Guide to 4Pin Connector Led Strip

- Introduction: Navigating the Global Market for 4pin connector led strip

- Understanding 4pin connector led strip Types and Variations

- Key Industrial Applications of 4pin connector led strip

- Strategic Material Selection Guide for 4pin connector led strip

- In-depth Look: Manufacturing Processes and Quality Assurance for 4pin connector led strip

- Manufacturing Processes for 4-Pin Connector LED Strips

- Quality Assurance and Control Framework

- Verifying Supplier Quality Assurance for International Buyers

- Conclusion

- Comprehensive Cost and Pricing Analysis for 4pin connector led strip Sourcing

- Spotlight on Potential 4pin connector led strip Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for 4pin connector led strip

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 4pin connector led strip Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 4pin connector led strip

- Strategic Sourcing Conclusion and Outlook for 4pin connector led strip

Introduction: Navigating the Global Market for 4pin connector led strip

The 4pin connector LED strip is a pivotal component in modern lighting solutions, offering unparalleled versatility and efficiency across commercial, industrial, and architectural applications. As global markets increasingly demand customizable, high-performance lighting, understanding the nuances of 4pin connector LED strips becomes essential for B2B buyers aiming to source quality products that meet stringent operational requirements. This guide serves as a comprehensive resource tailored to international buyers from diverse regions including Africa, South America, the Middle East, and Europe—markets where technological adoption is accelerating, and supply chain reliability is paramount.

In this guide, you will find detailed insights into the various types of 4pin connector LED strips, including their structural differences, wiring configurations, and performance characteristics. We explore the materials and manufacturing processes that ensure durability and consistent light quality, as well as rigorous quality control standards that suppliers implement to guarantee product reliability. Additionally, the guide navigates the global supplier landscape, highlighting sourcing strategies, cost considerations, and market trends relevant to buyers in France, Italy, and beyond.

By combining technical knowledge with market intelligence, this guide empowers procurement professionals to make informed decisions—whether evaluating supplier capabilities, optimizing installation designs, or negotiating cost-effective contracts. The inclusion of frequently asked questions addresses common challenges and clarifies technical specifications, making this an indispensable tool for those seeking to harness the full potential of 4pin connector LED strips in their projects. Equip your sourcing strategy with expert insights that bridge innovation and practical application in the evolving global lighting market.

Understanding 4pin connector led strip Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Common Anode 4-Pin RGB Strip | Shared positive voltage pin; individual negative pins for R, G, B | Commercial lighting, architectural installations | Pros: Industry standard, easier controller compatibility; Cons: Requires correct polarity, potential voltage drop on long runs |

| Common Cathode 4-Pin RGB Strip | Separate positive pins for each color; shared common negative pin | Specialized industrial or custom lighting systems | Pros: Flexible color channel control; Cons: Less common, limited controller options, higher wiring complexity |

| Waterproof 4-Pin Connector LED Strip | Encapsulated with IP65-IP68 rating; sealed connectors for moisture resistance | Outdoor signage, marine, and humid environments | Pros: Durable in harsh environments; Cons: Higher cost, more complex installation |

| High-Density 4-Pin LED Strip | Increased LEDs per meter (up to 120 LEDs/m), narrower PCB | Retail displays, high-end architectural lighting | Pros: Brighter and smoother light output; Cons: Higher power consumption, shorter max run lengths |

| Connector-Ready 4-Pin LED Strip | Pre-attached 4-pin connectors for tool-free installation | Modular installations, quick setup projects | Pros: Saves installation time, reduces soldering errors; Cons: Limited to compatible connectors, potential reliability issues over time |

Common Anode 4-Pin RGB Strip

This type is the prevalent standard in commercial and architectural lighting projects across global markets including Europe and emerging economies in Africa and South America. It features a shared positive voltage pin with separate negative pins for red, green, and blue channels, simplifying controller compatibility. Buyers should prioritize voltage rating (12V vs 24V) based on installation scale to minimize voltage drop and wiring costs. The common anode design ensures reliable color mixing and ease of integration with popular RGB controllers.

Common Cathode 4-Pin RGB Strip

Less frequently used, common cathode strips provide separate positive pins for each color and a shared negative connection. This configuration offers more granular control but demands specialized controllers and more complex wiring. It suits niche industrial applications or custom lighting where precise channel isolation is required. B2B buyers should assess controller availability and installation complexity before procurement, especially in regions with limited technical support.

Waterproof 4-Pin Connector LED Strip

Designed for outdoor and moisture-prone environments, these LED strips come with IP65 to IP68 ratings and sealed 4-pin connectors to prevent water ingress. They are ideal for signage, exterior architectural lighting, and marine applications common in Middle Eastern and coastal European markets. While offering superior durability, buyers should anticipate higher initial costs and ensure qualified installers to maintain seal integrity during setup.

High-Density 4-Pin LED Strip

Featuring up to 120 LEDs per meter, high-density strips deliver intense brightness and uniform light distribution, favored in retail displays and upscale architectural projects requiring premium illumination quality. However, they consume more power and have shorter maximum run lengths, necessitating careful power supply planning. Buyers should evaluate power infrastructure capabilities and consider 24V variants to optimize efficiency and reduce wiring bulk.

