Guide to Aluminium Led Strip Channel

- Introduction: Navigating the Global Market for aluminium led strip channel

- Understanding aluminium led strip channel Types and Variations

- Key Industrial Applications of aluminium led strip channel

- Strategic Material Selection Guide for aluminium led strip channel

- In-depth Look: Manufacturing Processes and Quality Assurance for aluminium led strip channel

- Comprehensive Cost and Pricing Analysis for aluminium led strip channel Sourcing

- Spotlight on Potential aluminium led strip channel Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for aluminium led strip channel

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the aluminium led strip channel Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of aluminium led strip channel

- Strategic Sourcing Conclusion and Outlook for aluminium led strip channel

Introduction: Navigating the Global Market for aluminium led strip channel

Aluminium LED strip channels have become indispensable components in the LED lighting industry, offering critical benefits that extend far beyond simple housing. For international B2B buyers—especially those operating in diverse markets across Africa, South America, the Middle East, and Europe—understanding the nuances of aluminium LED strip channels is essential to delivering durable, efficient, and aesthetically superior lighting solutions.

These channels serve multiple vital functions: they provide robust protection for LED strips against physical damage and environmental factors, facilitate superior heat dissipation to prolong LED lifespan, and enable the integration of diffusers that enhance light distribution and reduce glare. Such features are not only technical necessities but also key differentiators that elevate commercial projects’ quality and client satisfaction.

This comprehensive guide dives deep into the aluminium LED strip channel ecosystem, covering a broad spectrum of topics crucial for informed procurement and project success. Buyers will gain clarity on various channel types, material grades, and finish options tailored to different environmental and design requirements. The guide also addresses manufacturing standards and quality control processes that underpin product reliability. Additionally, it explores global supplier landscapes, cost considerations, and logistics challenges specific to international trade routes relevant to regions like Argentina, the UK, and beyond.

By consolidating technical insights, market intelligence, and practical sourcing advice, this resource empowers B2B professionals to make strategic decisions that optimize value, mitigate risks, and ensure seamless integration of aluminium LED strip channels into their lighting projects worldwide.

Understanding aluminium led strip channel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard U-Profile | Classic U-shaped aluminum extrusion, compatible with various diffusers | Retail displays, office lighting, residential and commercial interiors | Pros: Versatile, cost-effective, easy installation. Cons: Limited aesthetic customization. |

| Recessed Channel | Designed for flush mounting into surfaces, minimal protrusion | Architectural lighting, furniture integration, wall and ceiling installations | Pros: Sleek integration, hidden mounting. Cons: Requires precise installation, higher labor cost. |

| Surface-Mount Channel | Mounted directly onto surfaces with visible profile | Signage, showcase lighting, industrial environments | Pros: Easy retrofit, strong protection. Cons: More visible, may impact design aesthetics. |

| Corner Channel | Angled profile for 90° corner installations | Cove lighting, staircases, shelving edges | Pros: Enables unique lighting angles, enhances design flexibility. Cons: Limited to corner use, specialized fitting required. |

| Waterproof/IP-Rated Channel | Sealed design with weather-resistant materials and diffusers | Outdoor lighting, wet/damp industrial areas, hospitality venues | Pros: Durable in harsh environments, protects LEDs from moisture. Cons: Higher cost, heavier installation. |

Standard U-Profile

The Standard U-Profile is the most common aluminum LED strip channel, featuring a simple U-shaped extrusion that accommodates a wide range of LED strip widths and diffuser types. Its versatility makes it ideal for general-purpose indoor lighting applications across retail, office, and residential projects. For B2B buyers, this type offers a balance of affordability and functionality, with easy installation and replacement. When sourcing, ensure compatibility with LED strip dimensions and diffuser options to meet client aesthetic and performance requirements.

Recessed Channel

Recessed channels are designed to be embedded into walls, ceilings, or furniture surfaces, offering a flush, seamless lighting effect that is highly valued in architectural and high-end commercial projects. Their installation requires precision cutting and surface preparation, which may increase labor costs but delivers superior visual integration. B2B buyers should assess site conditions and coordinate closely with installation teams to ensure the recessed channels fit perfectly and meet design expectations.

Surface-Mount Channel

Surface-mount channels are installed directly onto visible surfaces, providing a sturdy and protective housing for LED strips without requiring structural modifications. This type is favored in retrofit projects, industrial settings, and areas where quick installation is essential. While more conspicuous than recessed profiles, they offer excellent durability and ease of maintenance. Buyers should consider the trade-off between aesthetics and practicality, especially for environments prioritizing functionality over minimalism.

Corner Channel

Corner channels are specialized profiles designed for mounting LED strips at 90-degree angles, perfect for accentuating architectural features such as coves, stair edges, or shelving. These channels allow for creative lighting designs that enhance spatial perception and highlight structural details. Due to their niche application, B2B buyers must ensure accurate measurements and compatibility with LED strips and diffusers to avoid installation challenges and ensure consistent lighting performance.

Waterproof/IP-Rated Channel

Waterproof or IP-rated aluminum channels come with sealed diffusers and weather-resistant materials, making them suitable for outdoor, wet, or industrial environments where moisture and dust pose risks. These channels protect LED strips from environmental damage, extending lifespan and reducing maintenance costs. However, they tend to be more expensive and heavier, requiring robust mounting solutions. B2B buyers targeting hospitality, outdoor signage, or industrial sectors should prioritize certified IP ratings and durability standards when selecting these channels.

