Introduction: Navigating the Global Market for battery led strip lights

Battery LED strip lights represent a dynamic and versatile segment within the global lighting market, offering unparalleled flexibility for applications where wired power sources are impractical or unavailable. For international B2B buyers across Africa, South America, the Middle East, and Europe—including emerging markets like Indonesia and Turkey—these portable lighting solutions unlock new possibilities in retail displays, event setups, signage, and remote installations. Their growing demand is driven by advancements in battery technology, energy efficiency, and ease of installation.

This comprehensive guide is designed to empower buyers with critical insights to confidently navigate the complexities of sourcing battery LED strip lights on a global scale. It covers a wide spectrum of essential topics, including:

- Types and configurations of battery-powered LED strips tailored to diverse industrial and commercial needs

- Material quality and manufacturing standards that impact durability and performance

- Quality control protocols to ensure product reliability and safety compliance

- Identification of trustworthy suppliers and manufacturers with proven track records and certifications

- Cost considerations, including pricing structures, shipping logistics, and import regulations

- Market trends and regional demand analysis relevant to your geographic area

- Frequently asked questions addressing common challenges in procurement and deployment

By consolidating these elements, the guide equips international buyers with actionable knowledge to make informed decisions, optimize supply chains, and establish lasting partnerships. Whether you are scaling a retail operation in Lagos, upgrading hospitality lighting in São Paulo, or outfitting an exhibition space in Istanbul, this resource ensures you select the right battery LED strip lights to meet your performance, budget, and compliance requirements efficiently.

Understanding battery led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Battery LED Strip Lights | Powered by replaceable AA/AAA or rechargeable batteries; flexible and portable | Retail displays, event lighting, temporary installations | + Easy deployment without wiring – Limited runtime, battery replacement needed |

| Rechargeable Battery LED Strip Lights | Integrated rechargeable lithium-ion batteries; USB or wireless charging options | Outdoor signage, emergency lighting, mobile setups | + Cost-effective over time – Requires charging infrastructure, initial higher cost |

| Solar-Powered Battery LED Strip Lights | Battery charged by integrated solar panels; eco-friendly and energy-saving | Remote locations, outdoor decorations, green projects | + Sustainable, low operating cost – Dependent on sunlight, slower charging |

| Smart Battery LED Strip Lights | Battery powered with smart controls (Wi-Fi/Bluetooth); customizable colors and automation | Hospitality, smart buildings, experiential marketing | + High customization, remote control – Higher price, potential compatibility issues |

| Waterproof Battery LED Strip Lights | Sealed battery compartments and strip coating for water resistance | Outdoor events, marine environments, signage in humid areas | + Durable in harsh conditions – Slightly bulkier, higher cost |

Standard Battery LED Strip Lights

These strips rely on common replaceable batteries, making them ideal for quick, portable lighting solutions without the need for external power sources. Their simplicity suits retail displays and short-term event lighting where ease of installation and mobility are priorities. B2B buyers should consider the ongoing costs of battery replacements and limited runtime, balancing convenience against operational expenses.

Rechargeable Battery LED Strip Lights

Equipped with built-in rechargeable lithium-ion batteries, these strips cater to businesses seeking sustainable and cost-effective lighting for repeated use. Charging via USB or wireless pads supports mobile setups and outdoor signage. Buyers should assess the availability of charging infrastructure and the initial investment against long-term savings and reduced waste.

Solar-Powered Battery LED Strip Lights

Ideal for remote or off-grid applications, these strips harness solar energy to recharge internal batteries. They are especially attractive for eco-conscious buyers focusing on sustainability and low operational costs in outdoor decorations or green energy projects. However, buyers must evaluate sunlight availability and potential slower charging times to ensure consistent performance.

Smart Battery LED Strip Lights

Incorporating wireless controls, these strips enable color customization, scheduling, and integration with building management systems. They are suited for hospitality venues, smart office environments, and experiential marketing where dynamic lighting enhances customer engagement. B2B buyers should weigh the benefits of advanced features against higher upfront costs and ensure compatibility with existing smart infrastructure.

Waterproof Battery LED Strip Lights

Designed with sealed batteries and protective coatings, these strips withstand water exposure, making them suitable for outdoor events, marine settings, and humid environments. Their durability supports long-term outdoor installations. Buyers should consider the slightly increased size and cost, balanced by the reduced risk of damage and maintenance in challenging conditions.

