Article Contents

Industry Insight: Waterproof Strip

The demand for durable, high-performance lighting solutions in commercial and industrial environments has driven significant innovation in waterproof lighting technology. Among these advancements, waterproof LED strips have emerged as a critical component for applications requiring resistance to moisture, dust, and harsh operating conditions. Widely used in warehouses, cold storage facilities, manufacturing plants, parking structures, and outdoor architectural installations, these lighting systems must meet stringent safety and performance standards. Compliance with ETL and CE certifications has become essential, ensuring that products adhere to North American and international electrical safety requirements, respectively. These certifications not only validate reliability and operational safety but also provide assurance to engineers, contractors, and facility managers tasked with specifying long-lasting lighting solutions.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in commercial and industrial-grade lighting products, Beauty STC combines advanced engineering with rigorous quality control to deliver waterproof LED strips that meet the demanding needs of modern facilities. With a strong commitment to performance, durability, and regulatory compliance, the company has earned a trusted reputation across global markets. Beauty STC’s waterproof strips are designed to perform in extreme environments while maintaining energy efficiency and long service life, making them a preferred choice for professionals who prioritize safety, reliability, and code-compliant installations.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance waterproof LED strip lights meeting stringent technical requirements for demanding applications. Our standard waterproof strip specifications prioritize efficiency, color fidelity, and environmental protection. Key technical parameters for our flagship high-CRI waterproof series are as follows.

Luminous efficacy for these strips typically ranges from 110 to 125 lumens per watt at 25°C ambient temperature, operating at standard 24V DC input. This efficiency is achieved while maintaining strict adherence to the CRI >90 requirement, utilizing premium Samsung LM301H or Epistar 3030 high-efficiency LED chips coupled with precisely engineered phosphor coatings. The efficacy balance ensures minimal energy waste without compromising the critical color rendering performance demanded in retail, museum, and high-end architectural installations.

Color Rendering Index (CRI) consistently exceeds 90 (Ra ≥ 92), with deep red (R9) values above 50 and Television Lighting Consistency Index (TLCI) ≥ 95. This is accomplished through rigorous LED binning processes at our Shenzhen facility, where chips are sorted to tight chromaticity tolerances (within a 3-step MacAdam ellipse) and paired with spectrally optimized phosphors. Independent lab reports verify these metrics across our 2700K to 6500K CCT range, ensuring accurate and vibrant color reproduction for critical visual tasks.

IP ratings are rigorously validated per IEC 60529 standards. Our standard offering provides IP67 protection, achieved through seamless silicone encapsulation (1.5mm thickness) applied via precision robotic potting lines, creating a continuous barrier against dust and temporary water immersion up to 1 meter for 30 minutes. For submersion applications, IP68-rated variants (tested at 1.5 meters for 72+ hours) utilize dual-layer silicone sealing with enhanced UV-stable formulations. All waterproofing processes undergo 100% post-production water ingress testing under pressure differentials simulating real-world conditions.

Beauty STC’s quality differentiation lies in our vertically integrated manufacturing control. We implement automated optical inspection (AOI) during SMT assembly, 72-hour accelerated life testing at 60°C/85% RH on every production batch, and UL/cUL certification for all electrical components. Our strips utilize 2oz copper PCBs for thermal management, reducing lumen depreciation to L70 > 50,000 hours at 45°C ambient. Unlike industry-standard 1-year warranties, Beauty STC provides a 5-year comprehensive warranty covering both LED performance and waterproof integrity, substantiated by third-party reliability data from SGS and TÜV Rheinland. This commitment ensures consistent output and longevity even in challenging environments like outdoor facades, marine settings, or refrigerated display cases.

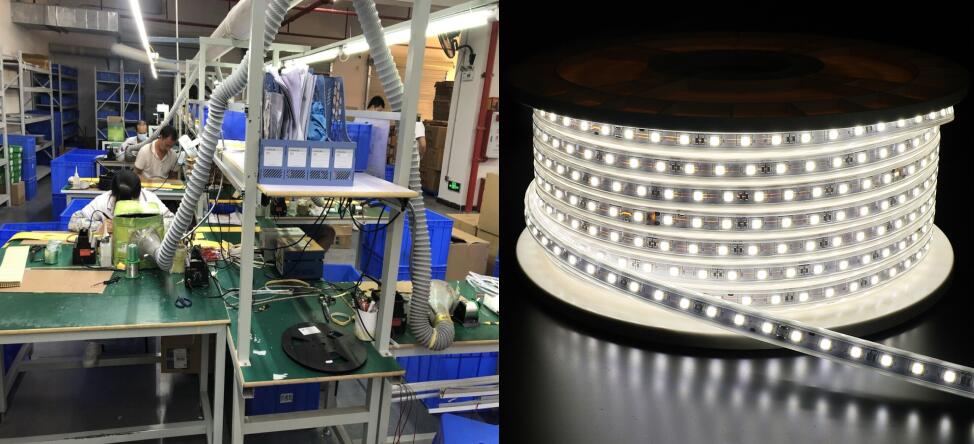

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern and well-equipped facility specializing in the production of LED lighting products. Strategically located in an industrial zone with strong manufacturing infrastructure, the Jiangmen plant supports high-volume production while maintaining strict quality control standards.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines, which are essential for the precise assembly of LED components onto flexible and rigid circuit boards. These SMT machines ensure high-speed, accurate placement of tiny LED chips, resistors, and other electronic elements, enabling consistent product performance and reliability. The use of automated optical inspection (AOI) systems further enhances quality by detecting any soldering or component placement defects immediately after the SMT process.

