Introduction: Navigating the Global Market for ws2811 vs ws2812b

The global demand for advanced addressable LED technologies has surged, making the choice between WS2811 and WS2812B LED strips a pivotal decision for businesses engaged in lighting, signage, and display solutions. For international B2B buyers—especially those sourcing from dynamic markets across Africa, South America, the Middle East, and Europe—understanding the nuanced differences between these two popular LED models is essential to optimize product performance, cost-efficiency, and supply chain reliability.

This guide offers an authoritative, in-depth exploration of WS2811 and WS2812B LED strips, focusing on their technical specifications, control capabilities, power requirements, and application suitability. It delves into material quality, manufacturing standards, and quality control benchmarks critical to maintaining consistency and durability in diverse operating environments. Additionally, buyers will find comprehensive insights into supplier evaluation, pricing trends, and market availability tailored for regions like Brazil, South Africa, and beyond.

Key topics include:

- Technical differentiation: Voltage operation, LED control granularity, and power consumption

- Material and build quality: Assessing durability and environmental resilience

- Manufacturing and QC: Ensuring compliance with international standards

- Supplier landscape: Identifying reputable manufacturers and distributors

- Cost analysis: Balancing upfront investment with long-term operational savings

- Market outlook and trends: Anticipating innovations and demand shifts

- Frequently asked questions: Addressing common buyer concerns and troubleshooting

By equipping decision-makers with actionable knowledge and market intelligence, this guide empowers B2B buyers to confidently source the most suitable LED technology for their projects—maximizing value while mitigating risks inherent in global procurement.

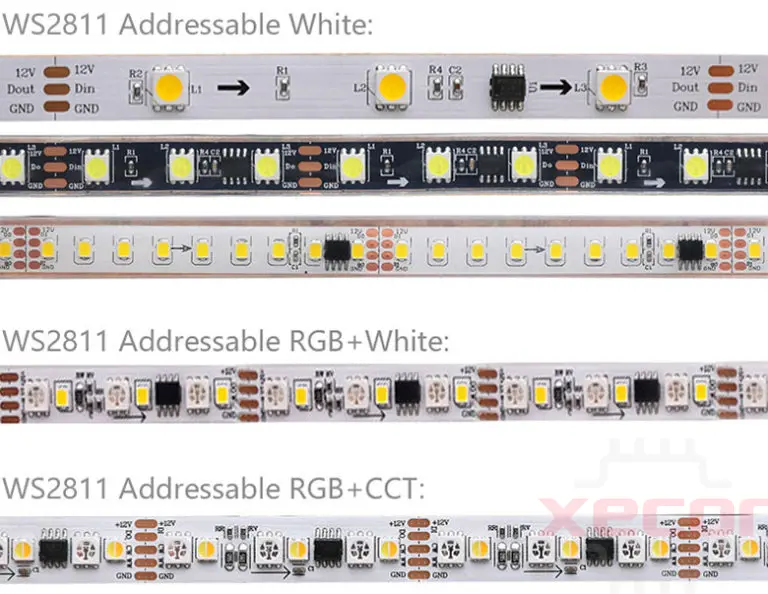

Understanding ws2811 vs ws2812b Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| WS2811 12V Standard | External IC, controls 3 LEDs per IC, operates at 12V | Large-scale architectural lighting, outdoor signage | Pros: Long runs with fewer power injections; robust voltage tolerance. Cons: Limited per-LED control, less suited for fine effects. |

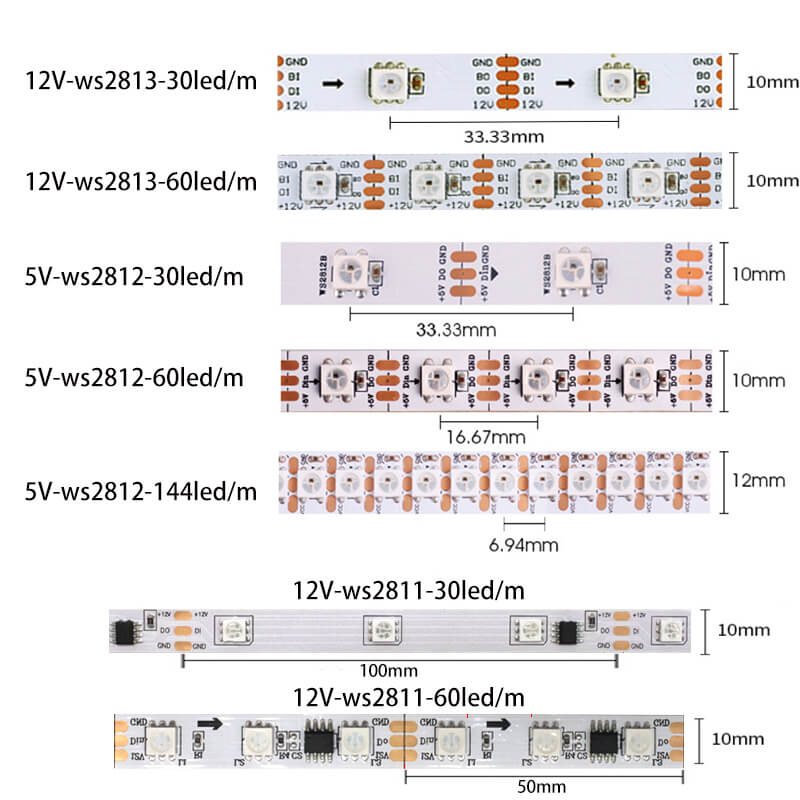

| WS2812B 5V Individually Addressable | Built-in IC per LED, individual LED control, operates at 5V | High-precision decorative lighting, smart lighting systems | Pros: Superior color control, easier wiring. Cons: Sensitive to voltage drops, requires power injection for long strips. |