Connector-Ready 4-Pin LED Strip

These strips come with pre-attached 4-pin connectors, enabling quick, solder-free installations. They are well-suited for modular or temporary setups where rapid deployment is critical, such as trade shows or event lighting across diverse regions. While they reduce installation time and error risk, buyers must ensure compatibility with available connectors and monitor connector durability over repeated use to avoid maintenance issues.

Key Industrial Applications of 4pin connector led strip

| Industry/Sector | Specific Application of 4pin connector led strip | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial | Dynamic store lighting and display illumination | Enhances product visibility, attracts customers, and boosts sales | Consistent color rendering, easy integration with control systems, reliable connectors for quick installation |

| Hospitality & Tourism | Ambient and accent lighting in hotels, restaurants, and resorts | Creates inviting atmospheres, improves guest experience, reduces energy consumption | Waterproofing (IP rating), compatibility with dimmers and controllers, long lifespan under continuous use |

| Automotive & Transport | Interior and exterior vehicle decorative and functional lighting | Customizable lighting effects, improved safety and aesthetics | Vibration-resistant connectors, temperature tolerance, compliance with automotive standards |

| Architecture & Urban Planning | Façade lighting and public space illumination | Highlights architectural features, improves nighttime safety, energy-efficient solutions | Weatherproofing, scalability for large installations, ease of maintenance and replacement |

| Manufacturing & Warehousing | Task and safety lighting in production lines and storage areas | Increases worker safety, enhances visibility and productivity | Robust connectors for industrial environments, voltage compatibility, ease of modular expansion |

Retail & Commercial Lighting

In retail environments across Europe, South America, and Africa, 4pin connector LED strips are extensively used for dynamic lighting solutions that highlight products and create immersive shopping experiences. These strips enable multicolor RGB control to adjust lighting moods and draw customer attention to displays. Buyers must ensure consistent color quality and reliable connectors for fast installation and maintenance, especially in fast-paced commercial settings. For international buyers, sourcing strips with compatible controllers and power supplies that meet local electrical standards is crucial.

Hospitality & Tourism Ambience

Hotels, resorts, and restaurants in the Middle East and Europe rely on 4pin connector LED strips for ambient lighting that enhances guest comfort and aesthetic appeal. The ability to produce millions of colors with smooth transitions allows for customizable atmospheres tailored to different times of day or events. Buyers should prioritize waterproof and dustproof LED strips (IP65 or higher) to withstand humid or outdoor environments, as well as compatibility with dimming controllers to optimize energy consumption and prolong product life.

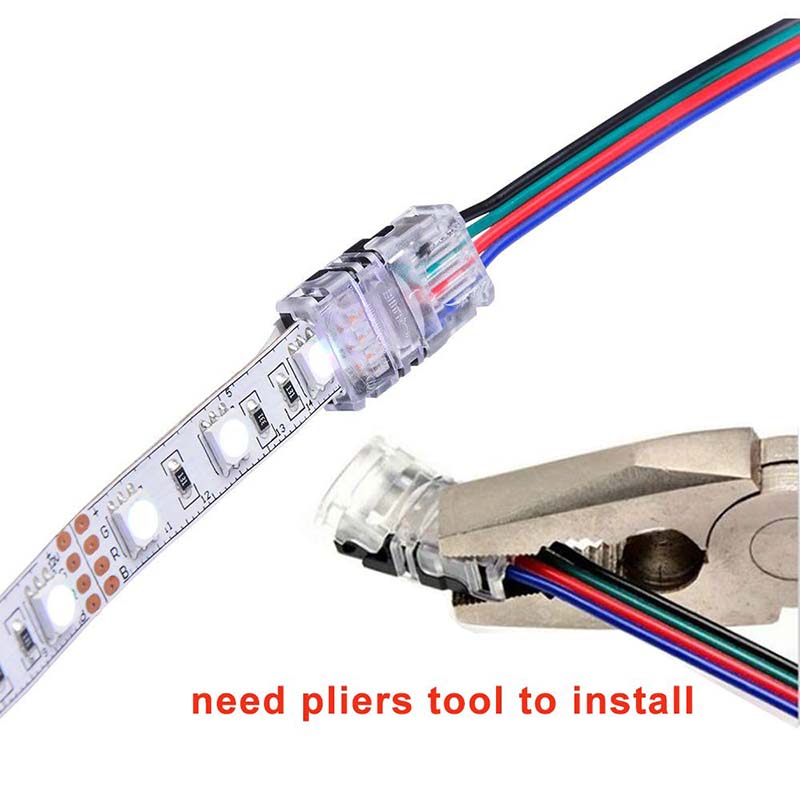

Illustrative Image (Source: Google Search)

Automotive & Transport Lighting

The automotive sector in markets like Italy and South America leverages 4pin connector LED strips for interior accent lighting and exterior decorative elements. These strips provide flexible, customizable lighting that enhances vehicle aesthetics and safety features such as footwell illumination or turn signal accents. Key sourcing factors include connectors designed to resist vibration and temperature extremes, as well as compliance with automotive electrical standards. International buyers should verify supplier certifications and product durability for demanding transport applications.

