for enhancing comfort, aesthetics, and energy efficiency in hospitality, healthcare, residential, and commercial environments. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—the ability to source high-quality bed LED lighting solutions is critical to meeting growing consumer expectations and regulatory demands.

The strategic procurement of bed LED lights involves navigating a complex array of product types, materials, manufacturing standards, and supplier capabilities. Buyers must balance cost-effectiveness with durability, energy consumption, and compliance with regional certifications such as CE in Europe or local safety standards in emerging markets like Nigeria and Indonesia. Additionally, understanding the nuances of customization options and integration with smart lighting controls can significantly differentiate your offerings in competitive markets.

This comprehensive guide offers a deep dive into the various types of bed LED lights, including ambient, task, and decorative lighting variants, alongside insights into materials and advanced manufacturing processes that ensure longevity and performance. You will find practical advice on evaluating suppliers, assessing quality control protocols, and interpreting pricing models tailored to different regional market dynamics. Moreover, the guide addresses common challenges and frequently asked questions to empower you with actionable knowledge.

By leveraging this resource, international B2B buyers can confidently streamline their sourcing strategies, minimize risks, and establish resilient partnerships that drive both operational efficiency and market success in the evolving world of bed LED lighting.

Understanding bed led lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ambient LED Bed Lights | Soft, diffused lighting strips or panels integrated into bed frames or headboards | Hospitality, residential furniture manufacturers, healthcare facilities | + Enhances ambiance and comfort; energy-efficient. – Requires careful design integration. |

| Motion Sensor LED Bed Lights | LED lights activated by movement or proximity sensors, often strip or puck lights | Hotels, eldercare facilities, luxury residential developments | + Improves safety and convenience; reduces energy use. – Sensor sensitivity and durability vary by supplier. |

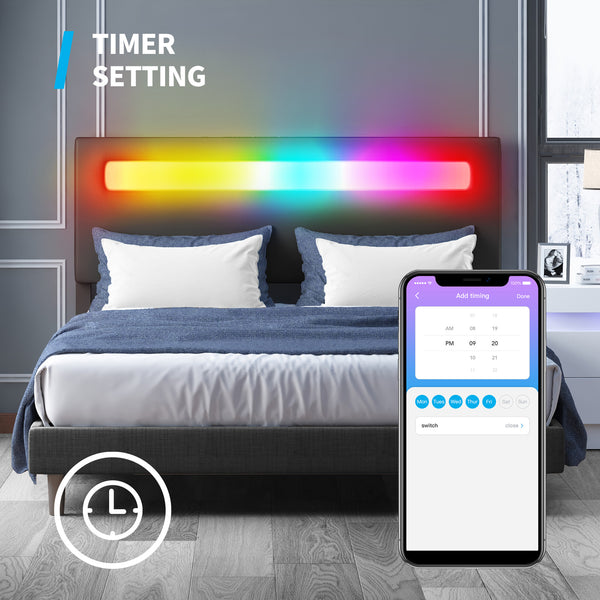

| RGB Color-Changing LED Bed Lights | Multi-color LEDs with remote or app control for mood lighting | High-end furniture, entertainment venues, wellness centers | + Customizable ambiance; appeals to tech-savvy markets. – Higher cost and complexity; requires compatible control systems. |

| Under-Bed LED Strip Lights | Low-profile LED strips mounted under the bed frame for subtle floor-level illumination | Retail furniture, children’s rooms, hospitality | + Low cost, easy retrofit; enhances safety at night. – Limited brightness; may need protective casing in some markets. |

| Rechargeable/Portable LED Bed Lights | Battery-powered, cordless LED units designed for bedside use and portability | Healthcare, travel accessories, emergency preparedness suppliers | + Flexible placement; no wiring needed. – Battery maintenance and lifespan concerns; higher unit cost. |

Ambient LED Bed Lights

These lights are integrated directly into the bed’s structure, such as headboards or side panels, providing soft, indirect illumination that enhances room ambiance. They are ideal for hospitality chains and healthcare providers aiming to improve guest or patient comfort while reducing energy costs. B2B buyers should focus on supplier capabilities for customization, durability, and compliance with local electrical safety standards, especially when sourcing for markets with strict certifications like Europe or the Middle East.

Motion Sensor LED Bed Lights

Equipped with motion or proximity sensors, these lights automatically illuminate when someone approaches or moves near the bed, significantly enhancing safety and convenience in hotels and eldercare environments. Buyers should evaluate sensor sensitivity, response time, and robustness to ensure reliable performance. Considering after-sales support and sensor calibration services is crucial, particularly when deploying in regions with variable power quality or environmental conditions.

RGB Color-Changing LED Bed Lights

These advanced LED systems offer dynamic color options controlled via remote or smartphone apps, appealing to upscale furniture manufacturers and wellness centers that target ambiance customization. While these units add significant value, buyers must verify compatibility with control software and assess the total cost of ownership, including installation complexity and potential need for specialized technical support in diverse markets.

