Guide to 4 Pin Led Strip Light Connectors

- Introduction: Navigating the Global Market for 4 pin led strip light connectors

- Understanding 4 pin led strip light connectors Types and Variations

- Key Industrial Applications of 4 pin led strip light connectors

- Strategic Material Selection Guide for 4 pin led strip light connectors

- In-depth Look: Manufacturing Processes and Quality Assurance for 4 pin led strip light connectors

- Manufacturing Processes for 4-Pin LED Strip Light Connectors

- Quality Assurance and Control (QA/QC) Framework

- Comprehensive Cost and Pricing Analysis for 4 pin led strip light connectors Sourcing

- Spotlight on Potential 4 pin led strip light connectors Manufacturers and Suppliers

- Essential Technical Properties and Trade Terminology for 4 pin led strip light connectors

- Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 4 pin led strip light connectors Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of 4 pin led strip light connectors

- Strategic Sourcing Conclusion and Outlook for 4 pin led strip light connectors

- Strategic Sourcing Insights and Future Perspectives for 4-Pin LED Strip Light Connectors

Introduction: Navigating the Global Market for 4 pin led strip light connectors

In the rapidly evolving LED lighting industry, 4-pin LED strip light connectors are indispensable components that enable seamless integration and dynamic color control for RGB lighting systems. These connectors not only facilitate efficient power and data transmission but also ensure ease of installation and reliable performance across diverse applications—from commercial architectural projects to innovative retail displays. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of these connectors is critical to sourcing high-quality products that meet regional standards and operational demands.

This guide offers a comprehensive exploration of the global market for 4-pin LED strip light connectors, addressing the full spectrum of considerations essential to informed procurement. Readers will gain insights into various connector types, materials, manufacturing processes, and quality control measures that influence product durability and functionality. Additionally, the guide highlights key supplier landscapes, pricing dynamics, and emerging market trends to help buyers identify reliable partners and cost-effective solutions tailored to their specific geographic and commercial contexts.

By navigating complex technical specifications and market variables, this resource empowers B2B buyers—whether from Colombia, Spain, or beyond—to make strategic decisions that optimize installation efficiency, ensure compatibility, and enhance end-user satisfaction. Leveraging this knowledge will not only streamline supply chain operations but also position businesses to capitalize on the growing demand for customizable, energy-efficient LED lighting solutions worldwide.

Understanding 4 pin led strip light connectors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solderless Clip-on Connector | Tool-free installation, clips directly onto strip contacts | Quick installations, retail displays, event lighting | Pros: Easy, fast installation; Cons: Less secure for heavy-duty use |

| Soldered 4-Pin Connector | Requires soldering for permanent, strong electrical joints | Industrial projects, permanent architectural lighting | Pros: Durable, reliable connections; Cons: Requires skilled labor |

| Waterproof 4-Pin Connector | Sealed with silicone or rubber gaskets for water resistance | Outdoor lighting, signage, marine applications | Pros: Weatherproof, extends lifespan; Cons: Slightly higher cost |

| Flexible Ribbon Connector | Flat, flexible design for bending and tight spaces | Automotive, creative installations, curved surfaces | Pros: Adaptable to shapes; Cons: May have lower current capacity |

| Extension 4-Pin Connector | Used to extend LED strip length without cutting | Large installations, long runs in commercial setups | Pros: Easy to extend; Cons: Additional connection points may reduce efficiency |

Solderless Clip-on Connectors are ideal for projects requiring rapid deployment and minimal technical expertise. Their tool-free design enables quick attachment to LED strips, making them popular in retail environments and temporary event setups across Africa, South America, and Europe. B2B buyers should consider these connectors for cost-effective, low-skill installations but evaluate the connection security for long-term or heavy-use applications.

Soldered 4-Pin Connectors provide the most robust and permanent electrical connection. They are suitable for industrial and commercial architectural lighting projects where durability is critical. Buyers from the Middle East and Europe often prefer soldered connectors for large-scale installations due to their reliability. However, these require skilled labor and additional installation time, impacting overall project cost and timeline.

Waterproof 4-Pin Connectors are engineered with sealing materials to withstand moisture and environmental exposure, making them essential for outdoor and marine lighting applications. For B2B buyers targeting regions with high humidity or outdoor commercial signage, these connectors offer longevity and reduced maintenance. The trade-off is a higher upfront cost and slightly bulkier design compared to non-waterproof variants.

Flexible Ribbon Connectors excel in applications demanding adaptability to curved or irregular surfaces, such as automotive lighting or creative architectural projects. Their slim, bendable form factor enables seamless integration into tight spaces. Buyers should weigh the benefits of flexibility against their typically lower current handling capacity, ensuring compatibility with their LED strip specifications.

