Introduction: Navigating the Global Market for aluminum led channel for led strip lights

The global demand for aluminum LED channels for LED strip lights is rapidly growing, driven by the need for high-quality, durable, and aesthetically superior lighting solutions across commercial and industrial sectors. For international B2B buyers—especially from emerging and established markets in Africa, South America, the Middle East, and Europe—understanding the critical role of aluminum channels is essential for sourcing products that enhance LED strip performance and longevity. These channels not only provide robust physical protection and refined heat dissipation but also deliver superior light diffusion and seamless integration, elevating the value proposition of LED installations.

This comprehensive guide delves into every facet of aluminum LED channels, empowering buyers with actionable insights on types and profiles, material grades, and manufacturing and quality control standards that impact product reliability. It also covers how to evaluate suppliers, compare costs, and navigate regional market dynamics—crucial for buyers in diverse economic environments such as Egypt’s growing infrastructure sector or Italy’s design-focused markets. Additionally, the guide addresses frequently asked questions to clarify common technical and procurement challenges.

By presenting a detailed roadmap from technical specifications to strategic sourcing considerations, this resource helps B2B professionals make informed decisions that optimize project outcomes and mitigate risks. Whether you are a contractor, distributor, or facility manager, this guide equips you with the knowledge to confidently select aluminum LED channels that meet stringent quality and performance criteria, ensuring your LED strip lighting projects succeed on a global scale.

Understanding aluminum led channel for led strip lights Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U-Channel | Classic U-shaped aluminum profile, compatible with most LED strips, typically with snap-in diffusers | Commercial retail lighting, office interiors, hospitality venues | Pros: Versatile, cost-effective, easy to install; Cons: Limited aesthetic customization, less suited for tight or curved spaces |

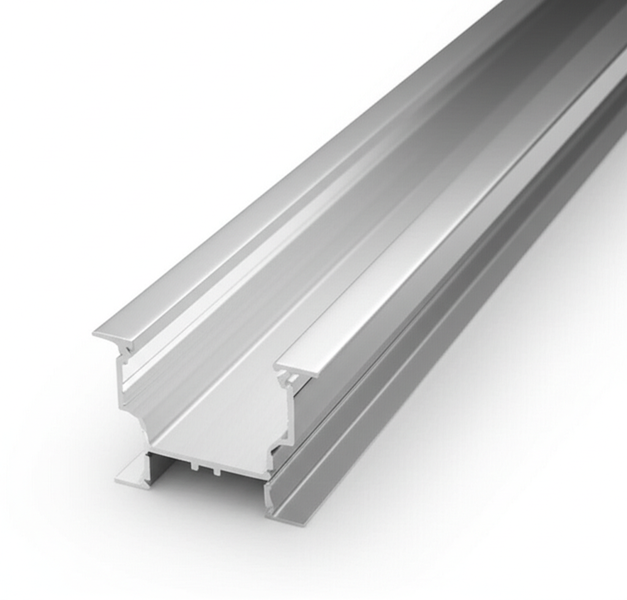

| Recessed Channel | Designed for flush mounting into walls, ceilings, or furniture, providing a seamless finish | Architectural lighting, high-end residential, museum displays | Pros: Sleek integration, hides wiring; Cons: Requires precise installation, higher labor costs |

| Surface Mount Channel | Mounts directly onto surfaces with visible profile, often with mounting clips | Industrial environments, warehouses, outdoor signage | Pros: Easy retrofit, robust; Cons: More visible, less aesthetic appeal |

| Corner Channel | L-shaped profiles designed to fit LED strips into corners or edges | Cove lighting, staircases, display cases | Pros: Enables creative lighting angles, space-saving; Cons: Limited strip width compatibility |

| Waterproof/Outdoor Channel | Sealed aluminum profiles with weather-resistant diffusers and end caps | Outdoor signage, landscape lighting, wet areas | Pros: Weatherproof, durable; Cons: Higher cost, heavier profile |

Standard U-Channel

The Standard U-Channel is the most widely used aluminum LED channel, featuring a simple U-shaped design that accommodates most LED strip widths. It is highly versatile and suits a broad range of commercial applications such as retail spaces, offices, and hospitality environments. For B2B buyers, the key considerations include selecting the right diffuser type (opal, frosted, clear) to optimize light diffusion and ensuring compatibility with LED strip dimensions. Its cost-effectiveness and ease of installation make it a reliable choice for projects prioritizing functionality and budget.

Recessed Channel

Recessed Channels are designed to be embedded flush into surfaces like drywall, ceilings, or furniture, creating a seamless and minimalist lighting effect. This type is ideal for architectural projects, luxury residential spaces, and museums where aesthetics and integration are paramount. B2B buyers must account for the increased installation complexity and potential higher labor costs but benefit from the premium finish and concealed wiring. Accurate measurements and planning are essential to avoid costly installation errors.

Surface Mount Channel

Surface Mount Channels are designed to be affixed directly onto visible surfaces using clips or screws. They are particularly suited for industrial settings, warehouses, and outdoor signage where ease of installation and durability outweigh the need for discreet aesthetics. These channels often have a more robust build to withstand harsher environments. B2B buyers should consider the trade-off between visibility and practicality, ensuring the channel material and finish meet environmental and operational demands.

Corner Channel

Corner Channels feature an L-shaped profile that fits snugly into corners, edges, or junctions, enabling creative lighting solutions such as cove lighting or accentuating architectural features like staircases and display cases. They maximize space efficiency and allow unique light distribution angles. Buyers should verify the compatibility with their LED strip dimensions and the mounting surface geometry. These channels are favored in design-driven projects that require both function and visual impact.

Waterproof/Outdoor Channel

Waterproof Channels are specialized aluminum profiles sealed with weather-resistant diffusers, end caps, and mounting hardware to withstand moisture, dust, and UV exposure. They are indispensable for outdoor signage, landscape lighting, and wet or damp environments such as bathrooms or kitchens. For B2B buyers, selecting channels with appropriate IP ratings and corrosion-resistant finishes is critical to ensure longevity and reduce maintenance costs. While more expensive, these channels protect the LED strips and maintain performance under challenging conditions.