Related Video: How to Install Aluminum Mounting Channel

Key Industrial Applications of aluminium led strip channel

| Industry/Sector | Specific Application of aluminium led strip channel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Display lighting and shelf illumination | Enhances product visibility, creates attractive store ambience, and improves customer engagement | Durable finishes, UV-resistant diffusers, compatibility with dimming systems, and ease of installation |

| Hospitality & Interior Design | Cove lighting, accent lighting in hotels and restaurants | Provides elegant, uniform lighting to elevate guest experience and brand perception | Aesthetic variety in profiles and finishes, compliance with fire safety standards, and moisture resistance |

| Architectural & Facade Lighting | Linear façade illumination and signage backlighting | Improves building aesthetics and visibility while protecting LED strips from environmental damage | Weatherproof channels (IP65+), corrosion-resistant materials, and compatibility with outdoor-rated LEDs |

| Industrial & Manufacturing | Task lighting in assembly lines and inspection stations | Delivers focused, consistent lighting for precision tasks, enhancing worker productivity and safety | Robust mechanical protection, high heat dissipation, and easy maintenance access |

| Transportation & Infrastructure | Lighting for tunnels, underpasses, and public transit areas | Provides durable, safe, and energy-efficient lighting solutions in harsh environments | High-impact resistance, IP-rated for dust and moisture, and compliance with local electrical codes |

Retail & Commercial Lighting Applications

In retail environments across Europe and South America, aluminium LED strip channels are widely used for display lighting and shelf illumination. These channels provide a sleek housing that protects LED strips while delivering uniform light distribution, crucial for enhancing product visibility and creating inviting store atmospheres. International buyers should prioritize channels with UV-stable diffusers and finishes that resist discoloration under prolonged exposure to sunlight. Compatibility with dimming controls and ease of retrofit installation are also key to meeting diverse retail design requirements and maximizing energy efficiency.

Hospitality & Interior Design

Hotels and restaurants in the Middle East and Africa increasingly rely on aluminium LED strip channels for cove and accent lighting to craft luxurious, ambient spaces. The channels allow for seamless integration of LED strips into architectural details, providing soft, glare-free illumination that improves guest comfort and elevates brand image. Buyers must ensure that the profiles comply with local fire safety standards and offer moisture resistance for humid environments. The availability of various aesthetic finishes and diffuser types enables designers to tailor lighting to specific themes and moods.

Architectural & Facade Lighting

In the UK and other European markets, aluminium LED strip channels are essential for architectural façade lighting and signage backlighting. These applications demand channels that protect LED strips from environmental factors such as rain, dust, and temperature fluctuations while enhancing light diffusion for striking visual effects. Selecting weatherproof channels with corrosion-resistant coatings is critical for durability. Additionally, buyers should verify that the channels are compatible with outdoor-rated LED strips and diffusers to ensure longevity and reduce maintenance costs.

Industrial & Manufacturing Environments

Industrial facilities in regions like South America and Africa benefit from aluminium LED strip channels for task lighting in assembly lines and inspection stations. The channels provide robust mechanical protection against dust and accidental impacts while facilitating effective heat dissipation to extend LED lifespan under continuous operation. For B2B buyers, sourcing channels with easy maintenance access and high thermal conductivity is vital to support productivity and safety standards. Ensuring compliance with industrial lighting regulations and compatibility with high-CRI LED strips helps improve visual accuracy for quality control.

Transportation & Infrastructure Lighting

Transportation hubs and infrastructure projects in the Middle East require durable lighting solutions for tunnels, underpasses, and public transit areas. Aluminium LED strip channels offer high-impact resistance and IP-rated protection against dust and moisture, making them ideal for harsh environments. For international B2B buyers, it is important to select channels that meet stringent local electrical codes and standards for public safety. Additionally, sourcing from suppliers who provide customizable lengths and accessories facilitates efficient installation and reduces project lead times.

Related Video: How to Install Recessed LED Channel and LED Strip Lights in Drywall for Recessed Linear Lighting

Strategic Material Selection Guide for aluminium led strip channel

When selecting materials for aluminium LED strip channels, B2B buyers must consider factors such as durability, heat dissipation, corrosion resistance, manufacturing complexity, and compliance with international standards. These factors directly impact the longevity, aesthetic integration, and overall performance of the LED installations, especially in diverse climates and regulatory environments found across Africa, South America, the Middle East, and Europe.

1. Extruded Aluminum (6063 Alloy)

Key Properties:

6063 aluminum alloy is the industry standard for LED strip channels due to its excellent extrusion capabilities, moderate strength, and good corrosion resistance. It typically offers a temperature rating up to 150°C and is lightweight yet structurally robust.

Pros & Cons:

Pros include excellent thermal conductivity for heat dissipation, ease of fabrication into complex profiles, and corrosion resistance suitable for indoor and moderately humid environments. It is cost-effective relative to higher-grade alloys and widely available globally. Cons include moderate mechanical strength compared to other alloys and potential surface oxidation if not anodized or powder-coated.

Impact on Application:

Ideal for commercial and residential LED lighting where heat dissipation and aesthetic finish are priorities. It performs well in dry to moderately humid environments but requires surface treatment for outdoor or harsh environments.

International B2B Considerations:

6063 aluminum channels are compliant with ASTM B221 and EN 755 standards, commonly accepted in Europe (e.g., UK) and South America (e.g., Argentina). Buyers in Africa and the Middle East should specify anodized or powder-coated finishes to enhance corrosion resistance against dust and saline air. Availability and cost are favorable due to widespread production.