Under-Bed LED Strip Lights

Low-profile LED strips mounted beneath beds provide subtle illumination that enhances nighttime safety and aesthetics, commonly used in children’s rooms and hospitality settings. Their cost-effectiveness and ease of installation make them attractive for large-scale furniture retailers and hotel chains. Buyers should ensure strips have adequate IP ratings for dust and moisture protection, especially for humid climates found in parts of Africa and South America.

Rechargeable/Portable LED Bed Lights

Battery-operated and cordless, these lights offer flexibility in placement and are suitable for healthcare facilities, travel accessory suppliers, and emergency preparedness markets. They eliminate wiring challenges and provide emergency lighting options. B2B purchasers must consider battery life, charging infrastructure, and warranty terms to mitigate risks related to maintenance and replacement in remote or resource-constrained regions.

Related Video: 2019+ Ram 1500 – Factory OEM LED Bed Light Upgrade – Easy DIY Plug & Play Installation

Key Industrial Applications of bed led lights

| Industry/Sector | Specific Application of bed led lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare & Hospitals | Patient beds with integrated LED lighting for therapy and monitoring | Enhances patient comfort and supports medical procedures; reduces energy consumption | Compliance with medical safety standards, durability, ease of sterilization, supplier certifications |

| Hospitality & Hotels | Ambient and functional lighting integrated into hotel beds | Improves guest experience through customizable lighting scenes; energy-efficient operation | Customizable lighting options, ease of installation, supplier ability to provide tailored solutions |

| Residential Care Homes | Bed LED lighting for elderly and disabled care facilities | Provides safe, low-glare illumination aiding mobility and nighttime monitoring | Reliability, low power consumption, compliance with safety regulations, long lifespan |

| Smart Furniture & Interior Design | Integration of LED lights into modern bed frames for aesthetic and functional purposes | Differentiates product offerings with innovative lighting; boosts market appeal | Quality of LEDs, supplier flexibility for design customization, warranty and after-sales support |

| Industrial Sleep Facilities | Lighting in worker rest pods or sleep rooms in industrial settings | Facilitates circadian rhythm regulation and improves worker well-being, enhancing productivity | Robustness, energy efficiency, compliance with workplace safety standards, ease of maintenance |

Healthcare & Hospitals

In healthcare settings, bed LED lights are increasingly integrated into patient beds to provide therapeutic lighting and facilitate medical monitoring. These lights can offer adjustable color temperatures and intensities that support patient recovery and create a calming environment. For international B2B buyers, particularly in Africa and the Middle East where hospital modernization is ongoing, sourcing LED solutions that meet stringent medical safety certifications (e.g., IEC 60601) and are easy to sanitize is critical. Durability and supplier reliability ensure long-term operational efficiency in demanding environments.

Hospitality & Hotels

Hotels leverage bed LED lights to enhance guest comfort by offering customizable ambient lighting directly integrated into bed frames or headboards. This application allows guests to adjust lighting for reading, relaxation, or ambiance, improving overall satisfaction and differentiating the property in competitive markets like Europe and South America. B2B buyers should prioritize suppliers capable of delivering flexible lighting designs with energy-efficient drivers and easy installation processes. Additionally, compatibility with smart room systems can add significant value.

Residential Care Homes

Care facilities for the elderly or disabled benefit from bed LED lighting that provides gentle, low-glare illumination during nighttime hours, reducing fall risks and enabling caregivers to monitor patients discreetly. Buyers from emerging markets such as Nigeria and Indonesia should focus on sourcing LEDs with high reliability, low power consumption, and compliance with local safety regulations. Long lifespan and maintenance ease are key to controlling operational costs in these sensitive environments.

Smart Furniture & Interior Design

The integration of LED lights into smart furniture, including modern bed frames, is a growing trend in interior design sectors across Europe and the Middle East. These LEDs serve both aesthetic and functional purposes, enhancing product appeal and enabling features like mood lighting or wake-up simulations. B2B buyers should seek suppliers offering high-quality LEDs with customizable color and brightness options, flexible form factors, and strong warranty support to meet diverse client needs and design specifications.

Industrial Sleep Facilities

In industrial environments where worker rest pods or sleep rooms are provided, bed LED lighting plays a vital role in regulating circadian rhythms and improving rest quality. This application supports workforce well-being and productivity, particularly important in regions with demanding industrial sectors such as South America and Africa. Buyers must consider LEDs that are robust, energy-efficient, and compliant with workplace safety standards. Easy maintenance and supplier responsiveness are also crucial for sustained facility operation.

Related Video: How to Install Access Truck Bed LED Lights

Strategic Material Selection Guide for bed led lights

When selecting materials for bed LED lights, international B2B buyers must consider factors such as durability, thermal management, corrosion resistance, and compliance with regional standards. The right material not only enhances product performance but also ensures longevity and customer satisfaction across diverse markets like Africa, South America, the Middle East, and Europe. Below is an analysis of four common materials used in bed LED light manufacturing, focusing on their properties, pros and cons, application impact, and considerations for global buyers.