Related Video: How to Install Recessed LED Channel and LED Strip Lights in Drywall for Recessed Linear Lighting

Key Industrial Applications of aluminum led channel for led strip lights

| Industry/Sector | Specific Application of aluminum led channel for led strip lights | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Commercial Retail | Ambient and accent lighting in shop interiors, display cases, and shelving units | Enhances product visibility, creates inviting atmosphere, and protects LEDs | Durable, UV-resistant channels with customizable diffuser options; IP rating for dust/moisture; aesthetic finishes matching brand identity |

| Hospitality & Hotels | Cove lighting, corridor illumination, and decorative lighting in lobbies and rooms | Improves guest experience with uniform, glare-free lighting; reduces maintenance costs | Corrosion-resistant materials for humid environments; easy installation profiles; compliance with regional safety standards (CE, UL) |

| Architectural & Interior Design | Integrated linear lighting for walls, ceilings, and staircases | Provides sleek, modern aesthetics with precise light diffusion; protects LEDs from damage | Variety of channel profiles and diffuser types; compatibility with different LED strip widths; thermal management features |

| Industrial & Warehousing | Task lighting in workstations, machinery, and storage areas | Increases safety and productivity with robust, well-protected lighting; extends LED lifespan | High-impact resistant channels; IP65 or higher ratings for dust and moisture; heat dissipation capabilities |

| Transportation & Infrastructure | Lighting for tunnels, underpasses, and public transit stations | Ensures durability under harsh conditions; enhances safety with uniform illumination | Weatherproof and vandal-resistant channels; compliance with local electrical codes; long-term UV and temperature stability |

Commercial Retail Lighting

In retail environments across Africa, South America, and Europe, aluminum LED channels are widely employed to house LED strip lights in shelving, display cases, and general ambient lighting. These channels enable retailers to present products under consistent, glare-free illumination that enhances visual appeal and encourages customer engagement. The aluminum housing protects delicate LED strips from dust, accidental impact, and moisture, especially in humid or dusty climates typical of some regions like Egypt or Brazil. Buyers should prioritize channels with customizable diffuser options and finishes that align with their store branding while ensuring IP ratings suitable for indoor retail environments.

Hospitality & Hotels

Hotels and resorts in the Middle East and Europe extensively use aluminum LED channels for cove lighting, corridors, and decorative fixtures. These channels facilitate the creation of warm, inviting atmospheres with evenly diffused light that minimizes glare—a critical factor for guest comfort. Given the higher humidity levels in some Middle Eastern locations, corrosion-resistant aluminum profiles and weatherproof end caps are essential to maintain longevity. International buyers must verify compliance with regional electrical safety certifications (such as CE in Europe) and select profiles designed for rapid installation to minimize downtime during refurbishments.

Architectural & Interior Design

Architects and interior designers leverage aluminum LED channels to integrate LED strips seamlessly into walls, ceilings, and staircases, delivering modern, minimalist lighting solutions that conceal wiring and circuitry. This application is prevalent in European commercial buildings and upscale residential projects in South America. Aluminum channels provide efficient heat dissipation, preventing premature LED failure, while diffusers offer smooth light distribution without hotspots. Buyers should seek suppliers offering a wide range of profiles and diffuser types to match diverse design requirements and ensure compatibility with various LED strip widths.

Industrial & Warehousing

In industrial sectors across Africa and Europe, aluminum LED channels are used to mount LED strip lights in workstations, machinery, and storage facilities where rugged, reliable lighting is vital for safety and operational efficiency. The channels safeguard LEDs from dust, moisture, and mechanical damage, crucial in harsh industrial environments. High ingress protection (IP65 or above) and impact-resistant profiles are necessary to withstand demanding conditions. International buyers should focus on sourcing channels with excellent thermal management to prolong LED lifespan and meet stringent workplace safety standards.

Transportation & Infrastructure

Transportation hubs and infrastructure projects in regions like the Middle East and South America utilize aluminum LED channels for lighting tunnels, underpasses, and transit stations. The channels provide robust protection against environmental stresses such as temperature fluctuations, UV exposure, and vandalism. Uniform light diffusion improves safety and visibility for commuters. Buyers must prioritize weatherproof, vandal-resistant profiles compliant with local electrical codes and designed for long-term durability under continuous operation. UV-stable diffusers and corrosion-resistant finishes are critical for outdoor and semi-outdoor installations.

Strategic Material Selection Guide for aluminum led channel for led strip lights

When selecting materials for aluminum LED channels designed for LED strip lights, B2B buyers must consider performance, durability, cost, and regional compliance standards. Below is an analysis of the most common materials used for these channels, focusing on their suitability for diverse international markets including Africa, South America, the Middle East, and Europe.

1. Extruded Aluminum (6063 Alloy)

Key Properties:

6063 aluminum alloy is the industry standard for LED channels due to its excellent corrosion resistance, good mechanical strength, and superior thermal conductivity (around 167 W/m·K). It withstands moderate temperature ranges (-40°C to 120°C) and is highly resistant to oxidation, making it suitable for indoor and outdoor applications.

Pros:

– High durability and corrosion resistance, ideal for humid or coastal environments common in regions like Egypt and South America.

– Excellent heat dissipation extends LED lifespan, critical for commercial projects.

– Lightweight and easy to machine or cut, reducing manufacturing complexity and installation labor.

– Widely compliant with international standards such as ASTM B221 and DIN 1748, facilitating cross-border trade and certification.

Cons:

– Moderate cost compared to cheaper metals or plastics.

– Requires anodizing or powder coating for enhanced surface protection in harsh outdoor environments, adding to cost and lead time.

Impact on Application:

6063 aluminum channels are versatile for commercial, residential, and industrial LED lighting projects. Their thermal properties ensure LEDs operate efficiently, which is essential in hot climates like the Middle East. The corrosion resistance supports outdoor installations in tropical or coastal African markets.