2. Anodized Aluminum

Key Properties:

Anodizing enhances aluminum’s natural oxide layer, improving corrosion resistance, surface hardness, and UV stability. The process typically increases resistance to temperatures up to 200°C and adds a decorative finish.

Pros & Cons:

Pros include superior corrosion resistance, excellent surface durability, and enhanced aesthetic appeal with various color options. It is ideal for outdoor and harsh environments. However, anodizing adds to manufacturing costs and may limit post-production modifications like welding or machining.

Impact on Application:

Best suited for outdoor LED installations, architectural lighting, and environments with high UV exposure or corrosive atmospheres such as coastal regions or industrial zones.

International B2B Considerations:

Anodized aluminum meets ISO 7599 and MIL-A-8625 standards, recognized internationally. Buyers in the Middle East and coastal African regions benefit from its corrosion protection. European buyers often require anodized finishes to comply with architectural project specifications. The higher cost is justified by longevity and reduced maintenance.

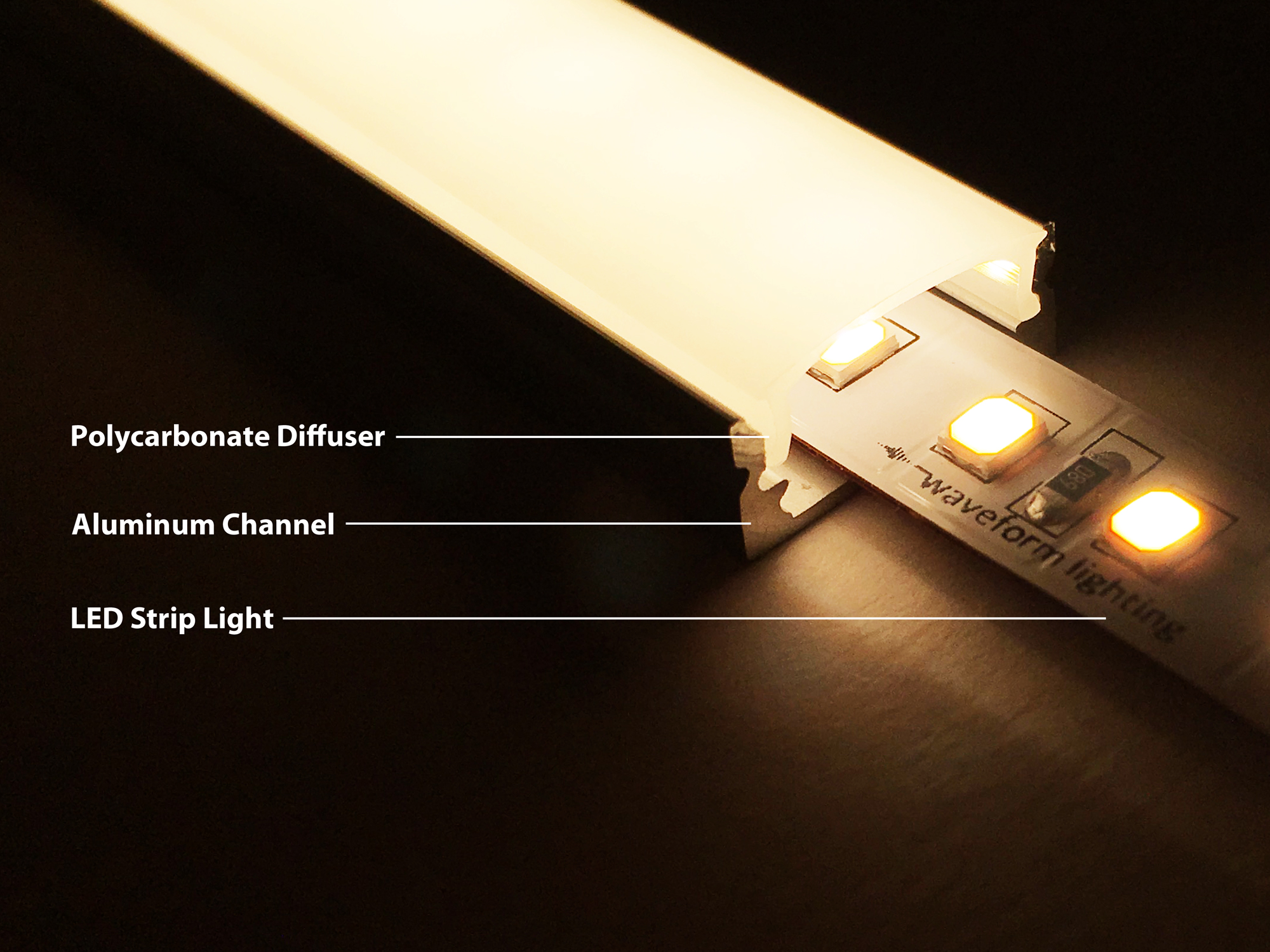

3. Polycarbonate Diffuser Covers

Key Properties:

While not the channel material itself, polycarbonate covers are critical components paired with aluminum channels. They offer high impact resistance, UV stability, and excellent light diffusion properties. Polycarbonate can withstand temperatures up to approximately 120°C.

Pros & Cons:

Pros include superior impact resistance compared to acrylic, good weatherability, and excellent light transmission with effective glare reduction. Cons are higher cost than acrylic, susceptibility to scratching, and potential yellowing over long-term UV exposure if not UV-stabilized.

Impact on Application:

Essential for protecting LED strips and achieving uniform light distribution in both indoor and outdoor settings. Particularly valuable in regions with intense sunlight (e.g., Middle East, parts of Africa) where UV resistance is critical.

