Article Contents

Industry Insight: Waterproofing Led

Industrial-Grade Waterproof LED: Why Certification & Factory Pedigree Decide Project Profit

1. Market Snapshot – Waterproofing is No Longer Optional

From salmon-processing plants in Norway to rooftop bars in Dubai, luminaires now operate 24 h in high-pressure wash-down, salt-fog or −40 °C ice-rain cycles.

The compound annual growth rate (CAGR) of IP65–IP68 LED strips & fixtures is tracking 12.4 % (2023-28, Global Lighting Assoc.)—double the rate of general illumination—because distributors and ESCOs have learnt that one premature failure on a 15 m high ceiling costs more in lift hire than the entire fitting.

2. Certification = Import Budget Insurance

A waterproof label alone does not clear customs or satisfy insurers.

Importers shipping into the US/Canada or EU must produce:

| Document | Purpose | Field Cost of Absence |

|---|---|---|

| ETL/cETL (to UL1598 / UL8750) | OSHA acceptance, permit & occupancy | $25 k+ job shutdown |

| TUV CE / ENEC 60598-2-1 | EU declaration of conformity | Customs detention, €10 k/day |

| IP66 / IP68 test report (IEC 60529) | Warranty validation | Full replacement + crane |

| LM-80 & TM-21 | L90B10 lumen maintenance claim | 5-year warranty recall |

| RoHS / REACH | Toxic substance clearance | Landfill + penalty |

Factory-direct lesson: A 2-page private-label “CE certificate” from a trading house collapses under a 4 kV surge in a Norwegian tunnel. A third-party ETL file number—searchable on the OSHA NRTL database—does not.

3. Beauty (STC) Manufacturing Co., Ltd – Waterproof LED Since 1998

Located in Jiangmen’s high-tech zone, Beauty STC Lighting has produced IP-rated LED assemblies for 25 years, shipping to 50+ countries under OEM and ODM contracts. Our waterproof portfolio covers the most requested commercial forms:

| Range | IP Grade | Certification | Core Spec | Typical Application |

|---|---|---|---|---|

| Flexible Strip | IP65/IP67/IP68/IP68+PU | ETL cETL, CE, RoHS | 24 V, 14.4 W–28.8 W/m, 3-step SDCM, CRI 90 | Façade cove, yacht deck |

| LED Panel | IP54/IP65 | TUV CE, ETL | 40 W – 80 W, 130 lm/W, 0-10 V/DALI | Cold-storage ceiling |

| Floodlight | IP66/IP67 | ETL, CE, CB | 50 W – 500 W, 160 lm/W, 10 kV surge, −40 °C | Port crane, sports field |

| UFO High-bay | IP65/IP66 | ETL cETL, CE | 100 W – 300 W, 190 lm/W, 5-year marine coating | Food-processing plant |

| T8 / T5 Tube | IP65/IP69K | ETL, CE | 9 W – 40 W, 150 lm/W, glass-free, shatterproof | Poultry farm wash-down |