Extension 4-Pin Connectors facilitate the extension of LED strips without the need for cutting or re-soldering, streamlining large commercial or industrial lighting installations. These connectors are favored by B2B customers managing expansive projects in sectors like retail chains or facility lighting across Europe and South America. While convenient, buyers should be mindful that additional connectors can introduce minor voltage drops, potentially affecting lighting uniformity.

Related Video: How to Use Solderless LED Strip Light Connectors

Key Industrial Applications of 4 pin led strip light connectors

| Industry/Sector | Specific Application of 4 pin led strip light connectors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Commercial Spaces | Dynamic RGB lighting for storefronts and displays | Enhanced visual appeal, increased customer engagement | Compatibility with RGB strips, durability, ease of installation |

| Hospitality & Entertainment | Ambient and accent lighting in hotels, restaurants, and theaters | Customizable atmosphere, energy-efficient operation | Quality certifications, connector IP rating, remote control compatibility |

| Automotive Manufacturing | Interior ambient lighting and dashboard illumination | Improved user experience, lightweight and flexible | Heat resistance, vibration durability, connector size and fit |

| Architectural & Urban Design | Façade lighting and outdoor decorative installations | Long-lasting, weather-resistant solutions, aesthetic enhancement | Waterproof connectors, UV resistance, compliance with local standards |

| Electronics & Consumer Goods | Integration in smart home lighting systems | Seamless connectivity, enhanced user control | Solderless connectors, compatibility with controllers, cable length options |

In retail and commercial spaces, 4 pin LED strip light connectors are widely used to create vibrant, dynamic RGB lighting effects in storefronts and product displays. These connectors enable easy installation and quick reconfiguration of lighting setups, which is crucial for seasonal promotions or branding updates. For international buyers, especially from regions like South America and Europe, ensuring compatibility with local power standards and sourcing connectors with robust build quality can minimize downtime and maintenance costs.

The hospitality and entertainment sector relies heavily on ambient and accent lighting to create immersive environments in hotels, restaurants, and theaters. 4 pin connectors facilitate the integration of RGB LED strips with sophisticated lighting controllers, enabling customizable color schemes and mood settings. Buyers from the Middle East and Africa should prioritize connectors with high IP ratings for dust and moisture resistance and certifications that align with local safety regulations to guarantee longevity and compliance.

In automotive manufacturing, 4 pin LED strip light connectors are essential for interior ambient lighting and dashboard illumination systems. These connectors must withstand heat and vibration, ensuring reliability in demanding automotive environments. International B2B buyers, particularly from regions with extreme climates like the Middle East, should focus on sourcing connectors with enhanced heat resistance and compact form factors to fit within tight vehicle spaces.

For architectural and urban design projects, 4 pin connectors enable the deployment of LED strips in façade lighting and outdoor decorative installations. The connectors must be waterproof and UV-resistant to endure harsh environmental conditions. Buyers in Europe and Africa should seek products compliant with regional standards such as CE marking or IEC certification to ensure safety and durability while enhancing the visual impact of urban spaces.

Finally, the electronics and consumer goods industry integrates 4 pin LED strip light connectors into smart home lighting systems, allowing seamless connectivity and user-friendly control via remotes or apps. Solderless connectors are preferred for ease of installation and maintenance. International buyers from Colombia, Spain, and other markets should evaluate connector compatibility with popular smart home platforms and consider cable length options to suit diverse installation scenarios.

Related Video: How to Use LED Strip Light Connectors

Strategic Material Selection Guide for 4 pin led strip light connectors

When selecting materials for 4-pin LED strip light connectors, international B2B buyers must consider the balance between electrical performance, durability, cost, and regional compliance standards. The choice of material directly influences connector reliability, ease of installation, and suitability for various environmental conditions. Below is an analysis of four common materials used in these connectors, highlighting their properties, advantages, limitations, and regional considerations.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a thermoplastic known for its high impact resistance, good electrical insulation, and moderate heat resistance (typically up to 115°C). It offers excellent dimensional stability and is resistant to many chemicals and UV radiation.

Pros & Cons:

Polycarbonate connectors are lightweight and cost-effective, making them suitable for mass production. Their transparency allows for easy visual inspection of connections. However, PC can be prone to yellowing over time when exposed to strong UV light and may become brittle under prolonged high temperatures.

Impact on Application:

PC is ideal for indoor LED strip installations where moderate heat and mechanical stress are expected. Its electrical insulation properties ensure safe operation in low-voltage lighting systems. However, it may not be suitable for outdoor or harsh industrial environments without additional protective coatings.

Regional Considerations:

In regions such as Europe (e.g., Spain) and the Middle East, compliance with RoHS and REACH regulations is critical; PC materials typically meet these standards. For African and South American markets (e.g., Colombia), buyers should verify local fire safety certifications and UV resistance due to intense sunlight exposure in some areas.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a versatile plastic with good electrical insulation, chemical resistance, and flame retardancy. It can operate at temperatures up to around 105°C and offers flexibility, which is beneficial for cable connectors.

