Article Contents

Industry Insight: Ws2811B Led Strip

The WS2811B LED strip has rapidly evolved from a niche addressable lighting solution into a critical workhorse for commercial and industrial lighting applications, where precise control, reliability, and scalability are non-negotiable. Unlike basic RGB strips, the WS2811B’s integrated constant-current driver IC per pixel ensures consistent color and brightness across long runs, eliminating the voltage drop and flicker that plague simpler designs in demanding environments like retail displays, architectural cove lighting, factory floor signage, and dynamic facade installations. Its 12V operation simplifies power distribution compared to 5V alternatives, reducing infrastructure costs for large-scale deployments, while the single-wire communication protocol minimizes cabling complexity and installation time—key factors for contractors managing tight project timelines and budgets. Crucially, for any specification in professional settings, compliance with rigorous safety standards is mandatory, making ETL certification for the North American market and CE marking for Europe essential baseline requirements, not optional extras, ensuring electrical safety, reducing liability risks, and guaranteeing compatibility with local building codes.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of translating such advanced LED technologies into robust, field-proven commercial and industrial solutions. With over 25 years of dedicated engineering and manufacturing expertise, we understand that real-world performance in warehouses, shopping centers, and outdoor installations demands more than just datasheet specifications. Our WS2811B strips are engineered with industrial-grade components, enhanced thermal management, and rigorous in-house testing protocols that go beyond basic ETL/CE compliance, delivering the sustained lumen maintenance, color stability, and operational longevity that facility managers and lighting specifiers require for trouble-free 24/7 operation. We bridge the gap between innovative chipset capabilities and the harsh realities of commercial environments, providing not just a product, but a reliable lighting system backed by decades of application knowledge and unwavering commitment to quality.

Technical Specs & Certifications

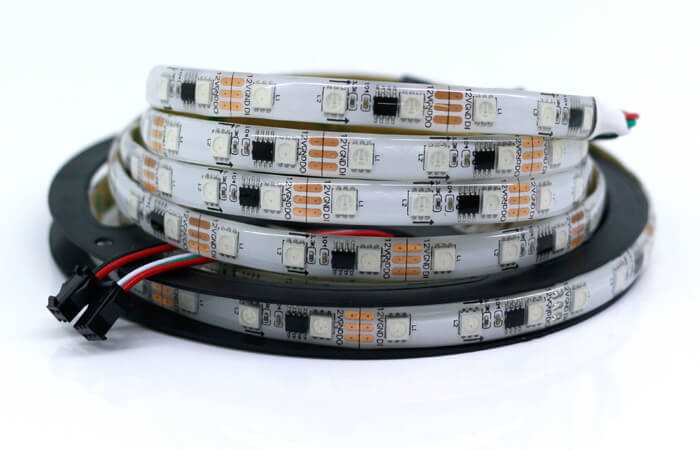

The WS2811B LED strip is a digitally addressable RGB LED strip that utilizes the WS2811B integrated control chip, offering precise color control and consistent performance across each LED node. While the WS2811B itself refers primarily to the driver IC, the complete LED strip assembly combines this IC with RGB light-emitting diodes on a flexible printed circuit board.

In terms of luminous efficacy, typical WS2811B LED strips produce approximately 18 to 22 lumens per watt, depending on the binning of the LEDs and the drive current used. This efficiency is standard for 5050-sized RGB LEDs commonly used in such configurations. However, it’s important to note that these strips are primarily designed for dynamic color effects and decorative lighting rather than high-lumen output or energy-efficient white light applications.

Regarding Color Rendering Index (CRI), standard WS2811B strips utilize RGB (red, green, blue) LEDs which inherently produce light through color mixing rather than broad-spectrum emission. As such, they do not have a CRI in the traditional sense when operating in full-color mode. When displaying white light by mixing RGB outputs, the resulting white is often cool and lacks spectral continuity, typically yielding an effective CRI below 70, which is significantly below the CRI >90 requirement. Therefore, the WS2811B strip is not suitable for applications requiring high color fidelity.