Related Video: How to connect LED strip to battery

Key Industrial Applications of battery led strip lights

| Industry/Sector | Specific Application of Battery LED Strip Lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Visual Merchandising | Portable product display and accent lighting in pop-up shops and kiosks | Enhances product visibility and customer engagement without wiring constraints | Battery life, brightness levels, ease of installation, and IP rating for durability |

| Construction & Site Management | Temporary lighting in remote or off-grid construction sites | Provides safe, reliable illumination for night shifts and inspections | Robustness, long battery runtime, rechargeable options, and compliance with safety standards |

| Hospitality & Event Management | Ambient and decorative lighting for outdoor events and venues | Flexible lighting solutions that enhance ambiance without permanent installation | Color options, remote control features, and weather resistance |

| Automotive & Transportation | Interior and exterior accent lighting for mobile units and vehicles | Improves aesthetics and visibility in vehicles where wiring is limited | Compact design, vibration resistance, and compatibility with vehicle voltage systems |

| Emergency & Security Services | Portable illumination for emergency response and security patrols | Quick deployment of reliable light sources in critical situations | Durability, brightness, ease of transport, and compliance with safety certifications |

Battery LED strip lights have found versatile applications across industries where mobility and ease of installation are critical. In retail and visual merchandising, battery-powered LED strips are used extensively in pop-up shops and kiosks to highlight products dynamically without the need for fixed electrical outlets. This solves the problem of limited power access in temporary retail setups, particularly relevant for markets in Africa and South America where infrastructure can be variable. Buyers should prioritize battery longevity and brightness to maintain consistent lighting throughout business hours.

In the construction sector, battery LED strip lights provide essential temporary illumination on sites that may lack stable power sources, especially in remote or developing regions like parts of the Middle East and Turkey. These lights enhance worker safety during night shifts and inspections, reducing accident risks. For procurement, durability against dust and moisture, rechargeable battery options, and compliance with international safety standards are vital considerations.

The hospitality and event management industry leverages battery LED strip lights for outdoor events, weddings, and festivals where flexible, wire-free lighting creates appealing atmospheres. This application is significant for event planners in Europe and emerging markets where venue electrification is limited or temporary. Buyers should seek products offering color customization, remote controls, and weatherproof features to ensure versatile and reliable performance.

In automotive and transportation, battery LED strips are applied to enhance vehicle interiors and exteriors, particularly in mobile units like caravans or commercial trucks. This improves visibility and aesthetic appeal without complex wiring modifications. For international buyers, especially in regions with diverse vehicle standards, it is crucial to select compact, vibration-resistant strips compatible with common vehicle voltage systems.

Finally, emergency and security services benefit from battery LED strip lights as portable, rapidly deployable illumination solutions during patrols, disaster response, or power outages. This application demands robust, high-brightness products that are easy to carry and operate under harsh conditions. Buyers in Africa, South America, and the Middle East should focus on durability, brightness, and certifications that guarantee safe use in critical environments.

These targeted applications highlight the value of battery LED strip lights as flexible, efficient lighting solutions that meet the unique challenges of various industries and geographies. Understanding the specific needs and sourcing criteria will enable B2B buyers to optimize their investments and operational outcomes.

Related Video: 12-volt vs. 24-volt LED strip lights – what is the difference?

Strategic Material Selection Guide for battery led strip lights

When selecting materials for battery LED strip lights, understanding the performance characteristics and regional compliance requirements is essential for international B2B buyers. The choice of materials influences durability, safety, cost-efficiency, and suitability for diverse environmental conditions commonly found in Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a flexible, lightweight polymer with good electrical insulation properties and moderate temperature resistance (typically up to 60°C). It offers decent resistance to moisture and chemicals but can degrade under prolonged UV exposure.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for LED strip casings. However, its limited heat tolerance can restrict use in high-temperature environments, and it may emit harmful gases if burned. Its flexibility aids installation in curved or irregular surfaces.

Impact on Application: PVC suits indoor applications or shaded outdoor settings where temperature extremes are minimal. It is less ideal for direct sunlight exposure or harsh chemical environments.

Considerations for International Buyers: PVC materials for LED strips must comply with regional fire safety and chemical standards such as ASTM D1784 or DIN EN 45545, especially in Europe and Turkey. African and South American markets may prioritize cost and availability, but buyers should verify compliance with local environmental regulations to avoid import restrictions.

Silicone Rubber

Key Properties: Silicone rubber offers excellent thermal stability (operating range from -60°C to 230°C), outstanding UV and weather resistance, and superior flexibility. It is highly resistant to moisture, ozone, and many chemicals.

Pros & Cons: Silicone’s durability and high-temperature tolerance make it ideal for outdoor and industrial LED strip applications. The main drawback is higher material and production costs compared to PVC. Manufacturing complexity is moderate due to curing processes.

Impact on Application: Silicone is preferred for LED strips used in harsh outdoor conditions, including tropical climates and desert environments common in the Middle East and parts of Africa. Its resistance to UV and chemicals ensures longevity.