Pros & Cons:

PVC connectors are cost-efficient and widely available. They provide good protection against moisture and dust, which is advantageous in humid or dusty environments. However, PVC is less heat resistant than some alternatives and may degrade or emit harmful fumes if exposed to high temperatures or fire.

Impact on Application:

PVC connectors are commonly used in residential and commercial LED strip lighting where flexibility and moisture resistance are necessary. They are less suited for high-temperature industrial settings but perform well in typical indoor and semi-outdoor applications.

Regional Considerations:

For buyers in South America and Africa, PVC is a popular choice due to its affordability and availability. However, buyers should ensure compliance with local environmental regulations regarding PVC disposal and recycling. European buyers often require PVC materials to meet stringent EU chemical safety standards.

Nylon (Polyamide)

Key Properties:

Nylon is a durable engineering plastic with excellent mechanical strength, abrasion resistance, and higher temperature tolerance (up to 150°C). It also exhibits good chemical resistance but can absorb moisture, which may affect dimensional stability.

Pros & Cons:

Nylon connectors offer superior durability and resistance to wear and tear, making them suitable for connectors that require frequent handling or reconfiguration. The material can withstand higher temperatures, reducing the risk of deformation. However, Nylon connectors are generally more expensive and may require more complex manufacturing processes.

Impact on Application:

Nylon is well-suited for industrial or commercial LED lighting projects where robustness and longevity are priorities. Its moisture absorption can be a drawback in very humid environments unless treated or combined with coatings.

Regional Considerations:

In Europe and the Middle East, Nylon connectors align well with high-quality and long-lasting product expectations. African and South American buyers should assess local humidity levels and consider Nylon grades with moisture resistance to ensure performance stability.

Brass (with Nickel or Tin Plating)

Key Properties:

Brass is a metal alloy known for excellent electrical conductivity, corrosion resistance, and mechanical strength. Nickel or tin plating enhances surface durability and prevents oxidation.

Pros & Cons:

Brass connectors provide superior electrical performance, ensuring minimal resistance and stable current flow, which is critical for RGB LED strips requiring precise color control. They are highly durable and resistant to corrosion, but the cost is significantly higher than plastic alternatives. Manufacturing complexity is also greater due to metalworking and plating processes.

Impact on Application:

Brass connectors are preferred in high-end or professional LED lighting applications where reliability and performance are paramount. They perform well in harsh environmental conditions, including outdoor installations, due to their corrosion resistance.

Regional Considerations:

European buyers often favor brass connectors for premium products, supported by compliance with international standards such as DIN and ASTM. Middle Eastern markets appreciate the corrosion resistance in saline or humid coastal areas. African and South American buyers should consider the higher upfront cost but benefit from the long-term durability and reduced maintenance.

Summary Table

| Material | Typical Use Case for 4 pin led strip light connectors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Indoor residential and commercial LED strip installations | High impact resistance, good insulation | UV yellowing, moderate heat resistance | Low |

| Polyvinyl Chloride (PVC) | Flexible connectors in residential and semi-outdoor settings | Cost-effective, moisture and dust resistant | Lower heat tolerance, environmental concerns | Low |

| Nylon (Polyamide) | Industrial and commercial applications requiring durability | High mechanical strength, heat resistant | Moisture absorption, higher cost | Medium |

| Brass (Nickel/Tin Plated) | Premium and outdoor LED lighting requiring stable conductivity | Excellent conductivity, corrosion resistant | Higher cost, complex manufacturing | High |

This material selection guide equips international B2B buyers with actionable insights to choose the most appropriate 4-pin LED strip light connector materials tailored to their specific regional and application needs. Understanding these material characteristics ensures optimized product performance, compliance, and cost-efficiency in diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 4 pin led strip light connectors

Manufacturing Processes for 4-Pin LED Strip Light Connectors

The production of 4-pin LED strip light connectors involves a series of well-defined stages designed to ensure precision, durability, and electrical reliability. Understanding these stages helps B2B buyers evaluate supplier capabilities and product quality effectively.

1. Material Preparation

The process begins with sourcing and preparing raw materials. Typically, connectors comprise:

- Conductive Pins: Made from high-conductivity metals such as phosphor bronze or brass, often plated with tin, nickel, or gold to enhance corrosion resistance and conductivity.

- Housing Components: Usually manufactured from engineering-grade plastics like polycarbonate (PC) or polybutylene terephthalate (PBT), selected for their heat resistance and electrical insulation properties.

- Sealing Elements: In cases of waterproof or dustproof connectors, silicone or rubber gaskets are prepared for integration.

Material inspection at this stage is critical to ensure compliance with specifications, such as metal purity and plastic flame retardancy ratings.

