Article Contents

Industry Insight: Wall Strip Mirrors

Wall strip mirrors have emerged as a sophisticated and functional lighting solution within the commercial and industrial sectors, combining sleek design with high-performance illumination. These fixtures are increasingly specified in environments such as retail spaces, healthcare facilities, office buildings, and manufacturing areas where precise, glare-free lighting is essential. Engineered for seamless integration into architectural surfaces, wall strip mirrors offer both ambient and task lighting while enhancing the perception of space through reflective surfaces and uniform light distribution. As energy efficiency and regulatory compliance become paramount, leading products in this category are designed and certified to meet rigorous international standards, including ETL and CE, ensuring electrical safety, electromagnetic compatibility, and adherence to environmental directives.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative LED lighting solutions for over two decades. Specializing in commercial and industrial applications, Beauty STC combines advanced optical engineering with robust construction to deliver reliable, code-compliant lighting systems. With a strong commitment to quality and sustainability, the company’s wall strip mirror series exemplifies precision manufacturing and intelligent design—backed by global certifications and trusted by architects, engineers, and facility managers worldwide.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces wall strip mirrors with integrated LED lighting engineered for demanding residential and commercial applications, particularly in premium bathrooms and vanity spaces. Our technical specifications prioritize optical performance, energy efficiency, and environmental resilience, meeting the stringent requirements of modern architectural lighting design.

Lumens per Watt (lm/W) efficiency is a core focus, with our standard integrated LED strips achieving a minimum of 110 lm/W at 25°C ambient temperature under continuous operation. This is realized through the use of high-efficacy 2835 or 3030 SMD LEDs paired with constant-current, high-efficiency drivers operating at >92% efficiency. We optimize thermal management via aluminum-backed PCBs and thermally conductive adhesives bonded directly to the mirror frame’s extruded aluminum housing, ensuring sustained lumen output and preventing thermal droop even during extended use. Typical systems deliver 1800-2200 lumens per 2-meter mirror length while consuming only 18-20 watts, significantly exceeding standard vanity lighting benchmarks.

Color Rendering Index (CRI) performance is non-negotiable for applications requiring true-to-life skin tone and color representation. All Beauty STC wall strip mirrors utilize LEDs with a minimum CRI of Ra 95, verified under TM-30-15 methodology with Rf (Fidelity Index) >90 and Rg (Gamut Index) tightly controlled between 98-102. This is achieved through rigorously selected tri-phosphor LED bins and spectral tuning to minimize cyan deficiency, critical for makeup application and grooming tasks. We reject any LED lots failing our in-house spectroradiometric validation, ensuring consistent high-fidelity rendering across all production batches.

IP Ratings are engineered for the harsh bathroom environment. Our standard offering provides IP65 protection along the entire illuminated perimeter, achieved through seamless silicone gasketing between the mirror substrate and aluminum housing, plus potted driver compartments and IP68-rated connector systems. This exceeds the IEC 60529 Zone 1 requirement (IPX4 minimum) for bathroom installations, offering robust resistance against water jets and steam ingress during showering. For specialized applications like steam rooms or outdoor-facing ensuites, we offer IP67 variants with double-sealed optical chambers and marine-grade anodized frames, validated through 30-minute submersion testing at 1-meter depth.

Beauty STC’s quality differentiation manifests in three critical areas beyond baseline specifications. First, our proprietary thermal interface technology maintains junction temperatures below 65°C at full load, extending LED L70 lifetime to 50,000 hours with <6% lumen depreciation. Second, we implement 100% end-of-line photometric testing using integrating spheres, not just spot checks, guaranteeing every unit meets published lm/W and CRI values. Third, our aluminum extrusions undergo electrocoating prior to anodization, eliminating micro-pores that cause premature white rust in humid conditions—a common failure point in lesser mirror systems. This commitment to materials science and process control ensures our wall strip mirrors deliver laboratory-grade optical performance with industrial-grade durability in real-world installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern, well-equipped facility specializing in the production of LED lighting products, including innovative solutions such as illuminated wall strip mirrors. The factory is strategically located in the Jiangmen High-Tech Industrial Zone, providing access to skilled labor, efficient logistics, and a robust supply chain network within the Pearl River Delta region.

The manufacturing floor features advanced Surface Mount Technology (SMT) production lines, which are critical for achieving high precision and consistency in LED circuit board assembly. These SMT machines are fully automated and include pick-and-place systems, reflow soldering ovens, and automated optical inspection (AOI) equipment. This ensures that LED components are mounted accurately and reliably on PCBs, resulting in high-quality, durable lighting modules used in products like wall strip mirrors.

