Article Contents

Industry Insight: Water Resistant Led Strip Lights

Water-resistant LED strip lights have become a cornerstone in commercial and industrial lighting applications, where durability, performance, and compliance are non-negotiable. From retail environments and cold storage facilities to manufacturing plants and outdoor architectural installations, these lighting solutions offer reliable illumination in challenging conditions. As demand grows for energy-efficient, long-lasting, and low-maintenance lighting, water-resistant LED strips stand out for their ability to withstand moisture, dust, and temperature fluctuations without compromising brightness or safety. Industry standards such as ETL and CE certifications are critical in this space, ensuring that products meet rigorous electrical, safety, and environmental requirements for use across North America and Europe.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED innovation for over two decades. Specializing in high-performance lighting solutions for commercial and industrial sectors, Beauty STC combines advanced engineering with stringent quality control to deliver water-resistant LED strip lights that meet and exceed global compliance standards. With a commitment to reliability and sustainability, the company continues to set benchmarks in durability and efficiency, supporting projects that demand consistent performance in demanding environments.

Technical Specs & Certifications

Water resistant LED strip lights from Beauty (STC) Manufacturing Co., Ltd. are engineered for demanding environments where moisture exposure is a concern, without compromising on optical performance or longevity. Our premium strips consistently achieve luminous efficacy ratings between 120 and 130 lumens per watt under standard operating conditions at 25°C ambient temperature. This efficiency is realized through the strategic selection of high-bin Samsung or Epistar LED chips, precision constant-current drivers, and optimized thermal management substrates. We rigorously test efficacy using integrating sphere methodology per LM-79 standards, ensuring real-world performance aligns with specifications even after waterproofing encapsulation, which can typically reduce output by 5-8% compared to non-protected counterparts.

Color rendering is a critical focus for high-end architectural and retail applications. All our water resistant strips targeting CRI >90 utilize multi-phosphor LED technology with R9 values exceeding 50 and a minimum TM-30 Rf of 85. We achieve CRI values of 95+ through proprietary phosphor blends and stringent binning processes during manufacturing. Each production batch undergoes spectrophotometric validation using calibrated Konica Minolta CS-2000 instruments, with spectral power distribution curves provided upon request. This ensures accurate color representation for merchandise, artwork, and skin tones in wet locations like retail changing rooms, spas, or marine environments where standard strips would fail.

For environmental protection, Beauty STC offers two primary IP-rated solutions. Our IP65-rated strips feature a flexible silicone jacket extruded directly over the PCB, providing complete dust ingress protection and resistance to low-pressure water jets from any direction (tested per IEC 60598-2-22). These are ideal for outdoor signage, covered patios, and kitchen under-cabinet installations. For submersion applications, our IP67-certified strips undergo double encapsulation: first with food-grade silicone conformal coating on the bare PCB, then secondary overmolding in marine-grade polyurethane. This construction withstands temporary immersion up to 1 meter for 30 minutes, making them suitable for pool coves, fountain lighting, and marine deck installations. Both ratings are validated through third-party testing at SGS facilities with documented test reports available.

Beauty STC’s quality differentiation lies in our vertical integration and process controls. Unlike competitors using generic components, we manufacture our own flexible PCBs with 2oz copper traces to minimize voltage drop over long runs, implement automated optical inspection during SMT assembly to catch micro-solder defects, and subject every waterproof strip to 100% Hi-Pot testing at 1500V AC for 60 seconds. Our silicone materials are UL 94 V-0 rated and resistant to UV degradation up to 50,000 hours, preventing yellowing that plagues cheaper alternatives. This commitment is reflected in our industry-leading 5-year warranty covering both lumen maintenance (L70/B50) and waterproofing integrity, backed by in-house accelerated lifecycle testing that simulates 10 years of coastal environment exposure. The result is a product that maintains >90% of initial lumen output and color consistency throughout its service life, even in continuously damp conditions where inferior strips typically fail within 18 months.

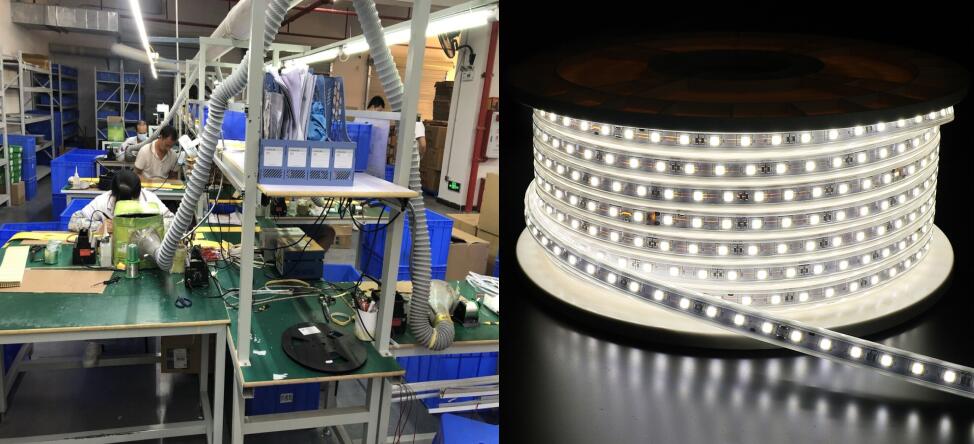

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for lighting and electronics production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and customization capabilities.