| WS2811 3-Channel RGB | Controls RGB LEDs in groups, simpler data protocol | Industrial lighting, simple color-changing displays | Pros: Cost-effective for uniform color zones. Cons: Not ideal for complex animations or gradients. |

| WS2812B High-Density | Higher LED count per meter (e.g., 144 LEDs/m), built-in IC | Detailed visual displays, LED art installations | Pros: Enables intricate animations, smooth gradients. Cons: Higher power consumption, increased complexity in power management. |

| WS2811 Waterproof Variants | Encapsulated for moisture resistance, 12V operation | Outdoor and harsh environment installations | Pros: Durable in challenging environments. Cons: Slightly bulkier, potential heat dissipation issues. |

The WS2811 12V Standard type is favored for extensive installations where long cable runs are necessary, such as large outdoor signage or architectural lighting in commercial buildings. Its 12V operation reduces voltage drop issues, minimizing the need for frequent power injection points. B2B buyers should consider this for projects prioritizing durability and cost-efficiency over detailed LED control.

The WS2812B 5V Individually Addressable type provides granular control over each LED, making it ideal for smart lighting and creative decorative applications. This type’s built-in IC simplifies wiring and programming but requires careful power management, especially in longer runs. Buyers from regions with limited stable power infrastructure should plan for additional power injection solutions.

Illustrative Image (Source: Google Search)

WS2811 3-Channel RGB variations are cost-effective solutions for industrial or commercial projects requiring uniform color zones rather than pixel-level control. This type suits applications like simple color-changing displays or background lighting where complex animations are unnecessary. Buyers should weigh cost savings against the lack of precision.

For projects demanding intricate visual effects, the WS2812B High-Density variation offers a higher LED count per meter, supporting detailed animations and smooth color gradients. This variation is popular in creative industries and high-end retail displays. B2B purchasers must factor in the increased power consumption and the need for advanced power distribution strategies.

Lastly, the WS2811 Waterproof Variants are designed for outdoor or harsh environmental conditions, featuring encapsulation to protect against moisture and dust. These are essential for outdoor advertising, stadium lighting, or industrial applications in Africa, South America, and the Middle East, where weather resilience is critical. Buyers should consider potential trade-offs in size and heat management when selecting these models.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of ws2811 vs ws2812b

| Industry/Sector | Specific Application of ws2811 vs ws2812b | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Entertainment & Events | Dynamic stage lighting and large-scale LED displays | Enables captivating visual effects with customizable color control | Choose WS2812B for fine pixel control; WS2811 for longer runs with fewer control points; ensure reliable voltage supply and quality ICs |

| Architectural Lighting | Facade illumination and ambient lighting in commercial buildings | Enhances building aesthetics and energy efficiency | WS2811 preferred for longer strips and voltage stability; WS2812B for detailed accents; assess power injection needs and IP ratings |

| Retail & Advertising | Digital signage and illuminated advertising panels | Attracts customers with vivid, programmable lighting effects | Prioritize WS2812B for precise LED control and animation; consider WS2811 for cost-effective larger installations; verify supplier support for firmware |

| Automotive & Transportation | Interior ambient lighting and exterior decorative lighting | Improves passenger experience and brand differentiation | WS2812B suits intricate interior designs; WS2811 better for longer exterior runs; confirm compliance with regional electrical standards |

| Smart City & Infrastructure | Public lighting installations and interactive urban displays | Supports energy-efficient, scalable lighting with remote control | WS2811 favored for durability over long distances; WS2812B for interactive elements; consider environmental robustness and maintenance support |

Entertainment & Events

In the entertainment industry, WS2811 and WS2812B LED strips are widely used for dynamic stage lighting and large-scale LED video walls. WS2812B’s individual LED control allows for intricate animations and color gradients essential for immersive visual experiences at concerts and festivals. Conversely, WS2811 is advantageous for long runs requiring fewer control points, reducing complexity and cost. B2B buyers in regions like South America and Europe should prioritize suppliers offering consistent IC quality and stable voltage support to avoid flickering or color inconsistencies during live events.

Illustrative Image (Source: Google Search)

Architectural Lighting

For commercial and public buildings, architectural lighting relies on LED strips to create ambient and accent lighting that enhances visual appeal while minimizing power consumption. WS2811’s 12V operation provides better voltage stability over long facade installations common in Middle Eastern and African urban projects, reducing the need for frequent power injections. WS2812B is ideal for close-up detailed lighting effects such as logos or decorative patterns. Buyers should verify IP ratings and ensure their suppliers provide technical guidance for integrating these LEDs into outdoor environments.

Retail & Advertising

Retailers and advertisers leverage WS2811 and WS2812B LED strips to create eye-catching digital signage and illuminated advertisements. WS2812B’s pixel-level control enables complex animations and color transitions that help brands stand out in competitive markets like Brazil and Europe. For larger, less detailed installations, WS2811 offers a cost-effective solution with simpler wiring. International buyers must confirm that suppliers can provide firmware customization and after-sales support to adapt lighting sequences to local market preferences and regulatory requirements.

