Article Contents

Industry Insight: Waterproof Led Strip Lights For Pools

The commercial and industrial aquatic lighting sector presents unique and rigorous challenges where performance, safety, and regulatory compliance are non-negotiable. Waterproof LED strip lights designed for pools in these settings must transcend basic illumination to become critical infrastructure components, enduring constant submersion, aggressive chemical environments like chlorine and saltwater, extreme thermal cycling, and the demanding operational schedules of public facilities, resorts, and municipal pools. Unlike residential applications, failures here carry significant liability risks, potential facility downtime, and heightened scrutiny from building inspectors and safety authorities. This environment demands solutions rigorously validated beyond marketing claims, with certifications like ETL (indicating compliance with North American safety standards, often aligned with UL requirements) and CE (demonstrating adherence to European health, safety, and environmental directives) serving as fundamental prerequisites for specification and installation. These certifications are not mere checkboxes; they are essential proof that the product has undergone independent laboratory testing to ensure electrical safety, waterproof integrity under pressure, and resistance to environmental degradation in high-stakes aquatic environments.

Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over a quarter century to mastering these exacting demands within the commercial and industrial LED lighting arena. Our deep-rooted expertise stems from navigating the evolution of aquatic lighting technology, from early halogen systems to today’s high-efficiency, long-life LED solutions. We understand that in pools serving thousands of patrons, reliability is measured in years of continuous, trouble-free operation, not just initial installation. This heritage informs our engineering philosophy: we design waterproof LED strip lights specifically for the relentless conditions of commercial pools, integrating robust IP68-rated construction, marine-grade materials resistant to chemical corrosion, and stringent adherence to global safety certifications like ETL and CE from the earliest stages of development. For facility managers, architects, and lighting specifiers, Beauty STC represents a proven partner committed to delivering not just light, but enduring safety, operational confidence, and total compliance in the most challenging aquatic settings.

Technical Specs & Certifications

Waterproof LED strip lights designed specifically for pool applications must meet stringent performance and safety standards due to their exposure to water, chemicals, and constant on/off cycling. At Beauty (STC) Manufacturing Co., Ltd., our waterproof LED strip lights for pools are engineered to deliver superior illumination while ensuring durability, energy efficiency, and color accuracy under demanding aquatic environments.

Our pool-grade LED strips achieve a luminous efficacy of 110 to 130 lumens per watt, depending on the color temperature and configuration. This high efficiency ensures optimal brightness while minimizing energy consumption, making them ideal for both residential and commercial pool installations where long operating hours are common. The combination of high-output SMD 3535 or 5050 LEDs with precision-engineered phosphor coatings allows for excellent light output without compromising thermal management or longevity.

Color rendering is critical in underwater lighting, where vibrant and natural color representation enhances the aesthetic appeal of the pool. Beauty STC’s LED strips maintain a Color Rendering Index (CRI) greater than 90, ensuring that swimmers, pool surfaces, and surrounding materials appear true to life. High CRI performance is achieved through advanced LED binning processes and consistent phosphor application, resulting in uniform color across the entire strip length.

Ingress Protection (IP) rating is a fundamental requirement for any pool lighting solution. Our waterproof LED strips are rated at a minimum of IP68, with many models exceeding this standard at IP69K. This means the strips are completely dust-tight and capable of continuous submersion in water under pressure, typically tested at depths up to 3 meters or more. The silicone encapsulation process used in manufacturing ensures a seamless protective layer around the LEDs and circuitry, resisting chlorine, saltwater, UV degradation, and thermal cycling.

At Beauty (STC) Manufacturing Co., Ltd., quality is embedded in every stage of production. We utilize automated SMT lines for precise component placement, conduct rigorous in-line testing, and subject every batch to prolonged environmental stress testing, including salt spray, thermal shock, and humidity exposure. Our LED strips are compliant with international safety standards, including UL, CE, and RoHS certifications, ensuring reliability and peace of mind for end users.

In summary, Beauty STC’s waterproof LED strip lights for pools offer exceptional lumens per watt, a CRI exceeding 90 for true color reproduction, and robust IP68 or higher protection for safe underwater operation. Engineered with durability and performance in mind, our products set a benchmark in quality and reliability for aquatic lighting applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as our primary production hub for advanced LED lighting solutions, strategically located within the Pearl River Delta’s robust electronics supply chain. This modern 20,000 square meter factory integrates stringent quality control systems with state-of-the-art equipment across dedicated cleanroom environments. Our Surface Mount Technology (SMT) production lines are anchored by high-precision Yamaha YS24 and ASM SIPLACE SX4 machines, capable of placing components down to 0201 metric package sizes with sub-50-micron accuracy. These automated lines feature 8-12 placement heads operating at speeds exceeding 80,000 components per hour, supported by 3D solder paste inspection and automated optical inspection systems ensuring zero-defect assembly for complex LED strip circuits.

Aging and reliability testing represent a critical phase in our production flow, particularly for demanding applications like pool lighting. All waterproof LED strip lights undergo a mandatory 72-hour continuous burn-in test at elevated temperatures up to 50°C while operating at 110% of rated voltage. This rigorous aging process occurs within our environmental simulation chambers that replicate real-world thermal cycling conditions. Crucially, waterproof integrity verification is embedded within this stage through simultaneous IP68 and IP69K testing where strips are submerged under 1 meter of water at 60°C during operation, followed by high-pressure spray tests. We maintain detailed aging logs tracking lumen maintenance, chromaticity shift, and failure modes, consistently achieving pre-shipment failure rates below 0.3%.