International B2B Considerations:

Polycarbonate covers should comply with standards such as ASTM D635 (flammability) and ISO 4892 (UV resistance testing). B2B buyers in South America and Europe often require certification for fire safety and UV stability. Sourcing from reputable suppliers ensures compliance and durability.

4. Powder-Coated Aluminum

Key Properties:

Powder coating applies a dry finishing process that creates a protective, decorative layer on aluminum channels. It enhances corrosion resistance and provides a wide range of color and texture options. Temperature resistance depends on the powder type but generally ranges up to 150-180°C.

Pros & Cons:

Pros include excellent corrosion protection, customizable aesthetics, and improved scratch resistance. Powder coating is environmentally friendly compared to liquid paints. Cons include potential for chipping if improperly applied and challenges in repairing damaged coatings on-site.

Impact on Application:

Ideal for architectural LED lighting requiring color matching and enhanced durability, especially in urban or industrial environments with pollution or moisture exposure.

International B2B Considerations:

Powder-coated aluminum channels should meet standards like Qualicoat or AAMA 2604/2605 for coating quality and durability, widely recognized in Europe and increasingly in South America and the Middle East. Buyers in Africa should verify local environmental conditions and ensure coatings are suitable for high UV and temperature variations.

| Material | Typical Use Case for aluminium led strip channel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Extruded Aluminum (6063 Alloy) | Indoor and moderate environment LED installations | Excellent thermal conductivity and fabrication ease | Moderate strength; requires surface treatment for outdoor use | Low |

| Anodized Aluminum | Outdoor, coastal, and high UV exposure installations | Superior corrosion resistance and surface hardness | Increased manufacturing cost; limited post-processing | Medium |

| Polycarbonate Diffuser Covers | Protective and light-diffusing covers for LED channels | High impact resistance and UV stability | Higher cost than acrylic; potential yellowing over time | Medium |

| Powder-Coated Aluminum | Architectural and industrial LED lighting requiring color finish | Enhanced corrosion protection and aesthetics | Possible chipping; repair challenges | Medium |

This material selection guide equips international B2B buyers with a clear understanding of the functional and economic trade-offs when specifying aluminium LED strip channels. Considering regional environmental conditions, regulatory compliance, and project-specific requirements will ensure optimal material choice and long-term client satisfaction.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminium led strip channel

Manufacturing aluminium LED strip channels involves a series of precise, controlled steps designed to ensure product durability, aesthetic quality, and functional performance. For international B2B buyers—especially those operating in markets across Africa, South America, the Middle East, and Europe—understanding these manufacturing processes and quality assurance protocols is essential to selecting reliable suppliers and ensuring project success.

Key Stages in Manufacturing Aluminium LED Strip Channels

1. Material Preparation

The process begins with selecting high-grade aluminium alloys, typically 6063 or 6061, known for their excellent extrusion qualities, corrosion resistance, and thermal conductivity. Raw aluminium billets undergo pre-treatment to remove impurities and ensure consistent composition. This phase also includes cutting billets to precise lengths for extrusion.

2. Extrusion and Forming

Extrusion is the core forming technique where heated aluminium billets are forced through a shaped die to create the channel’s U-shaped profile. This method guarantees dimensional accuracy, consistent wall thickness, and smooth surface finish. Modern extrusion presses allow for tight tolerances, critical for fitting LED strips and diffusers precisely.

Post-extrusion, channels may undergo secondary forming processes such as bending or cutting to accommodate custom lengths or complex installation designs. CNC machinery and laser cutting are often employed for precision.

3. Surface Finishing

To enhance durability and aesthetics, aluminium channels typically receive surface treatments. Anodizing is the most common, providing a protective oxide layer that improves corrosion resistance and allows for various color finishes. Powder coating is another option, offering thicker, more uniform coatings with superior wear resistance. These finishes also contribute to UV stability, essential for outdoor or high-exposure installations.

4. Assembly and Accessory Integration

Channels are often combined with polycarbonate or acrylic diffusers that snap or slide into place, ensuring light diffusion and protection of LED strips. End caps, mounting clips, and screws are assembled to create complete kits. Assembly lines incorporate automated and manual quality checks to verify fit and function.

Quality Assurance: International Standards and Industry-Specific Certifications

For B2B buyers, supplier adherence to recognized quality standards is a critical measure of product reliability and safety.

-

ISO 9001: This global quality management system standard is foundational. Suppliers certified under ISO 9001 demonstrate consistent manufacturing processes, traceability, and continuous improvement practices.

-

CE Marking: Mandatory for products sold within the European Economic Area, CE certification confirms compliance with EU safety, health, and environmental requirements. Aluminium LED channels with CE marking assure buyers in Europe and many other regions of conformity to high standards.

-

RoHS Compliance: Restriction of Hazardous Substances certification ensures that materials used, including aluminium alloys and coatings, do not contain harmful levels of lead, mercury, or other restricted substances—vital for environmentally conscious buyers.

-

UL Certification: Particularly relevant for markets like the UK and the Middle East, UL marks indicate adherence to rigorous electrical safety standards, especially when channels integrate with LED strips and power supplies.

-

Industry-Specific Standards: Some buyers may require additional certifications such as API (American Petroleum Institute) for channels intended for industrial or hazardous environments, or IP ratings verifying dust and water resistance for outdoor installations.

Quality Control Checkpoints Throughout Production

A robust QC framework is integral to delivering defect-free aluminium LED channels. Key checkpoints include:

-

Incoming Quality Control (IQC): Raw materials, including aluminium billets and diffusers, undergo chemical composition analysis, dimensional verification, and surface inspections to confirm supplier compliance before production begins.