2. Forming and Machining

Key techniques in this stage include:

- Stamping and Cutting: Metal sheets or strips are stamped to form connector pins with precise dimensions and shapes. This high-speed process ensures consistency and repeatability.

- Injection Molding: Plastic housings are produced via injection molding, enabling complex shapes and tight tolerances necessary for secure fit and insulation.

- Plating: Pins undergo electroplating to deposit protective and conductive metal layers, improving lifespan and reducing electrical resistance.

Advanced CNC machining may also be employed for custom or high-precision components.

3. Assembly

During assembly:

- Insertion of Pins into Housings: Automated or semi-automated machinery inserts the conductive pins into the molded housings, ensuring correct alignment and secure mechanical retention.

- Soldering or Crimping: For connectors that require wire terminations, soldering or crimping is performed to attach wires or cables to pins.

- Sealing and Encapsulation: For connectors designed for harsh environments, sealing components are added, and sometimes potting compounds are applied to protect internal contacts.

Modern assembly lines employ robotic systems to enhance accuracy and throughput, reducing human error.

4. Finishing and Packaging

Final steps include:

- Cleaning: Removal of residues from manufacturing processes, such as oils or debris, to prevent contamination.

- Marking: Labels or part numbers may be laser-etched or printed for traceability.

- Packaging: Connectors are packaged in anti-static bags or protective trays to prevent damage during shipping.

Quality packaging safeguards the product integrity, especially important for international shipments.

Quality Assurance and Control (QA/QC) Framework

For international B2B buyers, robust quality control ensures that 4-pin LED strip light connectors meet performance, safety, and regulatory requirements. Suppliers typically implement multi-level QC processes aligned with international standards.

Relevant International and Industry Standards

- ISO 9001: A globally recognized quality management system standard ensuring consistent product quality and continuous improvement in manufacturing processes.

- CE Marking: Mandatory for products sold within the European Economic Area (EEA), indicating compliance with EU safety, health, and environmental protection directives.

- RoHS Compliance: Restricts the use of hazardous substances in electrical and electronic equipment, critical for European and global markets.

- UL or ETL Certification: Relevant for North American markets, indicating safety testing passed for electrical components.

- IP (Ingress Protection) Ratings: For connectors intended for outdoor or harsh environments, IP65, IP67, or higher ratings confirm resistance to dust and water.

Buyers from regions such as Africa, South America, the Middle East, and Europe should verify that suppliers provide documentation proving compliance with these standards to meet local import regulations and customer expectations.

QC Checkpoints Throughout Manufacturing

- Incoming Quality Control (IQC): Inspection of raw materials and components before entering production. This includes dimensional checks, material certifications, and visual inspections.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing, including checking pin alignment, housing integrity, and assembly accuracy. Automated optical inspection (AOI) and functional testing may be used here.

- Final Quality Control (FQC): Comprehensive testing of finished connectors, including visual inspections, electrical continuity tests, insulation resistance measurements, and mechanical durability assessments such as insertion and withdrawal force tests.

Common Testing Methods

- Electrical Testing: Verifies conductivity and resistance of pins, ensuring minimal voltage drop and reliable signal transmission.

- Mechanical Testing: Includes durability tests for connector mating cycles, tensile strength of wire terminations, and resistance to vibration or shock.

- Environmental Testing: For connectors designed for outdoor or industrial use, tests simulate exposure to humidity, temperature extremes, salt spray, and UV radiation.

- Visual and Dimensional Inspection: Confirms absence of defects such as burrs, cracks, or misalignment, and verifies adherence to design specifications.

How B2B Buyers Can Verify Supplier QC

- Supplier Audits: Conducting on-site audits to review manufacturing processes, equipment, staff qualifications, and quality management systems is a best practice for high-volume or critical orders.

- Reviewing QC Reports: Request detailed inspection and test reports for sample batches or production lots, including certificates of compliance (CoC) and test data.

- Third-Party Inspections: Engaging independent inspection agencies to perform pre-shipment inspections adds an unbiased layer of quality assurance, particularly valuable when sourcing from unfamiliar regions.

- Sample Testing: Procuring samples for in-house or third-party laboratory testing to validate electrical, mechanical, and environmental performance before large-scale purchasing.

QC and Certification Nuances for International Buyers

- Africa and South America: Importers should be mindful of local certification requirements and customs regulations. Many countries accept CE and ISO certifications but may require additional documentation or testing to clear customs.

- Middle East: Certain markets may demand compliance with Gulf Conformity Mark (G Mark) or SASO standards. Buyers should confirm that suppliers are familiar with these regional standards.

- Europe (e.g., Spain): Emphasis is placed on CE marking and RoHS compliance. Additionally, buyers should verify that suppliers maintain traceability documentation and can support product lifecycle management for warranty and liability purposes.

Understanding these nuances helps buyers avoid shipment delays, regulatory penalties, and costly returns.

