Article Contents

Industry Insight: Wired Led Light Strips

The commercial and industrial lighting sector continues its decisive shift towards LED technology, driven by relentless demands for energy efficiency, operational cost reduction, and enhanced lighting quality in demanding environments. Within this landscape, wired LED light strips have emerged as a critical solution, moving far beyond simple decorative applications to become a fundamental component in architectural cove lighting, task illumination, signage, display cases, and critical industrial workspace lighting. Their inherent flexibility, precise light distribution, and robust performance make them uniquely suited for the complex layout requirements and high-utilization cycles characteristic of offices, retail spaces, warehouses, manufacturing facilities, and healthcare settings. Crucially, adoption in these professional environments hinges on more than just performance; stringent adherence to safety and regulatory standards is non-negotiable. Certifications such as ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) are essential gatekeepers, ensuring products meet rigorous electrical safety, electromagnetic compatibility, and operational reliability benchmarks required for specification and installation in commercial and industrial projects. These certifications are not merely checkboxes but foundational elements of risk mitigation and long-term operational confidence.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution for over 25 years. As a dedicated manufacturer specializing in high-performance LED lighting solutions, we understand the unique pressures and specifications of the commercial and industrial markets. Our engineering focus centers on developing wired LED light strips that deliver exceptional lumen maintenance, thermal management, and color consistency under continuous operation, while rigorously exceeding ETL, CE, and other relevant international safety and performance standards. We partner with lighting designers, electrical contractors, and facility managers to provide not just products, but engineered lighting systems that enhance productivity, reduce total cost of ownership, and meet the exacting demands of professional environments. This insight explores the current state, key considerations, and future trajectory of wired LED light strips specifically within the demanding realm of commercial and industrial lighting.

Technical Specs & Certifications

Wired LED light strips from Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability, meeting stringent technical standards for both residential and commercial lighting applications. A key performance metric, lumens per watt (lm/W), typically ranges from 110 to 130 lm/W across our standard high-efficiency product lines. This efficiency is achieved through the use of high-grade SMD LEDs—primarily 2835, 3528, and 5050 configurations—paired with optimized driver circuitry and thermally efficient flexible PCB substrates. Higher-end series, particularly those utilizing advanced chip-on-board (COB) or high-density SMD layouts, can exceed 130 lm/W under ideal thermal conditions, ensuring maximum light output with minimal energy consumption.

Color Rendering Index (CRI) is a critical factor in accurate color representation, and Beauty STC places strong emphasis on visual quality. Our premium wired LED strips consistently deliver a CRI greater than 90, with select models achieving CRI values of 95 or higher. This is accomplished through the integration of phosphor-coated diodes tuned to produce a broad and continuous spectral output, closely mimicking natural daylight. High CRI performance is especially beneficial in retail, hospitality, and professional photography environments where true color fidelity is essential.

In terms of environmental protection, Beauty STC offers wired LED strips across a range of Ingress Protection (IP) ratings to suit diverse installation conditions. Non-encapsulated strips are typically rated IP20, suitable for dry indoor environments. For damp or outdoor use, we provide conformal-coated versions rated IP65, offering protection against dust and low-pressure water jets. Fully encapsulated silicone-jacketed strips are available in IP67 and IP68 ratings, enabling safe operation when submerged in water up to 1 meter for extended durations. These ruggedized variants are ideal for architectural cove lighting, outdoor signage, and landscape applications.

Beauty STC’s commitment to quality is evident in every stage of production. Our LED strips undergo rigorous testing for thermal stability, lumen maintenance (L70/L90 over 50,000 hours), and electrical safety compliance. Components are sourced from trusted suppliers and assembled under ISO 9001-certified manufacturing processes. All products are RoHS compliant and undergo 100% functional testing prior to shipment. This dedication to precision engineering ensures consistent performance, long service life, and superior reliability—hallmarks of Beauty STC’s reputation in the global LED lighting market.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for LED lighting solutions, strategically located within Guangdong Province’s robust electronics supply chain ecosystem. This modern factory spans over 50,000 square meters and is purpose-built for high-volume, precision LED manufacturing with a strong emphasis on quality control and engineering flexibility. Our Jiangmen site houses dedicated production lines specifically optimized for wired LED light strips, integrating advanced surface mount technology with rigorous testing protocols.