Automotive & Transportation

In automotive interiors and exterior decorative lighting, WS2812B is preferred for its precise control, enabling customizable ambient lighting that enhances passenger comfort and brand identity. WS2811’s robustness and 12V operation make it suitable for exterior applications such as underbody or grille lighting, where longer runs are typical. Buyers from the Middle East and Africa should ensure compliance with local electrical standards and source LEDs with high thermal tolerance to withstand harsh climates.

Smart City & Infrastructure

Smart city initiatives employ LED strips for public lighting and interactive installations that require scalability and energy efficiency. WS2811’s higher voltage tolerance and longer run capability suit infrastructure lighting across urban areas in Europe and South America. WS2812B is used for interactive displays where individual LED control enables real-time feedback and dynamic patterns. B2B buyers must assess environmental durability, ease of maintenance, and supplier capacity to provide integrated solutions aligned with smart city technologies.

Related Video: What’s Behind the Light? – How WS2812B LED Strips Work

Strategic Material Selection Guide for ws2811 vs ws2812b

Material Considerations for WS2811 vs WS2812B LED Strip Manufacturing

When selecting materials for WS2811 and WS2812B LED strips, international B2B buyers must consider factors such as electrical performance, durability, environmental resistance, and regulatory compliance. The choice of substrate, encapsulant, solder, and protective coatings significantly impacts product longevity, installation flexibility, and suitability for diverse markets including Africa, South America, the Middle East, and Europe.

1. Flexible Polyimide (PI) Substrate

Key Properties:

Polyimide substrates offer excellent thermal stability (up to 400°C), good mechanical flexibility, and chemical resistance. They maintain dimensional stability under varying temperature and humidity, making them ideal for flexible LED strips.

Pros:

– High heat resistance supports soldering and long-term LED operation.

– Superior flexibility enables installation on curved or irregular surfaces.

– Good dielectric properties reduce electrical interference.

Cons:

– Higher cost compared to standard PET substrates.

– Manufacturing complexity requires precise handling to avoid damage.

Application Impact:

Ideal for WS2812B strips where compact, individually controlled LEDs demand precise circuit integrity and heat management. The flexibility suits architectural lighting and wearable tech, common in markets with emerging smart city projects like South Africa and Brazil.

Regional Considerations:

Polyimide substrates comply with international standards such as ASTM D3380 and DIN EN 60811, facilitating import/export in Europe and Middle Eastern countries. Buyers should verify supplier certifications to meet local quality and environmental regulations.

2. Polyethylene Terephthalate (PET) Substrate

Key Properties:

PET substrates provide moderate thermal resistance (up to 150°C), good dimensional stability, and cost-effectiveness. They are less flexible than polyimide but widely used for LED strips requiring moderate bending.

Pros:

– Lower cost and readily available material.

– Adequate for WS2811 strips operating at 12V with less heat generation per LED group.

– Easier to process and laminate during manufacturing.

Cons:

– Lower heat tolerance limits soldering and long-term durability.

– Reduced flexibility restricts use on highly curved surfaces.

Application Impact:

Suitable for WS2811 strips in large-scale installations such as stadium lighting or billboard backlighting, where individual LED control is less critical. The material’s affordability aligns with budget-conscious projects in developing regions like parts of Africa and South America.

Regional Considerations:

PET substrates meet common standards like JIS K 7105 and ASTM D882, supporting compliance in Asia-Pacific and European markets. Buyers should ensure UV resistance additives are included for outdoor applications in high-UV regions like the Middle East.

3. Silicone Encapsulation

Key Properties:

Silicone encapsulants provide excellent moisture resistance, UV stability, and flexibility. They maintain performance across wide temperature ranges (-50°C to 200°C) and protect LEDs from environmental degradation.

Pros:

– Superior protection against water ingress and dust.

– Enhances LED lifespan in harsh climates.

– Maintains flexibility without cracking or yellowing.

Cons:

– Higher material and processing costs.

– Requires specialized curing equipment, increasing manufacturing complexity.

Application Impact:

Highly recommended for outdoor WS2812B installations in humid or desert environments, such as coastal Brazil or Middle Eastern countries. Silicone encapsulation ensures consistent brightness and color accuracy by preventing moisture-induced failures.

Regional Considerations:

Silicone materials should comply with RoHS and REACH regulations prevalent in Europe and parts of South America. Buyers must verify certifications for food-grade or medical-grade silicone if used in specialty lighting applications.

4. Lead-Free Solder (SnAgCu Alloy)

Key Properties:

Lead-free solder composed of tin, silver, and copper offers strong mechanical bonds and good electrical conductivity. It supports high-temperature resistance required for LED strip assembly.

Pros:

– Complies with global environmental regulations (RoHS, WEEE).

– Reduces health risks in manufacturing and end-use environments.

– Provides reliable electrical connections for long-term performance.

Cons:

– Slightly higher melting point than traditional leaded solder, requiring precise temperature control.

– Potentially increased manufacturing costs due to material price and process adjustments.

Application Impact:

Essential for all WS2811 and WS2812B LED strips targeting international markets with strict environmental standards, including the EU and Middle East. Ensures product acceptance and reduces liability risks in global supply chains.