Considerations for International Buyers: Compliance with international standards such as RoHS and REACH is critical, especially for European markets. Buyers in South America and Africa should consider suppliers who provide certifications and warranties to ensure product reliability in demanding environments.

Polycarbonate (PC)

Key Properties: Polycarbonate is a rigid, transparent thermoplastic with high impact resistance, good thermal stability (up to 115°C), and excellent optical clarity. It also offers good flame retardance and UV resistance when treated.

Pros & Cons: PC provides robust protection for LED strips, ideal for applications requiring mechanical strength and light diffusion. It is more expensive and less flexible than PVC or silicone, which can limit installation versatility.

Impact on Application: PC is suitable for industrial or architectural LED strip lighting where physical protection and aesthetic clarity are priorities. It performs well in moderate outdoor conditions but may require UV stabilizers for prolonged sun exposure.

Considerations for International Buyers: European and Middle Eastern buyers often demand compliance with stringent fire safety standards (e.g., UL 94 V-0 rating) and environmental certifications. Buyers from Africa and South America should assess supplier capabilities in delivering consistent quality and consider the higher upfront cost justified by durability.

Thermoplastic Polyurethane (TPU)

Key Properties: TPU is a versatile elastomer known for its excellent abrasion resistance, flexibility, and moderate temperature tolerance (up to 80°C). It also exhibits good chemical resistance and elasticity.

Pros & Cons: TPU balances flexibility and toughness, making it suitable for LED strips exposed to mechanical stress or bending. It is more expensive than PVC but less costly than silicone. TPU’s manufacturing process is relatively complex due to extrusion and molding requirements.

Impact on Application: TPU is ideal for wearable or portable LED strip lights, as well as outdoor applications requiring impact resistance and flexibility. It performs well in humid and corrosive environments, which are common in coastal regions of South America and Southeast Asia.

Considerations for International Buyers: Buyers should ensure TPU materials meet ASTM D412 or ISO 527 standards for tensile strength and elongation. Compliance with RoHS and local chemical safety regulations is essential for markets in Europe and the Middle East. In Africa, TPU’s durability can reduce replacement frequency, offering long-term cost benefits despite higher initial investment.

| Material | Typical Use Case for battery led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Indoor LED strips, budget-sensitive projects | Cost-effective, flexible, easy to manufacture | Limited heat resistance, UV degradation | Low |

| Silicone Rubber | Outdoor, industrial, and harsh environment applications | High thermal stability, UV and chemical resistance | Higher cost, moderate manufacturing complexity | High |

| Polycarbonate (PC) | Architectural, industrial LED strips requiring durability | High impact resistance, optical clarity | Rigid, less flexible, higher cost | Medium |

| Thermoplastic Polyurethane (TPU) | Wearables, portable, and flexible outdoor strips | Excellent abrasion resistance and flexibility | Moderate heat tolerance, higher manufacturing complexity | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for battery led strip lights

Battery LED strip lights combine compact LED technology with portable power sources, requiring meticulous manufacturing and rigorous quality assurance to meet the expectations of international B2B buyers. Understanding the typical manufacturing stages and quality control practices helps buyers from Africa, South America, the Middle East, and Europe make informed sourcing decisions and ensure product reliability across diverse markets.

Manufacturing Process Overview

The production of battery-powered LED strip lights involves several key stages, each critical to the final product’s performance, durability, and safety.

1. Material Preparation

- Substrate Selection: Flexible printed circuit boards (FPCBs) serve as the base, typically made from polyimide or polyester films that offer flexibility and heat resistance.

- LED and Component Procurement: High-quality SMD LEDs (commonly 2835 or 3528 chip sizes) are sourced alongside resistors, battery holders, switches, and connectors.

- Battery Integration Materials: Rechargeable lithium-ion or alkaline batteries, wiring harnesses, and protective casings are prepared for assembly.

2. Forming and Circuit Fabrication

- PCB Patterning: The substrate is printed with conductive copper traces via photolithography or etching processes, defining the electrical pathways.

- Surface Mount Technology (SMT): Automated pick-and-place machines position LEDs and passive components onto the PCB, followed by soldering—typically using reflow ovens to ensure secure electrical and mechanical connections.

- Battery Holder Assembly: Battery compartments are molded or inserted, designed for ease of replacement or recharging.

3. Assembly

- Integration of Power Sources: Batteries are installed, and wiring is routed to the LED circuit, ensuring compactness and safety.

- Encapsulation and Waterproofing: Depending on the product specification, strips are coated with silicone or epoxy resins to protect against moisture and physical damage.

- Attachment of Control Features: Switches, dimmers, or remote control receivers are mounted and wired for user interface.

4. Finishing

- Cutting and Packaging: LED strips are cut to standard or custom lengths, with connectors attached. Products are packaged with user manuals and safety instructions.