The SMT assembly area forms the technological core of our wired LED strip production. We operate multiple high-speed Panasonic CM602 series placement machines configured in dual-lane setups, enabling simultaneous processing of different strip specifications. These machines handle components down to 0201 package size with placement accuracy of ±0.01mm, critical for the dense component layouts found in high-density LED strips. Each line includes automated solder paste printers with 3D verification, nitrogen-reflow ovens with precisely controlled thermal profiles, and AOI systems performing 100% post-reflow inspection. This SMT infrastructure supports both standard and custom flexible PCBs used in our wired strip products, ensuring consistent solder joint integrity and component alignment essential for strip reliability and light uniformity.

Aging and burn-in testing represent a non-negotiable phase in our quality assurance process for all wired LED light strips. Every production batch undergoes a minimum 72-hour continuous aging cycle at full rated voltage and 100% load within our climate-controlled aging chambers. These chambers maintain strict temperature and humidity parameters while subjecting strips to real-world operational stresses. We employ automated monitoring systems that log voltage, current, and thermal performance data at 15-minute intervals, with thermal imaging cameras scanning for hot spots indicative of potential failures. Any strip exhibiting luminance deviation exceeding 3% or thermal anomalies during this period is automatically quarantined for root cause analysis before shipment clearance. This comprehensive aging protocol significantly reduces field failure rates and validates long-term performance claims.

Our OEM capabilities for wired LED light strips are a cornerstone service at the Jiangmen facility, supporting clients from concept to certified finished product. We offer full vertical integration beginning with custom PCB design and layout optimization for specific voltage, density, and flexibility requirements. Engineering teams collaborate closely with clients on component selection including LEDs from Nichia, Samsung, or Seoul Semiconductor based on CRI, CCT, and efficacy targets. The factory accommodates customizations such as specialized diffusers, unique connector types, cut-point configurations, and bespoke packaging including reel labeling and box design. For quality validation, we provide complete photometric reports, LM-80 data, and assist with global certifications including UL, cUL, CE, and RoHS compliance documentation. Prototype development typically completes within 15 working days, with production scalability from small trial batches to monthly volumes exceeding 5 million meters. Crucially, all OEM projects benefit from our in-house quality management system that enforces IPC-A-610 Class 2 standards throughout the wired strip manufacturing process.

Application Scenarios

Wired LED light strips are versatile lighting solutions that can enhance both the functionality and aesthetics of various commercial environments such as hotels, malls, and offices. Their flexibility, energy efficiency, and design adaptability make them ideal for accentuating architectural features, improving ambient lighting, and creating visually appealing spaces.

In hotels, wired LED light strips are commonly used in guest rooms to illuminate under-bed frames, headboards, or cove lighting along ceilings and walls to create a relaxing and luxurious atmosphere. They are also effective in hallways, lobbies, and restrooms, where soft, indirect lighting improves guest comfort and wayfinding. Back-of-house areas like staff corridors and storage rooms benefit from their long lifespan and low maintenance requirements.

In malls, LED light strips are frequently installed in coves, display windows, signage, and along escalator handrails or stair treads to guide foot traffic and highlight brand areas. Their ability to be cut to length and customized in color temperature or RGB options allows for creative branding and dynamic lighting effects during events or holidays. Waterproof versions can also be used in food courts or outdoor-facing areas if protected from direct exposure.

In office environments, wired LED strips support modern, minimalist design by providing indirect lighting under cabinets, above suspended ceilings, or along workstation partitions. They help reduce glare and create uniform ambient light, contributing to a more comfortable and productive workspace. Task lighting under shelves or in filing areas improves visibility while maintaining a clean aesthetic.