Regional Considerations:

B2B buyers in Africa and South America should verify local import regulations and supplier adherence to international standards like IEC 61249-2-21. Lead-free solder supports sustainable manufacturing initiatives gaining traction in these regions.

Summary Table of Material Selection for WS2811 vs WS2812B

| Material | Typical Use Case for ws2811 vs ws2812b | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyimide (PI) Substrate | WS2812B flexible strips requiring high heat tolerance and flexibility | Excellent thermal stability and flexibility | Higher cost and manufacturing complexity | High |

| PET Substrate | WS2811 strips for budget-friendly, less flexible installations | Cost-effective and easy to process | Lower heat resistance and flexibility | Low |

| Silicone Encapsulation | Outdoor WS2812B installations in harsh environments | Superior moisture and UV resistance | Increased material and processing costs | High |

| Lead-Free Solder (SnAgCu) | Assembly for both WS2811 and WS2812B strips targeting regulated markets | Compliance with environmental standards | Higher melting point requires precise control | Medium |

This strategic material selection guide equips B2B buyers with critical insights to optimize LED strip performance, durability, and regulatory compliance. Considering regional environmental factors and market standards ensures successful procurement and long-term satisfaction across diverse international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for ws2811 vs ws2812b

Manufacturing Processes for WS2811 and WS2812B LED Strips

The production of WS2811 and WS2812B addressable LED strips involves a series of precise manufacturing stages to ensure product reliability, performance, and longevity. While both types share similarities in process, differences in chip integration and voltage requirements influence key manufacturing steps.

1. Material Preparation

- Raw Materials Sourcing: High-quality LED chips (WS2811 external IC or WS2812B integrated IC), flexible PCB substrates (typically polyimide or fiberglass-based), copper foils, resistors, capacitors, and protective coatings are sourced. For B2B buyers, verifying supplier compliance with material certifications (RoHS, REACH) is critical, particularly to meet environmental regulations in Europe and South America.

- Component Inspection: Incoming components undergo Incoming Quality Control (IQC) to check for defects such as incorrect dimensions, damaged leads, or improper packaging. This step is vital for maintaining consistency and avoiding downstream failures.

2. PCB Fabrication and Forming

- PCB Patterning: Flexible PCBs are patterned using photolithography and etching to create precise copper traces that accommodate the 12V or 5V power requirements of WS2811 and WS2812B strips respectively.

- Surface Treatment: PCBs receive surface finishes such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold) to improve solderability and corrosion resistance. This finishing is essential for long-term durability in varied climates, including humid or coastal regions common in Africa and the Middle East.

3. Assembly and Mounting

- SMD Placement: Automated pick-and-place machines position the LEDs, ICs, resistors, and capacitors on the PCB with high precision. For WS2811 strips, external driver ICs are placed separately, while WS2812B LEDs have integrated ICs within each LED package.

- Reflow Soldering: The assembly passes through reflow ovens where solder paste melts and forms strong electrical connections. Process parameters are tightly controlled to avoid thermal damage, especially for the delicate WS2812B integrated chips.

- Encapsulation: Protective coatings or silicone layers are applied to shield the LED strips from moisture, dust, and mechanical stress. Silicone encapsulation is preferred for outdoor or industrial applications and is a key quality factor for buyers in harsh environments such as parts of South America and the Middle East.

4. Finishing and Packaging

- Cutting and Marking: Strips are cut to standard lengths (e.g., 5 meters) or customized sizes. Markings indicate cut points to facilitate installation.

- Adhesive Backing Application: Self-adhesive layers are applied for easy mounting, a feature appreciated in retail and architectural projects worldwide.

- Final Packaging: Protective reels and moisture barrier bags are used to prevent electrostatic discharge (ESD) and humidity damage during transportation.

Quality Assurance and Control (QA/QC) Protocols

Ensuring consistent quality in WS2811 and WS2812B LED strips is paramount for international B2B buyers who demand reliable performance in diverse markets. Quality assurance spans multiple checkpoints and adheres to international and industry-specific standards.

Key Quality Standards

- ISO 9001: Most reputable manufacturers implement ISO 9001 quality management systems to standardize processes, documentation, and continuous improvement. Buyers should verify certification validity to ensure systematic quality governance.

- CE Marking: Essential for European market entry, CE certification confirms compliance with EU safety, health, and environmental requirements.

- RoHS & REACH Compliance: Restriction of hazardous substances and chemical safety are critical, especially for buyers in Europe and South America where regulations are strict.

- UL and FCC: Relevant for electrical safety and electromagnetic compatibility, particularly for products intended for the North American and Middle Eastern markets.

- Industry-Specific Certifications: Some buyers may require API (American Petroleum Institute) or IEC standards if LED strips are used in industrial or hazardous environments.

QC Checkpoints Throughout Production

- Incoming Quality Control (IQC): Inspection of raw materials and components before manufacturing to prevent defective inputs.

- In-Process Quality Control (IPQC): Continuous monitoring during assembly, including solder joint inspection, component placement accuracy, and thermal profiling during reflow.

- Final Quality Control (FQC): Comprehensive testing of finished LED strips before shipment, including functional, visual, and electrical tests.

Common Testing Methods for WS2811 and WS2812B Strips

- Visual Inspection: Automated optical inspection (AOI) systems detect soldering defects, missing components, or physical damage.