Architecture & Urban Planning Illumination

Architectural firms and urban planners in Africa and Europe utilize 4pin connector LED strips for façade lighting and public space illumination projects. These installations require scalable solutions that can cover large areas with uniform color and brightness. The strips’ flexibility and easy parallel wiring with 4pin connectors simplify complex layouts. Buyers must consider weatherproof ratings and ease of maintenance, as well as sourcing from manufacturers that provide technical support for large-scale commercial projects.

Manufacturing & Warehousing Safety Lighting

In industrial settings across the Middle East and South America, 4pin connector LED strips are applied to enhance task lighting and safety in production lines and storage facilities. Their robust design and reliable connectors ensure continuous operation in harsh environments. For B2B buyers, it is essential to source strips with appropriate voltage ratings (often 24V for longer runs), durable connectors, and modularity for future expansion. Ensuring compliance with local industrial safety regulations is also a key consideration.

Related Video: LED light Strip connector For Beginners

Strategic Material Selection Guide for 4pin connector led strip

When selecting materials for 4pin connector LED strips, international B2B buyers must consider factors such as electrical performance, environmental durability, manufacturing feasibility, and compliance with regional standards. The choice of material directly influences the product’s reliability, lifespan, and suitability for various commercial and industrial applications across diverse climates and regulatory environments in Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a widely used thermoplastic polymer known for its excellent electrical insulation, moderate flexibility, and resistance to moisture and chemicals. It typically withstands temperatures up to 60-80°C and offers good resistance to corrosion and abrasion.

Pros & Cons: PVC is cost-effective and easy to manufacture, making it a popular choice for LED strip connectors. It provides adequate protection against dust and moisture for indoor and some outdoor applications. However, PVC’s temperature resistance is limited, and prolonged exposure to UV light or extreme heat can cause brittleness and degradation.

Impact on Application: PVC connectors are suitable for general-purpose LED strip installations, particularly in controlled indoor environments or mild outdoor conditions. However, they may not perform well in harsh desert climates or high-humidity tropical regions without additional UV stabilization or protective coatings.

International Considerations: PVC materials generally comply with ASTM and DIN electrical insulation standards, which are widely recognized in Europe and parts of South America. Buyers in Africa and the Middle East should verify compliance with local fire retardancy and toxicity regulations, as PVC can emit hazardous fumes if burned.

Polycarbonate (PC)

Key Properties: Polycarbonate is a high-performance engineering plastic offering superior impact resistance, high temperature tolerance (up to 120°C), and excellent dimensional stability. It also provides good electrical insulation and UV resistance.

Pros & Cons: PC connectors are more durable and heat-resistant than PVC, making them suitable for demanding environments. They maintain structural integrity under mechanical stress and prolonged sunlight exposure. The downside is a higher material cost and more complex molding processes, which can increase production lead times.

Impact on Application: Polycarbonate is ideal for outdoor LED strip connectors in regions with high solar exposure, such as the Middle East and parts of Africa. Its robustness also benefits industrial installations requiring frequent handling or mechanical protection.

International Considerations: PC materials meet stringent European (EN) and international (ISO) standards for electrical components and UV resistance. Buyers from Italy and France often prefer PC for premium installations due to its longevity and compliance with EU RoHS and REACH directives.

Silicone Rubber

Key Properties: Silicone rubber is a flexible elastomer with excellent thermal stability (operating range from -60°C to 230°C), outstanding weather resistance, and superior electrical insulation properties. It is highly resistant to moisture, ozone, and UV radiation.

Pros & Cons: Silicone connectors provide exceptional sealing and flexibility, ideal for waterproof or harsh environmental applications. They are more expensive and require specialized manufacturing techniques like injection molding or extrusion. Silicone’s softness can sometimes compromise mechanical protection compared to rigid plastics.

Impact on Application: Silicone is preferred for outdoor and industrial LED strips exposed to extreme temperatures, humidity, or chemical exposure, such as coastal regions in South America or arid zones in the Middle East. It is particularly valuable for IP65/IP67-rated waterproof connectors.

International Considerations: Silicone materials conform to ASTM and IEC standards for electrical insulation and weather resistance. European buyers value silicone for sustainability and safety, while African and South American buyers appreciate its durability in tropical and desert climates.

Nylon (Polyamide)

Key Properties: Nylon is a tough, semi-rigid plastic with good mechanical strength, abrasion resistance, and moderate chemical resistance. It can operate in temperatures up to 100-120°C and offers good electrical insulating properties.

Pros & Cons: Nylon connectors are durable and resistant to wear, making them suitable for applications requiring frequent connector mating cycles. They are less UV resistant than polycarbonate or silicone and may absorb moisture, which can affect dimensional stability.

Impact on Application: Nylon is commonly used in industrial or commercial LED strip connectors where mechanical robustness is critical, such as in factory automation or architectural lighting in Europe and South America. It is less ideal for prolonged outdoor use in high UV environments unless UV-stabilized grades are employed.