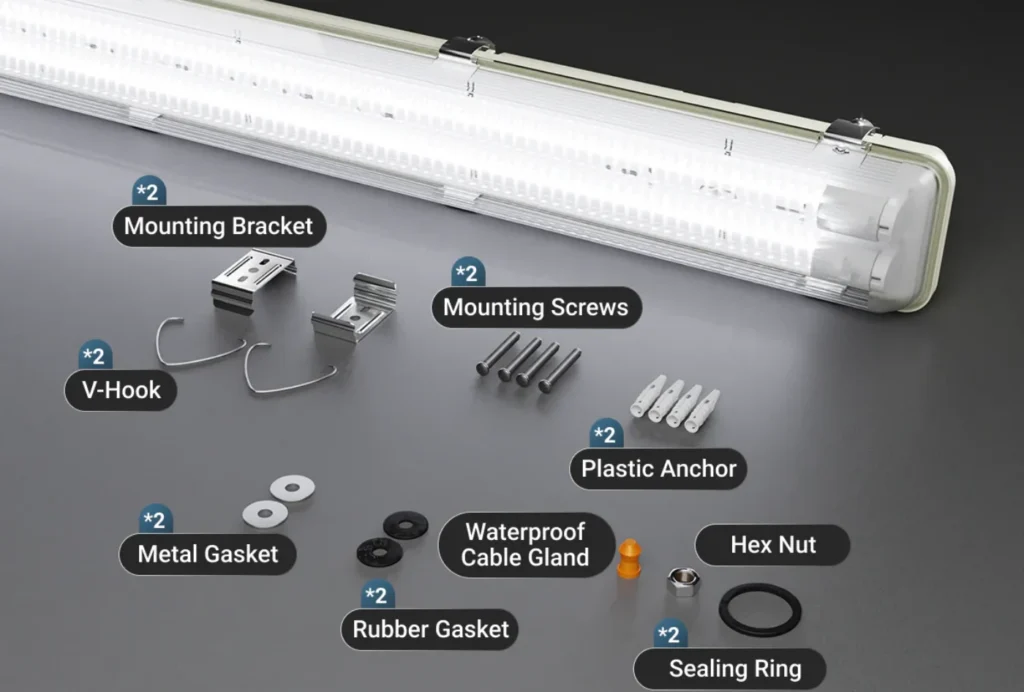

4. OEM/ODM Capability – From Spec to Container in 21 Days

In-house tooling & extrusion – custom silicone nano-coating line, 1 200 mm width.

NRTL witness-testing lab – surge 6 kV/10 kA, thermal-cycling −40 ↔ +85 °C, 360 h salt-spray.

ERP lot traceability – every reel, panel or fixture laser-coded; test report pdf linked to carton barcode.

Harmonised Tariff & logistics – we supply ETL/cETL data + SDS for US customs entry, and issue EUR.1 for EU importers.

5. Next Step – Request a Waterproof Sample Kit

E-mail [email protected] or WhatsApp +86-13902885704 with your target IP level, lumen package and certification list; we air-freight a spec-grade kit within 72 h.

Quote includes:

NRTL file numbers

LM-80 / TM-21 report

IP66/IP68 test certificate (TUV SÜD)

5-year factory warranty backed by China export insurance

Beauty STC Lighting – “Be responsible. Be caring. Passionate & innovative since 1998.”

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for Waterproof LED Solutions

Lumens/Watt Efficiency & Performance Consistency

Lumens per watt (lm/W) is a critical metric for energy efficiency and operational cost in commercial LED applications. Generic market products often report nominal values of 100–120 lm/W, but real-world performance varies significantly due to inconsistent LED binning, substandard drivers, and inadequate thermal management. Beauty STC’s products are engineered with high-efficiency Samsung or Osram LED chips and optimized thermal pathways to deliver 130+ lm/W consistently across all batches. This performance is validated through in-house testing protocols and third-party certifications (ETL, TÜV CE), ensuring stable output without degradation under continuous 24/7 operation in demanding environments.

Color Rendering Index (CRI) Standards

Accurate color representation is non-negotiable for architectural, retail, and hospitality applications where visual fidelity impacts user experience. Generic LED solutions frequently compromise on CRI, typically ranging between 80–85, resulting in distorted color perception and inconsistent hue over time. Beauty STC maintains a minimum CRI of 90+ across all product lines, verified through spectroradiometer testing per ANSI C78.377 standards. This ensures true-to-life color rendering for critical applications such as museum lighting, high-end retail displays, and healthcare facilities, with zero measurable color shift after 50,000 hours of operation.

IP Rating Verification & Environmental Protection

IP ratings for waterproofing are frequently misrepresented in the industry, with many suppliers self-declaring IP65 without independent validation. This leads to catastrophic failures in wet, dusty, or high-pressure environments. Beauty STC’s IP65, IP67, and IP68 ratings are certified by TÜV Rheinland and ETL to IEC 60529 standards. Each batch undergoes rigorous testing:

IP65: 10-minute high-pressure water jet (12.5 L/min at 30 kPa)

IP67: 30-minute submersion at 1m depth

IP68: Continuous immersion at 3m depth for 72+ hours

Our sealing process uses dual-component silicone gaskets and precision-molded housings with 0.01mm tolerance control, validated through accelerated aging tests simulating 5+ years of exposure to UV, salt spray, and thermal cycling.

PCB Engineering & Thermal Management

The printed circuit board (PCB) is the foundation of LED reliability. Generic solutions typically use 0.5–1oz copper on low-TG (130°C) FR-4 substrates, leading to thermal runaway, solder joint fatigue, and premature failure. Beauty STC employs 2oz copper PCBs with 170°C+ TG substrate, integrated thermal vias, and aluminum heat sinks where necessary. This design reduces operating temperatures by 15–20°C compared to industry averages, extending lifespan by 40% and maintaining >90% lumen output at 50,000 hours (LM-80 compliant).