- Electrical Testing: Verification of voltage, current consumption, and signal integrity ensures compliance with WS2811’s 12V and WS2812B’s 5V requirements.

- Color and Brightness Consistency: Using spectrophotometers and colorimeters, manufacturers measure RGB output accuracy and uniformity, crucial for applications demanding precise lighting effects.

- Durability Tests: Environmental stress tests such as thermal cycling, humidity exposure, and vibration simulate real-world conditions, validating strip longevity.

- Functionality Testing: Each LED or LED group is activated to confirm individual or grouped control capabilities, a distinguishing factor between WS2811 and WS2812B.

How B2B Buyers Can Verify Supplier Quality Assurance

For buyers from Africa, South America, the Middle East, and Europe, ensuring supplier reliability involves proactive engagement and verification beyond certificates.

- Factory Audits: On-site or third-party audits assess manufacturing capabilities, process controls, labor conditions, and compliance with international standards. Remote audits via video calls can be arranged where travel is restricted.

- Sample Testing: Requesting product samples for independent lab testing enables buyers to validate performance claims such as power consumption, brightness, and voltage tolerance.

- Quality Reports: Suppliers should provide detailed inspection reports covering IQC, IPQC, and FQC results, including defect rates and corrective actions.

- Third-Party Inspection Services: Engaging independent inspection agencies (e.g., SGS, Bureau Veritas) can offer unbiased verification of product quality and adherence to contractual specifications.

- Supply Chain Transparency: Verifying component traceability and raw material sourcing supports compliance with international trade regulations and sustainability commitments.

QC and Certification Nuances for International Buyers

- Voltage and Power Considerations: Buyers must ensure that the LED strips comply with the electrical standards of their target markets (e.g., 220-240V mains in Europe and South America versus 110-120V in some Middle Eastern countries) and that appropriate power supplies accompany the strips.

- Environmental Compliance: For buyers in regions with stringent environmental policies, confirming RoHS and REACH compliance is non-negotiable to avoid customs issues or market rejection.

- Documentation and Labeling: Proper labeling in native languages and comprehensive technical datasheets facilitate smoother importation and installation.

- After-Sales Support: Reliable warranty terms, technical support availability, and spare parts supply chains are crucial for B2B buyers planning long-term projects or large installations.

- Adaptation to Local Conditions: Suppliers should demonstrate testing for heat tolerance, humidity resistance, and UV stability to suit climates in Africa and the Middle East, where extreme environmental factors are common.

Summary for B2B Buyers

Understanding the manufacturing and quality assurance intricacies behind WS2811 and WS2812B LED strips empowers international buyers to make informed sourcing decisions. Prioritizing suppliers with robust ISO-certified processes, transparent QC checkpoints, and verifiable certifications ensures product consistency and compliance. Leveraging factory audits, independent testing, and detailed quality reports enhances supply chain confidence, especially for buyers in Africa, South America, the Middle East, and Europe, where regulatory and environmental conditions vary widely. Ultimately, a strategic approach to supplier evaluation will safeguard investment, optimize performance, and support successful project outcomes with WS2811 and WS2812B LED technologies.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for ws2811 vs ws2812b Sourcing

When sourcing WS2811 and WS2812B LED strips, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers aiming to optimize procurement strategies. These addressable LED strips differ technically, which impacts their cost components and pricing factors, influencing total acquisition expenses and project budgets.

Key Cost Components in WS2811 vs WS2812B Manufacturing

-

Materials

– WS2811: Requires a 12V power design with an external driver IC controlling groups of three LEDs, typically resulting in fewer ICs per meter but more complex wiring and PCB layout. The LED chips are standard RGB types without integrated control.

– WS2812B: Features integrated control ICs within each 5050 LED package, increasing the number of components per meter and the cost of more sophisticated chips. The 5V operation demands more precise power management components.

Material costs tend to be higher for WS2812B due to the integrated ICs and finer manufacturing tolerances. -

Labor and Manufacturing Overhead

WS2812B strips often require more precise assembly and testing processes due to their integrated chip complexity and tighter quality controls. WS2811 strips are simpler but may involve additional labor for external IC placement and wiring. Manufacturing overhead also includes cleanroom conditions and specialized equipment for WS2812B production. -

Tooling and Quality Control (QC)

Initial tooling for WS2812B production can be more capital-intensive given the microelectronics involved. QC processes for WS2812B are stringent to ensure individual LED functionality, signal integrity, and color accuracy. WS2811 QC focuses more on group LED control and voltage stability. Both require testing for electrical safety and compliance with international standards. -

Logistics and Shipping

Both products are lightweight but sensitive to environmental conditions. WS2812B’s higher value per unit makes insurance and secure packaging more critical. Shipping costs can vary significantly depending on shipment volume, destination, and chosen Incoterms. -

Margin and Markup

Suppliers typically factor in margins based on demand, competition, and exclusivity of components. WS2812B strips, being newer and more advanced, often carry higher margins, especially when sourced in smaller volumes or customized configurations.