Aluminum

Key Properties: Aluminum is prized for its excellent thermal conductivity, lightweight nature, and corrosion resistance. It typically withstands temperatures up to 200°C and is resistant to oxidation, making it ideal for heat dissipation in LED applications.

Pros & Cons: Aluminum offers superior heat management, which prolongs LED lifespan and maintains luminous efficiency. It is relatively cost-effective and easy to machine or extrude into complex shapes. However, aluminum can be prone to surface scratches and may require anodizing or powder coating for enhanced durability and aesthetic appeal.

Impact on Application: Its heat dissipation capability makes aluminum suitable for bed LED lights where thermal management is critical to prevent overheating. The material’s corrosion resistance is advantageous in humid or coastal environments common in regions like Nigeria or Brazil.

B2B Buyer Considerations: Buyers should verify compliance with international standards such as ASTM B209 or EN 573 for aluminum alloys. In Europe and the Middle East, anodized aluminum with RoHS certification is often preferred for environmental compliance. Suppliers offering customizable finishes and robust quality assurance are valuable for maintaining product consistency.

Polycarbonate (PC)

Key Properties: Polycarbonate is a durable, transparent thermoplastic with high impact resistance and good heat tolerance (typically up to 135°C). It offers excellent optical clarity, making it a popular choice for LED covers and diffusers.

Pros & Cons: Polycarbonate is lightweight, shatter-resistant, and easy to mold, allowing for innovative designs. However, it can yellow over time under UV exposure and may degrade if not UV-stabilized. Its thermal resistance is lower than metals, which can limit its use in high-heat applications.

Impact on Application: Polycarbonate is ideal for protective covers and lenses in bed LED lights, providing clear light diffusion while protecting internal components. Its impact resistance is beneficial in markets with rough handling or transportation challenges, such as in parts of Africa and South America.

B2B Buyer Considerations: Buyers should ensure the polycarbonate meets ISO 9001 quality standards and check for UV stabilization additives, especially for outdoor or high-exposure environments. Compliance with ASTM D3935 or EN 62262 (impact resistance) is critical. Cost sensitivity in emerging markets makes polycarbonate a balanced choice between performance and price.

Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, mechanical strength, and temperature tolerance (up to 870°C depending on grade). It is highly durable and resistant to wear, making it suitable for structural components.

Pros & Cons: While stainless steel provides superior longevity and aesthetic appeal, it is heavier and more expensive than aluminum or plastics. Manufacturing complexity is higher due to machining and finishing requirements, which can increase lead times and costs.

Impact on Application: Stainless steel is often used for mounting brackets, frames, or decorative trims in bed LED lights where robustness and corrosion resistance are paramount, especially in humid or saline environments like coastal Middle Eastern or European regions.

B2B Buyer Considerations: Buyers should specify grades such as 304 or 316 stainless steel, depending on corrosion resistance needs. Compliance with ASTM A240 or EN 10088 standards is essential. Given its higher cost, stainless steel is best suited for premium product lines or markets demanding long-term durability.

ABS Plastic (Acrylonitrile Butadiene Styrene)

Key Properties: ABS is a thermoplastic known for its toughness, impact resistance, and ease of molding. It can withstand temperatures up to about 105°C and offers good chemical resistance.

Pros & Cons: ABS is cost-effective and allows for high-volume production with consistent quality. However, it has lower heat resistance compared to metals and polycarbonate, which may limit its use near high-power LEDs. It is also less UV resistant unless specially treated.

Impact on Application: ABS is commonly used for housings and non-structural parts of bed LED lights, especially where cost constraints are significant. Its ease of coloring and finishing supports diverse design requirements for different markets.

B2B Buyer Considerations: Buyers should confirm compliance with international standards like ASTM D4761 or ISO 180 for mechanical properties. For regions with intense sunlight such as parts of Africa and the Middle East, UV-stabilized ABS variants are recommended. ABS is attractive for buyers prioritizing affordability and rapid production cycles.

| Material | Typical Use Case for bed led lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat sinks, structural frames | Excellent thermal management | Prone to surface scratches; requires finishing | Medium |

| Polycarbonate | Covers, lenses, diffusers | High impact resistance and optical clarity | Lower heat resistance; potential yellowing | Medium |

| Stainless Steel | Mounting brackets, decorative trims | Superior corrosion resistance and durability | Heavy and expensive; complex manufacturing | High |

| ABS Plastic | Housings, non-structural parts | Cost-effective and easy to mold | Limited heat and UV resistance | Low |

This material selection guide equips B2B buyers with critical insights to choose the optimal materials for bed LED lights, balancing performance, cost, and compliance with regional standards. Tailoring material choices to specific application needs and market conditions will enhance product success and supplier partnerships across Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for bed led lights

Manufacturing Processes for Bed LED Lights

The production of bed LED lights involves a series of meticulously controlled stages designed to ensure high performance, durability, and safety. For international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—understanding these manufacturing steps is essential to evaluate suppliers and mitigate risks in procurement.