International B2B Considerations:

Buyers in Europe (Italy) and the Middle East should verify compliance with CE and RoHS directives, while African and South American buyers should ensure materials meet ASTM or equivalent local standards. Anodized finishes are preferred for durability and aesthetics in these regions.

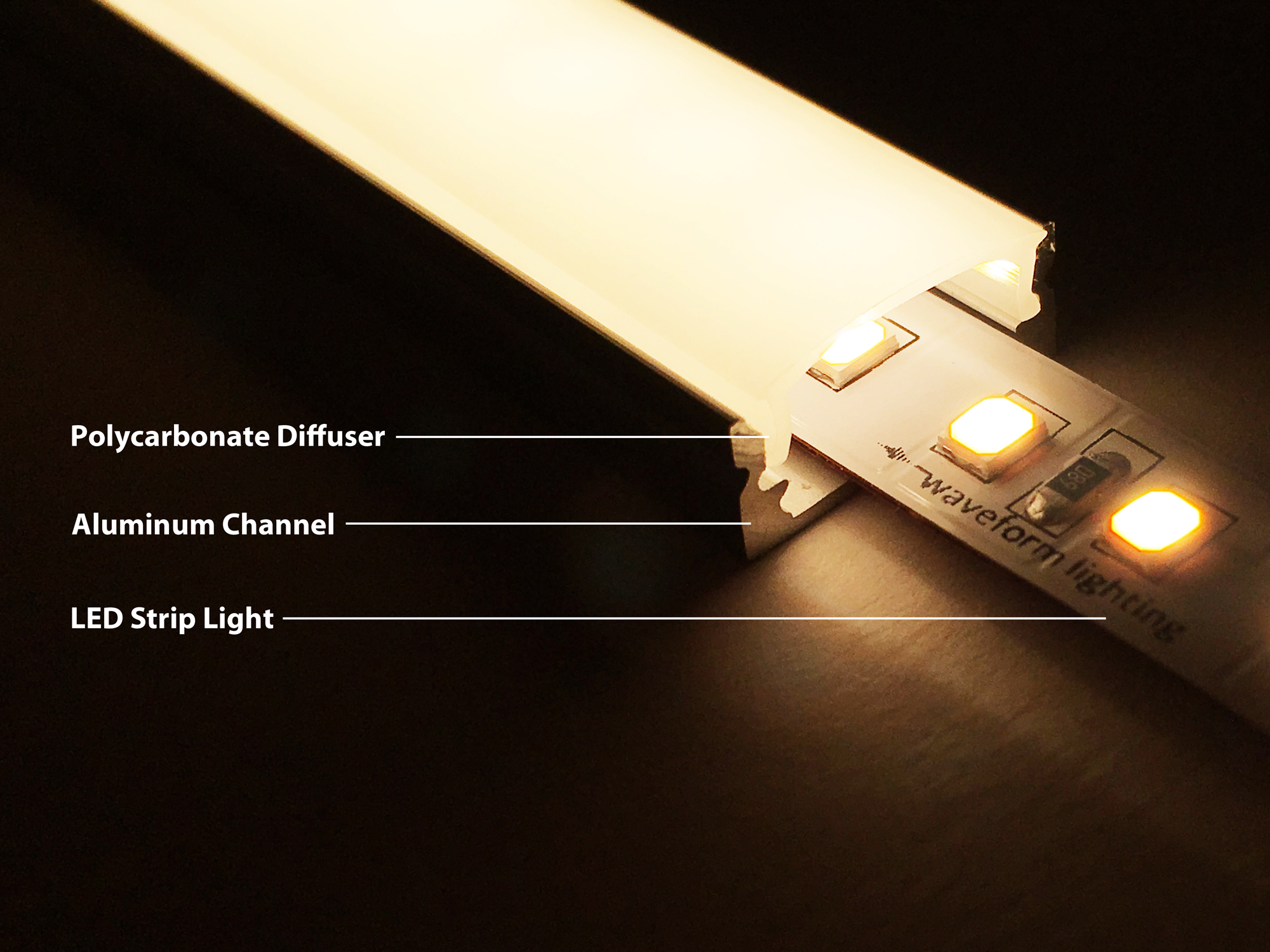

2. Polycarbonate (PC) Diffusers and Covers

Key Properties:

Polycarbonate is a high-impact, UV-resistant thermoplastic often used as a diffuser or cover atop aluminum channels. It offers excellent light transmission (up to 90%) and can withstand temperatures up to 135°C.

Pros:

– Superior impact resistance protects LED strips from mechanical damage, important in high-traffic commercial spaces.

– UV resistance prevents yellowing and degradation, suitable for outdoor or sun-exposed installations in Africa and South America.

– Lightweight and easy to snap-fit into aluminum channels, simplifying assembly.

Cons:

– Higher cost than acrylic alternatives.

– Susceptible to scratching, requiring additional coatings for abrasion resistance.

– Lower thermal conductivity than aluminum, so it cannot replace heat sinking but complements it.

Impact on Application:

Polycarbonate diffusers improve light diffusion and glare reduction, enhancing visual comfort in office or retail environments across all target regions. Their durability suits outdoor applications, especially in dusty or humid climates.

International B2B Considerations:

Ensure polycarbonate materials comply with EN 62262 (IK rating for impact resistance) in Europe and equivalent standards elsewhere. UV-stabilized grades are critical for Middle Eastern and African markets with intense sunlight exposure.

3. Acrylic (PMMA) Diffusers

Key Properties:

Acrylic offers excellent optical clarity (up to 92% light transmission) and is commonly used for diffusers in LED channels. It has moderate impact resistance and can tolerate temperatures up to 80°C.

Pros:

– Cost-effective compared to polycarbonate, making it attractive for budget-conscious projects in South America and Africa.

– Provides smooth light diffusion and reduces glare effectively.

– Easy to fabricate and cut, supporting custom designs.

Cons:

– Less impact resistant and more brittle than polycarbonate, limiting outdoor or high-impact use.

