Article Contents

Industry Insight: Ws2812 Led Strip

The WS2812 LED strip has emerged as a transformative solution in commercial and industrial lighting, offering dynamic color control, high energy efficiency, and precise addressability for large-scale architectural, signage, and facility lighting applications. Its integrated driver IC allows each LED to be individually programmed, enabling complex lighting effects, synchronized displays, and smart lighting systems ideal for retail environments, warehouses, transportation hubs, and exterior façades. As demand grows for intelligent and adaptive lighting solutions, compliance with international safety and performance standards has become critical. Leading WS2812 LED strips are now routinely certified to ETL and CE standards, ensuring electrical safety, electromagnetic compatibility, and reliability under rigorous operating conditions—key requirements for industrial deployments in North America and Europe.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting technology since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a premier manufacturer of high-performance LED strips, specializing in addressable and programmable solutions for commercial and industrial use. The company combines cutting-edge R&D, stringent quality control, and global compliance to deliver WS2812 LED strips that meet the demanding needs of system integrators, lighting designers, and facility managers worldwide. Backed by ETL and CE certifications, Beauty STC’s products exemplify safety, durability, and advanced functionality, reinforcing its commitment to excellence in smart lighting innovation.

Technical Specs & Certifications

The WS2812 refers specifically to the integrated circuit chip (IC) and embedded light-emitting diode (LED) package commonly used in digital addressable RGB LED strips. It is critical to understand that lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings are characteristics of the final manufactured LED strip product, not the WS2812 chip alone. These metrics depend heavily on the manufacturer’s design choices, component quality, and assembly processes. Beauty (STC) Manufacturing Co., Ltd. adheres to stringent engineering standards to deliver superior performance within the inherent constraints of the WS2812 platform.

Lumens per Watt (lm/W) for WS2812-based strips is inherently limited due to the fundamental nature of RGB color mixing. Standard WS2812 strips utilize only red, green, and blue LEDs; they do not contain a dedicated white LED. Generating white light requires mixing these three colors, which is significantly less efficient than using a dedicated white phosphor-converted LED. Consequently, the typical luminous efficacy for full-spectrum white light output on a standard WS2812 RGB strip ranges between 30 lm/W and 40 lm/W under standard operating conditions (e.g., 5V, 20mA per channel). This is substantially lower than high-efficiency single-color white LED strips, which can exceed 150 lm/W. Efficacy varies based on the specific white point targeted (e.g., 6500K is usually slightly more efficient than 2700K via RGB mix), drive current, LED binning, and thermal management. Beauty STC optimizes lm/W by utilizing tightly binned WS2812B-S or WS2812B-V chips, implementing precise constant-current drive circuits within the strip design, and employing high-conductivity copper traces (typically 2oz copper) to minimize resistive losses and maintain stable performance, ensuring our strips consistently achieve the upper end of the typical efficacy range for this technology.

Color Rendering Index (CRI) is not a meaningful specification for standard RGB WS2812 strips. CRI measures how accurately a light source renders colors compared to a natural reference source, but it is defined and relevant only for white light. Since a standard WS2812 strip produces white light by mixing red, green, and blue primaries, the resulting spectrum has significant gaps, particularly in the cyan and amber regions. This leads to very poor color rendering, with a calculated CRI (Ra) often below 60 for mixed white. Achieving a CRI >90 is fundamentally impossible with a standard three-channel RGB WS2812 strip due to the lack of spectral continuity. Beauty STC addresses high-CRI requirements for applications needing accurate color representation by offering specialized RGBW or RGBA strips. These incorporate a dedicated high-CRI (typically >90, often >95) white LED channel alongside the RGB channels, allowing true high-quality white light output while retaining addressable color capabilities. For pure WS2812 RGB strips, Beauty STC focuses on maximizing color consistency and stability through rigorous LED binning and calibrated driver ICs, but CRI remains an inapplicable metric.

