Article Contents

Industry Insight: Waterproof Pool Lighting

The commercial and industrial pool lighting sector operates under uniquely demanding conditions where safety, durability, and regulatory compliance are non-negotiable imperatives. Unlike residential applications, facilities such as public aquatic centers, hotels, cruise ships, water parks, and therapeutic pools require lighting solutions engineered for continuous operation, rigorous maintenance cycles, and strict adherence to international safety standards to mitigate significant electrical hazards in wet environments. Certifications like ETL (Electrical Testing Laboratories), signifying compliance with North American safety standards including UL 1598 and UL 8800 for LED equipment, and CE marking, demonstrating conformity with European health, safety, and environmental directives under the Low Voltage Directive and EMC Directive, are not merely optional credentials but fundamental requirements for market access and liability protection. These certifications validate that luminaires undergo rigorous third-party testing for waterproof integrity (typically IP68 rated), electrical safety, thermal management, and material resilience against chlorine, saltwater, and constant submersion—factors that directly impact facility safety records, operational uptime, and long-term total cost of ownership.

Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over two and a half decades to advancing this critical niche within the broader commercial lighting industry. Our engineering focus centers on developing robust, code-compliant LED pool and aquatic lighting systems specifically designed for the uncompromising demands of industrial-scale installations. Leveraging deep expertise in optical design, marine-grade materials, and stringent regulatory pathways, Beauty STC partners with facility operators, architects, and electrical contractors to deliver solutions where performance under pressure is measured not just in lumens, but in years of reliable, safe operation. Our commitment begins with foundational compliance and extends to innovation in energy efficiency, controllability, and serviceability—ensuring that every installation meets the exacting standards required for today’s sophisticated commercial aquatic environments.

Technical Specs & Certifications

Waterproof pool lighting requires robust technical specifications to ensure safety, performance, and longevity in wet and chemically treated environments. At Beauty (STC) Manufacturing Co., Ltd., our LED pool lights are engineered to exceed industry standards, combining high efficiency, accurate color rendering, and superior ingress protection.

Our waterproof pool lighting solutions deliver a minimum of 100 lumens per watt, with select high-performance models achieving up to 120 lumens per watt. This high efficacy ensures energy-efficient operation without compromising brightness, making them ideal for both residential and commercial aquatic installations. The luminous output is optimized for underwater dispersion, providing uniform illumination across pool surfaces and depths.

Color Rendering Index (CRI) is a critical factor in pool lighting, especially where visual clarity and natural color representation are essential. Beauty STC’s LED pool lights feature a CRI greater than 90, ensuring that skin tones, pool finishes, and surrounding architectural elements appear vibrant and true to life. This high CRI is achieved through precision-tuned phosphor coatings and strict binning processes during LED manufacturing.

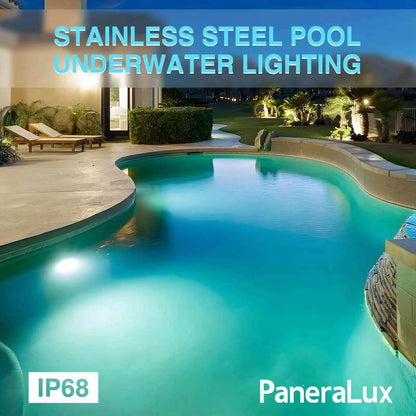

All our waterproof pool lighting fixtures are rated at a minimum of IP68, indicating complete protection against dust ingress and continuous submersion in water under specified pressure and depth conditions. Some models meet the more rigorous IP69K rating, offering resistance to high-pressure and high-temperature water jets, making them suitable for intensive cleaning protocols in commercial pools and aquatic centers. The housings are constructed from marine-grade stainless steel or corrosion-resistant thermoplastics, with double silicone sealing and UV-stabilized lenses to prevent moisture penetration and degradation over time.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process, adhering to international standards such as CE, RoHS, and ISO 9001. Each fixture undergoes extended submersion testing, thermal cycling, and photometric verification to ensure consistent performance and reliability. Our commitment to engineering excellence ensures that every waterproof LED pool light delivers long service life, minimal maintenance, and superior illumination in the most demanding aquatic environments.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as a core production hub for our specialized LED lighting products, including a significant focus on high-reliability waterproof pool and aquatic lighting solutions. The factory is strategically designed to integrate advanced automation with stringent quality control processes specifically tailored to the demanding requirements of underwater illumination applications.

Our Surface Mount Technology production lines are equipped with state-of-the-art Yamaha YS series SMT machines operating in dual-lane configurations. These systems handle precise placement of miniature components down to 0201 package sizes, critical for the compact, high-density circuit boards used in waterproof pool lights. The process incorporates fully automated solder paste inspection and post-reflow Automated Optical Inspection stations to ensure solder joint integrity—a non-negotiable requirement where any defect could compromise the watertight seal of the final fixture. All SMT processes adhere to lead-free soldering standards compliant with RoHS and REACH regulations, with environmental controls maintaining strict temperature and humidity parameters throughout the production floor.