– Prone to yellowing under prolonged UV exposure, reducing lifespan in sunny climates.

– Lower temperature tolerance restricts use in high-heat environments.

Impact on Application:

Acrylic diffusers are ideal for indoor applications in controlled environments such as offices and showrooms in Europe and the Middle East. For outdoor use, they require UV protective coatings or should be avoided in regions with intense sunlight.

International B2B Considerations:

European buyers should confirm compliance with EN ISO 7823-1 for acrylic sheets. Buyers in Africa and South America should evaluate local climate conditions carefully before selecting acrylic to avoid premature degradation.

4. Stainless Steel (304 or 316 Grade) for Mounting Accessories

Key Properties:

Though not the main channel material, stainless steel is often used for mounting clips, screws, and end caps due to its high corrosion resistance and mechanical strength. Grade 316 offers superior resistance to saltwater and harsh chemicals.

Pros:

– Exceptional corrosion resistance, especially in coastal or industrial environments common in Middle East and African ports.

– High mechanical strength ensures secure mounting and longevity.

– Low maintenance and excellent aesthetic finish.

Cons:

– Higher cost than aluminum or plastic mounting components.

– Heavier, potentially increasing shipping costs for large projects.

Impact on Application:

Stainless steel accessories enhance the durability and reliability of LED channel installations, particularly in outdoor or harsh environments. They ensure long-term structural integrity and reduce maintenance costs.

International B2B Considerations:

Buyers should specify compliance with ASTM A240 or EN 10088 standards. In Europe and the Middle East, corrosion resistance certifications are critical, especially for projects near the sea or in industrial zones.

Summary Table

| Material | Typical Use Case for aluminum led channel for led strip lights | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Extruded Aluminum (6063 Alloy) | Main channel body for indoor/outdoor LED strip installations | Excellent heat dissipation and corrosion resistance | Requires surface treatment for harsh environments | Medium |

| Polycarbonate (PC) Diffusers | Diffuser covers for outdoor/high-impact installations | High impact and UV resistance | Higher cost and prone to scratching | High |

| Acrylic (PMMA) Diffusers | Diffuser covers for indoor, budget-sensitive projects | Cost-effective with excellent light diffusion | Lower impact resistance, UV degradation risk | Low |

| Stainless Steel (304/316) | Mounting clips, screws, and end caps for harsh environments | Superior corrosion resistance and strength | Higher cost and weight | High |

This material selection guide empowers international B2B buyers to make informed decisions tailored to their project environments and regional standards, ensuring durable,

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum led channel for led strip lights

Manufacturing and quality assurance for aluminum LED channels designed for LED strip lights involve a series of precise, controlled processes to ensure durability, aesthetic appeal, and functional performance. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these manufacturing stages and quality controls is essential for selecting reliable suppliers and ensuring product compliance with regional standards.

Manufacturing Process of Aluminum LED Channels

The production of aluminum LED channels typically follows a structured sequence encompassing material preparation, forming, assembly, and finishing. Each stage incorporates specialized techniques to meet high commercial-grade expectations.

1. Material Preparation

- Raw Material Selection: High-grade aluminum alloys, commonly 6063-T5 or T6, are selected for their excellent corrosion resistance, thermal conductivity, and mechanical strength. For projects exposed to harsh environments (outdoor, humid, or coastal regions), suppliers may offer anodized or powder-coated aluminum for enhanced protection.

- Extrusion Billet Preparation: Aluminum billets are preheated to the optimal extrusion temperature (~400-500°C) to achieve the correct malleability for shaping.

- Quality Verification: Incoming aluminum billets undergo chemical composition analysis and mechanical property testing to ensure conformity with standards such as ASTM B221 or EN 573.

2. Forming (Extrusion)

- Extrusion Process: The preheated aluminum billet is forced through a precision-engineered die that shapes the channel’s U-profile and grooves for LED strip placement and diffuser mounting. This process allows for tight dimensional tolerances critical for seamless installation.

- Cutting to Length: Post-extrusion, channels are cut to customer-specified lengths using precision saws to maintain flat, burr-free edges, essential for a professional finish.

- Secondary Machining: If required, milling or drilling creates mounting holes or slots for clips and screws, ensuring compatibility with diverse mounting surfaces.

3. Assembly

- Diffuser Installation: Acrylic or polycarbonate diffusers are fabricated separately and clipped or snapped into the aluminum channel. Diffuser materials are selected for optimal light diffusion, UV resistance, and impact resistance.

- End Caps & Accessories: Injection-molded or machined end caps, mounting clips, and screws are assembled to complete the channel system, providing protection and aesthetic closure.

- Thermal Interface Application: For enhanced heat dissipation, some manufacturers apply thermal adhesive or paste between the LED strip and channel base during assembly.

4. Finishing

- Surface Treatment: Channels undergo anodizing, powder coating, or painting to enhance corrosion resistance, wear resistance, and aesthetic appeal. This step is particularly important for outdoor or decorative applications.

- Quality Cleaning and Packaging: Final products are cleaned to remove oils or residues, then carefully packaged with protective films and cushioning to prevent damage during transit.

Quality Assurance and Control (QA/QC)

Robust quality assurance ensures that aluminum LED channels meet or exceed international and regional standards. B2B buyers should prioritize suppliers with comprehensive QC systems aligned with recognized certifications and thorough testing protocols.

Key Quality Standards and Certifications

- ISO 9001: The foundational international standard for quality management systems (QMS), ensuring consistent manufacturing processes and continuous improvement.

- CE Marking (Europe): Confirms product compliance with EU safety, health, and environmental protection requirements.

- RoHS Compliance: Restricts hazardous substances in materials, critical for buyers in Europe and increasingly adopted worldwide.

- UL Certification (North America) & IEC Standards: Relevant for electrical safety and material performance, often requested by buyers in the Middle East and South America.

- API Standards: Though primarily for oil and gas, certain API specifications for aluminum products may be relevant depending on application environments.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Verification of raw materials’ chemical and physical properties before entering production. Includes visual inspections and dimensional measurements.