- Labeling: Compliance markings (e.g., CE, RoHS) and batch numbers are printed for traceability.

Quality Assurance and Control (QA/QC) Framework

Robust quality control ensures that battery LED strip lights meet international safety and performance standards, minimizing returns and enhancing buyer confidence.

Relevant International Standards and Certifications

- ISO 9001: This quality management system standard governs overall manufacturing quality processes, emphasizing consistency and continuous improvement.

- CE Marking: Mandatory for Europe, indicates conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Restricts hazardous substances, critical for European and many international markets.

- UL and ETL Certifications: Especially important for North American markets, these verify electrical safety.

- API and IEC Standards: Provide electrical and environmental testing guidelines relevant for LED lighting products.

- Country-Specific Requirements: Buyers from Turkey, Indonesia, or Middle Eastern countries should verify local certifications or import regulations that may supplement international standards.

Key QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Inspection of raw materials and components such as LEDs, batteries, PCBs, and casings for defects or deviations before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly to detect soldering defects, component placement errors, and battery integration issues.

- Final Quality Control (FQC): Comprehensive testing of the finished product, including visual inspection, functional testing, and packaging verification.

Common Testing Methods for Battery LED Strip Lights

- Electrical Testing: Verifies voltage, current, and resistance to ensure proper circuit function and battery compatibility.

- Luminosity and Color Consistency Tests: Measures light output and color temperature uniformity across batches.

- Durability Testing: Includes bending, vibration, and drop tests to simulate real-world usage.

- Waterproofing Tests: For IP65 or higher rated products, immersion or spray tests confirm sealing integrity.

- Battery Safety Testing: Checks for overheating, short circuit resistance, and charge/discharge cycles to ensure battery safety and longevity.

How B2B Buyers Can Verify Supplier Quality Control

For international buyers, especially those operating in emerging markets or regions with complex import standards, verifying supplier quality control practices is essential.

1. Supplier Audits and Factory Visits

- On-site Audits: Conduct or commission audits to inspect manufacturing processes, equipment condition, and worker training.

- Third-Party Inspections: Engage independent quality assurance firms to perform random batch inspections and process audits.

2. Review of QC Documentation

- Certification Verification: Request copies of ISO 9001, CE, RoHS, and other relevant certificates, ensuring authenticity through official registries.

- Test Reports: Analyze detailed test reports for electrical safety, luminosity, and battery performance.

- Production and QC Records: Examine batch-level inspection logs, non-conformance reports, and corrective action records.

3. Sample Testing

- Pre-Order Samples: Obtain product samples for in-house or third-party lab testing to verify claims regarding brightness, battery life, and safety.

- Pilot Orders: Start with small-volume orders to assess consistency before scaling up.

Quality Control Nuances for Diverse International Markets

- Africa and South America: Buyers should prioritize suppliers with certifications recognized by local regulatory authorities and ensure that battery safety standards comply with regional import rules. Environmental conditions such as heat and humidity necessitate stringent waterproofing and durability tests.

- Middle East: Given the extreme temperatures and dust exposure, QC should emphasize robust encapsulation and thermal management. Compliance with Gulf Cooperation Council (GCC) electrical standards may also be required.

- Europe: Strict adherence to CE and RoHS is mandatory, with additional focus on energy efficiency standards (e.g., ErP directive). Traceability through clear labeling and documentation is critical.

- Indonesia and Turkey: These markets often require a blend of international and local certifications. Buyers should confirm supplier familiarity with local import duties, testing protocols, and labeling requirements to avoid customs delays.

Summary for B2B Buyers:

Selecting battery LED strip light suppliers with transparent, well-documented manufacturing and quality assurance processes mitigates risks associated with product failure and regulatory non-compliance. Buyers should insist on suppliers adhering to international standards, provide comprehensive QC evidence, and be open to audits and sample testing. Tailoring supplier evaluation to the specific regulatory and environmental context of your target market ensures a smooth supply chain and satisfied end customers.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for battery led strip lights Sourcing

Battery LED strip lights sourcing involves a complex cost structure influenced by multiple factors that international B2B buyers must understand to optimize purchasing decisions. This analysis breaks down key cost components, pricing influencers, and strategic buyer tips relevant for markets in Africa, South America, the Middle East, and Europe, including emerging hubs such as Indonesia and Turkey.