Price Influencers Affecting WS2811 and WS2812B Procurement

-

Order Volume and Minimum Order Quantities (MOQ):

Larger volume orders generally yield better unit pricing. WS2811 strips, being older technology, often have lower MOQs and more competitive pricing. WS2812B suppliers may require higher MOQs due to more complex manufacturing processes. -

Specifications and Customization:

Customized lengths, LED densities (e.g., 60 LEDs/meter), or special waterproofing add to costs. WS2812B’s individual LED control capability allows for more complex programming and firmware integration, increasing development and customization expenses. -

Material Quality and Certifications:

Compliance with certifications like CE, RoHS, and UL can increase costs but are essential for buyers targeting European and Middle Eastern markets. Higher-grade LED chips with better color accuracy and longevity also influence price. -

Supplier Reliability and Location:

Established manufacturers with solid reputations may charge premium prices but offer better quality assurance. Buyers in Africa, South America, and the Middle East should consider suppliers with regional logistics hubs to reduce shipping times and costs. -

Incoterms and Payment Terms:

Shipping terms (FOB, CIF, DDP) significantly impact landed costs. Buyers should negotiate terms that optimize customs clearance and minimize unexpected fees. Favorable payment terms can improve cash flow and reduce financial risk.

Strategic Buyer Tips for International B2B Procurement

-

Negotiate Based on Total Cost of Ownership (TCO):

Evaluate not just unit price but also power consumption differences (WS2812B typically consumes more power per meter), installation complexity, and maintenance costs. WS2811’s 12V operation may reduce power injection points and related labor costs for long runs. -

Leverage Volume Discounts and Long-Term Contracts:

Consolidate orders and establish long-term partnerships to secure better pricing and priority manufacturing slots, especially important for WS2812B which may have supply constraints. -

Request Samples and Conduct Quality Audits:

Before large-scale procurement, obtain samples for performance verification. Consider third-party testing or factory audits to ensure compliance with buyer specifications and international standards. -

Account for Regional Import Duties and Taxes:

Understand local import regulations in target markets like Brazil or South Africa, as tariffs and taxes can add substantially to landed cost. Factor these into pricing negotiations. -

Consider Supplier Location for Logistics Efficiency:

Suppliers closer to key markets or with distribution centers in strategic hubs (e.g., Dubai for Middle East, Rotterdam for Europe) can reduce transit times and logistics costs.

Indicative Pricing Overview

While prices fluctuate based on market conditions and supplier specifics, WS2811 LED strips generally range lower in unit cost due to simpler IC design and 12V operation, often priced around $5–$8 per meter for standard configurations. WS2812B strips, offering individual LED control and integrated ICs, typically command higher prices, roughly $7–$12 per meter, reflecting their advanced features and power requirements.

Note: These figures are indicative and subject to

Spotlight on Potential ws2811 vs ws2812b Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ws2811 vs ws2812b’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ws2811 vs ws2812b

Critical Technical Properties for WS2811 and WS2812B LED Strips

1. Operating Voltage

– WS2811: Typically operates at 12V DC.

– WS2812B: Operates at 5V DC.

B2B Importance: Voltage affects power infrastructure and energy costs. Higher voltage (WS2811) is advantageous for longer installations due to reduced voltage drop, minimizing the need for frequent power injection. Conversely, WS2812B’s lower voltage means easier integration with low-voltage systems but may require additional power management on extended runs.

2. LED Control Granularity

– WS2811: Controls LEDs in groups of three (one IC per three LEDs).

– WS2812B: Provides individual LED control with an integrated IC per LED.

B2B Importance: Individual LED control enables more detailed lighting effects, essential for high-end decorative or signaling applications. Group control (WS2811) suits simpler, large-scale lighting where cost and ease are priorities.

3. Power Consumption

– WS2811: Approximately 14 watts per meter.

– WS2812B: Approximately 18 watts per meter.

B2B Importance: Power consumption impacts operational costs and heat management. WS2811’s lower power draw per meter can be cost-effective for large-scale installations, while WS2812B’s higher consumption is justified by enhanced functionality.

4. Signal Transmission and Data Protocol

– Both use a single data line with serial communication, but WS2812B features auto-reshaping technology to maintain signal integrity over long chains.

B2B Importance: Reliable data transmission ensures consistent lighting performance. WS2812B’s auto-reshaping reduces signal degradation, beneficial for complex or long installations.

5. LED Density and Pixel Pitch

– Commonly available in 60 LEDs per meter for both types, but WS2812B’s pixel-level control means higher effective resolution.

B2B Importance: Higher pixel density and individual control translate to finer visual detail, crucial for applications like digital signage, while WS2811 fits well for ambient or architectural lighting.

6. Physical Integration and Installation

– WS2811 strips require external driver ICs; WS2812B integrates driver chips within each LED package.

B2B Importance: WS2812B’s integrated design simplifies wiring and reduces assembly complexity, lowering installation time and potential points of failure.

Essential Trade Terminology for International B2B Buyers

1. OEM (Original Equipment Manufacturer)

Refers to companies that produce components or products that are rebranded and sold by another company.

Why it matters: Many buyers seek OEM partnerships to customize LED strips under their brand or obtain cost advantages through bulk manufacturing contracts.

2. MOQ (Minimum Order Quantity)

The smallest quantity a supplier is willing to sell in a single order.

Why it matters: Understanding MOQ helps buyers plan procurement and budget effectively, especially when testing new products or entering new markets.

3. RFQ (Request for Quotation)

A formal request sent to suppliers to obtain pricing, lead times, and terms for specific product quantities and specifications.

Why it matters: RFQs enable buyers to compare offers objectively, negotiate better deals, and ensure compliance with technical requirements.