At the core of the production process are state-of-the-art SMT (Surface Mount Technology) lines, which enable precise placement of LED components and electronic parts onto flexible and rigid PCBs used in LED strip lights. These SMT machines ensure high-speed assembly with exceptional accuracy, supporting consistent product performance and reliability. The automated lines are integrated with AOI (Automated Optical Inspection) systems to detect placement errors and soldering defects in real time, minimizing defects and enhancing overall yield.

For quality assurance, the factory implements comprehensive aging and environmental testing procedures. Completed LED strip lights undergo rigorous aging tests, typically running at full power for 24 to 72 hours under controlled temperature and humidity conditions. This process helps identify early-life failures and ensures long-term stability. Additional tests include waterproof performance verification (especially for water-resistant models), thermal cycling, and electrical safety checks, all conducted in dedicated testing chambers and labs within the facility.

Beauty STC has robust OEM/ODM capabilities, particularly for water-resistant LED strip lights. The company supports full customization, including PCB design, LED density, color temperature, lumens output, IP rating (such as IP65, IP67), reel length, packaging, and branding. Clients can provide technical specifications or work with Beauty STC’s engineering team to develop tailored solutions. The factory’s flexible production lines allow for both small-batch prototyping and large-scale manufacturing, making it well-suited for global brands, lighting distributors, and project-based clients.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and strong engineering support to deliver high-performance, water-resistant LED strip lights under OEM arrangements, meeting international standards and customer-specific requirements.

Application Scenarios

Water-resistant LED strip lights serve specific purposes in commercial environments where exposure to moisture, humidity, or occasional splashes occurs, but they are not suitable for full submersion or constant direct water contact unless explicitly rated for such use. Understanding the correct IP (Ingress Protection) rating is critical. For instance, IP65 denotes protection against low-pressure water jets and dust, making it suitable for damp indoor areas, while IP67 or IP68 is required for temporary submersion or high-moisture zones. Misapplication can lead to premature failure or safety hazards. Below are precise applications and installation guidance for hotels, malls, and offices.

In hotels, water-resistant LED strips (IP65 minimum) are ideal for guest bathroom cove lighting, especially under vanities or above mirrors where splashes occur, but never inside shower stalls unless IP68-rated and installed per electrical codes for wet locations. They also work well in pool perimeter cove lighting for ambiance, provided IP68-rated strips are used below the waterline and external drivers are housed in dry, accessible locations. Avoid using them in steam rooms or saunas, as high heat and condensation exceed typical IP65/IP67 capabilities. For exterior applications like covered balconies or porte-cochères, IP67 strips may be used if protected from direct rainfall, but always pair with UV-resistant silicone coating to prevent yellowing.

Within malls, these strips suit decorative water feature edging—such as fountains or artificial streams—where IP68-rated strips must be fully submerged and powered via GFCI-protected, low-voltage drivers. They are also appropriate for refrigerated display cases in food courts, where condensation forms, but ensure the strip’s operating temperature range aligns with the cold environment to avoid delamination. Do not install them in open-air facades or uncovered walkways; even IP67 strips degrade under prolonged UV exposure and thermal cycling. For indoor food court under-counter lighting near sinks, IP65 strips suffice if mounted away from direct spray zones and sealed at connectors.

Offices rarely require water resistance beyond standard dry-location strips, but exceptions exist. Use IP65 strips in staff kitchenettes under sinks or near dishwashers where leaks might occur, ensuring the strip is mounted on a non-porous channel to prevent moisture wicking. Server rooms with high humidity may benefit from IP65 strips in ceiling coves if ambient moisture exceeds 60%, though dehumidification is preferable. Never install them in standard workstations, corridors, or meeting rooms—these are dry locations where non-water-resistant strips perform better thermally and cost-effectively.

Installation demands meticulous attention to detail. Always use aluminum channels with frosted diffusers to manage heat dissipation; water-resistant strips often have thicker silicone coatings that trap heat, accelerating lumen depreciation. For connections, apply dielectric grease inside IP68-rated connectors before sealing to prevent corrosion, and never splice strips beyond manufacturer-specified lengths without additional power feeds to avoid voltage drop. In all cases, route low-voltage wiring through conduit where exposed to physical damage, and position drivers outside the moisture zone—in ceiling voids for bathrooms or locked electrical closets for pools—with a minimum 1.5-meter separation from water sources. Finally, conduct a 24-hour moisture test post-installation: power the strips while simulating worst-case humidity (e.g., running a hot shower nearby) to verify no flickering or failure occurs before final commissioning. Cutting corners here risks costly callbacks and reputational damage.

Why Choose Beauty STC Lighting

Upgrade your lighting projects with high-performance water resistant LED strip lights designed for durability and brilliant illumination in any environment. At Beauty (STC) Manufacturing Co., Ltd., we specialize in premium, waterproof LED solutions trusted by professionals worldwide. Partner with us to access reliable, energy-efficient lighting products backed by expert support and global delivery. For inquiries and collaboration opportunities, contact our sales manager at [email protected] and discover how Beauty STC can power your next innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.