Key Cost Components in Battery LED Strip Lights

-

Materials:

The core raw materials include LED chips, flexible PCB substrates, battery cells (commonly lithium-ion or lithium-polymer), integrated circuits for control, adhesives, and protective coatings. Material quality significantly impacts durability and performance, especially battery capacity and LED efficiency. -

Labor:

Labor costs vary widely based on the manufacturing location. Countries with advanced manufacturing capabilities may have higher labor costs but deliver superior quality and faster turnaround. Conversely, emerging manufacturing hubs might offer lower labor expenses but require diligent quality oversight. -

Manufacturing Overhead:

This includes factory utilities, equipment depreciation, and indirect labor such as supervisors and maintenance staff. Efficient factories with automated production lines can reduce overhead per unit. -

Tooling and Setup Costs:

Initial investment in molds, assembly jigs, and testing equipment is amortized over production runs. Custom designs or new models may incur higher tooling costs, which influence pricing, particularly for low-volume orders. -

Quality Control (QC):

Rigorous QC ensures compliance with international standards (e.g., CE, RoHS). QC involves inspection of incoming materials, in-process checks, and final product testing, especially for battery safety and LED longevity. -

Logistics and Shipping:

Battery LED strip lights are often shipped internationally via sea or air freight. Batteries are classified as hazardous goods, potentially increasing shipping costs and documentation complexity. Import duties, taxes, and local distribution expenses also add to the landed cost. -

Supplier Margin:

Suppliers price products to cover their costs and earn profit margins. Margins vary by supplier reputation, product exclusivity, and market demand.

Influential Pricing Factors

-

Order Volume and Minimum Order Quantity (MOQ):

Higher volumes typically unlock lower per-unit prices due to economies of scale. MOQ requirements can vary; buyers should negotiate to match their capacity while considering inventory costs. -

Product Specifications and Customization:

Enhanced features such as waterproofing, color temperature options, brightness levels, and smart controls add to costs. Custom packaging or branding also influences price. -

Material Quality and Certifications:

Certified components compliant with international safety and environmental standards command premium pricing but reduce risk of returns or regulatory issues. -

Supplier Reliability and Location:

Established suppliers with proven track records often price higher but offer consistent quality and reliable delivery. Proximity to buyer markets reduces shipping lead times and costs. -

Incoterms and Payment Terms:

Terms such as FOB, CIF, or DDP affect who bears shipping and customs responsibilities, impacting total cost. Flexible payment terms may improve cash flow but sometimes come at a premium.

Actionable Buyer Tips for International B2B Procurement

-

Negotiate on Volume and Terms:

Leverage bulk purchasing power to negotiate better pricing, extended payment terms, or free shipping options. Consider multi-year contracts for price stability. -

Evaluate Total Cost of Ownership (TCO):

Factor in not just purchase price but also shipping, customs duties, inventory holding, warranty service, and potential downtime costs due to product failure. -

Prioritize Certified Quality:

For regions with strict regulatory environments, insist on products with CE, RoHS, or UL certifications to avoid import delays and ensure safety compliance. -

Understand Regional Logistics Nuances:

In Africa and South America, port inefficiencies and customs delays may increase lead times and costs. In the Middle East and Europe, faster logistics can reduce inventory buffer needs. -

Use Sample Testing:

Before committing to large orders, obtain samples to verify product quality, battery life, and compatibility with local power standards. -

Consider Local Partnerships:

Collaborating with local distributors or agents can simplify logistics, provide after-sales support, and improve market responsiveness. -

Beware of Pricing Too Good to Be True:

Extremely low prices may indicate substandard materials or omitted certifications, leading to higher long-term costs.

Indicative Pricing Disclaimer

Battery LED strip lights pricing varies widely depending on specifications, order size, and supplier location. As a rough benchmark, wholesale prices can range from approximately $3 to $15 per meter, excluding shipping and taxes. Buyers should request detailed quotations including all cost components and verify supplier credentials before finalizing purchases.

By understanding these cost drivers and pricing dynamics, international B2B buyers can strategically source battery LED strip lights that balance quality, cost-efficiency, and compliance, ensuring sustainable business success across diverse global markets.

Spotlight on Potential battery led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘battery led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for battery led strip lights

Understanding the critical technical properties and common trade terminology associated with battery LED strip lights empowers international B2B buyers to make informed purchasing decisions, negotiate effectively, and ensure product suitability for their markets. Below is a detailed overview tailored for buyers from Africa, South America, the Middle East, and Europe.

Key Technical Properties of Battery LED Strip Lights

-

Voltage and Current Ratings

Battery LED strip lights commonly operate at 12V or 24V DC. The voltage rating must match the battery pack and driver specifications to ensure safe and efficient operation. Current ratings indicate power consumption and impact battery life. For B2B buyers, confirming voltage compatibility prevents costly mismatches and product failures in the field. -

Material Grade and Waterproof Rating (IP Code)

The strip’s substrate material (usually flexible PCB) and LED encapsulation affect durability and heat dissipation. Waterproof ratings, such as IP65, IP67, or IP68, specify resistance to water and dust ingress. For buyers targeting outdoor or humid environments, selecting strips with appropriate IP ratings is critical for long-term reliability and customer satisfaction.