Ingress Protection (IP) ratings define the strip’s resistance to dust and moisture ingress. The IP rating is determined by the strip’s physical construction and sealing, not the WS2812 chip itself. Common IP ratings for WS2812 strips include IP20 (basic indoor use, no protection), IP65 (protected against low-pressure water jets and dust, achieved with a silicone coating or jacket), IP67 (protected against temporary immersion), and IP68 (protected against continuous immersion, typically requiring a robust silicone extrusion). Beauty STC manufactures WS2812 strips to various IP ratings based on customer requirements. Our IP65 strips utilize a precision-applied, optically clear silicone conformal coating that protects against splashes and dust without significantly diffusing light. For IP67 and IP68, we employ high-purity, flexible silicone extrusion processes ensuring a seamless, durable barrier around the entire PCB assembly. All sealed strips undergo rigorous post-production testing, including submersion tests for IP68 units, to guarantee long-term environmental resilience in demanding installations.

Beauty STC distinguishes itself through uncompromising quality control in WS2812 strip manufacturing. We source only top-bin WS2812B-S or WS2812B-V chips from verified suppliers, ensuring consistent color point and performance. Our strips feature 2oz copper PCBs for superior current handling and thermal dissipation, reducing lumen depreciation and color shift over time. The soldering process utilizes lead-free SAC305 alloy with automated optical inspection (AOI) to eliminate cold joints or micro-cracks. For sealed strips, we apply medical-grade silicones with UV stabilizers to prevent yellowing. Every reel undergoes 100% functional testing, including signal integrity checks at maximum data rates (800kHz), voltage drop verification, and visual inspection under high-intensity lighting. This commitment to precision engineering and rigorous validation ensures Beauty STC WS2812 strips deliver exceptional reliability, stable color output, and extended operational life, meeting the demanding standards expected in professional architectural, entertainment, and high-end commercial lighting applications. For applications requiring high-CRI white light, our RGBW variants with dedicated >90 CRI white LEDs provide the necessary solution while leveraging the addressability of the WS2812 platform.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern LED lighting production facility strategically located in the Guangdong province, known for its strong manufacturing ecosystem and supply chain efficiency. The Jiangmen facility is equipped with advanced surface mount technology (SMT) production lines that support high-precision assembly of LED components, including the popular ws2812 LED strip. These SMT machines are fully automated, featuring high-speed pick-and-place units, precision stencil printers, reflow ovens, and automated optical inspection (AOI) systems. This ensures consistent soldering quality, component alignment, and overall product reliability.

For quality assurance, the factory conducts comprehensive aging tests on all ws2812 LED strips. Finished products undergo extended burn-in periods—typically 24 to 72 hours—under controlled thermal and electrical conditions to identify early failures and verify long-term performance. These aging tests are conducted in dedicated environmental chambers that simulate real-world operating scenarios, helping to ensure that only stable, durable products reach customers.

Beauty STC has strong OEM capabilities and actively supports custom manufacturing for ws2812 LED strips. The company can customize parameters such as strip length, density of LEDs per meter (e.g., 30, 60, or 144 LEDs/m), input voltage (5V or 12V), color options (RGB, RGBW), waterproof ratings (IP20, IP65, IP67), and flexible PCB configurations. Additionally, they offer custom packaging, private labeling, and tailored control protocols to meet specific client requirements. Their engineering team works closely with clients to provide design support, prototyping, and compliance testing, ensuring that OEM products meet international standards including CE, RoHS, and UL.

Overall, the Jiangmen factory combines automation, rigorous quality control, and flexible manufacturing to deliver high-performance, reliable ws2812 LED strips for a wide range of commercial, residential, and industrial applications.