-

In-Process Quality Control (IPQC): During extrusion and finishing, ongoing inspections monitor dimensional accuracy, surface finish quality, and extrusion integrity. Automated measurement tools and visual inspections detect warping, surface defects, or coating inconsistencies.

-

Final Quality Control (FQC): Completed channels are tested for fit with diffusers and mounting accessories, coating adhesion (e.g., using cross-hatch tests), and mechanical strength. Packaging is verified to ensure protection during transit.

-

Functional Testing: Some suppliers perform thermal conductivity testing to validate heat dissipation claims, and light diffusion tests to assess diffuser performance and glare reduction.

Common Testing Methods and Verification Tools

-

Dimensional Inspection: Coordinate measuring machines (CMM) and laser scanners provide high-precision measurements to ensure adherence to design specifications.

-

Surface Roughness and Coating Thickness: Portable coating thickness gauges and gloss meters assess anodizing or powder coating uniformity.

-

Mechanical Testing: Tensile and impact tests evaluate channel strength and flexibility.

-

Environmental Testing: Salt spray chambers simulate corrosion resistance for outdoor applications; UV exposure tests assess finish durability.

-

Electrical Safety Checks: For assembled products integrating LED strips, insulation resistance and dielectric withstand tests ensure safety compliance.

How B2B Buyers Can Verify Supplier Quality Assurance

International buyers should adopt proactive verification strategies to mitigate risks:

-

Factory Audits: On-site or third-party audits assess manufacturing capabilities, QC procedures, equipment condition, and workforce training. Audits provide direct insight into supplier reliability and compliance with international standards.

-

Review of Quality Documentation: Request certificates (ISO 9001, CE, RoHS, UL), test reports, material traceability documents, and process flowcharts. Suppliers with transparent documentation demonstrate commitment to quality.

-

Third-Party Inspections: Engaging independent inspection agencies to perform pre-shipment inspections or random batch testing adds an extra layer of assurance.

-

Sample Testing: Ordering pre-production samples or small batches for in-house testing can verify material quality, fit, and finish before committing to large orders.

-

Supplier Performance Monitoring: Establish KPIs such as defect rates, delivery punctuality, and responsiveness to quality issues. Continuous feedback loops help maintain standards over time.

QC and Certification Considerations for Buyers in Africa, South America, Middle East, and Europe

-

Regional Compliance Variations: While ISO 9001 and CE marking are widely recognized, certain regions have additional or variant requirements. For example, South American markets may require INMETRO certification (Brazil), while Middle Eastern countries often reference SASO (Saudi Arabia) or ESMA (UAE) standards. Understanding these local regulations ensures smooth customs clearance and market acceptance.

-

Climate and Environmental Factors: Buyers from tropical or desert regions should prioritize channels with enhanced corrosion resistance and UV stability. Confirm that QC testing includes environmental simulations relevant to local conditions.

-

Supply Chain Transparency: In markets such as Argentina or the UK, there is growing emphasis on ethical sourcing and sustainability. Suppliers with certifications like ISO 14001 (Environmental Management) and documented sustainable practices may offer competitive advantages.

-

Logistics and Packaging: For long-distance shipments, quality packaging verified during FQC reduces damage risk. Buyers should specify packaging standards and inspect packaging integrity upon receipt.

By thoroughly understanding the manufacturing processes and quality assurance measures behind aluminium LED strip channels, international B2B buyers can confidently select suppliers who deliver products that meet stringent performance, safety, and aesthetic requirements. This knowledge helps mitigate project risks, ensures regulatory compliance, and supports long-term partnerships across diverse global markets.

Related Video: Factory IO – Students Project – Production line

Comprehensive Cost and Pricing Analysis for aluminium led strip channel Sourcing

Understanding the cost and pricing dynamics of aluminium LED strip channels is essential for international B2B buyers aiming to optimize procurement and maximize project ROI. The pricing structure is influenced by multiple factors spanning raw materials, manufacturing, logistics, and market conditions, all of which vary significantly across regions such as Africa, South America, the Middle East, and Europe.

Key Cost Components

-

Raw Materials: The primary cost driver is the aluminium alloy used, typically high-grade anodized or powder-coated aluminium for durability and aesthetics. Material prices fluctuate with global aluminium markets and are affected by quality certifications (e.g., RoHS, REACH compliance), which are crucial for buyers targeting European or UK markets.

-

Manufacturing Overhead: Includes labor costs, energy consumption, and factory overhead. Labor rates differ widely by country; for example, manufacturing in China or Southeast Asia may offer cost advantages over European facilities, but buyers must weigh this against quality control and lead times.

-

Tooling and Setup: Initial tooling for extrusion dies and cutting equipment represents a fixed cost that suppliers amortize over production volume. Custom profiles or intricate designs increase tooling expenses and minimum order quantities (MOQs).

-

Quality Control (QC): QC processes—such as dimensional inspections, anodizing thickness tests, and durability assessments—add to costs but ensure product reliability and compliance with international standards, a non-negotiable factor in B2B contracts.

-

Logistics and Duties: Freight charges, import duties, VAT, and customs clearance fees significantly impact landed cost. Buyers from Africa and South America should particularly consider port infrastructure and inland transport costs, which may add 10-20% to the base price.

-

Supplier Margin: This varies with supplier location, brand reputation, and service level. Established European or UK suppliers often price higher but offer superior warranty, support, and certifications.