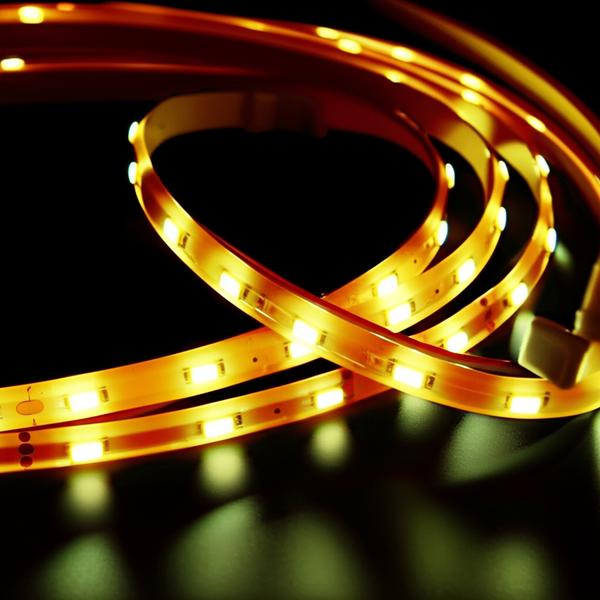

Illustrative Image (Source: Google Search)

-

Color Temperature and CRI (Color Rendering Index)

Color temperature (measured in Kelvin) defines the light’s warmth or coolness, ranging typically from 2700K (warm white) to 6500K (daylight). CRI measures how accurately colors appear under the light source, with values above 80 preferred for retail and hospitality sectors. Understanding these specs enables buyers to align product offerings with end-user preferences and application requirements. -

LED Density and Brightness (Lumens per Meter)

LED density (number of LEDs per meter) influences brightness and uniformity. Higher density strips produce more intense illumination but consume more power. Brightness, measured in lumens per meter, helps buyers compare lighting output across suppliers. This property is especially important in markets where energy efficiency and visual impact are selling points. -

Battery Capacity and Runtime

Since these strips are battery-powered, the battery’s capacity (measured in mAh or Wh) and expected runtime under typical usage conditions are crucial. Buyers must verify that suppliers provide accurate runtime data to ensure the product meets market expectations, especially in regions with limited access to frequent recharging. -

Tolerance and Quality Control Standards

Tolerance refers to permissible deviations in voltage, brightness, and other specs during manufacturing. Tight tolerances indicate higher quality and consistent product performance. Buyers should inquire about suppliers’ quality control processes and certifications to minimize defects and returns.

Common Industry and Trade Terms

-

OEM (Original Equipment Manufacturer)

OEM refers to manufacturers producing products that other companies rebrand and sell. B2B buyers benefit from OEM partnerships by customizing LED strip designs, packaging, and branding to fit their unique market needs, enhancing competitiveness. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity a supplier will accept for an order. Understanding MOQ helps buyers plan inventory and budget, especially important for emerging markets or smaller distributors where cash flow and storage are constrained. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain detailed pricing, specifications, and terms. Using RFQs allows buyers to compare offers transparently and negotiate better deals, ensuring procurement aligns with quality and cost targets. -

Incoterms (International Commercial Terms)

Incoterms define responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Common terms include FOB (Free On Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Knowing Incoterms prevents misunderstandings about cost allocation and logistics, crucial for cross-border trade. -

BOM (Bill of Materials)

BOM lists all components and materials used in the LED strip assembly. Reviewing the BOM helps buyers assess product complexity, sourcing risks, and potential customization options. -

Certification Compliance (CE, RoHS, UL)

Certifications ensure products meet safety, environmental, and performance standards. CE and RoHS are critical for European markets, while UL is often required in the Middle East and some African countries. Buyers must verify certification documents to avoid regulatory issues and enhance product credibility.

Illustrative Image (Source: Google Search)

By mastering these technical properties and trade terms, international B2B buyers can confidently source battery LED strip lights that meet performance expectations, comply with regional standards, and optimize supply chain efficiency. This knowledge facilitates strategic partnerships and successful market entry across diverse global regions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the battery led strip lights Sector

Market Overview & Key Trends

The global battery LED strip lights market is experiencing robust growth driven by increasing demand for flexible, energy-efficient lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe (including emerging markets like Indonesia and Turkey), this sector presents significant opportunities fueled by urbanization, infrastructure development, and rising awareness of energy conservation.

Key Market Drivers:

- Energy Efficiency and Portability: Battery-powered LED strip lights offer ease of installation without wiring constraints, making them ideal for retrofit projects and temporary installations in regions with inconsistent grid access.

- Technological Advancements: Integration of smart controls, improved battery technology (such as lithium-ion and rechargeable variants), and longer lifespan LEDs are enhancing product appeal.