For applications demanding both addressability and high CRI, alternative solutions such as RGBW strips with a dedicated warm white LED (e.g., 2835 or 5050 with CRI 90+ white diodes) may be considered, though these typically use different driver ICs or configurations.

As for Ingress Protection (IP) ratings, the WS2811B LED strip is available in multiple variants depending on the level of environmental protection. Common configurations include:

IP20 – Uncoated or bare strip, suitable for indoor, dry environments with no exposure to moisture or dust.

IP65 – Silicone-coated strip offering protection against dust and low-pressure water jets. Ideal for outdoor use in covered areas or damp indoor environments.

IP67 – Fully encapsulated in a silicone sleeve, capable of temporary submersion in water up to 1 meter for 30 minutes. Suitable for harsh outdoor environments or installations exposed to moisture.

IP68 – Similar to IP67 but rated for continuous submersion under deeper water, depending on the manufacturer’s specifications.

At Beauty (STC) Manufacturing Co., Ltd., our WS2811B LED strips are engineered to meet stringent quality standards. We use high-grade PCB materials with excellent thermal conductivity, consistent LED binning for uniform color output, and robust silicone encapsulation for higher IP-rated versions. Our production process includes rigorous aging tests, waterproof integrity checks, and signal stability validation to ensure long-term reliability and performance. Components are sourced from trusted suppliers, and all strips undergo 100% functional testing before shipment. Beauty STC’s commitment to quality ensures stable data transmission, reduced pixel failure rates, and extended operational life—making our WS2811B LED strips a reliable choice for both commercial displays and demanding architectural installations.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern manufacturing facility in Jiangmen, China, serving as a core production hub for our LED lighting solutions. This factory is strategically equipped to handle high-volume, precision manufacturing with a strong emphasis on quality control and technical flexibility, particularly for complex products like addressable LED strips.

The surface mount technology (SMT) production line within the Jiangmen facility utilizes state-of-the-art automated machinery. We deploy high-speed, high-precision Yamaha and Siemens SMT placement systems capable of handling the fine-pitch components critical for WS2811B ICs and miniature LEDs. These machines operate with placement accuracy down to ±25 micrometers and achieve significant throughput, ensuring efficient production of dense LED strip assemblies. The line includes automated solder paste printing with laser alignment, multi-zone reflow ovens with precise thermal profiling, and automated optical inspection (AOI) stations immediately post-reflow to verify component placement, solder joint integrity, and detect any defects before the strips proceed to further assembly stages. This robust SMT capability is fundamental to producing the reliable, high-density WS2811B strips our customers require.

Quality assurance is rigorously enforced through comprehensive aging and burn-in testing protocols. Every batch of WS2811B LED strips undergoes mandatory aging tests under controlled thermal and electrical conditions. Strips are operated at or above their rated voltage and current for extended periods, typically ranging from 24 to 72 hours, within dedicated environmental chambers. These chambers maintain stable temperatures while monitoring each strip’s performance in real-time. We actively check for pixel failures, color consistency shifts, voltage drop issues, and overall stability throughout the aging cycle. Any strip exhibiting instability, flickering, or dead pixels during this critical phase is automatically rejected, ensuring only units demonstrating proven reliability reach our customers. This step is non-negotiable in our process for WS2811B products due to the complexity of the integrated control ICs.

Beauty STC possesses extensive OEM capabilities specifically tailored for the WS2811B LED strip and similar addressable products. We offer full customization starting from the ground up. This includes designing and manufacturing custom PCB layouts optimized for specific voltage requirements, pixel density, and physical dimensions requested by the client. We source and integrate the WS2811B ICs along with the chosen LED types, such as specific SMD 5050 or 2216 packages, in the required colors or white light temperatures. Our engineering team collaborates closely with clients to modify control protocols if needed, adjust power input configurations, incorporate custom connectors, and apply specialized coatings like IP65 or IP67 silicone encapsulation. We manage all aspects of the supply chain for components, handle the entire manufacturing process from SMT assembly through aging and final QC, and provide flexible packaging solutions branded to the client’s specifications. Our Jiangmen factory’s integration of SMT precision, stringent aging validation, and deep technical expertise in addressable LED technology makes us a reliable partner for demanding WS2811B OEM projects.