Application Scenarios

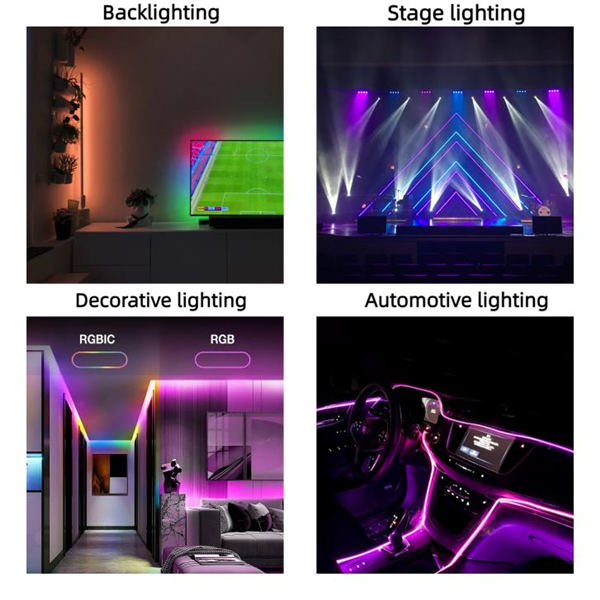

WS2812 LED strips offer dynamic RGB color control and addressability, making them suitable for specific high-impact applications in commercial environments where visual engagement is prioritized. However, their use requires careful consideration of functionality, maintenance, and user experience in professional settings like hotels, malls, and offices.

In hotels, WS2812 strips are best deployed in high-traffic public areas designed for guest experience rather than functional lighting. The lobby ceiling coves or feature walls can utilize these strips for dynamic color-changing effects during evening hours to create a welcoming ambiance, particularly near reception or lounge zones. Bars and restaurants benefit from under-bar counter lighting or backlighting for shelving, where programmable colors enhance the atmosphere for social settings. Avoid guest rooms entirely due to potential sleep disruption from bright colors and the impracticality of maintenance access in occupied spaces. Always prioritize warm white or dimmable neutral tones for general illumination, reserving RGB effects for designated accent zones.

For malls, focus on transient high-visibility zones where attention-grabbing displays drive engagement. Escalator undersides, central atrium columns, or tunnel entrances between wings are ideal for creating immersive pathways with motion-synchronized color flows. Food courts can integrate subtle under-counter lighting in vendor stalls for brand identity, though ensure IP67-rated strips are used near food preparation areas to withstand cleaning. Retail storefronts often use these strips in window displays for animated promotions, but confirm landlord approval as temporary installations may require permits. Avoid corridors or general walkways where constant color changes could cause visual fatigue or distraction for shoppers.

Offices present the most restrictive use case due to productivity and well-being concerns. WS2812 strips should only be considered in non-work areas like reception feature walls, executive lounge accents, or break room ceilings for limited evening events. Never install them in open-plan workspaces, meeting rooms, or near workstations—flickering or vibrant colors can trigger headaches and reduce concentration. If used in executive areas, implement strict scheduling to default to static warm white during business hours, with RGB modes accessible only via controlled events. The primary lighting in offices must remain stable, glare-free, and CCT-tunable white for task performance.

Installation demands meticulous planning to avoid failures. Calculate power requirements precisely: WS2812B strips draw up to 60W per 5-meter reel at full brightness, necessitating power injection every 5 meters for runs exceeding 2 meters to prevent voltage drop and color shift. Use 18AWG silicone-jacketed cables for main feeds and secure all connections with waterproof heat-shrink tubing, especially in high-humidity zones like mall food courts. Conceal controllers in lockable, ventilated enclosures near power sources—never within ceiling voids where heat buildup risks fire hazards. Always pair strips with opal silicone diffusers (minimum 20mm width) to eliminate pixelation and create uniform glow; bare strips appear cheap in premium commercial settings. Crucially, integrate with a commercial-grade DMX or Art-Net controller managed by facility staff, avoiding consumer-grade solutions that lack reliability for 24/7 operation. Finally, verify all installations comply with local electrical codes and include emergency lighting overrides where required by fire safety regulations.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with high-quality WS2812 LED strips designed for vibrant performance and reliability. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our WS2812 strips offer seamless color control, durable construction, and excellent compatibility for a wide range of applications.

To learn more or start a collaboration, contact our sales manager at [email protected]. Let Beauty STC power your next lighting innovation with precision-engineered LED technology.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.