International Considerations: Nylon complies with DIN and ISO standards relevant to electrical and mechanical performance. European buyers often specify nylon for connectors requiring certification under EN standards, while buyers in Africa and the Middle East should assess moisture exposure risks.

| Material | Typical Use Case for 4pin connector led strip | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General indoor LED strip connectors, mild outdoor use | Cost-effective, good electrical insulation | Limited temperature and UV resistance | Low |

| Polycarbonate | Outdoor and industrial connectors requiring impact and UV resistance | High durability, excellent heat and UV resistance | Higher cost, complex manufacturing | High |

| Silicone Rubber | Waterproof and harsh environment connectors | Exceptional flexibility, thermal stability | Higher cost, less mechanical protection | High |

| Nylon | Industrial and commercial connectors with mechanical wear | Good mechanical strength and abrasion resistance | Moisture absorption, moderate UV resistance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for 4pin connector led strip

Manufacturing Processes for 4-Pin Connector LED Strips

The production of 4-pin connector LED strips involves a series of precise, well-controlled stages designed to ensure consistent quality and performance. Understanding these stages helps B2B buyers evaluate potential suppliers and verify manufacturing robustness.

Illustrative Image (Source: Google Search)

1. Material Preparation

- PCB Fabrication: The base of the LED strip is a flexible printed circuit board (PCB), typically made from polyimide or polyester substrates with copper traces. The manufacturing process starts with cutting and cleaning the PCB material to exact dimensions and specifications.

- LED Chips and Components: High-quality RGB LED chips, resistors, capacitors, and connectors are sourced from reputable suppliers. Material traceability is critical here to guarantee consistent electrical and luminous performance.

- Connector Components: The 4-pin connectors are precision-molded using durable plastics and plated metal contacts to ensure reliable electrical connectivity and mechanical strength.

2. Forming and Assembly

- Solder Paste Application: Automated screen printing machines deposit solder paste on the PCB pads, ensuring precise placement for surface mount devices (SMDs).

- Pick-and-Place Machine: Advanced robotic systems place LED chips, resistors, and connectors on the PCB with high accuracy to maintain circuit integrity and optimize light output.

- Reflow Soldering: The assembled PCB passes through a reflow oven where solder paste melts and solidifies, forming secure electrical and mechanical joints.

- Connector Attachment: The 4-pin connectors are either soldered or attached via specialized connectors that eliminate the need for soldering, depending on supplier capability and buyer preference.

- Cutting and Segmentation: LED strips are cut into specified lengths, typically at designated cut points, ensuring easy installation and customization.

3. Finishing

- Protective Coating: Depending on the product specification, the strips receive conformal coatings or encapsulation to enhance durability and water resistance (e.g., IP65 or higher ratings).

- Labeling and Packaging: Each strip is labeled with batch codes and electrical specifications. Packaging is designed to prevent damage during transit and facilitate bulk handling.

Quality Assurance and Control Framework

For B2B buyers, especially those operating across diverse international markets such as Africa, South America, the Middle East, and Europe, understanding the quality assurance (QA) and quality control (QC) practices is essential for reliable procurement.

Key International and Industry Standards

- ISO 9001: This international standard governs quality management systems (QMS), requiring manufacturers to implement structured processes for continual improvement and customer satisfaction. Verified ISO 9001 certification is a strong indicator of a supplier’s commitment to consistent quality.

- CE Marking: Mandatory for products sold in the European Economic Area (EEA), CE certification confirms compliance with EU safety, health, and environmental requirements. For LED strips, this includes electrical safety and electromagnetic compatibility (EMC).

- RoHS Compliance: Restriction of Hazardous Substances ensures that LED strips are free from harmful materials like lead and mercury, critical for environmentally conscious buyers and regulatory adherence in Europe and beyond.

- UL and ETL Listings: Particularly important for North American markets but increasingly recognized globally, these certifications indicate compliance with stringent electrical safety standards.

- IP Rating Verification: Water and dust resistance levels (e.g., IP20, IP65, IP68) are verified through standardized tests, crucial for outdoor or industrial applications common in African and Middle Eastern markets.

Quality Control Checkpoints

A robust QC process integrates multiple checkpoints throughout production:

- Incoming Quality Control (IQC): Raw materials and components (LED chips, PCBs, connectors) are inspected for dimensional accuracy, electrical parameters, and defects before entering production.

- In-Process Quality Control (IPQC): During assembly, continuous monitoring of soldering quality, component placement, and connector integrity helps identify and rectify issues early, minimizing scrap rates.

- Final Quality Control (FQC): Completed LED strips undergo comprehensive testing, including visual inspection, electrical functionality, and mechanical strength. Packaging and labeling accuracy are also verified.

Common Testing Methods

- Electrical Testing: Verification of operating voltage, current draw, and continuity for each color channel ensures performance consistency and safety.

- Color Consistency and Brightness: Photometric testing with spectrometers measures color accuracy and luminous intensity to guarantee uniform lighting effects.