Illustrative Image (Source: Google Search)

1. Material Preparation

High-quality raw materials form the backbone of reliable bed LED lights. Key components include:

– LED Chips and Modules: Often sourced from specialized manufacturers; buyers should verify chip binning consistency for uniform brightness and color temperature.

– PCB (Printed Circuit Board): Typically made of aluminum or FR4 material for heat dissipation; precise copper layering is essential to support electrical pathways.

– Housing Materials: Aluminum alloys or ABS plastic are common, chosen for thermal management and mechanical strength.

– Optical Components: Lenses, diffusers, and covers are crafted from polycarbonate or PMMA to shape light output and ensure user comfort.

Suppliers generally perform initial material inspections to confirm compliance with specifications and certifications, such as RoHS (Restriction of Hazardous Substances) to ensure environmental safety.

2. Forming and Component Fabrication

This stage shapes and prepares the physical parts of the LED light:

– Metal Stamping and CNC Machining: Used to create heat sinks and structural frames with precision, ensuring thermal efficiency.

– Injection Molding: For plastic components like diffusers and housings, injection molding guarantees repeatable quality and surface finish.

– Solder Paste Application: Automated solder paste printing on PCBs prepares the boards for chip placement.

Precision in forming processes is critical to maintain alignment and durability, directly impacting the final product’s lifespan.

3. Assembly

Assembly integrates all components into a functional lighting unit:

– SMT (Surface Mount Technology) Placement: LED chips and electronic components are mounted on PCBs via automated pick-and-place machines to ensure accuracy and repeatability.

– Reflow Soldering: This process solidifies connections, ensuring electrical reliability and mechanical stability.

– Manual or Automated Housing Assembly: Components are joined, often with screws or clips, incorporating thermal interface materials to optimize heat transfer.

– Wiring and Driver Integration: LED drivers are installed and tested for compatibility with input voltages and dimming functions, tailored to the target market’s electrical standards.

Automated assembly lines reduce human error and improve throughput, but critical steps may still require manual inspection.

4. Finishing and Packaging

Final touches ensure product readiness for shipment and end-use:

– Surface Treatment: Anodizing or powder coating of metal parts enhances corrosion resistance and aesthetic appeal.

– Optical Calibration: Lenses and diffusers may be adjusted or replaced to meet luminous flux and beam angle specifications.

– Labeling and Certification Marking: Products are marked with necessary compliance logos (e.g., CE, RoHS) and batch numbers for traceability.

– Protective Packaging: Customized packaging minimizes damage during transit, often including anti-static bags and foam inserts.

This stage safeguards product integrity and supports brand positioning in international markets.

Quality Assurance (QA) and Quality Control (QC) for Bed LED Lights

Robust QA/QC frameworks are indispensable for bed LED lights, as they directly affect performance, safety, and regulatory compliance. For B2B buyers, especially from regions with strict import regulations like Europe or emerging markets like Nigeria and Indonesia, understanding these quality checkpoints can inform supplier selection and contract negotiation.

Key International and Industry Standards

- ISO 9001: The foundational international standard for quality management systems, ensuring consistent production processes and continuous improvement. Buyers should request supplier ISO 9001 certification as a baseline.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), confirming compliance with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances in electrical equipment, critical for environmentally conscious procurement.

- CB Scheme: Facilitates mutual recognition of safety test results, valuable for multi-regional buyers.

- Local Certifications: Buyers from the Middle East may require SASO (Saudi Standards), while South American markets might request INMETRO (Brazil) or other regional marks. Understanding local certification requirements is vital to avoid customs issues.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw materials and components upon receipt, including dimensional checks, material composition tests, and electrical property validation. This stage prevents defective inputs from entering production.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly phases, such as solder joint inspections, alignment verification, and functional testing of LED modules. Automated optical inspection (AOI) and X-ray inspection are common techniques here.

- Final Quality Control (FQC): Comprehensive testing of finished products before shipment, covering:

- Electrical Safety Tests: Insulation resistance, leakage current, and high-voltage withstand tests.

- Photometric Testing: Measuring luminous flux, color temperature, CRI (Color Rendering Index), and beam angle to ensure product meets specifications.

- Thermal Testing: Assessing heat dissipation performance to prevent premature failure.

- Environmental Testing: Checking resistance to humidity, vibration, and temperature cycles to simulate real-world conditions.

- Functional Testing: Verifying dimming functionality, flicker-free operation, and driver compatibility.

How B2B Buyers Can Verify Supplier Quality Assurance

- Supplier Audits: Conduct on-site factory audits or commission third-party inspections to evaluate manufacturing capabilities, process controls, and worker training. Buyers from Africa and South America often benefit from localized audit firms familiar with regional compliance nuances.

- Review of Quality Documentation: Request detailed quality manuals, test reports, and certifications. Inspect batch traceability records to ensure accountability.

- Third-Party Testing and Certification: Engage independent labs to verify product compliance with international and local standards before shipment. This is especially critical for markets like Europe or the Middle East where non-compliant products face rejection.

