Article Contents

Industry Insight: Waterproofing Led Strip

In the realm of commercial and industrial lighting, reliability under demanding environmental conditions is non-negotiable. Waterproof LED strips have emerged as a critical solution in applications ranging from outdoor architectural lighting and parking structures to food processing facilities and marine environments. As industries increasingly prioritize durability, energy efficiency, and compliance, the demand for high-performance, sealed LED strip systems has surged. A key factor in ensuring product safety and market acceptance is certification—ETL and CE markings have become essential benchmarks, verifying that lighting products meet rigorous North American and European safety standards.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED innovation for over two decades. Specializing in high-quality, industrial-grade LED solutions, Beauty STC combines advanced engineering with stringent quality control to deliver waterproof LED strips that perform reliably in harsh conditions. With a strong focus on compliance, durability, and scalable performance, the company has earned a trusted reputation among commercial developers, electrical contractors, and OEM partners worldwide.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance waterproof LED strips meeting stringent technical requirements for demanding applications. Our waterproofing methodology directly impacts key specifications like efficacy, color quality, and environmental resilience. We utilize advanced double-layer silicone jacketing for superior protection, distinct from inferior single-layer epoxy coatings which degrade faster under UV exposure and thermal cycling. This construction is fundamental to achieving consistent performance metrics.

Lumens per Watt (Efficacy) is optimized through our proprietary SMD3528 and SMD5050 chip selection combined with high-efficiency constant-current drivers. Standard waterproof strips achieve 120-130 lm/W at 25°C ambient temperature while maintaining CRI >90. Higher-density configurations (e.g., 120 LEDs/meter) operate at 110-120 lm/W due to thermal constraints within the sealed silicone jacket. Efficacy is rigorously validated under IES LM-79 testing protocols, with thermal management integrated into the strip design to minimize lumen depreciation at elevated temperatures. Voltage drop over run length is minimized through 2oz copper PCB construction, ensuring uniform output.

Color Rendering Index (CRI) consistently exceeds 90 (Ra >90) across our waterproof product line, with special attention to R9 (saturated red) values above 50 to ensure vibrant, accurate color reproduction critical for retail, hospitality, and architectural applications. This is achieved using multi-phosphor LED chips binned to stringent MacAdam Ellipse 3-step standards. Unlike competitors who may advertise high average CRI while sacrificing specific color points, Beauty STC guarantees full-spectrum accuracy through spectrophotometric batch calibration. Our silicone encapsulation is formulated to prevent yellowing, maintaining CRI integrity over 50,000 hours of operation.

IP Ratings define our waterproofing performance tiers. IP65 strips feature flexible silicone extrusion providing robust protection against low-pressure water jets from any direction, suitable for outdoor facades and damp indoor environments. For submersion applications, IP67 strips withstand temporary immersion up to 1 meter for 30 minutes, validated through 72-hour continuous submersion testing beyond IEC 60529 standards. Our premium IP68 strips exceed 1 meter depth for continuous operation (tested to 5 meters), utilizing a dual-durometer silicone jacket with hermetically sealed end caps resistant to saltwater corrosion. All ratings are certified by independent laboratories with full traceability.

Beauty STC’s quality differentiation lies in our integrated manufacturing control. We implement in-line spectral analysis during production, ensuring every meter meets lumen, CCT, and CRI tolerances before jacketing. The silicone material undergoes accelerated aging tests equivalent to 10 years of UV exposure per IEC 60068-2-5, with zero cracking or haze development. Rigorous batch-level LM-80 testing confirms L70 lumen maintenance beyond 50,000 hours at 70°C case temperature. Each reel includes traceable calibration data, and we enforce a strict 0.5% maximum failure rate in final QA – significantly below industry averages. This commitment to precision engineering ensures our waterproof strips deliver reliable, high-fidelity illumination in the most challenging environments, backed by a comprehensive 5-year warranty.