Influential Pricing Factors

-

Order Volume and MOQs: Larger orders typically reduce unit cost due to economies of scale and lower per-unit tooling amortization. However, some suppliers impose high MOQs, which may not be practical for smaller projects or diverse applications common in emerging markets.

-

Customization and Specifications: Custom anodizing colors, diffuser compatibility, special end caps, or weather-resistant finishes increase complexity and cost. Buyers should balance customization benefits against standard profiles to maintain competitive pricing.

-

Material Quality and Certification: Certified raw materials with traceability command premium prices but are critical for compliance, especially in regulated markets like the EU and UK. For buyers in Africa or the Middle East, verifying certifications can mitigate risks of substandard imports.

-

Supplier Reliability and Lead Time: Premium suppliers with shorter lead times and flexible service may charge a premium, but this often translates into lower indirect costs such as project delays or reworks.

-

Incoterms and Payment Terms: FOB, CIF, or DDP terms affect who bears shipping risk and costs. For international buyers, choosing DDP can simplify customs clearance but usually comes at a higher price. Negotiating favorable payment terms (e.g., letters of credit, net 30/60) can improve cash flow.

Strategic Buyer Tips

-

Negotiate on Volume and Repeat Business: Leverage projected order volumes or long-term partnerships to negotiate price breaks, better payment terms, or value-added services like free samples or extended warranties.

-

Consider Total Cost of Ownership (TCO): Evaluate not just unit price but installation ease, durability, warranty, and after-sales service. Investing slightly more upfront in certified, high-quality channels can reduce maintenance and replacement costs.

-

Account for Regional Logistics Complexities: Buyers in South America or Africa should factor in port congestion, customs delays, and inland transport reliability, which can erode cost savings from lower base prices.

-

Verify Supplier Certifications and Compliance: Request documentation for material quality, environmental standards, and safety certifications. This is particularly important for European and UK buyers adhering to strict regulations.

-

Beware of Pricing Nuances: Currency fluctuations, sudden tariffs, or geopolitical tensions can affect pricing unpredictably. Establishing multiple sourcing options and flexible contracts can mitigate risks.

Indicative Pricing Disclaimer

Prices for aluminium LED strip channels vary widely based on specifications, volume, and supplier location. As a rough benchmark, standard profiles typically range from USD 3 to USD 10 per meter excluding shipping and taxes. Customized or certified products can command higher prices. Buyers should request detailed quotations reflecting their exact requirements and logistics scenarios to obtain accurate cost assessments.

By thoroughly analyzing these cost and pricing factors and adopting a strategic procurement approach, international B2B buyers can secure competitive pricing while ensuring product quality and compliance across diverse markets.

Spotlight on Potential aluminium led strip channel Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘aluminium led strip channel’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for aluminium led strip channel

Critical Technical Properties of Aluminium LED Strip Channels

Understanding the key technical specifications of aluminium LED strip channels is essential for B2B buyers to ensure product quality, compatibility, and longevity in diverse international markets.

-

Material Grade (Aluminium Alloy Type)

Most aluminium channels are made from 6063-T5 or 6060 alloys, prized for their excellent extrusion quality, corrosion resistance, and thermal conductivity. Selecting the correct alloy grade ensures robust heat dissipation, structural integrity, and resistance to environmental factors — vital for installations in humid or outdoor climates common across Africa, South America, the Middle East, and Europe. -

Dimensional Tolerance

Precision in channel dimensions (width, height, wall thickness) is critical. Tight tolerance levels (often ±0.1mm) guarantee a snug fit for LED strips and diffusers, preventing gaps that can cause dust ingress or light leakage. For B2B projects, especially architectural or retail lighting, dimensional accuracy impacts installation speed and aesthetic quality. -

Surface Finish

Common finishes include anodized, powder-coated, or brushed aluminium. Anodizing enhances corrosion resistance and UV stability, important for outdoor or high-humidity environments. Powder coating offers color customization and additional protection. The finish affects not only durability but also visual integration with interior or exterior design themes. -

Thermal Conductivity

Aluminium’s high thermal conductivity (~200 W/m·K) allows efficient heat dissipation from LED strips, extending their operational lifespan. Although newer LED strips generate less heat, B2B buyers should still prioritize channels that optimize thermal management, especially in long runs or enclosed spaces where heat buildup could reduce LED performance. -

Compatibility with Diffusers

Aluminium channels are designed to accommodate specific diffuser profiles—opal, frosted, or clear polycarbonate/acrylic covers. Diffusers soften light output, reduce glare, and protect the LEDs. Ensuring channel-diffuser compatibility is crucial for achieving uniform light distribution and meeting client specifications for ambiance and visual comfort. -

Mounting and Installation Features

Channels often include integrated mounting grooves or clip systems for secure attachment to surfaces such as drywall, wood, or metal. Weatherproof end caps and mounting clips are essential for outdoor or damp locations. These features influence installation efficiency and long-term durability, reducing maintenance costs and downtime.