- Sample Testing: Before mass orders, procure samples for in-house testing to validate performance claims and compatibility with local electrical systems.

- Long-Term Quality Monitoring: Establish KPIs related to product failure rates and warranty claims, fostering continuous supplier improvement.

QC and Certification Nuances for International Buyers

- Africa and South America: Markets such as Nigeria and Brazil are increasingly enforcing quality and safety standards but may have gaps in local enforcement. Buyers should insist on internationally recognized certifications and conduct stringent quality checks to avoid counterfeit or substandard products.

- Middle East: Compliance with regional standards like SASO is mandatory; buyers should verify that suppliers have experience navigating these certifications. Additionally, consider supplier capability in handling customs documentation and labeling requirements.

- Europe: The most stringent regulatory environment, demanding full compliance with CE, RoHS, and REACH regulations. Buyers must prioritize suppliers with transparent quality systems and comprehensive documentation to facilitate seamless market entry.

Actionable Insights for B2B Buyers

- Prioritize Suppliers with ISO 9001 and Relevant Regional Certifications: This reduces risk and streamlines compliance.

- Insist on Detailed QC Protocols and Transparent Reporting: Ensure your supplier uses IQC, IPQC, and FQC checkpoints with documented results.

- Leverage Third-Party Inspection Services: Particularly when sourcing from new or remote suppliers, third-party audits and lab testing add an essential layer of confidence.

- Understand Local Market Requirements: Tailor your procurement strategy to regional regulations and electrical standards—this avoids costly delays and rejections.

- Request Product Samples Early: Validate technical specifications and compatibility before committing to large volumes.

- Evaluate Supplier Manufacturing Technology: Automated SMT lines, AOI systems, and thermal testing equipment indicate higher quality manufacturing capability.

By integrating these insights into the procurement process, B2B buyers can secure high-quality bed LED lights that meet performance expectations, comply with regulations, and deliver lasting value across diverse international markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for bed led lights Sourcing

When sourcing bed LED lights on an international scale, understanding the detailed cost structure and pricing dynamics is crucial for making informed procurement decisions. For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, a strategic approach to pricing evaluation can significantly enhance cost-efficiency and supply chain resilience.

Key Cost Components in Bed LED Lights Procurement

-

Materials

The primary cost driver includes high-quality LEDs (often SMD or COB types), PCBs, housing materials (commonly aluminum or plastic), and lenses or diffusers. Material quality directly affects durability and light performance. Premium components with certifications (CE, RoHS, CCC) typically command higher prices but reduce risks associated with compliance and product failure. -

Labor and Manufacturing Overhead

Labor costs vary widely depending on the supplier’s geographic location and manufacturing sophistication. Automated assembly lines lower unit labor costs but may increase tooling expenses. Overhead includes utilities, factory maintenance, and management, which are factored into the unit price. -

Tooling and Customization

Initial tooling for molds or specialized fixtures adds upfront costs, particularly for customized designs or integrated features like touch controls or color temperature adjustment. Higher customization levels increase tooling and engineering expenses but can yield better market differentiation. -

Quality Control (QC)

Rigorous QC processes—including binning LEDs for consistent brightness, testing electrical safety, and verifying certifications—add to costs but are vital to ensure reliability and reduce returns or warranty claims. -

Logistics and Import Duties

Shipping, customs clearance, and insurance constitute a significant portion of the landed cost. For buyers in Nigeria, Brazil, UAE, or European countries, understanding port fees, import tariffs, and local taxes is essential. Choosing optimal Incoterms (e.g., FOB, CIF, DDP) affects risk allocation and cost transparency. -

Supplier Margin

Suppliers include profit margins that reflect market positioning, production scale, and demand conditions. High-volume orders generally attract better pricing due to economies of scale.

Influencing Factors on Pricing

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes typically reduce per-unit costs. Some suppliers offer tiered pricing that can significantly improve margins for bulk orders. However, buyers should balance inventory costs and demand forecasts to avoid overstocking. -

Product Specifications and Customization

Features such as adjustable brightness, color temperature, smart controls, or integration with hospital beds increase complexity and cost. Buyers should prioritize specifications aligned with end-user needs to avoid unnecessary expense. -

Material Quality and Certifications

Certified components ensure compliance with regional standards and affect warranty terms. Non-certified, cheaper alternatives may reduce upfront cost but increase risks of product rejection or legal issues. -

Supplier Reputation and Reliability

Established suppliers with proven quality control and timely delivery may command premium pricing but reduce long-term operational risks and hidden costs. -

Incoterms and Payment Terms

Selecting favorable Incoterms can shift cost and risk responsibility between buyer and supplier. For example, DDP (Delivered Duty Paid) offers price certainty but at a higher cost, while FOB (Free on Board) requires the buyer to manage shipping logistics.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Price:

Engage suppliers on payment terms, warranty conditions, after-sales support, and flexibility on MOQ. Strong supplier relationships can unlock volume discounts and priority production slots. -

Evaluate Total Cost of Ownership (TCO):

Consider energy efficiency, maintenance needs, and product lifespan alongside purchase price. Higher upfront costs for premium LEDs often translate into lower operational expenses, a critical factor for markets with high electricity tariffs. -

Leverage Local Regulations and Incentives:

In regions like Europe and the Middle East, compliance with energy efficiency standards can unlock subsidies or tax benefits. Align procurement with such incentives to optimize overall cost. -

Account for Currency Fluctuations:

For buyers in volatile currency regions (e.g., Nigeria or South America), locking prices via forward contracts or negotiating in stable currencies (USD, EUR) can mitigate financial risks. -

Request Detailed Cost Breakdowns:

Transparency on cost components helps identify negotiation levers and avoid hidden charges. Insist on clear invoicing that separates product cost, shipping, duties, and taxes.