Summary for B2B Buyers:

Evaluating a 4-pin LED strip light connector supplier requires a thorough understanding of their manufacturing processes and quality assurance protocols. Prioritize suppliers with transparent QC systems aligned with international standards like ISO 9001 and CE marking. Insist on detailed testing documentation and consider third-party inspections to mitigate risks. For buyers across Africa, South America, the Middle East, and Europe, ensuring compliance with both international and local standards is essential for seamless procurement and sustained business success.

Related Video: Inside LEDYi LED Strip Factory | Full Manufacturing Process by Leading LED Strip Manufacturer

Comprehensive Cost and Pricing Analysis for 4 pin led strip light connectors Sourcing

Understanding the cost and pricing structure of 4-pin LED strip light connectors is crucial for international B2B buyers aiming to optimize procurement strategies and total cost of ownership. This analysis breaks down key cost components, price influencers, and actionable buyer tips to navigate the global sourcing landscape effectively, with a focus on markets in Africa, South America, the Middle East, and Europe.

Key Cost Components in 4-Pin LED Strip Light Connectors

-

Materials:

The primary raw materials include plastic housing, copper pins, and sometimes gold or nickel plating for corrosion resistance and conductivity. Material quality significantly affects both performance and price, especially when certifications like RoHS or CE compliance are required. -

Labor:

Labor costs depend on the manufacturing location and complexity of assembly. Solderless connectors may reduce labor intensity compared to soldered types but still require precision in clipping mechanisms and quality checks. -

Manufacturing Overhead:

This covers factory utilities, equipment depreciation, and indirect labor. Efficient production lines and automation can lower overhead costs, impacting the final price. -

Tooling and Equipment:

Injection molding tools for plastic components and stamping dies for metal pins represent upfront capital expenditures. Higher tooling costs are amortized over production volume, affecting unit costs especially for small order quantities. -

Quality Control (QC):

Rigorous testing for electrical continuity, durability, and safety standards adds to cost but ensures product reliability, a critical factor for professional applications. -

Logistics and Shipping:

Freight costs vary widely depending on origin (e.g., China, Vietnam) and destination (e.g., Colombia, Spain). Customs duties, taxes, and import regulations also add to landed costs. -

Supplier Margin:

Margins reflect supplier positioning, brand reputation, and market demand. Premium brands or certified suppliers may command higher prices but offer greater assurance of quality.

Price Influencers for International Buyers

-

Order Volume and Minimum Order Quantity (MOQ):

Larger orders typically secure volume discounts. For buyers in emerging markets, negotiating MOQ flexibility can balance upfront investment and inventory risk. -

Specifications and Customization:

Customized pin configurations, enhanced waterproofing, or reinforced connectors increase production complexity and cost. Standardized products are usually more cost-effective. -

Material Grade and Certifications:

Higher-grade materials or compliance with international standards (e.g., CE for Europe) influence price but reduce long-term risks like product failure or regulatory non-compliance. -

Supplier Location and Reliability:

Sourcing from countries with established electronics manufacturing infrastructure generally lowers costs. However, suppliers with proven track records, certifications, and responsive communication provide added value. -

Incoterms and Payment Terms:

Understanding shipping terms (FOB, CIF, DDP) is vital as they define the cost and risk distribution. Buyers from Africa or South America should consider DDP to avoid unexpected customs delays and charges.

Practical Buyer Tips for Cost-Efficient Sourcing

-

Negotiate Beyond Price:

Engage suppliers on payment terms, lead times, and after-sales support. Sometimes, a slightly higher unit price with favorable terms reduces total procurement risk. -

Calculate Total Cost of Ownership (TCO):

Consider logistics, customs duties, potential quality failures, and warranty claims alongside unit price. For example, higher upfront cost for certified connectors might save costs on rework or replacements. -

Leverage Local Distributors vs. Direct Sourcing:

In regions like the Middle East or Europe, local distributors might offer faster delivery and easier returns, though at a higher price premium. Assess trade-offs based on project timelines and budget. -

Verify Supplier Credentials and Samples:

Request product samples and certifications before bulk purchase. This is particularly important for buyers in Africa and South America where product authenticity and compliance are critical to avoid market entry issues. -

Be Aware of Pricing Fluctuations:

Raw material price volatility (e.g., copper) can affect connector costs. Locking in prices via contracts or bulk orders can mitigate risks.

Indicative Pricing Disclaimer

Prices for 4-pin LED strip light connectors vary widely based on specifications, order volume, and sourcing region. Typical FOB prices from Asian manufacturers can range from $0.10 to $0.50 per piece, excluding shipping and duties. Buyers should conduct market-specific inquiries and factor in all ancillary costs for accurate budgeting.

By understanding these cost drivers and market dynamics, international B2B buyers—whether in Colombia, Spain, or beyond—can make informed decisions to secure quality 4-pin LED strip light connectors at competitive prices while minimizing risks and ensuring timely delivery.