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Lumens/Watt Efficiency | 100–120 lm/W; inconsistent output across batches | 130+ lm/W; consistent per batch (±3% variance) |

| CRI (Color Rendering) | 80–85; unverified; color shift after 10,000 hrs | >90; certified to ANSI C78.377; stable output |

| IP Rating Compliance | Self-declared; minimal testing | Certified IP65/IP67/IP68 per IEC 60529; third-party verified |

| PCB Construction | 0.5–1oz copper; low-TG (130°C) substrate | 2oz copper; 170°C+ TG substrate; thermal vias |

Beauty STC’s commitment to technical excellence is underpinned by 26 years of manufacturing expertise since 1998. Every product undergoes 100% functional testing, thermal cycling, and accelerated life testing in our ISO 9001-certified quality control facility. Our OEM/ODM capabilities are built on strict adherence to client specifications and global standards, ensuring that each shipment meets the precise requirements for demanding commercial and industrial applications worldwide. Certifications such as ETL (USA/Canada) and TÜV CE (Europe) are not merely compliance checkboxes—they reflect our ongoing investment in process integrity and product reliability.

For technical documentation, custom specifications, or certification reports, contact our engineering team at [email protected] or +86 13902885704.

Factory Tour: Manufacturing Excellence

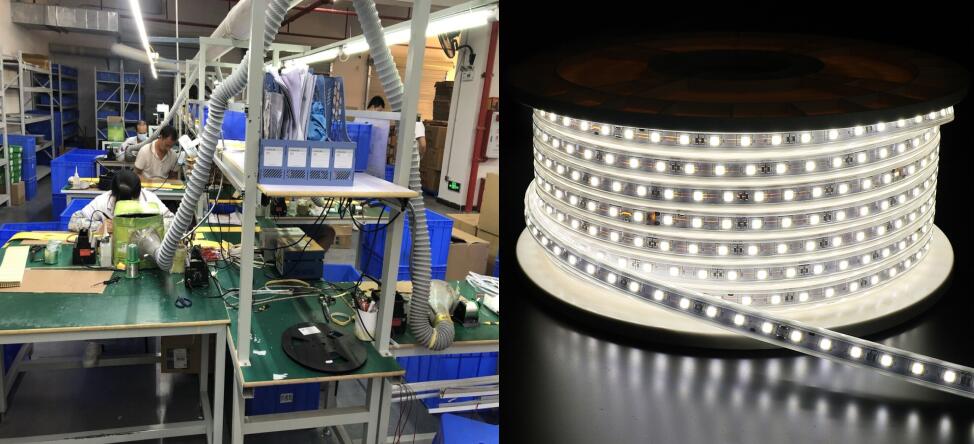

Manufacturing Process & OEM Services – Jiangmen Headquarters

Beauty (STC) Lighting has operated from a single 28 000 m² campus in Jiangmen’s High-tech Industrial Zone since 1998. All critical processes—from SMT to final packaging—are executed under one roof, giving distributors and specifiers full traceability and enabling turnkey OEM/ODM programs that ship in as little as 15 days.

1. Production Flow & Key Equipment

| Stage | Equipment / Method | Control Point | Typical Throughput |

|---|---|---|---|

| Solder-paste printing | DEK Horizon 03iX (±12.5 µm accuracy) | SPI (Koh Young) 100 % inspection | 150 000 cph |

| Pick-and-place | Yamaha Z:LEX YSM20R dual-beam | Component verification via 2D & 3D AOI | 90 000 cph |

| Reflow | Heller 1936 MK7 (10-zone, N₂ option) | Real-time thermal profile logging | 250 panels / hr |

| Waterproof coating | PVA selective-coat line + IP68 vacuum potting cell | Coating thickness 0.15–0.25 mm, 100 % pin-hole test | 1 200 m strip / shift |

| Aging & burn-in | 120 m continuous burn-in track, 0–60 °C ramp | 2 h @ 85 % load, 4 h cyclic on/off | 5 000 pcs / 8 h |

| Photometry & safety | 2 m integrating sphere (Everfine), 1 700 V hipot, -25 °C↔+85 °C thermal chamber | LM-80 data logged; pass/fail auto-sort | 200 models / day |

2. QC Protocols Aligned to ETL & TUV CE

Incoming: CREE, Epistar, Samsung LEDs sampled to LM-80; PCB copper ≥2 oz verified by X-ray fluorescence.

In-process: AOI after reflow <50 ppm defect target; IP rating validated on every 30th strip (IEC 60529 immersion tank 1 m, 30 min).