A critical part of the production workflow at the Jiangmen facility is the aging test procedure. After assembly, all LED products—including waterproof strips—undergo rigorous aging tests that typically last 24 to 72 hours under elevated temperature and full-load operation. This process helps identify early-stage failures and ensures that only stable, durable products reach customers. The aging chambers simulate real-world operating conditions, allowing the engineering team to verify thermal management, light output consistency, and driver performance over extended periods.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly for customized waterproof LED strip lights. The company supports clients in developing tailored solutions—including specific color temperatures, lumen outputs, IP ratings (such as IP65, IP67, or IP68), reel lengths, and PCB configurations. The factory can accommodate private labeling, custom packaging, and specialized electrical specifications to meet diverse market requirements. With in-house engineering and R&D support, Beauty STC provides full-service OEM development from prototype to mass production, ensuring compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines automation, rigorous testing, and flexible manufacturing to deliver high-quality, reliable waterproof LED strip lighting solutions for global partners.

Application Scenarios

Waterproof strips, specifically referring to the integrated silicone gaskets or compression seals within IP-rated LED fixtures, are critical components for moisture and dust ingress protection in commercial environments. Their application varies significantly across hotels, malls, and offices based on exposure risks and required IP ratings. Proper installation is non-negotiable for maintaining the fixture’s integrity.

In hotels, waterproof strips are essential in all wet zones. This includes guest and public bathroom ceilings and vanities where steam and splashes occur daily, demanding IP65-rated downlights or strips. Pool and spa areas require even higher protection with IP67 or IP68-rated fixtures for underwater or submerged applications, where the strip must withstand constant water pressure. Exterior applications like covered walkways, porte-cochères, and outdoor signage housings also rely on these strips to resist rain and humidity, typically needing IP65 minimum. Kitchens and laundry rooms, subject to high humidity and potential splashes during cleaning, similarly require IP65-rated fixtures with intact seals.

Malls present diverse challenges requiring waterproof strips. Food courts are high-priority zones due to grease, steam, and frequent high-pressure cleaning; fixtures here must be IP66-rated to handle direct water jets, with strips ensuring the seal survives repeated washdowns. Exterior entrances, canopies, and any semi-outdoor mall sections exposed to weather need IP65-rated linear strips or downlights. Restrooms throughout the mall, similar to hotels, require IP65 protection. Back-of-house areas like loading docks, waste handling zones, and service corridors often face hose-down cleaning, mandating IP66-rated fixtures where the strip’s resilience is tested by mechanical cleaning equipment.

Offices generally have lower moisture exposure but still require strategic use. Server rooms and data centers, where condensation from cooling systems is a risk, benefit from IP54-rated fixtures to prevent dust and minor moisture ingress, relying on the strip for basic environmental sealing. Janitor closets and utility rooms, subject to mop water and cleaning chemical splashes, need IP65-rated fixtures. Exterior-facing applications like lobbies with glass walls prone to condensation, covered parking structures, and outdoor perimeter lighting must incorporate IP65 or higher fixtures. While standard office workspaces rarely need them, any area with potential water exposure during maintenance or emergencies necessitates consideration.

Installation demands meticulous attention to preserve the strip’s function. Always start with perfectly clean, dry, and smooth mounting surfaces; any debris, oil, or unevenness compromises the seal. Handle the silicone strip gently during fixture assembly, ensuring it sits fully within its groove without twisting, pinching, or stretching, as deformation creates leak paths. When securing the fixture, follow the manufacturer’s torque specifications precisely for mounting screws or clamps; under-tightening fails to compress the strip adequately, while over-tightening can crush or extrude the silicone, destroying the seal. Verify the strip forms a continuous, unbroken loop around the fixture perimeter before final tightening. Never apply additional silicone sealant over the strip, as this often traps moisture or prevents proper compression. After installation, periodically inspect the seal, especially in high-maintenance areas like food courts or pools, for signs of degradation, compression set, or physical damage requiring fixture replacement. Remember, the waterproof strip is only effective when the entire fixture system—including lenses, housings, and wiring entries—meets the specified IP rating for the environment.

Why Choose Beauty STC Lighting

Looking for a reliable waterproof strip solution? Partner with Beauty STC, a trusted name in high-quality LED lighting manufacturing. Our waterproof strips are built to perform in demanding environments, offering durability, efficiency, and consistent brightness. Whether you’re working on architectural, commercial, or industrial projects, our products meet international standards and can be customized to your needs.

Take the next step in your lighting projects by collaborating with a manufacturer that values quality and innovation. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can support your business goals.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.