- In-Process Quality Control (IPQC): Monitoring extrusion dimensions, surface finish, and assembly precision. Ensures adherence to tolerances and prevents defects such as warping or burrs.

- Final Quality Control (FQC): Comprehensive inspection of finished products, including surface treatment uniformity, diffuser fit, and packaging integrity.

Common Testing Methods

- Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines (CMM) to verify channel dimensions against design specifications.

- Surface Finish Testing: Visual and microscopic inspection for anodizing or coating defects such as peeling, bubbles, or uneven coverage.

- Mechanical Testing: Tensile strength and hardness tests to confirm material properties.

- Thermal Conductivity Tests: Ensuring the channel effectively dissipates heat from LED strips.

- Environmental Resistance Tests: Salt spray and UV exposure tests to simulate long-term outdoor durability.

- Light Diffusion and Transmission Testing: For diffusers, photometric measurements ensure consistent light quality and glare reduction.

Verifying Supplier Quality for International B2B Buyers

For buyers in regions such as Africa (e.g., Egypt), South America, the Middle East, and Europe (e.g., Italy), verifying supplier quality assurance involves a strategic approach:

1. Supplier Audits

- Onsite Factory Audits: Evaluate manufacturing capabilities, equipment maintenance, workforce training, and compliance with ISO 9001 or equivalent QMS.

- Process Audits: Examine extrusion, assembly, and finishing workflows for process controls and defect prevention.

- Social Compliance: For buyers with CSR requirements, audits may include labor practices and environmental impact assessments.

2. Documentation and Certification Review

- Request copies of ISO 9001 certificates, CE declarations of conformity, RoHS compliance reports, and relevant test reports.

- Verify authenticity through certification bodies or third-party databases.

3. Third-Party Inspection and Testing

- Engage independent inspection agencies to conduct pre-shipment inspections (PSI) or factory acceptance tests (FAT).

- Third-party labs can perform material and performance testing, providing unbiased verification.

4. Sample Evaluation

- Obtain product samples for in-house testing or pilot installations, assessing fit, finish, and functional performance under local environmental conditions.

QC and Certification Nuances for Global Markets

- Africa and Middle East: Buyers should emphasize corrosion resistance and UV stability due to harsh climates. Local electrical codes may require specific certifications; collaborating with suppliers familiar with regional standards mitigates compliance risks.

- South America: Import regulations often mandate certifications such as INMETRO (Brazil). Confirm supplier capability to provide region-specific documentation.

- Europe: Strict compliance with CE, RoHS, and REACH regulations is mandatory. Buyers should insist on full traceability and environmental compliance.

- Cross-Border Logistics: Packaging quality and product robustness are critical to withstand long transit times and varying climate conditions.

Summary for B2B Buyers

- Demand transparent manufacturing processes with clear visibility into extrusion, assembly, and finishing stages.

- Prioritize suppliers certified to ISO 9001 and regionally relevant standards such as CE, RoHS, or UL.

- Insist on documented QC checkpoints and testing results to minimize risk of defects and ensure longevity.

- Leverage audits, third-party inspections, and sample evaluations to verify supplier claims before large-scale procurement.

- Consider environmental and regulatory nuances specific to your region to ensure compliance and avoid costly delays.

By investing time in understanding and verifying manufacturing and quality assurance processes, B2B buyers can secure aluminum LED channels that deliver superior performance, aesthetic appeal, and long-term reliability across diverse international markets.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for aluminum led channel for led strip lights Sourcing

Understanding the detailed cost structure and pricing dynamics of aluminum LED channels for LED strip lights is essential for international B2B buyers aiming to optimize procurement strategies and total project costs. This analysis breaks down key cost components, pricing influencers, and practical buyer tips to navigate this complex market effectively.

Key Cost Components in Aluminum LED Channel Production

-

Materials

The primary raw material is aluminum, which varies in cost depending on alloy grade and market fluctuations. Higher-grade aluminum alloys provide better corrosion resistance and thermal conductivity but come at a premium. Additionally, costs include polycarbonate or acrylic diffusers, end caps, mounting clips, and fasteners. Buyers should anticipate approximately 60-70% of total cost arising from raw materials, making material selection critical. -

Labor

Skilled labor for extrusion, cutting, finishing (anodizing or powder coating), assembly, and packaging contributes to cost. Labor costs vary significantly by manufacturing location, impacting final pricing. Precision cutting and quality control are labor-intensive steps that ensure product reliability, especially for commercial-grade applications. -

Manufacturing Overhead

This includes factory utilities, equipment depreciation, maintenance, and administrative expenses. Efficient production lines with automated extrusion and cutting can reduce overhead per unit but require upfront investment in tooling. -

Tooling and Equipment

Extrusion dies and cutting tools represent significant capital expenditure amortized over production volume. Custom profiles or unique diffuser designs elevate tooling costs, which typically reflect in higher unit prices for smaller orders. -

Quality Control (QC)

Rigorous QC processes—dimensional inspections, surface finish checks, and material certifications—ensure compliance with international standards. QC is critical for B2B buyers who require consistent product quality to maintain their own brand reputation. -

Logistics and Shipping

Given the bulky and sometimes fragile nature of aluminum channels and diffusers, packaging and freight costs (sea, air, or land) form a significant part of landed cost. Import tariffs, customs duties, and inland transportation in the destination country add further expenses. -

Supplier Margin

Suppliers include a profit margin to cover business risks, market demand, and service value. Margins vary by supplier reputation, contract terms, and order volume.