- Durability Tests: Mechanical bending, vibration, and thermal cycling tests simulate real-world conditions to assess long-term reliability.

- Waterproofing Tests: For IP-rated products, immersion and spray tests confirm resistance to moisture ingress.

- Connector Reliability: Repeated mating and unmating cycles test connector durability, essential for modular or replaceable installations.

Verifying Supplier Quality Assurance for International Buyers

B2B buyers should adopt a proactive approach to ensure supplier QC systems meet international and local market demands:

- Factory Audits: Conduct on-site inspections or hire third-party auditors to evaluate manufacturing processes, equipment maintenance, workforce training, and QC documentation. Audits should verify compliance with ISO 9001 and relevant certifications.

- Review of QC Reports and Certificates: Request comprehensive batch-level QC reports, including test data and certification copies (CE, RoHS, UL). This transparency aids in risk mitigation and traceability.

- Third-Party Inspections: Employ independent inspection agencies (e.g., SGS, Bureau Veritas) to perform random sampling, functional testing, and compliance verification before shipment, reducing the risk of receiving substandard products.

- Sample Evaluation: Prior to large orders, obtain and test samples under expected application conditions to validate performance and durability.

- Supplier Quality Agreements: Negotiate clear contractual terms defining quality expectations, inspection procedures, and corrective action protocols.

Quality Assurance Nuances for Specific Regions

- Africa and South America: Logistics challenges and variable regulatory environments necessitate thorough QC verification and robust packaging. Buyers should prioritize suppliers with proven export experience and certifications recognized locally.

- Middle East: Environmental conditions such as high temperatures and dust exposure require LED strips with enhanced thermal management and IP ratings. Quality documentation should confirm suitability for harsh climates.

- Europe (France, Italy, etc.): Stringent EU regulations make CE and RoHS certifications mandatory. Buyers should also expect detailed technical datasheets and compliance with eco-design directives.

Conclusion

For international B2B buyers, understanding the manufacturing and QC landscape of 4-pin connector LED strips is critical to sourcing reliable, high-performance lighting solutions. By scrutinizing supplier processes, certifications, and testing protocols, buyers across Africa, South America, the Middle East, and Europe can confidently select products tailored to their technical and regulatory requirements, ensuring long-term satisfaction and operational efficiency.

Related Video: LED Light Making Process | How LED Lights Made Inside Factory | Manufacturing Process

Comprehensive Cost and Pricing Analysis for 4pin connector led strip Sourcing

When sourcing 4-pin connector LED strips, understanding the detailed cost and pricing structure is crucial for international B2B buyers aiming to optimize procurement and total cost of ownership. This analysis breaks down key cost components, pricing influencers, and strategic buyer tips tailored for markets in Africa, South America, the Middle East, and Europe, including France and Italy.

Key Cost Components in 4-Pin Connector LED Strip Pricing

-

Materials

The core material costs include the flexible PCB substrate, RGB LED chips (typically SMD 5050 or similar), 4-pin connectors, resistors, and solder. Higher-grade LEDs or waterproof coatings (e.g., IP65, IP68) significantly increase material costs. Additionally, the choice between 12V and 24V strips affects PCB thickness and copper weight, influencing raw material expenses. -

Labor and Manufacturing Overhead

Labor costs vary widely by manufacturing location. Automated assembly lines reduce labor input but add capital expenditure amortization. Overhead covers factory utilities, equipment maintenance, and indirect labor such as quality control and packaging. -

Tooling and Setup Costs

Initial tooling for connector molds and PCB assembly jigs is a fixed cost often amortized over production volume. Custom connectors or specific PCB designs can increase tooling costs, especially for smaller order quantities. -

Quality Control (QC) and Certifications

Rigorous QC processes (e.g., LED binning, voltage testing) add to the cost but ensure reliability. Certifications such as CE, RoHS, UL, or regional standards (e.g., ENEC for Europe) also add compliance costs but can be crucial for market acceptance and legal importation. -

Logistics and Freight

Shipping costs depend on volume, weight, and destination. Buyers from Africa or South America often face higher freight charges and longer lead times compared to Europe or the Middle East. Customs duties, import taxes, and local handling fees further impact landed cost. -

Supplier Margin

Supplier pricing includes profit margins that vary based on market competition, supplier reputation, and service level agreements (SLAs). Established suppliers with strong technical support may charge premiums that are justified by reduced risk and better after-sales service.