Application Scenarios

The WS2811B LED strip is a digitally addressable RGB LED strip that offers individual control over each LED, making it ideal for dynamic lighting effects, color-changing displays, and architectural accent lighting. While its application depends on design intent and environmental conditions, it is particularly well-suited for decorative and ambient lighting in commercial environments such as hotels, malls, and certain office spaces.

In hotels, the WS2811B LED strip is commonly used to enhance guest experiences through mood lighting in lobbies, hallways, and above ceilings or coves. It is effective for backlighting headboards, under-bar counters, and along stair edges for both safety and visual appeal. The ability to program color transitions and animations adds a modern, luxurious feel to high-end accommodations.

Malls benefit from the versatility of WS2811B strips in signage illumination, display window highlights, and feature walls. The strips can be used to draw attention to promotions or create immersive environments in entertainment zones and food courts. Their programmability allows for synchronized lighting shows during holidays or events, enhancing customer engagement.

In office environments, use is more limited and should be carefully considered. While general office workspaces typically require consistent, neutral lighting, the WS2811B can be used in reception areas, conference room accents, or breakout zones to add brand-aligned color accents or support wellness-focused lighting schemes. However, it should not replace task lighting and is best reserved for decorative applications.

When installing WS2811B LED strips, proper planning and execution are essential for optimal performance and longevity. Always ensure the power supply matches the voltage and current requirements of the strip—most WS2811B strips operate at 12V or 24V DC. Calculate total power draw based on strip length and LED density to avoid overloading the power source.

Install the strip in a clean, dry environment. While some versions are available with silicone coating for moisture resistance, they are generally not suitable for outdoor or high-humidity areas unless properly protected. Use aluminum channels with diffusers to protect the strip, improve heat dissipation, and provide a smooth, even light output.

Secure the strip using its adhesive backing only on clean, dry, and smooth surfaces. For long runs or areas with vibration, mechanical fasteners or clips are recommended to prevent peeling. Avoid sharp bends—follow the minimum bend radius specified by the manufacturer to prevent damage to the PCB.

For data signal integrity, especially in long installations, consider signal amplification every 5 to 10 meters depending on data speed and controller capability. Connect the data line in the correct direction (input to controller, output to next segment) and use twisted-pair cables for data transmission when extending connections.

Finally, use a compatible controller and software platform that supports WS2811B protocol for smooth color transitions and reliable performance. Test the installation before final mounting and ensure all connections are insulated and protected from accidental contact.

Why Choose Beauty STC Lighting

Elevate your lighting projects with the precision and reliability of Beauty STC’s WS2811B LED strip, engineered for seamless animations and vibrant color control in demanding commercial and architectural applications. Our strips feature integrated 12V operation, consistent pixel density options from 30 to 60 LEDs per meter, and robust signal stability for flicker-free performance even in large-scale installations. As a certified manufacturing partner, Beauty STC delivers rigorous quality control, custom configuration support, and scalable production to ensure your specifications are met without compromise.

Leverage our decade of LED innovation and in-house engineering expertise to streamline your supply chain and enhance product differentiation. We specialize in providing tailored solutions for integrators and OEMs seeking dependable, high-performance addressable lighting with minimal lead times. Partner with Beauty STC to transform your vision into reality with components built to exceed industry standards.

Initiate your collaboration today by contacting our dedicated partnership manager at [email protected] to discuss volume pricing, technical integration, and how our WS2811B LED strips can accelerate your next project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.