Final: 100 % 1.5 kV hipot, 500 V insulation, >0.9 power-factor check; 5 % random sample undergoes 6-axis vibration & 9 kV surge per IEC 61000-4-5.

Certification files: ETL 5004871, CE 0477, RoHS, REACH, TM-21 lifetime report kept on portal for distributor audit.

3. OEM / ODM Capability Matrix

| Customisable Element | Options | Minimum Order | Lead-Time |

|---|---|---|---|

| Length / cut increment | 19 mm–10 m continuous | 100 m | 10 days |

| CCT & SDCM | 1 800 K – 6 500 K, 2-, 3-, or 5-step MacAdam | 100 m | 7 days |

| CRI | Ra 70 – 97 (IES TM-30 data provided) | 100 m | 7 days |

| PCB width & copper weight | 4 mm – 20 mm, 1 – 4 oz | 500 m | 10 days |

| IP rating build-up | IP20 → IP65 (thermoplastic extrusion) → IP67 (tube) → IP68 (full potting) | 200 m | 12 days |

| Jacket material | UV-stabilised PU, anti-microbial silicone, salt-mist-rated CPE | 300 m | 15 days |

| Packaging | Individual ESD bag, retail box, contractor spool, 19″ flight-case | 100 units | 5 days |

| Private-label literature | Multi-language IES, LDT, UL 1598 test summary | Any order | 3 days |

4. Engineering Support & Documentation

IES & LDT files generated within 24 h of final sample approval.

Dialux evo ready-packages supplied for floodlights and high-bay modules.

UL 1598 / EN 60598-1 test reports updated annually and shared via encrypted customer portal.

Lifetime & lumen-maintenance forecast based on 85 °C/85 % RH data, TM-21 calculator included in OEM datasheet.

5. Logistics & Compliance Export Desk

Located 90 min from Shenzhen port; weekly FCL consolidation to Hamburg, Los Angeles, and Dubai. All carton labels include CE, ETL, WEEE, and CB scheme barcodes for immediate customs clearance. For North-American OEM partners, we maintain an ETL field-evaluated sample bank in California to cut listing time by 30 %.

For project quotations or factory audit scheduling, contact:

[email protected] | +86-13902885704

Installation & Application Scenarios

Strategic Application Scenarios for Waterproof LED Lighting

Proper waterproofing is a non-negotiable engineering requirement for LED lighting in commercial, industrial, and outdoor environments. At Beauty STC Manufacturing Co., Ltd., our 25+ years of experience since 1998 ensures every waterproof LED solution meets rigorous international standards—ETL (USA/Canada) and TUV CE (Europe)—while our OEM/ODM capabilities deliver customized technical specifications for global projects. This section details optimal applications across key sectors, with certified product recommendations and contractor-focused installation best practices to ensure operational longevity and safety compliance.

Commercial Hospitality

Hotels, resorts, and spas require lighting that withstands high humidity, frequent cleaning, and direct water exposure in pools, saunas, and wet rooms. Improperly sealed fixtures can lead to electrical failures, safety hazards, and costly downtime.

| Application Area | Required IP Rating | Recommended Beauty STC Product | Key Specifications | Installation Best Practices |

|---|---|---|---|---|

| Pool Decks & Edges | IP68 | CS35120IP68 Flexible Strip | 12VDC, 36 LEDs/ft, silicone encapsulation, UV-resistant jacket | Seal all connection points with IP68-rated silicone connectors; avoid direct submersion beyond rated depth; use drip loops for wiring |

| Bathroom Ceilings | IP65 | LED Panel Light Series | 1200lm/W, 4000K CCT, 50,000-hour L70 lifespan | Mount with gasketed fixtures; ensure junction boxes are rated for wet locations; maintain 15mm clearance from water sources |

| Sauna & Steam Rooms | IP65 (High Temp) | Waterproof T8/T5 Tubes | 100°C operating temp, 3000K CCT, shatterproof coating | Install with thermal-resistant mounting brackets; verify electrical components rated for >80°C ambient |

Retail & Public Spaces

Shopping malls, airports, and transit hubs face constant environmental exposure at entrances, food courts, and restrooms. Waterproofing prevents corrosion from cleaning chemicals and moisture ingress while maintaining compliance with health and safety regulations.