Aging and reliability testing represent a cornerstone of our quality assurance for waterproof products. Every batch of pool lighting fixtures undergoes a rigorous 72-hour accelerated aging test sequence. Units operate at 100% rated power in temperature-controlled chambers cycling between 25°C and 50°C while simultaneously subjected to simulated wet/dry cycling. Crucially, this is followed by mandatory IP68 validation testing where fixtures remain fully operational under continuous submersion at 3 meters depth for 48 hours, monitored via pressure sensors and visual inspection for any moisture ingress. All test parameters are digitally logged with serialized traceability, and units failing any phase are automatically quarantined for root cause analysis before production continuation is authorized. This protocol exceeds IEC 60598-2-18 standards for underwater luminaires.

Our OEM capabilities for waterproof pool lighting are comprehensive and engineered for seamless client integration. We support full turnkey manufacturing from initial concept through to mass production, including custom optical design, thermal management solutions for submerged operation, and proprietary sealing technologies validated through our in-house testing protocols. Clients provide specifications or reference designs, and our engineering team collaborates on DFM optimization specifically for aquatic environments—addressing challenges like pressure differentials, chemical exposure to pool treatments, and long-term UV resistance. We maintain dedicated cleanroom areas for final assembly of waterproof components and offer flexible production scaling with minimum order quantities adaptable to project needs. All OEM work is protected under strict confidentiality agreements, and we facilitate compliance with regional certifications including UL, CE, and PSE through our established testing partnerships. The facility’s vertical integration extends to custom injection molding for polycarbonate housings and precision aluminum heat sinks, ensuring complete control over critical waterproofing elements from raw material to finished product.

Application Scenarios

Waterproof pool lighting is specifically designed for environments where direct exposure to water and high humidity levels are present. While hotels, malls, and offices each have different lighting needs, the application of waterproof pool lighting is most relevant and necessary in specific areas within hotels. It is generally not required in standard areas of malls or offices unless they include water features or aquatic facilities.

In hotels, waterproof pool lighting is essential for swimming pools, spas, fountains, and water features located in indoor or outdoor recreational areas. These lights enhance safety by improving visibility at night and contribute to the ambiance and aesthetic appeal of the space. Underwater LED pool lights are commonly installed in both leisure and luxury hotel settings to create inviting nighttime environments.

Malls typically do not require waterproof pool lighting unless they house indoor aquariums, decorative fountains, or family entertainment areas with water play zones. In such cases, only the submerged or wet-location fixtures need to be waterproof-rated. Standard mall corridors, food courts, or retail areas do not require this type of lighting.

Offices almost never require waterproof pool lighting unless the building includes a wellness center or rooftop pool area for employee use. In typical office environments with no water immersion zones, standard indoor or outdoor lighting suffices.

When installing waterproof pool lighting, several critical tips should be followed to ensure safety, performance, and longevity:

Always use lighting fixtures rated at least IP68, indicating complete protection against dust and continuous submersion in water. This rating is essential for any light that will be placed below the waterline.

Ensure all electrical components, including transformers and junction boxes, are installed outside the pool structure and away from direct water exposure. Use low-voltage systems, preferably 12V, to minimize electrical hazards.

Follow local electrical codes and regulations, including grounding requirements and the use of ground-fault circuit interrupters (GFCIs) for all circuits powering pool lights.

Position lights to minimize glare and provide even illumination across the pool surface. Typically, lights are placed along the pool walls at regular intervals, with careful attention to depth and beam angle.

Avoid placing lights directly at deep ends or in high-traffic swim zones to prevent accidental damage. Embed fixtures securely into recessed niches and seal all connections with manufacturer-approved waterproof gaskets and sealants.

Regular maintenance is crucial. Inspect lights periodically for cracks, seal degradation, or lens clouding, and clean them to prevent algae or mineral buildup.

By selecting the right locations and adhering to proper installation practices, waterproof pool lighting can provide safe, efficient, and visually appealing illumination for aquatic environments in appropriate settings.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I understand the critical importance of reliable waterproof pool lighting in demanding aquatic environments. Standard fixtures often fail prematurely due to inadequate sealing, material corrosion, or thermal management issues, leading to costly maintenance, safety hazards, and client dissatisfaction. Beauty STC addresses these challenges head-on with our rigorously engineered IP68-rated submersible LED systems, built using marine-grade 316 stainless steel housings and dual-sealed optical chambers that withstand constant immersion, chemical exposure, and thermal cycling without compromise.

Our solutions integrate advanced thermal dissipation technology and precision optics to deliver consistent lumen output and color stability while meeting stringent international safety certifications including UL, CE, and IEC standards. We prioritize long-term performance over initial cost savings, ensuring your pool installations maintain integrity for over 50,000 hours with minimal maintenance. Partnering with Beauty STC means gaining access to custom engineering support, bulk procurement advantages, and dedicated technical documentation tailored to commercial pool builders, resorts, and municipal projects.

To discuss how our waterproof pool lighting systems can solve your specific application challenges and elevate your project specifications, contact our engineering management team directly at [email protected]. We’ll provide technical datasheets, sample testing protocols, and collaborative design support to ensure seamless integration into your next project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.