Factory Tour: Manufacturing Excellence

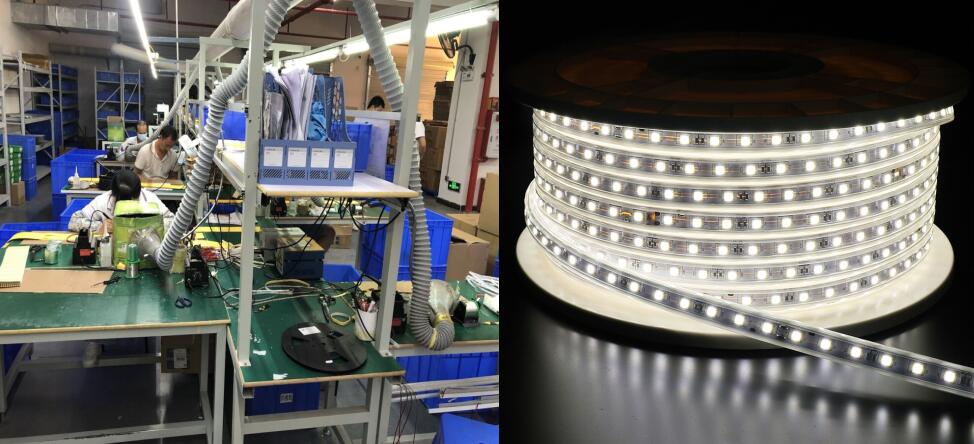

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located to support efficient production and logistics for both domestic and international markets. The factory is designed to meet high standards of quality control and manufacturing efficiency, particularly in the production of LED lighting products, including flexible LED strips.

At the core of the production line are advanced SMT (Surface Mount Technology) machines that ensure precision in placing LED components onto PCBs. These automated SMT lines are capable of handling high-volume output with consistent accuracy, supporting a wide range of LED chip sizes including 2835, 3528, 5050, and others commonly used in LED strip manufacturing. The use of automated optical inspection (AOI) systems integrated with the SMT process enables real-time defect detection, ensuring high yield and reliability.

The factory incorporates comprehensive aging and reliability testing procedures as part of its quality assurance protocol. Completed LED strips undergo extended aging tests, typically 24 to 72 hours under elevated temperature and full load conditions, to identify early failure risks and verify long-term performance. Additional testing includes waterproof performance verification, high-voltage insulation tests, and light distribution measurements, all conducted in dedicated testing labs within the facility.

Beauty STC has strong OEM capabilities, particularly in the customization of waterproof LED strips. The company supports tailored solutions including custom IP ratings (such as IP65, IP67, and IP68), different silicone or PVC jacketing materials, varied strip lengths, and customized packaging. Their production line includes automated coating and extrusion processes for applying waterproofing layers, ensuring consistent and durable protection for outdoor and high-moisture environments. Clients can also request private labeling, custom color temperatures, and specialized dimming functions, all supported by in-house engineering and R&D teams.

Overall, the Jiangmen factory combines automation, rigorous testing, and flexible manufacturing to deliver high-quality, reliable, and customized waterproof LED strip solutions for global OEM partners.

Application Scenarios

Waterproof LED strips, specifically those rated IP65, IP67, or IP68, are essential in environments where moisture, humidity, or direct water exposure is present. While hotels, malls, and offices are primarily dry interior spaces, specific zones within these facilities demand waterproof-rated strips to ensure safety, longevity, and compliance with electrical codes. Using standard non-waterproof strips in these areas risks short circuits, corrosion, and premature failure.

In hotels, waterproof LED strips are critical for pool and spa perimeters, underwater pool lighting (requiring IP68 submersion-rated strips), steam rooms, saunas, and exterior architectural features like eaves, canopies, or outdoor signage exposed to rain. Bathroom applications such as under-vanity toe-kick lighting or shower niche accents also require IP65 or higher to withstand daily humidity and splashes. Never install non-waterproof strips in these zones, as condensation alone can cause failure within months.

For malls, prioritize waterproof strips in fountain and water feature installations, food court drainage channels, exterior storefront canopies, and landscape lighting for outdoor seating areas. Service corridors near loading docks or waste handling zones may also experience damp conditions where IP65 strips prevent moisture ingress. Avoid using them in standard retail displays or dry corridors, as the added cost isn’t justified where no moisture risk exists.