Spotlight on Potential 4 pin led strip light connectors Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘4 pin led strip light connectors’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 4 pin led strip light connectors

Critical Technical Properties of 4-Pin LED Strip Light Connectors

When sourcing 4-pin LED strip light connectors for international B2B projects, understanding key technical specifications is essential to ensure compatibility, durability, and performance. Here are the most important properties to evaluate:

-

Material Grade

Connectors are typically made from high-grade plastics such as polycarbonate or ABS for housing, combined with copper or phosphor bronze pins with a nickel or gold plating. High-quality materials ensure corrosion resistance, electrical conductivity, and mechanical strength, which are critical for long-term reliability, especially in humid or outdoor environments common in Africa, South America, and the Middle East. -

Pin Configuration and Pitch

The standard 4-pin connector aligns with RGB + Common (ground or voltage). The pin pitch—the distance between pins, often 2.54mm or 10mm—must match the LED strip’s solder pads precisely. Mismatched pitch can lead to poor electrical contact or damage during installation, affecting lighting consistency and requiring costly rework. -

Current and Voltage Ratings

Connectors must support the operating voltage (commonly 12V or 24V DC) and the current load of the LED strips. Overloading connectors can cause overheating or failure. For B2B buyers, specifying connectors rated for at least 2-3A per pin provides a safety margin suitable for commercial or architectural lighting projects. -

Tolerance and Fit

Manufacturing tolerance affects connector fit and sealing. Tight tolerances ensure secure, solderless connections that prevent signal loss or disconnection due to vibration or movement. For international buyers, requesting connectors with tolerance specifications under ±0.1mm helps guarantee consistent quality across production batches. -

Ingress Protection (IP) Rating

For outdoor or industrial applications, connectors with IP65 or higher rating protect against dust and water ingress. This property is vital for markets with harsh climates, such as the Middle East or coastal regions in South America, ensuring durability and reducing maintenance costs. -

Solderless vs. Soldered Design

Solderless connectors facilitate faster installation without specialized tools, ideal for large projects or locations with limited technical skills. Soldered connectors provide a more permanent and vibration-resistant connection, preferred in high-end or industrial setups. Understanding this distinction helps buyers balance installation speed with long-term reliability.

Essential Trade Terminology for International B2B Buyers

Navigating international procurement requires familiarity with common trade and industry terms. Here are key terms every buyer should know when dealing with 4-pin LED strip light connectors:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or products that other companies rebrand and sell. Buyers seeking custom branding or specifications often negotiate OEM agreements to tailor connectors to their needs while leveraging the manufacturer’s production capabilities. -

MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in one order. MOQs vary widely—from hundreds to thousands of pieces—and impact inventory planning and pricing. Buyers from emerging markets should clarify MOQ upfront to balance cost-effectiveness with storage capacity. -

RFQ (Request for Quotation)

A formal inquiry sent by buyers to suppliers asking for detailed pricing, lead times, and terms based on specific product requirements. Crafting precise RFQs with technical specs ensures accurate quotes and reduces negotiation cycles, critical for managing cross-border procurement timelines. -

Incoterms (International Commercial Terms)

Standardized trade terms defining the responsibilities of buyers and sellers regarding shipping, insurance, and customs clearance. Common terms include FOB (Free on Board), CIF (Cost, Insurance, and Freight), and DDP (Delivered Duty Paid). Understanding Incoterms helps buyers from Africa, Europe, and South America plan logistics and total landed costs. -

Lead Time

The period between placing an order and receiving the goods. For LED lighting projects with tight schedules, shorter lead times are advantageous but may come at a premium. Buyers should negotiate lead times based on project urgency and supplier capacity. -

Batch Consistency

The uniformity of product quality across production runs. Consistent batches minimize compatibility issues and installation delays, especially important for large-scale or phased lighting projects spanning multiple countries or regions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, negotiate better terms, and ensure the successful deployment of 4-pin LED strip light connectors tailored to diverse market needs.

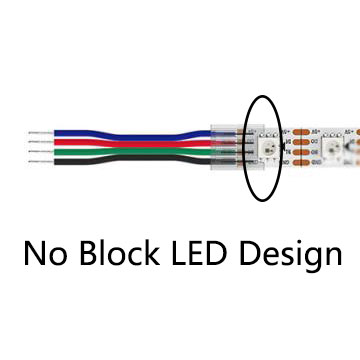

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 4 pin led strip light connectors Sector

Market Overview & Key Trends

The global market for 4-pin LED strip light connectors is experiencing robust growth, driven by the expanding adoption of LED lighting solutions across commercial, industrial, and residential sectors. International B2B buyers, particularly in emerging regions such as Africa, South America, the Middle East, and established markets in Europe (e.g., Spain), are increasingly investing in advanced lighting systems that prioritize energy efficiency, customization, and ease of installation. The 4-pin connectors are crucial for RGB LED strips, enabling dynamic color control and seamless integration with smart lighting systems, which is a key selling point in markets focused on modern, flexible lighting solutions.