Influencing Factors on Pricing

-

Order Volume and Minimum Order Quantity (MOQ)

Larger volumes typically attract significant discounts due to economies of scale. MOQ requirements vary but often start at 500-1000 meters per SKU. Negotiating MOQ flexibility can be a cost lever for smaller buyers. -

Technical Specifications and Customization

Customized lengths, connector types, or additional features (e.g., dimmable controllers, waterproofing) increase unit costs. Standardized products are more cost-effective but may limit application flexibility. -

Material Quality and Certification Level

Premium LEDs with higher lumen efficacy or longer lifespan cost more but reduce replacement frequency and energy consumption, impacting total cost of ownership favorably. -

Supplier Location and Incoterms

Sourcing from Asia (e.g., China) is often cheaper but involves higher shipping times and potential tariffs. European or Middle Eastern suppliers may offer faster delivery and easier communication at a higher price. Incoterms like FOB, CIF, or DDP affect who bears shipping, insurance, and customs responsibilities, influencing the final landed cost.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Beyond Unit Price

Engage suppliers on payment terms, shipping arrangements, and after-sales support. Bundling purchases or committing to longer contracts can secure better pricing and priority production slots. -

Assess Total Cost of Ownership (TCO)

Consider energy efficiency, product lifespan, and maintenance costs alongside upfront price. For example, higher-quality 24V strips may cost more initially but reduce voltage drop and power losses in long runs, especially relevant for large commercial projects. -

Factor in Regional Import and Compliance Costs

Ensure products meet local electrical and safety standards to avoid costly customs delays or rejections. Engage local consultants or agents familiar with import regulations in Africa, South America, or Europe. -

Prioritize Supplier Transparency and Quality Assurance

Request samples and detailed technical datasheets. Suppliers with robust QC processes and certifications reduce risk of defective shipments, which is critical when sourcing remotely. -

Leverage Shipping Consolidation and Incoterm Optimization

For buyers in regions with higher freight costs, consolidating shipments or choosing DDP (Delivered Duty Paid) terms can simplify logistics and reduce unexpected expenses.

Indicative Pricing Disclaimer

Pricing for 4-pin connector LED strips varies widely based on specifications, order volume, and supplier. Indicative unit prices typically range from $1.50 to $5.00 per meter for standard density 12V strips, excluding shipping and taxes. Custom or high-density configurations command higher prices. Buyers should treat quoted prices as starting points and conduct thorough cost comparisons including all landed costs before finalizing procurement.

By carefully analyzing cost drivers and negotiating strategically, international B2B buyers can secure competitive pricing on 4-pin connector LED strips while ensuring quality and compliance tailored to their regional market needs.

Spotlight on Potential 4pin connector led strip Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘4pin connector led strip’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 4pin connector led strip

Key Technical Properties of 4-Pin Connector LED Strips

Understanding the essential technical specifications of 4-pin connector LED strips is crucial for international B2B buyers to ensure product compatibility, performance, and longevity in various commercial applications.

-

Operating Voltage (12V / 24V DC)

Most 4-pin RGB LED strips operate on either 12V or 24V DC power supplies. The choice affects power efficiency and installation scale. For example, 24V strips support longer runs with reduced voltage drop, lowering wiring costs and improving color consistency—important for large-scale projects common in Africa, Europe, and the Middle East. -

LED Density (LEDs per Meter)

LED density determines brightness and resolution. Typical densities are 30, 60, or 120 LEDs per meter. Higher density strips consume more power but deliver smoother color gradients and increased luminosity, vital for premium retail displays or architectural lighting in demanding markets like Italy or Brazil. -

Power Consumption (Watts per Meter)

Power consumption varies with LED density and operating voltage, typically ranging from 7.2W/m (30 LEDs/m at 12V) up to 28.8W/m (120 LEDs/m at 12V). Buyers must match power supplies accordingly to avoid underpowering or overheating, ensuring system reliability and safety standards compliance. -

Cut Points and Flexibility

LED strips have designated cut points (e.g., every 5cm or 10cm) allowing customization of length without damaging the circuitry. This feature facilitates tailored installations and reduces waste, a critical consideration for cost-conscious buyers managing inventory and project-specific requirements. -

Connection Type and Wire Gauge

The 4-pin connectors correspond to a common anode or less common common cathode wiring configuration. Correct matching ensures proper color control and prevents damage. Wire gauge recommendations (e.g., 18-22 AWG) vary by run length and current, influencing installation complexity and cost, especially for longer commercial runs. -

Material Quality and IP Rating

The PCB base and protective coatings (e.g., waterproof IP65 or IP68 ratings) determine durability against environmental factors like moisture or dust. Buyers targeting outdoor or industrial applications in humid or dusty climates (e.g., Middle East deserts or South American rainforests) must prioritize these ratings to ensure product longevity.

Common Trade and Industry Terminology for B2B LED Strip Transactions

Familiarity with key trade terms empowers buyers to navigate international procurement processes confidently and negotiate effectively.

-

OEM (Original Equipment Manufacturer)

Refers to products manufactured by one company but branded and sold by another. Many LED strip suppliers offer OEM services, allowing buyers to customize branding and specifications. This is ideal for businesses in Europe or Africa aiming to differentiate their product lines without investing in manufacturing infrastructure. -

MOQ (Minimum Order Quantity)

The smallest quantity a supplier will accept for an order. MOQs vary widely and impact pricing, lead times, and inventory management. Understanding MOQ is essential for buyers in emerging markets to balance upfront investment with demand forecasts. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers to obtain pricing, lead times, and terms for specific product quantities and specifications. RFQs are critical for transparent supplier evaluation and cost negotiation, especially for bulk orders spanning multiple countries. -

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and tariffs between buyer and seller. Common Incoterms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Knowledge of Incoterms helps buyers from diverse regions (e.g., Middle East or South America) minimize risks and clarify logistics responsibilities. -

Lead Time

The duration from order placement to product delivery. Accurate lead time information is vital for project planning and inventory control, especially when coordinating multi-phase installations across different countries. -

Voltage Drop

A reduction in voltage along the length of the LED strip due to resistance in wiring. Excessive voltage drop can cause uneven brightness and color shifts. Buyers should factor this into system design, opting for 24V strips or parallel wiring configurations for longer runs to maintain quality.