Influential Factors Affecting Pricing

-

Order Volume and Minimum Order Quantities (MOQ)

Larger volume orders benefit from economies of scale, reducing per-unit cost. MOQ requirements often exist due to tooling and setup costs, which may be restrictive for smaller buyers. -

Specifications and Customization

Custom profiles, finishes (anodized, powder coated, brushed), diffuser types, and accessory sets increase complexity and price. Standardized profiles are more cost-effective. -

Material Quality and Certifications

Certified aluminum alloys (e.g., 6063-T5), UV-stable diffusers, and compliance with CE, RoHS, or UL standards command higher prices but ensure longevity and safety. -

Supplier Location and Capabilities

Suppliers in Asia often offer competitive pricing due to lower labor costs but may have longer lead times and logistical challenges. European or Middle Eastern suppliers might charge a premium but provide faster delivery and localized support. -

Incoterms and Shipping Terms

Delivered Duty Paid (DDP) vs. Ex Works (EXW) terms drastically affect total cost and buyer responsibilities. Understanding Incoterms is crucial to accurately assess landed costs.

Practical Tips for International B2B Buyers

-

Negotiate Beyond Price

Focus on total value including quality certifications, warranty, lead times, and after-sales support. Buyers from regions like Africa, South America, and the Middle East should consider supplier flexibility on payment terms and local regulatory compliance. -

Optimize Total Cost of Ownership (TCO)

Evaluate not just unit price but also durability, installation ease, and maintenance costs. Higher upfront investment in premium aluminum channels often reduces replacement and service expenses. -

Factor in Import Costs and Local Market Conditions

Customs duties, VAT, and logistics infrastructure in countries like Egypt or Italy significantly influence final pricing. Partner with freight forwarders experienced in your region. -

Request Detailed Quotes with Breakdowns

A transparent cost breakdown helps identify negotiable components and avoid hidden fees. Clarify MOQ, lead times, and penalties for order changes. -

Consider Long-Term Supplier Relationships

Establishing partnerships with trusted suppliers can unlock volume discounts, customized solutions, and priority production slots.

Indicative Pricing Disclaimer

Due to market volatility, regional variations, and customization levels, prices for aluminum LED channels can range widely—from approximately $3 to $15 per meter for standard profiles excluding shipping and taxes. Buyers should treat these figures as indicative and conduct direct supplier inquiries for precise quotations tailored to their specific project requirements.

By understanding these cost drivers and leveraging strategic negotiation and sourcing practices, international B2B buyers can secure high-quality aluminum LED channels that align with both budgetary constraints and project performance expectations.

Spotlight on Potential aluminum led channel for led strip lights Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘aluminum led channel for led strip lights’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for aluminum led channel for led strip lights

Key Technical Properties of Aluminum LED Channels for LED Strip Lights

When sourcing aluminum LED channels for LED strip lights, understanding critical technical specifications is essential to ensure product quality, durability, and compatibility with your lighting projects. Here are the most important properties B2B buyers should evaluate:

-

Material Grade (Aluminum Alloy Type)

The aluminum used is typically a high-purity alloy such as 6063-T5 or 6060, known for excellent extrusion quality, corrosion resistance, and thermal conductivity. For B2B buyers, selecting the correct alloy grade ensures structural integrity and effective heat dissipation, which extends LED lifespan and maintains installation quality in various environments, including humid or outdoor settings. -

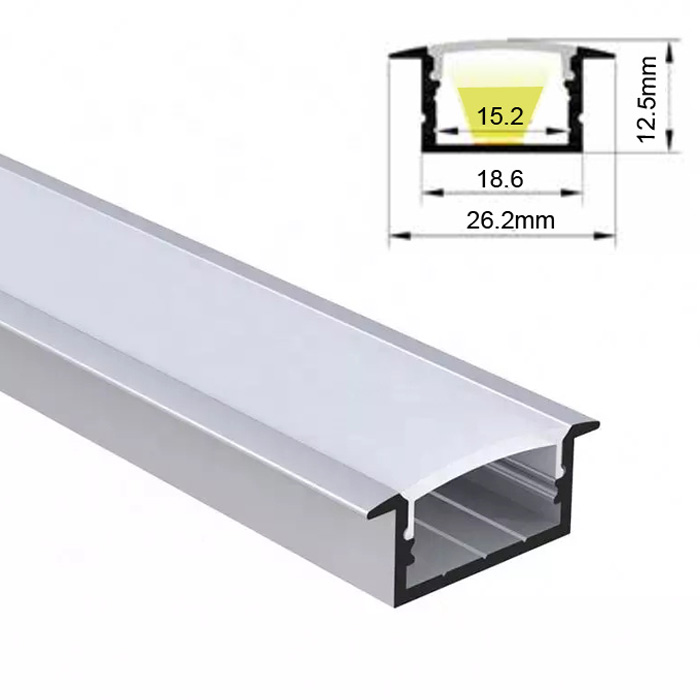

Dimensional Tolerance and Profile Precision

Precision in channel dimensions, including width, height, and groove size, is critical. Tight tolerances (usually ±0.1 mm) guarantee that LED strips fit securely without movement or sagging and that diffusers align properly. This precision prevents installation issues and reduces rework costs—vital for large-scale or repeat B2B orders. -

Surface Finish and Anodizing

Channels often come with anodized finishes that enhance corrosion resistance and improve aesthetics. The anodizing layer thickness and finish type (matte, brushed, or glossy) affect durability and visual appeal. Buyers should verify finish specifications to ensure products meet both functional and design requirements, especially for projects in demanding environments like coastal regions or commercial interiors. -

Heat Dissipation Capability

Aluminum’s thermal conductivity helps dissipate heat generated by LED strips, preventing premature LED failure. The channel’s cross-sectional design and wall thickness influence heat sink efficiency. For B2B projects with long LED runs or high-power LEDs, choosing channels optimized for thermal management supports longer-lasting installations. -

Compatibility with Diffusers and Accessories

The channel profile must accommodate standard diffuser types—opal, frosted, or clear—securely. Compatibility with mounting clips, end caps, and connectors is equally important. Ensuring these accessories match the channel dimensions and material enhances installation speed and end-user satisfaction. -

Ingress Protection (IP) Rating Considerations

While channels themselves may not always have an IP rating, their design and associated diffusers/end caps contribute to the overall protection of the LED strip from dust and moisture. For outdoor or damp-location projects, selecting channels and accessories that help achieve an appropriate IP rating (e.g., IP65 or higher) is crucial for compliance and durability.