- Customization and Versatility: Modular designs and various color temperature options cater to diverse applications, from decorative lighting in hospitality to task lighting in manufacturing.

- Cost-Effectiveness: Declining costs of LED components and batteries are enabling competitive pricing, which is crucial for buyers in price-sensitive emerging markets.

Emerging Sourcing Trends:

- Regional Sourcing Hubs: Buyers are increasingly sourcing from specialized manufacturers in Asia and Europe who offer OEM/ODM services, allowing customization to meet local market needs.

- Supply Chain Resilience: The COVID-19 pandemic highlighted vulnerabilities in global supply chains; as a result, buyers prioritize suppliers with diversified manufacturing bases and transparent logistics.

- Digital Procurement Platforms: B2B buyers leverage online marketplaces with verified suppliers to streamline procurement, compare certifications, and access real-time inventory data.

- Value-Added Services: Suppliers offering technical support, quick sample dispatch, and after-sales service are favored to reduce installation risks and improve project timelines.

For B2B buyers in regions with emerging infrastructure, partnering with suppliers that understand local regulatory environments and provide tailored solutions is increasingly vital to maximize ROI and market competitiveness.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone in the procurement of battery LED strip lights, reflecting broader corporate responsibility goals and regulatory pressures across multiple continents. International B2B buyers are demanding products that not only deliver performance but also minimize environmental impact throughout the product lifecycle.

Environmental Considerations:

- Energy Consumption: Battery LED strips inherently consume less power than traditional lighting, but the sustainability focus extends to battery efficiency and recyclability.

- Material Selection: Use of lead-free solder, halogen-free components, and recyclable packaging reduces ecological footprint.

- Battery Disposal and Recycling: Suppliers adopting circular economy principles ensure batteries are designed for safe disposal or refurbishment, mitigating hazardous waste concerns.

Ethical Supply Chains:

- Transparency in sourcing raw materials such as lithium and rare earth elements is critical to avoid human rights violations and environmental degradation.

- Certifications like RoHS (Restriction of Hazardous Substances), CE, and UL not only guarantee product safety but also compliance with environmental standards.

- Increasingly, buyers seek suppliers with ISO 14001 environmental management certification and commitments to conflict-free minerals sourcing.

Actionable Insights for B2B Buyers:

- Prioritize suppliers offering detailed sustainability reports and third-party audits.

- Engage in long-term partnerships that foster continuous improvement in environmental and social governance (ESG) practices.

- Incorporate sustainability criteria into tender processes, balancing cost with ecological and ethical performance to future-proof procurement strategies.

By integrating sustainability into sourcing decisions, buyers can reduce risks, enhance brand reputation, and meet growing consumer and regulatory demands across their target markets.

Evolution of Battery LED Strip Lights in B2B Context

Battery LED strip lights have evolved from simple decorative products to sophisticated lighting solutions with broad industrial and commercial applications. Initially popularized for consumer use due to their flexibility and low power consumption, advances in battery technology and LED efficiency have expanded their utility in professional settings.

Early models relied on disposable alkaline batteries with limited run times, constraining their deployment in large-scale projects. The transition to rechargeable lithium-ion batteries and integration with smart control systems has significantly extended operational lifespan and functionality.

Today, battery LED strip lights are integral to sectors such as event management, retail display, emergency lighting, and remote installations where traditional power sources are inaccessible or impractical. This evolution underscores the importance of sourcing from manufacturers who invest in R&D and provide scalable solutions tailored to the rigorous demands of international B2B buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of battery led strip lights

-

How can I effectively vet suppliers of battery LED strip lights to ensure product quality and reliability?

To vet suppliers, prioritize those with verifiable certifications such as CE, RoHS, and UL, which confirm compliance with international safety and environmental standards. Request detailed product datasheets and sample units to evaluate build quality and battery performance. Check the supplier’s track record by reviewing customer testimonials, case studies, and references, particularly from similar markets like Africa, South America, or the Middle East. Engage in direct communication to assess responsiveness and technical expertise. Participating in industry trade shows or using verified B2B platforms can also help identify reputable suppliers with transparent business practices. -

What customization options are typically available for battery LED strip lights in B2B orders?

Most reputable manufacturers offer customization including strip length, LED density, battery capacity, color temperature, and waterproof ratings. OEM and ODM services often allow branding with custom logos, packaging, and user manuals tailored to regional languages or regulations. Buyers should clarify technical specifications upfront to ensure compatibility with target markets (e.g., voltage requirements or battery types preferred in Europe vs. Africa). Custom firmware or control options like remote or app-based dimming may also be available. Establishing clear communication and prototyping early in the negotiation phase reduces risks of misaligned expectations. -

What are common minimum order quantities (MOQs), lead times, and payment terms for international B2B purchases of battery LED strip lights?