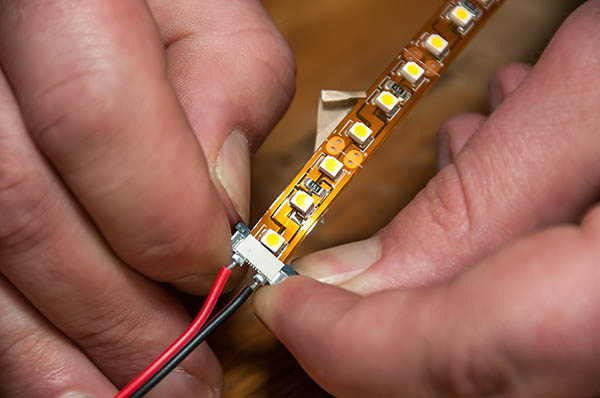

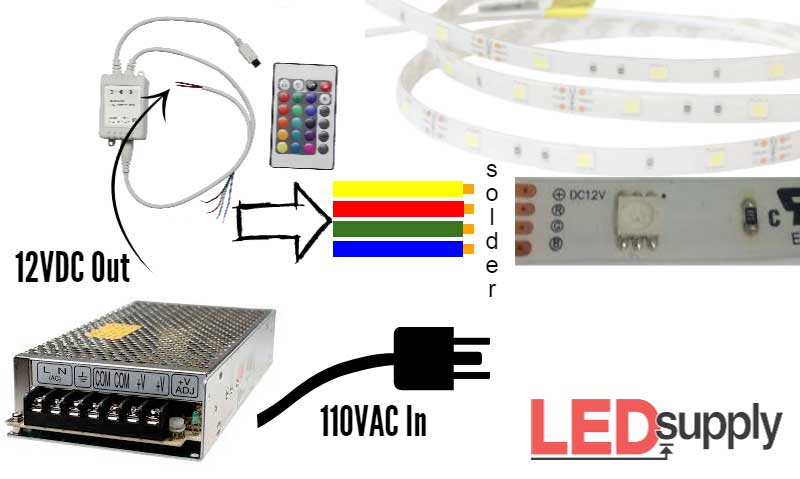

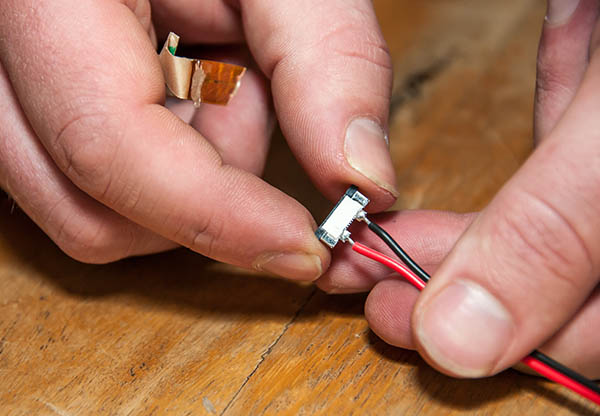

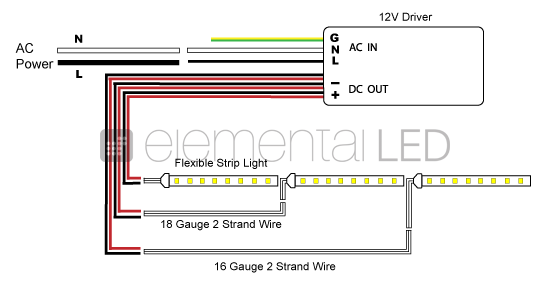

When installing wired LED light strips, begin by planning the layout and measuring the required length to minimize waste. Always ensure the power supply matches the voltage and current requirements of the strip—typically 12V or 24V DC—and use a compatible driver. For long runs, consider feeding power from both ends to avoid voltage drop, which can cause dimming at the far end. Use aluminum channels to improve heat dissipation and prolong LED life, especially in enclosed or high-temperature areas.

Secure the strips using the adhesive backing only on clean, dry, and grease-free surfaces. For added durability, use mechanical clips or mounting brackets. Conceal wiring using raceways or within architectural features to maintain a professional appearance. In humid or high-traffic areas, opt for IP65 or higher rated strips with proper insulation. Finally, test the system before finalizing the installation and label connections for future maintenance.

Why Choose Beauty STC Lighting

For businesses seeking reliable and high-performance wired LED light strips, Beauty STC Manufacturing Co., Ltd. offers an exceptional partnership opportunity grounded in engineering excellence and manufacturing precision. Our wired LED strip solutions are meticulously designed for stability, longevity, and seamless integration into diverse commercial and industrial applications, eliminating concerns about signal interference or battery dependency common in wireless alternatives. As your dedicated manufacturing partner, we provide custom engineering support, rigorous quality control adhering to international standards, and scalable production capabilities to meet your specific project demands.

Partnering with Beauty STC means gaining access to our decade-long expertise in LED innovation, where every product undergoes stringent thermal and electrical validation to ensure consistent output and durability under real-world conditions. We prioritize collaborative development, working closely with your team to refine specifications, optimize cost-efficiency, and accelerate time-to-market without compromising on safety or performance.

To explore how our wired LED light strips can elevate your product offerings and strengthen your market position, contact our Partnership Manager directly at [email protected]. Include your project requirements or integration challenges in your inquiry, and we will promptly provide tailored technical documentation, sample coordination details, and a dedicated engineering consultation to address your unique needs. Let Beauty STC become your trusted ally in delivering lighting solutions that perform flawlessly, every time.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.