By prioritizing these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and ensure successful deployment of 4-pin connector LED strip lighting solutions across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 4pin connector led strip Sector

Market Overview & Key Trends

The global 4pin connector LED strip market is witnessing robust growth driven by increasing adoption of energy-efficient lighting solutions across commercial, industrial, and architectural sectors. International B2B buyers from Africa, South America, the Middle East, and Europe—especially countries with strong construction and manufacturing bases like France and Italy—are actively sourcing these components to meet rising demand for customizable, scalable RGB lighting systems. Key market drivers include urbanization, smart city initiatives, and advancements in LED technology that enable longer run lengths, improved color accuracy, and greater power efficiency.

Emerging trends highlight a shift towards 24V LED strips with 4pin connectors, favored for their ability to reduce voltage drop and support longer installations, which is crucial for large-scale commercial projects. Additionally, modular wiring solutions and plug-and-play connectors are gaining traction, simplifying installation and reducing labor costs—a critical factor for markets with limited access to skilled electrical professionals. Buyers are also prioritizing suppliers who offer comprehensive technical support, including detailed wiring diagrams and controller integration guidance, to ensure optimal system performance and reliability.

Regional market dynamics vary:

– Africa and the Middle East are rapidly expanding infrastructure projects and government-backed smart lighting programs, creating demand for durable, waterproof LED strips with robust 4pin connectors.

– South America focuses on cost-effective sourcing, balancing quality with affordability, often sourcing from Asian manufacturers who can provide competitive pricing and flexible MOQ (minimum order quantities).

– Europe emphasizes high-quality standards and compliance with strict electrical and safety regulations, driving demand for certified products with consistent performance and longevity.

For B2B buyers, forging partnerships with manufacturers offering customization, rapid prototyping, and scalable production capabilities can unlock competitive advantages in these diverse regional markets.

Sustainability & Ethical Sourcing in B2B

Sustainability considerations are becoming paramount in the procurement of 4pin connector LED strips, as buyers worldwide face increasing pressure to reduce environmental footprints and comply with evolving regulations. The manufacturing of LED strips involves materials such as copper, plastics, and rare earth elements—each carrying environmental and ethical implications. Responsible sourcing of raw materials, especially conflict-free metals for connectors and circuit boards, is essential to uphold corporate social responsibility (CSR) commitments.

International buyers are actively seeking suppliers who adhere to green certifications like RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and Energy Star ratings. These certifications ensure that LED strips are free from hazardous substances like lead and mercury, promoting safer disposal and recycling at end-of-life. Additionally, products designed for energy efficiency with low power consumption (e.g., 24V RGB strips with optimized current draw) contribute to long-term operational savings and reduced carbon emissions.

Ethical supply chains in the LED strip sector increasingly involve transparency and traceability of component sourcing, factory labor conditions, and environmental impact mitigation. Buyers from Europe and parts of the Middle East often require comprehensive compliance documentation, including conflict mineral declarations and third-party audit reports. For regions like Africa and South America, where regulatory frameworks may be evolving, partnering with suppliers committed to ethical practices can help future-proof procurement strategies and build brand trust.

In summary, integrating sustainability into sourcing decisions not only aligns with global ESG goals but also enhances product appeal to end-users demanding eco-friendly and socially responsible lighting solutions.

Brief Evolution of 4pin Connector LED Strips

The 4pin connector LED strip technology has evolved significantly since its inception as a niche lighting solution. Initially, LED strips were simple single-color tapes with limited control and short run lengths, primarily used for accent lighting. The introduction of RGB LED strips with 4pin connectors revolutionized the market by enabling full-color customization through separate control of red, green, and blue channels.

Over time, enhancements in PCB flexibility, LED chip density, and connector reliability have expanded their application from decorative uses to critical commercial and industrial lighting systems. The adoption of standardized 4pin connectors simplified installation and maintenance, making them the industry standard for programmable RGB lighting. More recently, developments in higher voltage (24V) strips, waterproofing, and plug-and-play connectors have addressed longstanding challenges such as voltage drop and installation complexity, further driving global adoption.

For B2B buyers, understanding this evolution underscores the importance of selecting modern, standardized 4pin connector LED strips that combine technical sophistication with ease of integration, ensuring future-ready lighting solutions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of 4pin connector led strip

-

How can I effectively vet suppliers of 4pin connector LED strips for international B2B purchases?