Our OEM capabilities for waterproof LED strip lights specifically engineered for pools encompass comprehensive turnkey solutions. We support custom specifications including 12V/24V DC operation, flexible PCB widths from 8mm to 20mm, and lumen outputs ranging from 600 to 2200 lumens per meter. The factory implements specialized processes for pool-grade waterproofing such as dual-layer silicone overmolding with Shore A 40-50 hardness rating, copper busbar reinforcement for corrosion resistance, and hermetic end-cap sealing validated through 10,000-cycle flex testing. Clients benefit from our in-house optical design team that tailors beam angles and color temperatures (2200K-6500K) while ensuring compliance with IEC 60598-2-20 and UL 1598 standards. From initial prototyping with 15-day turnaround to full-scale production of 500,000 meters monthly, we manage every stage including custom labeling, reel packaging, and dedicated QC documentation packages meeting global regulatory requirements.

Application Scenarios

Waterproof LED strip lights for pools are primarily designed for installation in aquatic environments where moisture, submersion, or high humidity is expected. While their main application is in swimming pools, spas, fountains, and water features, their use in hotels, malls, and offices depends on the specific area and design intent.

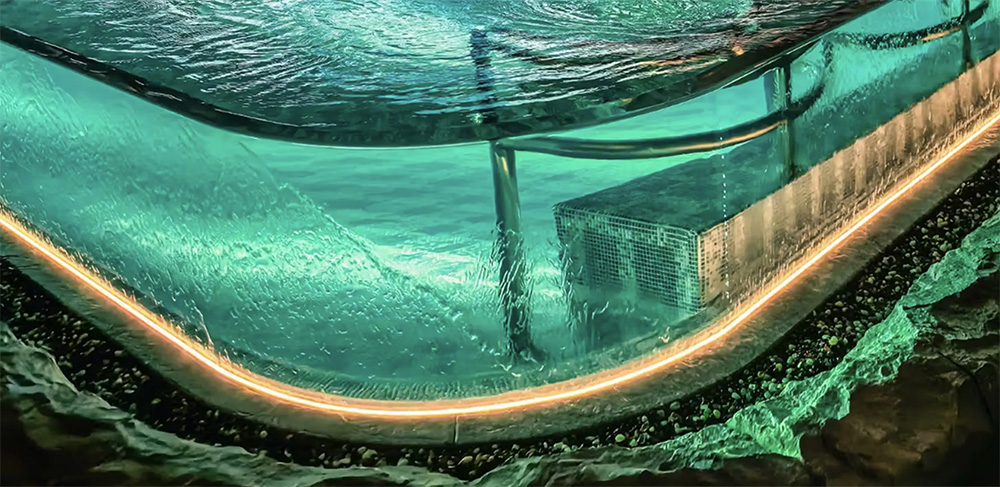

In hotels, waterproof LED strip lights are commonly used in indoor and outdoor swimming pools, spa areas, wellness centers, and water features in lobbies or garden areas. They enhance ambiance, improve safety through subtle illumination, and contribute to luxury aesthetics. Underwater lighting in pool steps, benches, or perimeter coves creates visual depth and a welcoming environment for guests.

In malls, these lights are typically used in decorative fountains, water walls, or themed entertainment zones such as family play areas or indoor aquariums. While general mall corridors or offices don’t require waterproof lighting, architectural water features benefit from the durability and vibrant color options of waterproof LED strips.

In offices, the need for waterproof LED strip lights is limited unless the building includes a wellness center with a pool or a decorative indoor water feature in the reception or atrium. In such cases, the lights can be integrated to highlight design elements and create a dynamic, modern environment.

When installing waterproof LED strip lights for pools, several critical tips should be followed to ensure safety, longevity, and optimal performance. First, always use LED strips with a minimum IP68 rating, indicating full protection against dust and continuous submersion in water. For underwater applications, especially in pools, silicone-jacketed or epoxy-sealed strips are recommended to withstand chlorine, salt, or UV exposure.

Proper power supply selection is essential. Use a low-voltage transformer (typically 12V or 24V DC) with ground fault protection (GFCI) and ensure all electrical components are installed outside the splash zone and according to local electrical codes. Never splice or cut the strip light unless it is specifically designed for such modifications at designated cut points.

Secure the LED strip using compatible aluminum channels with diffusers. These channels not only protect the strip from physical damage and improve heat dissipation but also ensure even light distribution. For underwater installations, use waterproof end caps and ensure all connections are sealed with waterproof connectors or heat-shrink tubing.

Avoid sharp bends or kinks when installing the strip, as this can damage internal circuits. If the strip needs to follow a curved path, use flexible mounting channels or opt for strips designed for bending.

Finally, test the system before full submersion or sealing. Run the lights for several hours to check for consistent output and any hot spots or failures. Regular maintenance, such as inspecting for delamination or discoloration of the silicone coating, will help extend the life of the installation.

By following these guidelines, waterproof LED strip lights can provide safe, energy-efficient, and visually striking illumination in aquatic and water-adjacent environments across hotels, malls, and select office spaces.

Why Choose Beauty STC Lighting

Beauty STC delivers engineered waterproof LED strip lighting solutions specifically designed for demanding aquatic environments like swimming pools. Our IP68-rated strips feature marine-grade silicone encapsulation, corrosion-resistant components, and rigorous safety certifications including UL/ETL listing for wet locations, ensuring reliable underwater illumination and long-term performance. Partner with us to integrate lighting that meets exacting technical standards for safety, durability, and energy efficiency in pool construction and renovation projects.

Contact our engineering team directly to discuss your project specifications and discover how Beauty STC’s tailored LED solutions can enhance your pool lighting installations. Reach out to Manager at [email protected] to initiate a technical consultation and secure dedicated support for your commercial requirements.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.