Indicative Pricing Disclaimer

Due to varying specifications, order volumes, supplier capabilities, and market conditions, bed LED light prices can range widely. Buyers should treat pricing information as indicative and conduct thorough due diligence with multiple suppliers to secure competitive and reliable offers.

By comprehensively analyzing these cost and pricing factors, international B2B buyers can optimize procurement strategies for bed LED lights, ensuring quality, compliance, and cost-effectiveness tailored to their regional market needs.

Spotlight on Potential bed led lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘bed led lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bed led lights

Critical Technical Properties of Bed LED Lights

-

Lumen Output (Brightness)

– Definition: Measures the total amount of visible light emitted by the LED light source, expressed in lumens (lm).

– B2B Importance: Determines the effectiveness of illumination for bed lighting applications. Buyers must assess lumen levels to ensure sufficient brightness for user comfort and functionality, balancing energy consumption and lighting quality. -

Color Temperature (Kelvin, K)

– Definition: Indicates the color appearance of the light, ranging from warm (2700K–3000K) to cool (5000K–6500K) tones.

– B2B Importance: Influences ambiance and user experience in bedrooms or hospitality settings. Warm tones create a cozy atmosphere, while cooler tones offer a more modern, crisp look. Selecting the appropriate temperature aligns with market preferences and end-user expectations. -

Material Grade and Build Quality

– Definition: Refers to the quality of materials used in the LED housing, diffuser, and circuit components, often involving aluminum alloys for heat dissipation and polycarbonate or acrylic for covers.

– B2B Importance: High-grade materials improve durability, heat management, and lifespan, reducing maintenance costs. Buyers should verify supplier material certifications and test reports to ensure product reliability, especially in humid or variable climates common in target regions. -

Power Consumption and Efficiency (Wattage and lm/W)

– Definition: Power usage in watts (W) and luminous efficacy measured as lumens per watt (lm/W).

– B2B Importance: Critical for managing operational costs and achieving sustainability goals. Buyers should prioritize LEDs with high efficacy to lower energy bills and comply with regional energy regulations, which vary significantly across Africa, South America, Middle East, and Europe. -

IP Rating (Ingress Protection)

– Definition: Classification that defines the degree of protection against solids and liquids, e.g., IP20 (indoor use) to IP65 (dust-tight and water-resistant).

– B2B Importance: Ensures the LED light’s suitability for specific environments. For bed LED lights, an IP rating suitable for indoor residential use (typically IP20–IP44) is essential. Buyers must confirm appropriate ratings to prevent early failures due to dust or moisture exposure. -

Dimmability and Control Compatibility

– Definition: The ability of the LED light to adjust brightness levels and integrate with control systems such as remote dimmers or smart home automation.

– B2B Importance: Enhances user comfort and energy savings. Buyers targeting premium or hospitality markets should verify compatibility with popular control protocols (e.g., TRIAC, 0-10V, Zigbee) to meet advanced lighting requirements.

Key Trade Terminology for Bed LED Lights Procurement

-

OEM (Original Equipment Manufacturer)

– Refers to a manufacturer that produces products or components that are purchased by another company and retailed under that purchasing company’s brand. For B2B buyers, partnering with OEMs can allow customization and branding flexibility while ensuring quality standards. -

MOQ (Minimum Order Quantity)

– The smallest quantity of units that a supplier is willing to sell in a single order. Understanding MOQ is vital for budget planning and inventory management, especially for buyers from emerging markets who may need to balance order size with cash flow constraints. -

RFQ (Request for Quotation)

– A formal process where buyers solicit price and terms from suppliers for specific products or services. Crafting clear RFQs with detailed technical specifications helps streamline supplier responses and facilitates more accurate cost comparisons. -

Incoterms (International Commercial Terms)

– Standardized trade terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers regarding shipment, insurance, and tariffs. Common terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Familiarity with Incoterms enables buyers to negotiate favorable shipping terms and control logistics risks. -

Binning

– A quality control process where LEDs are sorted based on color, brightness, and voltage to ensure consistency across batches. For B2B buyers, understanding binning helps in selecting suppliers who provide uniform lighting quality, critical for large-scale installations requiring visual consistency. -

Lead Time

– The period between placing an order and receiving the goods. Accurate knowledge of lead times is crucial for project scheduling and inventory planning, especially for international buyers facing logistical challenges and customs clearance in their regions.