4. Incoterms (International Commercial Terms)

Standardized trade terms that define responsibilities for shipping, insurance, and tariffs between buyers and sellers. Examples include FOB (Free On Board) and CIF (Cost, Insurance, Freight).

Why it matters: Clear understanding of Incoterms protects buyers from unexpected costs and logistical risks during international shipments.

5. Lead Time

The duration between placing an order and receiving the goods.

Why it matters: Accurate lead time estimates are crucial for project planning, inventory management, and meeting delivery deadlines.

6. Tolerance

The acceptable range of variation in product specifications (e.g., voltage, brightness, color accuracy).

Why it matters: Tight tolerances ensure consistent product quality, essential for projects requiring uniform lighting performance and regulatory compliance.

By mastering these technical properties and trade terms, international B2B buyers—particularly from regions like Africa, South America, the Middle East, and Europe—can make informed procurement decisions that optimize cost, quality, and operational efficiency for WS2811 and WS2812B LED solutions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ws2811 vs ws2812b Sector

Market Overview & Key Trends

The global market for addressable LED strips, particularly WS2811 and WS2812B models, is experiencing robust growth fueled by expanding applications in architectural lighting, entertainment, advertising, and smart city infrastructure. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking solutions that balance performance, energy efficiency, and scalability to meet diverse project requirements.

Key market drivers include rising urbanization, increasing investments in smart lighting systems, and demand for customizable lighting effects in commercial and public spaces. The WS2812B’s fine-grained individual LED control makes it popular for intricate lighting designs, while WS2811’s 12V operation suits longer installations with reduced voltage drop concerns. This bifurcation allows buyers to select products aligned with specific project scales and technical needs.

Emerging sourcing trends emphasize modularity and ease of integration. Suppliers now offer LED strips with enhanced waterproofing, flexible form factors, and built-in ICs, reducing installation complexity. Moreover, the rising adoption of microcontroller-based lighting control platforms (e.g., Arduino, Raspberry Pi) has standardized communication protocols, simplifying cross-border procurement and deployment.

From a regional perspective, buyers in Africa and South America prioritize cost-effective, durable solutions that tolerate challenging environmental conditions, such as humidity and temperature fluctuations. In contrast, European and Middle Eastern markets often focus on cutting-edge features like high color accuracy, advanced dimming capabilities, and energy efficiency certifications to comply with stringent regulations.

Market dynamics also reflect supply chain diversification, with increasing sourcing from Asian manufacturers balanced by regional distributors offering localized support. For buyers in emerging markets, partnering with suppliers providing technical training and after-sales services is becoming a critical factor in procurement decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration for B2B buyers evaluating WS2811 and WS2812B LED strips, particularly for large-scale or long-term projects. Both product lines present opportunities for energy savings compared to traditional lighting, but their environmental footprints vary due to operational voltage, power consumption, and manufacturing processes.

WS2812B strips, operating at 5V, generally offer higher energy efficiency and lower heat output, which can translate into reduced operational costs and a smaller carbon footprint over their lifecycle. However, they require more frequent power injections for longer runs, potentially increasing material usage. Conversely, WS2811’s 12V design supports longer uninterrupted runs but consumes slightly more power per meter.

Ethical sourcing remains a critical focus amid growing concerns over supply chain transparency and labor practices. Buyers are advised to verify suppliers’ adherence to internationally recognized standards such as RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), and ISO 14001 environmental management systems. These certifications help ensure the LEDs are free from harmful substances and manufactured with minimized environmental impact.

Additionally, responsible procurement encourages suppliers to utilize lead-free soldering and recyclable packaging materials. Buyers from environmentally conscious markets like Europe and parts of the Middle East increasingly demand documentation on carbon footprint and waste management practices.

Incorporating sustainability into purchasing decisions also involves evaluating end-of-life recyclability of LED strips and the potential for refurbishing or repurposing components. Engaging suppliers who invest in circular economy initiatives can enhance corporate social responsibility profiles and future-proof investments.

Brief Evolution and Industry Context

The evolution of addressable LED technology has been marked by a transition from externally controlled multi-LED groups to integrated single-LED control solutions. The WS2811, introduced as a 12V external IC-driven strip, offered a significant step forward from non-addressable LED arrays by enabling basic color sequencing and effects. However, its limitation in controlling only triads of LEDs simultaneously constrained design flexibility.

The advent of the WS2812B, featuring an integrated control IC per LED and operating at 5V, revolutionized the sector by enabling precise, pixel-level control. This advancement unlocked new possibilities in dynamic lighting, from complex animations to interactive displays, and facilitated easier wiring and installation.

For B2B buyers, understanding this historical progression is essential as it underscores the technological trade-offs between voltage, control granularity, and installation scale—factors that directly impact sourcing strategy, project design, and total cost of ownership in international markets.

Related Video: Exim Trade Conclave 2025 LIVE | Finance Minister Nirmala Sitharaman Delivers Keynote Address | N18L

Frequently Asked Questions (FAQs) for B2B Buyers of ws2811 vs ws2812b

-

How can I effectively vet suppliers of WS2811 and WS2812B LED strips for international B2B purchases?

To vet suppliers, request detailed product datasheets, certifications (CE, RoHS, UL), and sample orders to assess quality firsthand. Verify factory audits or third-party inspection reports, especially for suppliers in regions like China or Southeast Asia. Check customer reviews and references, focusing on previous exports to your region (Africa, South America, Middle East, Europe). Assess communication responsiveness and technical support availability. Additionally, inquire about their compliance with international standards and export licenses to ensure smooth customs clearance and regulatory compliance. -

What customization options are typically available for WS2811 and WS2812B LED strips when sourcing for large-scale projects?