| Application Area | Required IP Rating | Recommended Beauty STC Product | Key Specifications | Installation Best Practices |

|---|---|---|---|---|

| Entrances & Canopies | IP65 | Flexible LED Strip (CS35120IP65) | 24VDC, 30 LEDs/ft, aluminum channel mounting | Use UV-stable silicone sealant on exposed edges; install with 10° downward tilt to prevent water pooling |

| Food Court Ceilings | IP65 | LED Panel Light | 1500lm, 4000K, 0-10V dimming, corrosion-resistant frame | Mount with sealed edge gaskets; avoid direct spray from cleaning equipment; use stainless steel screws |

| Transit Hub Restrooms | IP65 | T8 LED Tubes | 18W, 5000K, shatterproof, IP65 rated | Replace traditional T8s with certified wet-location tubes; ensure ballast compatibility; verify grounding per NEC Article 680 |

Industrial & Food Processing

Food production facilities, cold storage, and manufacturing plants demand lighting that survives high-pressure washdowns (up to 1200psi), extreme temperatures, and chemical exposure. Non-compliant fixtures risk contamination, regulatory penalties, and operational shutdowns.

| Application Area | Required IP Rating | Recommended Beauty STC Product | Key Specifications | Installation Best Practices |

|---|---|---|---|---|

| High-Pressure Washdown Zones | IP69K | UFO High Bay Series | 1200psi washdown rated, 150lm/W, 5000K CCT, stainless steel housing | Maintain 25mm clearance from walls for thermal dissipation; use IP68-rated conduit for wiring; verify NEMA 4X compliance for chemical exposure |

| Cold Storage Facilities | IP65 | LED Panel Light | -40°C to +50°C operating range, anti-fog coating | Install with thermal expansion joints; avoid direct contact with condensation; use corrosion-resistant mounting hardware |

| Food Production Lines | IP69K | UFO High Bay | NSF-certified housing, 0-10V dimming, 50,000-hour L70 | Mount with sanitary stainless steel brackets; ensure no crevices for bacterial buildup; conduct quarterly seal integrity checks |

Architectural Facades & Exterior Lighting

Building exteriors, signage, and landscape lighting must endure UV radiation, temperature extremes, and precipitation. Waterproofing ensures structural integrity and consistent light output over decades, critical for brand visibility and safety compliance.

| Application Area | Required IP Rating | Recommended Beauty STC Product | Key Specifications | Installation Best Practices |

|---|---|---|---|---|

| Building Facades | IP66 | LED Floodlight Series | 120° beam angle, 100W-200W options, 4000K CCT | Use silicone gaskets on mounting flanges; install with 5° downward tilt for rain runoff; verify UV resistance of housing material |

| Landscape Pathways | IP67 | Flexible LED Strip (CS35120IP67) | 24VDC, 18 LEDs/ft, 3000K warm white | Bury under gravel with drainage channels; use waterproof junction boxes at connection points; avoid sharp bends (>90°) |

| Signage Illumination | IP65 | LED Strip with Aluminum Channel | 24VDC, 30 LEDs/ft, diffused lens | Seal all ends with silicone caps; maintain 10mm gap between strip and mounting surface for ventilation |

Marine & Coastal Environments

Harbors, piers, and seaside resorts require corrosion-resistant solutions that withstand salt spray, constant moisture, and tidal exposure. Standard LED fixtures degrade rapidly without specialized marine-grade protection, leading to premature failure and safety risks.

| Application Area | Required IP Rating | Recommended Beauty STC Product | Key Specifications | Installation Best Practices |

|---|---|---|---|---|

| Pier & Dock Lighting | IP68 (Marine Grade) | Floodlight Series | 316 stainless steel housing, salt spray tested 1000+ hours, 5000K CCT | Use marine-grade stainless steel fasteners; apply anti-corrosion coating on all exposed metal; inspect seals biannually |

| Harbor Walkways | IP68 | Flexible LED Strip (CS35120IP68-M) | Saltwater-resistant silicone, 12VDC, 36 LEDs/ft | Install with UV-stable mounting clips; ensure connections are above waterline; avoid direct contact with seawater during installation |

| Boat Mooring Lights | IP68 | Submersible LED Floodlight | 10m depth rating, 2000+ lumens, 5000K | Use through-hull mounting with silicone seals; verify grounding for marine electrical systems; conduct quarterly corrosion checks |