By mastering these technical specifications and trade terms, international B2B buyers can make informed decisions, optimize procurement strategies, and establish resilient supply chains for bed LED lights tailored to their regional market needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bed led lights Sector

Market Overview & Key Trends

The bed LED lights sector is witnessing accelerated growth globally, driven by rising demand for energy-efficient, customizable, and smart lighting solutions in residential, hospitality, healthcare, and wellness industries. For international B2B buyers—particularly from regions like Africa, South America, the Middle East, and Europe—this market offers significant opportunity due to expanding urbanization, increasing disposable incomes, and the growing preference for ambient and functional lighting in bedrooms and relaxation spaces.

Key market drivers include the integration of smart technology such as app-controlled lighting, voice activation, and adjustable color temperatures to enhance user comfort and wellbeing. This is especially relevant in markets like Nigeria and Indonesia, where tech adoption is rapidly increasing. Additionally, modular designs and ease of installation have become critical sourcing criteria, enabling efficient deployment in hotels, hospitals, and modern homes.

Sourcing trends emphasize supplier transparency, product certification compliance (e.g., CE for Europe, SASO for the Middle East), and customization capabilities to meet local standards and aesthetic preferences. Buyers are prioritizing suppliers who can offer high lumen efficacy with low heat emission, durable materials, and innovative features such as motion sensors or wireless connectivity. The fluctuating costs of raw materials like aluminum and semiconductors also influence procurement strategies, encouraging bulk purchasing and long-term contracts to mitigate price volatility.

Logistics and supply chain resilience are paramount, particularly for buyers in Africa and South America, where infrastructure challenges can impact delivery timelines. Partnering with suppliers who maintain robust quality control and offer after-sales support is essential to avoid costly disruptions. Furthermore, emerging markets are increasingly demanding energy-saving certifications and warranties as part of their procurement requirements, reflecting a broader shift towards sustainable and reliable lighting solutions.

Sustainability & Ethical Sourcing in B2B

Sustainability in the bed LED lights sector is no longer optional but a critical factor shaping procurement decisions across global markets. Buyers are increasingly aware that environmentally responsible sourcing not only reduces carbon footprints but also aligns with regulatory frameworks and consumer expectations. For B2B buyers from Europe and the Middle East, adherence to standards such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives is mandatory, ensuring that products do not contain harmful materials and are recyclable at end-of-life.

Ethical sourcing also involves scrutinizing the entire supply chain—from raw material extraction to manufacturing and distribution—to ensure fair labor practices and minimize environmental degradation. Buyers are encouraged to engage with suppliers who maintain transparent corporate social responsibility (CSR) policies and certifications like ISO 14001 (Environmental Management Systems) or SA8000 (Social Accountability).

Illustrative Image (Source: Google Search)

Material selection plays a pivotal role in sustainability. Bed LED lights utilizing recycled aluminum housings, non-toxic phosphor coatings, and energy-efficient drivers contribute to lower environmental impact. Additionally, innovations in low-power consumption LEDs and smart dimming controls further enhance energy savings over the product lifecycle.

For international B2B buyers, especially in emerging economies, sourcing from suppliers committed to sustainability can improve brand reputation and access to eco-conscious markets. It also helps mitigate risks related to regulatory non-compliance and supply chain disruptions caused by environmental or social controversies. Building partnerships with manufacturers who prioritize green certifications and offer transparent lifecycle assessments will ensure long-term value and align with global sustainability goals.

Evolution of Bed LED Lights: A Brief Overview

The evolution of bed LED lights reflects broader advancements in LED technology and changing consumer expectations. Initially, bed lighting was limited to simple nightlights or fixed-position bulbs primarily designed for visibility. The shift began with the development of compact, low-heat LEDs that could be integrated into furniture and headboards without safety concerns or discomfort.

Over the past decade, innovation has accelerated with the introduction of color-tunable LEDs, allowing users to customize lighting ambiance to suit mood or circadian rhythms. Integration with smart home ecosystems marked a significant milestone, enabling remote control and automation that enhance convenience and energy efficiency.

This progression has transformed bed LED lights from basic functional elements into sophisticated components of interior design and wellness solutions. Today’s buyers benefit from a diverse range of products that combine aesthetics, technology, and sustainability—meeting the complex demands of international markets and driving new opportunities for B2B sourcing partnerships.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of bed led lights

-

How can I effectively vet suppliers of bed LED lights to ensure product quality and reliability?

Start by requesting detailed product specifications, certifications (such as CE, RoHS, or region-specific marks), and sample units for testing. Verify the supplier’s manufacturing capabilities through factory audits or third-party inspections, focusing on quality control processes and material sourcing. Review their history of international shipments and client references, especially from markets similar to yours. Establish clear communication channels and assess responsiveness. For buyers in regions like Africa or South America, prioritize suppliers experienced in exporting to your region to mitigate logistical and compliance risks. -

What customization options are typically available for bed LED lights, and how should I approach these with suppliers?