Common Trade Terminology in Aluminum LED Channel Procurement

Navigating international B2B transactions requires familiarity with industry jargon and trade terms. Here are key terms relevant to purchasing aluminum LED channels:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers producing aluminum LED channels that other companies brand and sell. OEM partnerships allow buyers, especially distributors or designers, to customize profiles, finishes, or packaging while leveraging the OEM’s production expertise. Understanding OEM options can reduce costs and improve product differentiation. -

MOQ (Minimum Order Quantity)

The smallest batch size a supplier is willing to manufacture or sell. MOQs for aluminum LED channels can vary widely—from a few hundred meters to thousands—impacting inventory planning and cash flow. Buyers from emerging markets or smaller enterprises should negotiate MOQ flexibility or consider group purchasing to optimize procurement. -

RFQ (Request for Quotation)

A formal document or inquiry sent to suppliers requesting detailed pricing, lead times, and terms for specified quantities and specifications. A clear, comprehensive RFQ helps international buyers compare offers accurately, ensuring competitive pricing and reliable delivery schedules. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities for shipping, insurance, and customs clearance between buyers and sellers. Common Incoterms include FOB (Free on Board), CIF (Cost, Insurance, Freight), and DDP (Delivered Duty Paid). Selecting appropriate Incoterms is critical for cost control and risk management in cross-border aluminum channel procurement. -

Lead Time

The period from order confirmation to product shipment or delivery. Understanding lead times helps buyers coordinate project schedules and avoid costly delays. Aluminum channel production lead times depend on order size, customization, and supplier location. -

Batch Consistency

Refers to uniformity in product quality and specifications across production runs. For B2B buyers managing multiple projects or repeat orders, ensuring batch consistency prevents compatibility issues and maintains brand reputation.

By mastering these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that optimize project outcomes, reduce risks, and enhance client satisfaction across diverse markets such as Africa, South America, the Middle East, and Europe.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the aluminum led channel for led strip lights Sector

Market Overview & Key Trends

The global aluminum LED channel market for LED strip lights is experiencing robust growth, driven by the expanding demand for energy-efficient, aesthetically pleasing lighting solutions across commercial, industrial, and residential sectors. Key growth markets include Europe, the Middle East, Africa, and South America, where infrastructure development, urbanization, and rising consumer awareness about sustainable lighting are fueling adoption. Countries such as Italy and Egypt showcase strong demand for premium LED lighting installations, especially in hospitality, retail, and architectural projects.

B2B buyers in these regions face dynamic market conditions influenced by technological advancements, evolving regulatory standards, and supply chain complexities. A significant trend is the shift towards modular, customizable aluminum profiles that facilitate rapid installation and integration with smart lighting controls. Aluminum channels with enhanced thermal management and compatibility with various diffuser types are preferred to ensure durability and superior lighting quality.

Illustrative Image (Source: Google Search)

Sourcing trends highlight a growing preference for manufacturers who can offer comprehensive solutions—combining aluminum channels, diffusers, and certified power supplies—to reduce procurement complexity and improve project timelines. Additionally, buyers are increasingly valuing suppliers with agile production capabilities capable of catering to varied regional standards and climate considerations, such as moisture-resistant profiles for tropical or humid environments in Africa and the Middle East.

The rise of e-commerce platforms and digital B2B marketplaces has also transformed sourcing strategies, enabling buyers to access a broader supplier base and conduct detailed technical comparisons before procurement. However, buyers must remain vigilant about quality control and certifications, especially when sourcing from emerging markets, to ensure compliance with CE, RoHS, and local safety standards.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical factor in the procurement of aluminum LED channels for LED strip lights. Aluminum is inherently recyclable, which presents an opportunity to reduce environmental impact through the use of recycled or secondary aluminum in channel production. Buyers prioritizing sustainability seek suppliers who can provide clear documentation on recycled content and life cycle assessments, minimizing carbon footprint and resource depletion.

Ethical sourcing is equally important, particularly for international buyers mindful of supply chain transparency. Ensuring that aluminum is sourced from smelters adhering to responsible mining practices and labor standards protects brand reputation and aligns with global environmental, social, and governance (ESG) commitments. Certifications such as the Aluminium Stewardship Initiative (ASI) and ISO 14001 environmental management standards serve as benchmarks for ethical and sustainable production.

Moreover, the use of low-VOC (volatile organic compounds) powder coatings and UV-stable polycarbonate diffusers enhances the environmental profile of aluminum LED channels, reducing harmful emissions and extending product lifespan. In regions like Europe and the Middle East, green building certifications (e.g., LEED, BREEAM) increasingly require lighting components to meet strict sustainability criteria, making compliance essential for B2B buyers targeting commercial construction projects.

By integrating sustainability and ethical considerations into procurement strategies, buyers not only contribute to global environmental goals but also differentiate their offerings in competitive markets where clients demand responsible and future-proof lighting solutions.

Evolution and Historical Context

The aluminum LED channel market has evolved significantly over the past two decades, paralleling the rise of LED strip lighting technology. Initially, aluminum profiles were primarily valued for their robust heat dissipation capabilities, essential for preventing LED overheating and premature failure. Early LED strips, less efficient and more heat-sensitive, necessitated metal housings to maintain performance and longevity.

As LED chip technology advanced, thermal management requirements relaxed somewhat, but aluminum channels retained their importance due to their protective function and aesthetic benefits. Over time, the integration of diffusers and mounting accessories transformed simple channels into versatile lighting fixtures, enabling seamless integration into architectural designs.

The shift towards modular, customizable aluminum profiles corresponds with rising demand for flexible lighting solutions in diverse applications—from linear cove lighting in European commercial buildings to outdoor installations in the Middle East’s challenging environments. Today, aluminum LED channels are a standard component in professional LED strip lighting projects, valued not only for function but also for enhancing design quality and sustainability.