Key Trade Terminology for Aluminium LED Strip Channels

Navigating international B2B transactions requires familiarity with common industry terms. Here are essential trade terms to know when sourcing aluminium LED strip channels:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers who produce products or components that are purchased by another company and retailed under that purchasing company’s brand. B2B buyers may work with OEMs for customized channel profiles or finishes tailored to project specifications, enabling brand differentiation and exclusivity. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in one order. MOQs vary widely depending on production scale and complexity. For buyers in emerging markets like Africa or South America, understanding MOQ helps in budgeting and inventory planning, avoiding overstock or supply shortages. -

RFQ (Request for Quotation)

A formal document sent to suppliers to obtain pricing, lead times, and terms for specified products. An accurate RFQ detailing channel dimensions, material grade, finish, and accessories ensures competitive bids and reduces misunderstandings, streamlining procurement processes. -

Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce defining responsibilities of buyers and sellers in international shipments. Common terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Clear agreement on Incoterms is critical to avoid disputes over shipping costs, customs clearance, and risk transfer. -

Lead Time

The period from order placement to product delivery. Aluminium channel lead times depend on order volume, customization, and supplier location. For international buyers, factoring in lead time is crucial for project scheduling and managing client expectations. -

IP Rating (Ingress Protection)

Indicates the level of protection against solids and liquids. Channels with IP65 or higher are recommended for outdoor or humid environments to prevent dust and water ingress, protecting both the channel and the LED strips inside. Selecting appropriate IP-rated components safeguards investments in challenging climates.

By mastering these technical properties and trade terms, international B2B buyers can make informed purchasing decisions that optimize product performance, minimize risks, and enhance client satisfaction across diverse regional markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the aluminium led strip channel Sector

Market Overview & Key Trends

The global aluminium LED strip channel market is experiencing robust growth driven by increasing demand for energy-efficient, durable, and aesthetically versatile lighting solutions across commercial, industrial, and residential sectors. For international B2B buyers—particularly from regions such as Africa, South America, the Middle East, and Europe—several key market dynamics shape sourcing decisions today.

Illustrative Image (Source: Google Search)

Firstly, energy efficiency and longevity remain critical. Aluminium channels provide superior heat dissipation, extending LED strip lifespan and reducing maintenance costs, which is especially attractive for large-scale commercial projects in emerging markets like South Africa and Argentina. Secondly, customization and modularity have become prominent trends. Buyers increasingly seek tailored profiles, finishes, and diffuser options (opal, frosted, clear) to meet diverse architectural and branding requirements. This trend is especially prevalent in Europe and the UK, where design integration is a priority.

Supply chain resilience and regional sourcing are also influential. The COVID-19 pandemic and geopolitical shifts have spotlighted the importance of reliable, diversified suppliers. Buyers in the Middle East and South America often prioritize partnerships with manufacturers offering local warehouses or regional distribution hubs to minimize lead times and logistics costs. Additionally, digital procurement platforms and virtual factory tours have gained traction, enabling buyers to vet suppliers remotely and streamline purchasing processes.

Technological innovation is another market driver. Advances in extrusion technology enable more complex aluminium channel profiles that improve light diffusion and ease of installation. Integration with smart lighting systems and compatibility with dimming controls is becoming a standard expectation in Europe and the Middle East, reflecting a shift towards intelligent building infrastructure.

Lastly, cost competitiveness remains a balancing act. While premium aluminium grades and advanced diffusers add value, buyers in price-sensitive markets like parts of Africa and South America require flexible sourcing strategies that optimize quality without inflating costs. Strategic sourcing from suppliers offering scalable production and volume discounts can unlock significant advantages.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly a decisive factor in the aluminium LED strip channel sector. Aluminium production is energy-intensive, but its inherent recyclability and long lifecycle make it a preferred material for eco-conscious B2B buyers. The use of recycled aluminium significantly reduces carbon footprints and raw material consumption, aligning with global environmental goals and regional regulations in Europe and the UK, where green building certifications are often mandatory.

B2B buyers from Africa, South America, and the Middle East should prioritize suppliers who demonstrate transparency in their supply chains and adhere to ethical sourcing practices. This includes compliance with international labor standards, conflict-free material sourcing, and robust environmental management systems. Certifications such as ISO 14001 (Environmental Management), LEED (Leadership in Energy and Environmental Design), and Cradle to Cradle provide verifiable benchmarks for sustainability.

Additionally, the growing demand for ‘green’ aluminium channels incorporates innovations such as powder coatings free from volatile organic compounds (VOCs), UV-stable diffusers made from recyclable polycarbonate or acrylic, and energy-efficient manufacturing processes. Buyers can leverage supplier audits and request environmental product declarations (EPDs) to assess the true sustainability impact.

By integrating sustainability into procurement criteria, international buyers not only mitigate environmental risks but also enhance their corporate social responsibility profiles. This is especially important for businesses operating in regulated markets like the European Union, where carbon reporting and eco-labeling increasingly influence tender outcomes.

Brief Evolution and Industry Context

The aluminium LED strip channel sector has evolved significantly over the past two decades. Initially, LED strips were installed without specialized housings, leading to issues such as poor heat management, fragility, and unattractive installations. The introduction of aluminium channels revolutionized the market by offering robust thermal management, protection, and aesthetic enhancement.

Early aluminium profiles were simple U-shaped extrusions primarily focused on mounting convenience. Over time, innovation introduced diverse profiles with integrated diffusers, mounting clips, and end caps, enabling seamless integration into architectural elements. The rise of LED technology improvements, including more compact and efficient strips, further propelled the demand for sophisticated aluminium channels.

Today, aluminium LED strip channels are integral to professional lighting design and construction projects worldwide, supporting the transition to sustainable, smart, and customizable lighting solutions. Their development reflects a broader industry shift towards combining functionality with environmental responsibility—key considerations for modern B2B buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of aluminium led strip channel

-

How can I effectively vet and select reliable suppliers of aluminium LED strip channels for international B2B purchases?