MOQs vary widely depending on supplier scale and customization level, typically ranging from 500 to 5,000 units. Lead times for standard products often fall between 3 to 6 weeks, while customized orders may take 6 to 12 weeks due to tooling and battery certification processes. Payment terms frequently include 30% upfront deposit with balance before shipment or against documents, though some suppliers may accept letters of credit or escrow arrangements for added security. Negotiating flexible payment terms and staggered shipments can help manage cash flow, especially for new market entrants in regions like South America or the Middle East. -

Which quality assurance (QA) processes and certifications should I verify for battery LED strip lights?

Ensure suppliers conduct rigorous QA steps including battery safety testing (overcharge, short circuit, thermal stability), LED lumen and color consistency tests, and waterproof or dustproof certifications (IP ratings). Certifications such as UN38.3 for lithium batteries, CE for European compliance, and RoHS for hazardous substance restrictions are essential. Request production batch test reports and inquire about third-party lab audits. A strong QA protocol minimizes returns and warranty claims, critical when shipping internationally to markets with varying regulatory demands.

-

What logistical considerations should international B2B buyers keep in mind when importing battery LED strip lights?

Battery-powered LED strips involve shipping lithium batteries, which are classified as dangerous goods requiring compliance with IATA and IMDG regulations. Confirm your supplier uses approved packaging and carriers experienced in handling hazardous materials. Evaluate shipping options balancing cost, speed, and reliability—air freight is faster but more expensive, while sea freight reduces costs but increases transit time. Customs clearance may require specific documentation such as MSDS (Material Safety Data Sheets) and import permits in certain countries. Partnering with freight forwarders familiar with your destination market’s import regulations can streamline logistics. -

How can I mitigate and resolve disputes with battery LED strip light suppliers in international trade?

Establish clear contractual terms upfront, detailing product specifications, quality standards, delivery timelines, payment schedules, and dispute resolution mechanisms including arbitration venues or governing law. Maintain thorough documentation of all communications and inspections. Use third-party inspection services before shipment to detect defects early. If disputes arise, engage suppliers in good faith negotiations to seek remedies such as replacement shipments or refunds. Leveraging international trade bodies or mediation services can be effective, especially when dealing with suppliers from different legal jurisdictions. -

Are there regional differences in battery LED strip light specifications or regulations I should consider when sourcing for Africa, South America, the Middle East, or Europe?

Yes, regional standards and power infrastructure influence product requirements. For example, European buyers often require CE certification and compliance with RoHS and WEEE directives, while Middle Eastern and African markets may prioritize robustness against heat and dust, requiring higher IP ratings. Voltage standards and battery chemistries favored can differ; some regions prefer rechargeable lithium-ion batteries with specific safety certifications. Additionally, export/import restrictions on lithium batteries vary—understanding local regulations avoids shipment delays. Collaborate with suppliers familiar with your target regions to customize products accordingly. -

What are best practices for ensuring ongoing supply chain stability for battery LED strip lights in international B2B trade?

Develop long-term partnerships with multiple vetted suppliers to mitigate risks of stockouts or quality fluctuations. Negotiate framework agreements that include volume forecasts, priority production slots, and penalties for delays. Regularly monitor supplier performance through KPIs such as on-time delivery and defect rates. Invest in supply chain visibility tools or ERP integrations to track inventory and shipments in real time. Consider local warehousing or regional distribution centers to reduce lead times and improve responsiveness in markets like Turkey or Indonesia. Staying informed on global battery material trends also helps anticipate cost or availability issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for battery led strip lights

Strategic sourcing of battery LED strip lights is pivotal for international B2B buyers aiming to balance cost-efficiency, quality, and supply reliability. Key takeaways include prioritizing suppliers with strong certifications (CE, RoHS, UL), proven product durability, and comprehensive after-sales support. Leveraging partnerships with reputable manufacturers and verified wholesale distributors can mitigate risks related to component compatibility and ensure consistent product performance in diverse markets like Africa, South America, the Middle East, and Europe.

Understanding regional market nuances—such as local certification requirements and environmental conditions—is equally important to tailor sourcing strategies effectively. Buyers should also consider suppliers offering flexible customization and scalable order volumes to adapt to evolving project demands.

Looking ahead, the battery LED strip light market is poised for growth driven by increasing demand for portable, energy-efficient lighting solutions in emerging economies and smart infrastructure projects worldwide. International buyers are encouraged to engage proactively with suppliers who invest in innovation and sustainability, fostering long-term collaborations that secure competitive advantage.

By adopting a strategic sourcing mindset focused on quality, compliance, and partnership, B2B buyers can confidently navigate the evolving LED lighting landscape and capitalize on new opportunities across global markets.