Related Video: How to choose LED aluminum channel – Muzata U1SB installation tutorial 2019

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum led channel for led strip lights

-

How can I effectively vet suppliers of aluminum LED channels for international B2B procurement?

Thorough supplier vetting is critical to ensure product quality and reliability. Begin by requesting detailed product specifications, certifications (such as CE, RoHS, ISO), and quality assurance processes. Verify the supplier’s track record through client references or case studies, especially with international projects. Assess their communication responsiveness and willingness to provide samples. For buyers in Africa, South America, the Middle East, and Europe, consider suppliers experienced with export regulations and capable of providing compliance documentation for customs clearance. Engaging third-party inspection services before shipment can further safeguard your investment. -

What customization options are typically available for aluminum LED channels, and how should I approach these with suppliers?

Customization can include channel length, profile shape, finish (anodized, powder-coated), diffuser type (opal, frosted, clear), and mounting accessories. B2B buyers should clearly specify project requirements such as dimensions, thermal management needs, and aesthetic preferences upfront. Discuss minimum order quantities (MOQs) for custom items, as these are often higher than standard products. Request 3D drawings or prototypes to validate design compatibility. Partnering with suppliers who offer flexible customization and transparent lead times helps ensure your project’s unique needs are met without delays. -

What are typical MOQ and lead time considerations when ordering aluminum LED channels for international markets like Egypt or Italy?

MOQs vary widely depending on supplier capacity and customization level, often ranging from a few hundred to several thousand meters per order. Lead times typically span 3 to 8 weeks, influenced by order size, customization complexity, and shipping mode. Buyers should plan procurement timelines accordingly and negotiate MOQs that align with their project scale. Consolidating orders or partnering with distributors can reduce MOQs. For African and South American markets, factor in customs clearance and potential logistical delays, choosing suppliers with experience in these regions to optimize delivery schedules. -

Which quality certifications and standards should I require to ensure aluminum LED channels meet international B2B expectations?

Demand certifications that confirm product safety, environmental compliance, and manufacturing quality. Key certifications include CE marking (for European markets), RoHS (restriction of hazardous substances), UL or ETL listings (for electrical safety), and ISO 9001 (quality management). For outdoor or damp environment applications common in Middle East or Africa, verify IP ratings for water and dust resistance. Additionally, request material test reports confirming aluminum grade and diffuser UV stability. Ensuring adherence to these standards mitigates risks of product failure and facilitates smoother customs approval. -

How can I optimize logistics and shipping when importing aluminum LED channels internationally?

Aluminum channels are lightweight but bulky, so selecting efficient packaging to minimize volume while protecting products is essential. Choose suppliers who offer consolidated shipments and multiple shipping options (sea freight, air freight, express courier) tailored to your urgency and budget. Coordinate with freight forwarders experienced in your region’s import regulations, such as Egypt’s port requirements or EU customs protocols. Pre-arranging Incoterms (e.g., FOB, CIF) clarifies responsibility and cost allocation. Lastly, maintain clear documentation including commercial invoices, packing lists, and certificates of origin to expedite customs clearance.

Illustrative Image (Source: Google Search)

-

What payment terms are standard for international B2B transactions involving aluminum LED channels, and how can I mitigate financial risks?

Common payment terms include 30-50% advance with order confirmation and balance upon shipment or delivery. Letters of credit (LCs) provide added security by ensuring funds are released only after contractual conditions are met, beneficial for buyers in emerging markets. Negotiate clear contract terms covering product specifications, delivery schedules, and penalties for non-compliance. Employ escrow services or trade finance solutions if available. Always confirm supplier legitimacy through due diligence to avoid fraud. Diversifying suppliers can also reduce dependence and financial exposure. -

How should disputes regarding product quality or delivery delays be handled with international aluminum LED channel suppliers?

Establish dispute resolution protocols in your purchase agreement, specifying governing law and arbitration venues, ideally aligned with your jurisdiction or an internationally recognized body. Maintain detailed records of communications, contracts, and inspection reports. On receiving defective goods, promptly notify the supplier with photographic evidence and request corrective actions such as replacements or refunds. Engage third-party quality inspectors or mediators if necessary. Building strong relationships and clear communication channels with suppliers fosters cooperation and quicker resolution of issues. -

Are there specific considerations for aluminum LED channel installations in diverse climatic regions like the Middle East or South America that buyers should communicate to suppliers?

Yes, environmental factors such as extreme heat, humidity, dust, or UV exposure impact material selection and product design. Buyers should specify required IP ratings for moisture and dust ingress protection, UV-stable diffuser materials, and corrosion-resistant finishes suitable for coastal or desert environments. Inform suppliers about installation conditions to ensure channels and accessories meet durability expectations. For example, anodized aluminum with weatherproof seals is preferable in harsh climates. Early communication prevents product failure and reduces maintenance costs, critical for long-term B2B project success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for aluminum led channel for led strip lights

Achieving excellence in LED strip lighting projects hinges on selecting the right aluminum LED channels that balance performance, durability, and aesthetics. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, strategic sourcing means prioritizing suppliers who offer certified, high-quality aluminum profiles with compatible diffusers, reliable mounting accessories, and robust power supplies. This ensures projects meet stringent standards while minimizing installation risks and long-term maintenance costs.

Key takeaways include the importance of meticulous pre-installation planning, precise measurement, and choosing aluminum channels that enhance heat dissipation and provide superior light diffusion. These factors collectively improve product lifespan and client satisfaction—crucial for maintaining competitive advantage in B2B markets. Furthermore, sourcing from manufacturers with transparent supply chains and proven quality control fosters trust and reduces project delays.

Looking ahead, the demand for sustainable, energy-efficient lighting solutions will intensify, driving innovation in aluminum channel design and materials. Buyers are encouraged to engage proactively with suppliers to explore customized profiles and integrated smart lighting options that align with evolving market needs. By investing in strategic partnerships and cutting-edge products today, international businesses can secure a future-ready portfolio that delivers both aesthetic appeal and operational excellence.