To vet suppliers, start by verifying their business licenses and certifications relevant to your region (e.g., CE for Europe, UL for Middle East). Request detailed product datasheets, quality assurance procedures, and customer references. Evaluate their production capacity and export experience, especially for shipments to Africa, South America, and Europe. Conduct video factory tours or third-party audits if possible. Assess their responsiveness and after-sales support. Prioritize suppliers with transparent communication, proven compliance with international standards, and strong track records in fulfilling large B2B orders reliably. -

What customization options are typically available for aluminium LED strip channels in B2B orders?

Most manufacturers offer customization on channel length, profile shape, finish (anodized, powder-coated), and diffuser type (opal, frosted, clear). You can also specify end caps, mounting hardware, and cut-to-length services tailored to your project needs. Custom colors or branding may be possible for large orders. For international buyers, clarify lead times and minimum order quantities (MOQs) for customized products upfront, as these can be longer and higher than standard items. Clear technical drawings and samples help ensure your specifications are accurately met. -

What are common MOQ (Minimum Order Quantity), lead times, and payment terms I should expect when ordering aluminium LED strip channels internationally?

MOQs vary widely but typically start around 100-500 meters or equivalent channel units per style. Lead times for standard profiles usually range from 2 to 6 weeks, longer for customized orders. Payment terms often include a 30-50% deposit upfront, with balance before shipment or via letter of credit. For established buyers, suppliers may offer net payment terms (30-60 days). Always negotiate terms explicitly and confirm incoterms (FOB, CIF, DDP) to clarify who handles shipping and customs costs. -

What quality assurance certifications and testing should I require from aluminium LED strip channel suppliers?

Insist on certifications like ISO 9001 for quality management and product-specific marks such as CE (Europe), RoHS compliance, and UL listing for safety. Suppliers should provide test reports on anodizing thickness, corrosion resistance, and diffuser UV stability. Thermal performance data is important to ensure effective heat dissipation. Request samples for inspection and testing before large orders. Additionally, verify that the channels meet IP ratings suitable for your application environment (e.g., outdoor or damp locations). -

How do I manage logistics and shipping challenges when importing aluminium LED strip channels to regions like Africa, South America, or the Middle East?

Choose suppliers experienced with international freight forwarders and familiar with your destination country’s import regulations. Clarify packaging standards to prevent damage during transit. Use consolidated shipments where possible to reduce costs. Account for customs duties, taxes, and documentation requirements such as commercial invoices, packing lists, and certificates of origin. Engage reliable local customs brokers and factor in potential delays at ports. Insure shipments against loss or damage. Transparent communication with your supplier and freight partners is critical for smooth delivery. -

What are best practices for handling disputes or quality issues with aluminium LED strip channel suppliers internationally?

Establish clear contractual terms covering product specifications, inspection procedures, and remedies for defects or delays. Conduct pre-shipment inspections or third-party quality audits to catch issues early. Document all communications and discrepancies with photos and reports. Negotiate amicable solutions such as partial refunds, replacements, or rework. For unresolved disputes, consider arbitration clauses under international trade frameworks (e.g., ICC rules). Working with suppliers who provide warranties and maintain open communication minimizes risks.

Illustrative Image (Source: Google Search)

-

How important is thermal management in aluminium LED strip channel selection, and how can I verify this with suppliers?

Thermal management remains critical to prolong LED lifespan and maintain performance. Aluminium channels act as heat sinks, dissipating heat away from LED strips. Ask suppliers for thermal conductivity data and evidence of design features that optimize heat dissipation, such as channel thickness and surface finish. Verify compatibility with your specific LED strip wattage and installation environment. Proper thermal management reduces failure rates and maintenance costs, which is essential for commercial B2B projects. -

Can aluminium LED strip channels be used for outdoor applications, and what should I consider for such installations?

Yes, but outdoor use requires channels made from corrosion-resistant aluminum alloys with weatherproof finishes like anodizing or powder coating. Ensure diffusers and end caps have appropriate IP ratings (e.g., IP65 or higher) to protect against moisture and dust ingress. Confirm that mounting hardware is stainless steel or otherwise rust-resistant. Check UV stability of diffusers to prevent yellowing over time in strong sunlight. Verify supplier compliance with outdoor durability standards and request warranty terms covering environmental exposure.

Strategic Sourcing Conclusion and Outlook for aluminium led strip channel

Successful integration of aluminium LED strip channels hinges on meticulous strategic sourcing and installation precision. For B2B buyers across Africa, South America, the Middle East, and Europe, prioritizing quality materials—such as corrosion-resistant aluminum profiles and UV-stable diffusers—ensures durability and aesthetic excellence in diverse environmental conditions. Moreover, aligning procurement with suppliers who offer certified power supplies, compatible accessories, and technical support mitigates risks related to electrical safety and project delays.

Key takeaways for B2B buyers include:

- Selecting profiles tailored to project specifications to optimize heat dissipation and lighting diffusion.

- Demanding compliance with international safety and quality certifications (CE, UL) to safeguard investments.

- Emphasizing supplier reliability and after-sales service to support complex installations and maintenance.

- Accounting for regional environmental factors—such as humidity or dust—to choose appropriate IP-rated components.

Looking ahead, the aluminium LED strip channel market is poised for growth driven by rising demand for energy-efficient, customizable lighting solutions in commercial and architectural sectors. Buyers who leverage strategic sourcing—focusing on innovation, sustainability, and supplier partnerships—will gain competitive advantages and deliver superior lighting experiences. International buyers are encouraged to engage with reputable manufacturers offering tailored solutions and comprehensive technical guidance to future-proof their lighting projects.