Offices typically have fewer wet zones, but waterproof strips are necessary for rooftop terraces with exposed lighting, indoor planters with irrigation systems, and exterior window sills or signage. Some modern offices incorporate water features in lobbies—these demand IP67-rated strips. Standard office workspaces, meeting rooms, and dry corridors do not require waterproofing; using such strips here adds unnecessary expense without benefit.

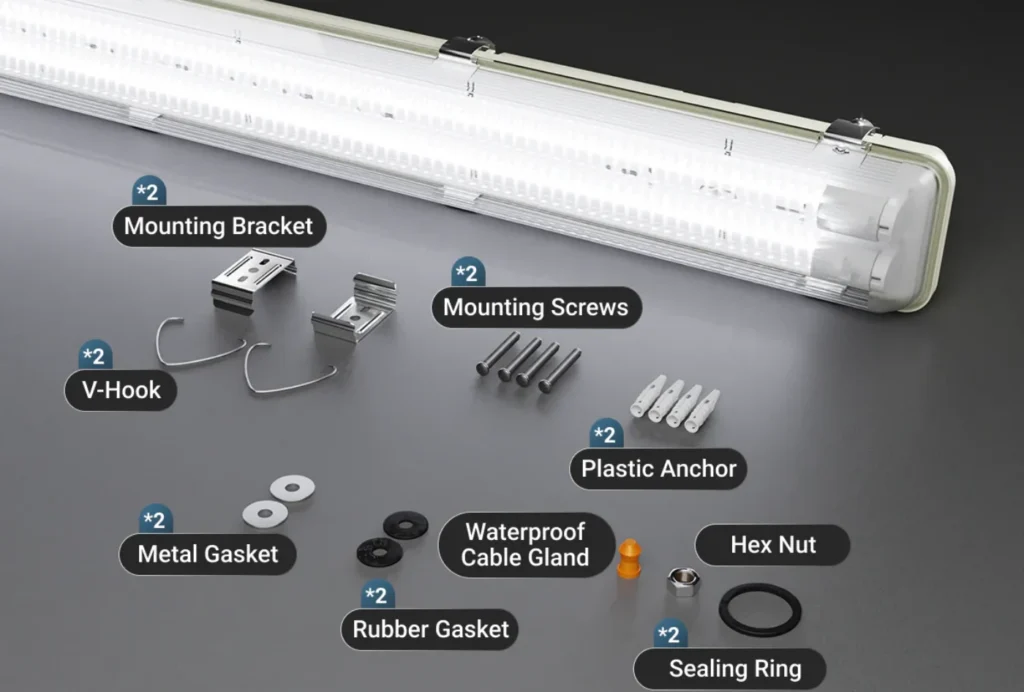

Installation requires strict adherence to best practices. Always verify the IP rating matches the environment: IP65 for splash protection, IP67 for temporary submersion, IP68 for continuous underwater use. Never cut the strip except at designated cut points, as this compromises the silicone coating and seals. Use manufacturer-approved waterproof connectors and end caps, applying dielectric grease to all connections before sealing to prevent corrosion. For outdoor or high-humidity areas, mount strips in aluminum channels with diffusers to manage heat dissipation—trapped heat accelerates lumen depreciation even in waterproof designs. Ensure all power supplies and controllers are housed in IP-rated enclosures away from direct exposure. In linear runs exceeding 5 meters, especially with 12V strips, inject power at multiple points to avoid voltage drop, which causes uneven brightness and overheating. Finally, test the entire circuit before final sealing and avoid stretching or kinking the strip during installation, as this can crack the silicone jacket. Never retrofit non-waterproof strips with aftermarket sealants; this is unreliable and violates safety certifications.

Why Choose Beauty STC Lighting

Transform your lighting projects with premium waterproof LED strips engineered for durability and performance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our waterproof LED strips are built to withstand moisture, humidity, and outdoor elements—ideal for architectural accents, outdoor signage, marine applications, and more.

At Beauty STC, we combine advanced technology with rigorous quality control to deliver reliable, high-efficiency lighting products tailored to your needs. Whether you’re working on residential, commercial, or industrial installations, our team is ready to support your success.

Take the next step toward superior lighting performance. Contact us today at [email protected] to discuss your project and discover how Beauty STC can be your trusted manufacturing partner.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.