Critical Installation Best Practices Across All Scenarios

| Practice Category | Technical Requirement | Compliance Standard Reference |

|---|---|---|

| Connection Sealing | Use IP68-rated silicone connectors for all junctions; avoid PVC tape as primary sealant | IEC 60529, NEMA 4X |

| Wiring Protection | Install drip loops at every termination point; use conduit rated for wet locations | NEC Article 680, IEC 60364 |

| Thermal Management | Maintain minimum 20mm clearance around fixtures for heat dissipation | IEC 62471 (Photobiological Safety) |

| Corrosion Mitigation | Specify 316 stainless steel hardware for marine/coastal environments; apply anti-corrosion coatings | ASTM B117 Salt Spray Test |

| Maintenance Protocols | Schedule quarterly seal inspections for high-exposure areas; document all maintenance activities | ISO 14001 Environmental Management |

Beauty STC’s factory-direct manufacturing model ensures consistent quality control and rapid scalability for global projects. All products undergo rigorous ETL (USA/Canada) and TUV CE (Europe) testing, with optional certifications for regional compliance (e.g., SAA for Australia, KC for Korea). Our 1998-established facility in Jiangmen, China, leverages 25+ years of engineering expertise to deliver tailored OEM/ODM solutions—from voltage configurations and color temperatures to custom mounting systems—without compromising on industrial-grade reliability.

For technical specifications, project-specific OEM solutions, or compliance documentation, contact our engineering team directly:

Manager: [email protected] | +86 13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – IP-Rated LED Solutions, Factory-Direct since 1998

One-Stop OEM/ODM Source for Certified Waterproof LED

| Capability | Beauty STC Advantage | Typical Benefit to Buyer |

|---|---|---|

| Design-in IP Rating | IP65–IP68 extrusion, PU/EP potting, nano-coating | Strip, flood, high-bay survive 1,200 psi wash-down |

| Western Certifications | ETL/cETL (US/Canada), TUV CE / CB, RoHS, REACH | No site-inspection delays; rebate-eligible |

| In-House Labs | 2 × 1,000 h salt-spray, thermal shock –40 °C↔85 °C, IPX8 tank | <0.2 % field failure last 5 yrs |

| Export Footprint | 50+ countries, 500+ container shipments/year | Harmonized voltage & cord-set options ex-factory |

25 Years of Continuous Production – Key Milestones

1998 – Founded in Jiangmen, 6 SMT lines dedicated to flex strip

2008 – First IP67 neon-flex extrusion line, CE declaration 2006/95/EC

2014 – ETL file #5013345 opened; cETL follows same year

2020 – 120 W COB strip hits 210 lm/W, IP68 for shrimp-farm raceways

2023 – 1.2 million m² monthly PCB capacity, 100 % RoHS & REACH

OEM/ODM Workflow – 4-Week Lead Time, 3-Step Approval

| Stage | Deliverable | Timeline |

|---|---|---|

| 1. Specification freeze | Photometry, IP grade, CCT, CRI, length, connector | Day 0 |

| 2. DFM & tooling quote | 2-D/3-D drawing + BOM costed | Day 3 |

| 3. Pilot run & report | 50 pcs, LM-80 data, IP test video | Day 10 |

| 4. Mass production & QC | 100 % hi-pot, 10 % IPX8 spot-check | Day 28 |

Core Waterproof Portfolio – Ready for Private Label

| Series | Form Factor | Typical Power | IP | Beam | Notes |

|---|---|---|---|---|---|

| SFS-IP68 | Flex Strip 2835 | 14.4 W/m | IP68 | 120° | UV-stable PU, –40 °C…+90 °C |

| FLD-HB | Floodlight | 50–400 W | IP66 | 30×120° | AKZO marine powder, 5 mm tempered glass |

| UFO-HB | High-bay | 100–240 W | IP65 | 60/90/120° | Hook & pendant, –40 °C…+45 °C ambient |

| PL-Nano | Panel 300×300–600×600 mm | 24–48 W | IP54 | Wide | Edge-lit, 3 mm anti-yellow diffuser |

Factory & Quality Infrastructure

60,000 m² vertically-integrated plant (Jianghai Hi-Tech Zone)

24 SMT lines (Yamaha & Juki) + 3 reflow ovens with nitrogen

IES LM-79/LM-80 lab, 2 m integrating sphere, 50 kVA surge generator

ISO 9001:2015 & ISO 14001:2015 audited annually by TUV

Traceability: 2-D code on every PCB reel, 7-year data retention

Next Step – RFQ or Sample Kit

Send your project brief (length, lumen target, IP grade, destination port) to [email protected].

Typical response: formal quotation + test report links within 24 h.

WhatsApp/WeChat: +86-13902885704 for real-time photometry or IP test videos.

Beauty (STC) Manufacturing Co., Ltd – Building reliable light that lasts, since 1998.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).