Key market drivers include:

- Rising Demand for Smart Lighting: Integration with IoT and home automation platforms is accelerating, pushing manufacturers to innovate connector designs for better compatibility and durability.

- Customization and Modularity: Buyers prioritize connectors that support solderless installation and modular setups, reducing labor costs and installation complexity.

- Supply Chain Localization: Buyers in Africa, South America, and the Middle East increasingly seek suppliers capable of local distribution or regional warehouses to reduce lead times and tariffs.

- Competitive Pricing with Quality Assurance: While cost remains a significant factor, there is a growing emphasis on sourcing connectors that balance affordability with high-quality materials and reliability, especially for large-scale commercial projects.

Emerging trends include the adoption of connectors designed for higher IP ratings to support outdoor and harsh environment applications, and increased interest in connectors compatible with higher voltage and wattage LED strips for industrial lighting. European buyers, including those in Spain, often demand compliance with regional standards and certifications, emphasizing safety and interoperability.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the procurement of 4-pin LED strip light connectors. International buyers are increasingly aware of the environmental impact associated with electronic components, including raw material extraction, manufacturing processes, and end-of-life disposal. Ethical sourcing practices and green certifications are now essential criteria for many companies aiming to align their supply chains with global sustainability goals.

Environmental Impact Considerations:

- Material Selection: Connectors made with recyclable plastics, lead-free solder, and RoHS-compliant metals reduce hazardous waste and toxic emissions.

- Energy-Efficient Manufacturing: Suppliers who utilize renewable energy sources and minimize waste during production are preferred partners.

- Longevity and Reusability: Durable connectors that extend the lifespan of LED lighting installations reduce the frequency of replacement and electronic waste.

Ethical Supply Chain Importance:

- Buyers from regions such as Africa and South America are increasingly scrutinizing suppliers for labor practices, ensuring no exploitation occurs within the manufacturing chain.

- Certifications such as ISO 14001 (Environmental Management), RoHS (Restriction of Hazardous Substances), and WEEE (Waste Electrical and Electronic Equipment Directive) provide assurance of compliance with environmental and ethical standards.

- Transparent supplier audits and traceability in the supply chain help mitigate risks related to conflict minerals and unethical labor.

For B2B buyers, incorporating sustainability criteria not only enhances corporate social responsibility profiles but can also unlock preferential terms with governments and large multinational clients that mandate green procurement.

Brief Evolution of 4-Pin LED Strip Light Connectors

The evolution of 4-pin LED strip light connectors parallels the rapid advancement of LED lighting technology itself. Initially, LED strips required manual soldering for connections, limiting scalability and increasing installation complexity. The introduction of solderless 4-pin connectors revolutionized the sector by enabling quick, reliable, and tool-free connections, which significantly reduced labor costs and installation errors.

Over time, these connectors have evolved to incorporate improved materials for enhanced durability, better sealing for outdoor use, and smart integration capabilities to support RGB control and IoT connectivity. This evolution has made 4-pin connectors indispensable in modern lighting projects, from simple decorative lighting to complex architectural and industrial applications, meeting the growing demand for flexible, efficient, and smart lighting solutions worldwide.

In summary, international B2B buyers targeting the 4-pin LED strip light connector market must navigate a landscape shaped by technological innovation, regional supply chain dynamics, and increasing sustainability expectations. Understanding these factors enables strategic sourcing that balances cost, quality, compliance, and environmental stewardship—key drivers for success in this competitive and evolving sector.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of 4 pin led strip light connectors

-

How can I effectively vet suppliers of 4 pin LED strip light connectors to ensure quality and reliability?

To vet suppliers, request detailed product specifications, certifications (e.g., CE, RoHS), and sample connectors for testing. Evaluate their manufacturing capabilities, quality control processes, and customer references, especially from your region. Verify their compliance with international standards and assess responsiveness and transparency in communication. Consider visiting factories or using third-party inspection services to confirm production capacity and quality. Prioritize suppliers with proven export experience to regions like Africa, South America, the Middle East, and Europe to mitigate risks associated with logistics and regulatory compliance. -

What customization options are typically available for 4 pin LED strip light connectors, and how should I approach this with suppliers?

Common customizations include connector size, pin configuration, cable length, waterproof ratings, and branding. When approaching suppliers, clearly specify your technical requirements, application environment, and compliance needs. Request prototypes or samples for evaluation before bulk orders. Discuss minimum order quantities (MOQs) and lead times associated with custom products, as these may differ from standard items. Collaborate closely with suppliers to ensure that customized connectors meet your target markets’ electrical and safety standards, enhancing product differentiation and customer satisfaction. -

What are typical MOQs and lead times for 4 pin LED strip light connectors, and how can these impact my supply chain planning?