Many manufacturers offer customization including LED density (LEDs per meter), strip length, voltage options (5V or 12V), waterproofing levels (IP65, IP67), and connector types to fit specific installation needs. Custom firmware or control protocols may also be available for complex lighting effects. For international buyers, confirm the lead time and MOQ for custom orders, as bespoke products often require longer production schedules. Tailoring packaging and labeling for your market can also be negotiated to comply with local regulations or branding requirements. -

What are common MOQ (Minimum Order Quantity) and lead times for WS2811 vs WS2812B LED strips in international B2B trade?

MOQ varies by supplier but typically ranges from 100 to 500 meters per model, with WS2812B often having higher MOQs due to its integrated IC complexity. Lead times generally span 3 to 6 weeks, influenced by customization, order size, and current global supply chain conditions. For buyers in Africa, South America, and the Middle East, factor in additional time for shipping and customs clearance. Early engagement with suppliers about production schedules and logistics is critical to align expectations and avoid delays. -

Which quality assurance certifications should international buyers insist on when purchasing WS2811 or WS2812B LED strips?

Ensure suppliers provide internationally recognized certifications such as CE (European Conformity), RoHS (Restriction of Hazardous Substances), and UL (Underwriters Laboratories) for electrical safety. ISO 9001 certification indicates consistent manufacturing quality. For export to regions like Europe and the Middle East, compliance with REACH and EMC directives may be necessary. Request batch testing reports and warranty terms to guarantee product reliability and longevity, especially in harsh environmental conditions common in African or Middle Eastern markets. -

What payment terms are advisable for international transactions involving WS2811 and WS2812B LED strips?

Secure payment terms typically include a 30% deposit upfront with the balance paid upon shipment or after inspection. Letter of Credit (L/C) is recommended for larger orders to minimize risk. Escrow services or trade assurance platforms can provide additional security for first-time buyers. Negotiate clear terms on currency, payment deadlines, and penalties for late payments. Also, confirm if suppliers accept flexible terms like Net 30 or Net 60, which may be advantageous for buyers managing cash flow across different continents. -

How should international buyers handle logistics and shipping challenges for WS2811 vs WS2812B LED strips?

Due to voltage and packaging differences, WS2811 strips (12V) are generally bulkier but less sensitive to voltage drops, while WS2812B (5V) require careful packaging to avoid damage to integrated ICs. Choose reliable freight forwarders experienced in handling electronics shipments to Africa, South America, or the Middle East. Opt for air freight for urgent orders and sea freight for cost efficiency on bulk shipments. Track shipments closely and prepare for customs documentation in compliance with local import regulations to prevent clearance delays. -

What are the best practices for dispute resolution when quality or delivery issues arise with WS2811 or WS2812B suppliers?

Establish clear contractual terms detailing product specifications, delivery schedules, and quality acceptance criteria before order confirmation. Include clauses for penalties or compensation in case of defects or delays. Maintain comprehensive communication records and inspection reports. In case of disputes, initiate amicable negotiation first, leveraging third-party inspection reports if necessary. For unresolved issues, consider arbitration through international bodies like ICC or local trade chambers relevant to your region. Utilizing platforms with trade assurance can also provide legal recourse. -

How do I ensure after-sales support and warranty coverage for WS2811 and WS2812B LED strips from overseas suppliers?

Verify the supplier’s warranty policy, typically ranging from 6 months to 2 years, covering defects and performance issues. Confirm availability of technical support for installation guidance and troubleshooting, ideally via multiple channels (email, phone, video). For international buyers, ensure spare parts or replacement LEDs are accessible without excessive shipping delays or costs. Establish communication protocols upfront and consider suppliers offering training or documentation tailored to your local market conditions for smoother post-purchase experience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ws2811 vs ws2812b

When selecting between WS2811 and WS2812B addressable LED strips, international B2B buyers must weigh critical factors such as voltage requirements, control precision, power consumption, and installation scale. The WS2811’s 12V operation and group-based LED control offer robustness for long-distance, large-scale applications with moderate precision needs, making it a strong candidate for expansive commercial or architectural lighting projects. Conversely, the WS2812B’s 5V operation with individual LED control excels in environments demanding intricate lighting effects, superior color accuracy, and energy efficiency—ideal for smart lighting, artistic displays, and compact installations.

Strategic sourcing decisions should prioritize:

- Compatibility with existing infrastructure (power supply and control systems)

- Project scale and control granularity requirements

- Energy consumption constraints and sustainability goals

- Supplier reliability and access to technical support

For buyers in Africa, South America, the Middle East, and Europe, where logistics, power stability, and environmental factors vary widely, partnering with experienced suppliers who understand regional nuances can optimize procurement outcomes and reduce operational risks.

Looking ahead, the LED industry is trending toward integrated, energy-efficient solutions with enhanced digital control capabilities. To maintain a competitive edge, B2B buyers are encouraged to engage with manufacturers offering cutting-edge innovations, flexible customization, and comprehensive after-sales service. Proactive strategic sourcing now will ensure that your lighting solutions remain future-proof, cost-effective, and aligned with evolving market demands.