Many manufacturers offer customization in color temperature, brightness levels, size, design aesthetics, and control interfaces (e.g., remote or app-based dimming). When negotiating customization, provide precise technical requirements and intended use cases to avoid misunderstandings. Confirm the supplier’s ability to produce prototypes and small batches to validate custom features before large orders. Factor in additional costs and lead times associated with customization, and secure agreements on intellectual property rights and exclusivity if applicable, especially for unique designs. -

What are common minimum order quantities (MOQs) and lead times for bed LED light orders, and how can I manage these in international trade?

MOQs vary widely but typically range from 100 to 1,000 units depending on complexity and customization. Lead times can span 4 to 12 weeks, influenced by production schedules, customization, and shipping logistics. To optimize, consolidate orders to meet MOQs without overstocking, and plan procurement well ahead of demand cycles. Discuss flexible MOQ options for initial orders to test quality and market response. Use Incoterms clearly defining delivery responsibilities to align expectations and avoid delays, especially when shipping to Africa, the Middle East, or South America. -

Which quality assurance certifications should I prioritize when sourcing bed LED lights for different international markets?

Key certifications include CE and RoHS for Europe, UL or FCC for North America, and CCC for China exports. For Middle Eastern markets, SASO or G-Mark may be required, while some African countries adhere to IEC standards or regional certification bodies. Additionally, look for ISO 9001 certification to verify manufacturing quality systems. Confirm that certifications apply specifically to the product model you intend to purchase, not just the manufacturer. This ensures compliance with local regulations and facilitates smoother customs clearance. -

What payment terms are standard in international B2B transactions for bed LED lights, and how can I mitigate payment risks?

Common payment terms include 30% advance deposit with order confirmation and 70% balance before shipment, or payment via Letter of Credit (L/C) to secure both parties. For new suppliers, use escrow services or trade finance solutions to reduce risks. Negotiate clear contract terms specifying penalties for delays or quality issues. Regularly verify supplier banking details to avoid fraud. Buyers in emerging markets should also consider currency fluctuation risks and explore options for forward contracts or local financing support. -

How can I best handle shipping and logistics challenges when importing bed LED lights internationally?

Choose suppliers experienced in international shipping with knowledge of your destination country’s import regulations, taxes, and documentation requirements. Opt for consolidated shipments or full container loads to reduce per-unit freight costs. Clarify Incoterms like FOB or CIF to define responsibilities for freight, insurance, and customs clearance. Work with reliable freight forwarders familiar with your region to navigate port congestion or customs delays. Additionally, plan for buffer time to accommodate unexpected transit disruptions, particularly when shipping to remote or less-developed logistics hubs. -

What strategies can I use to resolve disputes related to product quality or delivery delays in international bed LED light procurement?

Establish clear contractual terms upfront, including quality acceptance criteria, inspection rights, and dispute resolution mechanisms such as arbitration or mediation. Document all communications and inspections thoroughly. Engage third-party inspection agencies for pre-shipment quality checks. In case of disputes, promptly communicate with suppliers to seek amicable solutions, such as partial refunds, replacements, or extended warranties. If unresolved, leverage trade associations or legal counsel specializing in international trade. Maintaining good supplier relationships and transparent dialogue helps prevent escalation. -

How important is after-sales support and warranty coverage when purchasing bed LED lights from international suppliers?

After-sales support is critical to ensure long-term satisfaction and operational reliability. Verify warranty terms covering defects, lifespan guarantees, and replacement procedures. Confirm availability of spare parts and technical assistance, especially for complex or customized LED systems. For buyers in regions with limited local support infrastructure, prioritize suppliers offering remote troubleshooting, training, or on-site service options. Strong after-sales services reduce downtime and total cost of ownership, enhancing your competitive advantage in local markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bed led lights

Strategic sourcing of bed LED lights demands a comprehensive understanding of product types, quality standards, and regional regulatory requirements. For international B2B buyers in Africa, South America, the Middle East, and Europe, prioritizing suppliers with proven certifications, reliable logistics, and customizable solutions is crucial to ensuring both compliance and operational efficiency. Emphasizing thermal management, warranty coverage, and after-sales support will mitigate risks associated with product longevity and performance.

Key takeaways include the importance of aligning LED specifications with end-use conditions, such as energy efficiency and durability, while also considering retrofit compatibility to optimize cost-effectiveness. Buyers should leverage supplier partnerships that offer transparency in manufacturing processes and quality assurance to safeguard against inconsistent product batches. Additionally, staying informed about evolving regional standards—like CE in Europe or CCC in Asia—ensures seamless market entry and reduces potential trade barriers.

Looking ahead, the bed LED lighting market is poised for continued growth driven by sustainability goals and technological innovation. International buyers are encouraged to adopt a strategic sourcing approach that balances cost, quality, and compliance to secure competitive advantage. Engaging early with manufacturers who demonstrate agility and a commitment to innovation will position businesses to capitalize on emerging opportunities and evolving customer demands in their respective markets.