MOQs vary widely, often ranging from a few hundred to several thousand units depending on customization and supplier scale. Lead times generally span 2 to 6 weeks, influenced by order complexity and factory workload. For international buyers, factor in additional time for shipping, customs clearance, and potential delays. To optimize your supply chain, communicate your demand forecasts clearly and negotiate flexible MOQs or batch deliveries where possible. Establishing a buffer stock is advisable to prevent disruptions, especially when serving markets with fluctuating demand such as those in Africa and South America. -

Which quality assurance certifications should I look for when purchasing 4 pin LED strip light connectors for international markets?

Key certifications include CE (European conformity), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and ISO 9001 (quality management). These attest to product safety, environmental compliance, and consistent manufacturing quality. In markets like Europe and the Middle East, CE and RoHS compliance is often mandatory. Confirm that your supplier provides up-to-date certification documents and third-party testing reports. Such certifications not only facilitate customs clearance but also build trust with your customers by ensuring product reliability and safety. -

What logistical considerations should I be aware of when importing 4 pin LED strip light connectors from overseas suppliers?

Consider factors like shipping method (air vs. sea), customs regulations, import duties, and local compliance requirements. Choose suppliers experienced in handling international shipments and capable of providing necessary documentation (e.g., commercial invoice, packing list, certificate of origin). For regions like Africa and South America, customs clearance can be complex, so partnering with reliable freight forwarders or customs brokers is crucial. Additionally, evaluate packaging robustness to prevent damage during transit. Efficient logistics planning reduces lead times and helps maintain a steady supply to your customers. -

How should I manage payment terms and mitigate financial risks when sourcing 4 pin LED strip light connectors internationally?

Negotiating balanced payment terms is vital; common options include a 30% deposit upfront and 70% upon shipment or after inspection. Use secure payment methods such as letters of credit or escrow services to protect both parties. Establish clear contractual agreements detailing product specifications, delivery schedules, and penalties for non-compliance. For new suppliers, consider smaller initial orders to build trust. Conduct due diligence on supplier financial stability and reputation. Maintaining open communication and transparency helps prevent disputes and fosters long-term partnerships. -

What common disputes arise in international B2B transactions for 4 pin LED strip light connectors, and how can I proactively avoid them?

Typical disputes involve product quality discrepancies, delayed deliveries, and miscommunication regarding specifications. To avoid these, ensure detailed purchase agreements with clear technical drawings, quality standards, and delivery timelines. Implement pre-shipment inspections or third-party quality checks. Maintain consistent communication throughout the order process to promptly address any issues. If disputes occur, attempt resolution through negotiation or mediation before escalating to legal channels. Building strong relationships with suppliers and having well-documented contracts significantly reduces conflict risks. -

How can I ensure compliance with regional regulations when importing 4 pin LED strip light connectors into markets like Colombia, Spain, or the Middle East?

Research specific electrical and safety standards applicable in each target market, such as UNE standards in Spain or SASO in Saudi Arabia. Verify that your supplier’s products meet these regulations and have appropriate certifications. Work with local agents or consultants knowledgeable about import requirements and labeling laws. Additionally, confirm that packaging and documentation comply with local languages and customs mandates. Staying informed about regulatory updates and engaging with local industry associations can facilitate smoother market entry and reduce the risk of customs rejections or penalties.

Strategic Sourcing Conclusion and Outlook for 4 pin led strip light connectors

Strategic Sourcing Insights and Future Perspectives for 4-Pin LED Strip Light Connectors

For international B2B buyers in Africa, South America, the Middle East, and Europe, strategically sourcing 4-pin LED strip light connectors is critical to ensuring reliable, scalable, and cost-effective lighting solutions. Prioritizing compatibility with specific LED strip types, material quality, and connector durability directly influences system performance and reduces costly downtime or returns. Additionally, selecting suppliers who offer flexible packaging options and technical support can streamline procurement and installation workflows, especially for large-scale or customized projects.

Illustrative Image (Source: Google Search)

Understanding regional market dynamics—such as voltage standards, climate resilience needs, and supply chain constraints—empowers buyers to make informed sourcing decisions that align with local infrastructure and consumer expectations. Leveraging suppliers with proven expertise and certifications can also mitigate risks associated with counterfeit or substandard components.

Looking ahead, the 4-pin LED connector market is evolving with trends toward enhanced smart integration, improved solderless designs, and sustainable manufacturing practices. Buyers are encouraged to engage with forward-thinking manufacturers and monitor innovation pipelines to future-proof their lighting offerings.

Actionable takeaway: Build strategic partnerships with reputable connector suppliers who demonstrate adaptability and commitment to quality. This approach will not only optimize current projects but also position your business competitively as LED lighting technologies continue to advance globally.