When sourcing 4pin connector LED strips internationally, prioritize suppliers with verifiable credentials such as ISO certifications and compliance with international standards (e.g., CE, RoHS). Request product samples and detailed technical datasheets to assess quality. Check references or reviews from other B2B buyers in your region, especially within Africa, South America, the Middle East, or Europe. Utilize third-party inspection services to audit manufacturing facilities if possible. Establish clear communication channels early to evaluate responsiveness and technical support capabilities. -

What customization options are typically available for 4pin connector LED strips in bulk orders?

Most manufacturers offer customization including LED density (e.g., 30, 60, or 120 LEDs/meter), strip length, waterproof rating (IP20 to IP68), voltage options (12V or 24V), and connector types. Color calibration or specific RGB controller compatibility can also be tailored. Discuss your application requirements upfront to ensure the supplier can meet technical specifications and packaging needs. Custom firmware for controllers or unique branding on strips may be available for larger MOQ orders, enhancing your product’s market differentiation. -

What are common minimum order quantities (MOQs) and lead times when importing 4pin connector LED strips?

MOQs typically range from 500 to 2000 meters depending on the supplier’s production scale and customization level. Lead times vary between 3 to 8 weeks, influenced by order complexity, customization, and shipping method. For buyers in Africa or South America, consider additional time for customs clearance and inland logistics. Negotiate MOQs early and explore sample orders before committing to large volumes. Establish clear timelines and penalties in contracts to mitigate delays. -

Which payment terms are advisable for international transactions with 4pin LED strip manufacturers?

Common payment terms include 30% deposit upon order confirmation and 70% balance before shipment or upon receiving the bill of lading. Letters of credit (L/C) offer more security for buyers, especially in new supplier relationships. For trusted suppliers, net 30 or net 60 terms may be negotiated. Use escrow services or trade platforms with payment protection to reduce risks. Always verify supplier banking details to avoid fraud, particularly in cross-border transactions involving Africa, the Middle East, or South America. -

What quality assurance certifications should I look for in 4pin connector LED strip suppliers?

Essential certifications include CE (European Conformity), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories) for electrical safety. ISO 9001 certification signals robust quality management processes. For buyers in Europe and the Middle East, compliance with regional standards like ENEC or SASO is crucial. Request factory quality control reports, and insist on pre-shipment inspections or third-party lab testing to verify luminous efficacy, voltage consistency, and waterproof ratings. This ensures product reliability and reduces return rates. -

How should I plan logistics and shipping for large orders of 4pin connector LED strips internationally?

Choose shipping modes based on urgency and budget: sea freight for cost efficiency on large volumes, air freight for faster delivery. Consolidate shipments to optimize costs and avoid partial deliveries. Work with freight forwarders experienced in handling electronics and flexible lighting products to ensure proper packaging and customs documentation. Factor in customs duties, import taxes, and possible delays in ports common to Africa, South America, or the Middle East. Establish Incoterms (e.g., FOB, CIF) clearly in contracts to define responsibilities. -

What are best practices for managing disputes or quality issues with 4pin LED strip suppliers?

Address issues promptly by documenting discrepancies with photos, videos, and inspection reports. Maintain open communication and seek amicable resolutions such as partial refunds, replacements, or rework. Include dispute resolution clauses in contracts specifying arbitration venues or courts, preferably aligned with your jurisdiction or neutral locations. For recurring problems, consider third-party quality audits before shipment. Building long-term partnerships with suppliers who demonstrate accountability minimizes risks and ensures consistent product quality. -

How do voltage and wiring configurations affect the selection of 4pin connector LED strips for commercial projects?

Understanding the standard common anode 4-pin wiring (V+, R-, G-, B-) is crucial for compatibility with controllers and power supplies. Choose between 12V and 24V strips based on run length and power efficiency; 24V strips support longer runs with less voltage drop, ideal for large commercial installations common in Europe and the Middle East. Confirm that your power supply and controllers match the LED strip voltage and wiring configuration to avoid damage. Proper wiring and connector quality directly impact system reliability and installation safety.

Strategic Sourcing Conclusion and Outlook for 4pin connector led strip

Understanding the technical nuances and application-specific requirements of 4-pin connector LED strips empowers international B2B buyers to make informed sourcing decisions. Key takeaways emphasize the importance of selecting the right voltage (favoring 24V for extended runs and efficiency), ensuring proper wiring configurations, and leveraging parallel connections to maintain consistent performance in commercial installations. Additionally, integrating reliable controllers and quality connectors enhances both system longevity and ease of maintenance.

Strategic sourcing in this sector is not just about cost efficiency but also about securing suppliers who offer robust technical support, consistent quality standards, and scalable solutions. Buyers from Africa, South America, the Middle East, and Europe should prioritize partners with proven expertise in meeting diverse regulatory requirements and providing adaptable logistics solutions that address regional market dynamics.

Looking ahead, the 4-pin connector LED strip market is poised for innovation driven by energy efficiency demands and smart lighting integration. International buyers are encouraged to proactively engage with manufacturers and distributors who invest in R&D and can provide future-ready products. Establishing strong supplier relationships today will ensure competitive advantage and operational excellence tomorrow. Act now to align your sourcing strategy with evolving industry trends and regional growth opportunities.