To ensure long-term product reliability, the Jiangmen factory conducts comprehensive aging tests on all lighting products. Completed units undergo 24 to 72 hours of continuous operation under controlled temperature and humidity conditions. During these tests, performance parameters such as luminous output, color consistency, power consumption, and thermal management are closely monitored. This rigorous quality control process helps identify early failures and ensures that only products meeting strict performance standards are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, particularly for customized wall strip mirrors. The company supports clients from concept development through to mass production, offering services such as custom design, PCB layout, optical engineering, and branding. Clients can specify dimensions, lighting color temperatures (e.g., 3000K, 4000K, 6000K), control methods (touch sensors, motion sensors, app control), and mirror finish. The factory’s flexible production lines allow for both low-volume custom runs and high-volume manufacturing, making it suitable for global brands, hospitality projects, and retail chains.

Overall, the Jiangmen factory combines advanced automation, rigorous testing, and flexible OEM services to deliver high-performance, aesthetically refined LED wall strip mirrors tailored to diverse market needs.

Application Scenarios

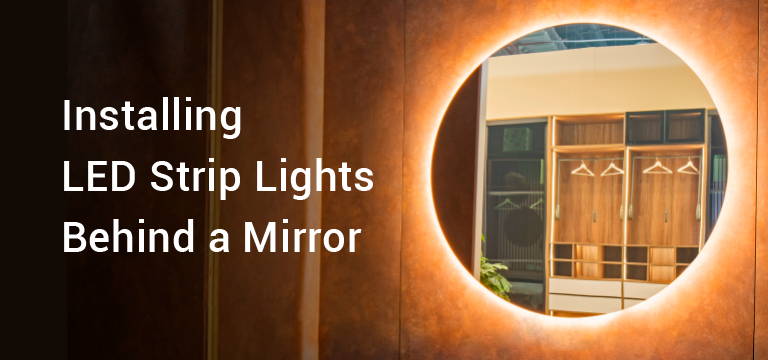

Wall strip mirrors are not a standard lighting term; the query likely refers to linear LED lighting strips installed behind or adjacent to wall-mounted mirrors to create illuminated mirror effects. This technique is widely used across commercial spaces for both functional and aesthetic purposes. Below is guidance on application locations and critical installation considerations.

In hotels, illuminated mirror strips are essential in guest room bathrooms, specifically around vanity mirrors. This provides optimal, shadow-free lighting for grooming tasks while enhancing the perceived luxury of the space. The strips should be mounted in a continuous channel above or on three sides of the mirror, ensuring even illumination without visible hotspots. Corridor accent lighting also benefits from this technique, where thin strips behind wall mirrors create depth and guide movement in low-light environments. For spas or fitness centers within hotel complexes, these installations add a modern, high-end feel to locker room mirrors.

Shopping malls deploy these systems prominently in retail dressing rooms, where accurate color rendering is critical. High-CRI LED strips (90+ CRI) installed around full-length mirrors help customers assess true garment colors, directly impacting purchase decisions. Feature walls in common areas often incorporate large mirrored panels with concealed linear lighting to amplify spatial perception and highlight architectural elements. Entryway lobbies use this method to create grand, welcoming reflections that enhance the mall’s upscale image while improving ambient light distribution.

Office environments utilize illuminated mirror strips primarily in executive washrooms and high-end meeting room restrooms to convey professionalism. Lobbies and reception areas employ them on feature walls with mirrored sections to visually expand confined spaces and reflect branded elements. Some modern offices integrate them into wellness rooms or meditation spaces, where soft, diffused mirror lighting promotes calmness. Avoid overuse in standard workspaces, as excessive reflections can cause glare on monitors.

Installation requires precise execution to achieve seamless results. Always mount LED strips within an aluminum channel with a frosted diffuser to eliminate individual diode visibility and ensure uniform light output. Position the channel 10-15mm behind the mirror edge to create a floating halo effect without light spill onto adjacent walls. For vertical mirror installations, run strips along the top edge only to prevent unflattering upward shadows on faces. Maintain strict adherence to electrical codes: use Class 2 drivers for safety, secure all wiring in conduit, and verify IP65 rating for wet areas like bathrooms. Thermal management is critical—aluminum channels must have adequate cross-section to dissipate heat, especially for high-output strips, to prevent lumen depreciation. Avoid mounting strips directly on insulating surfaces; leave minimum 3mm air gaps beneath channels. Finally, conduct mock-up tests under actual ambient lighting conditions to fine-tune color temperature and brightness before full-scale installation, as perceived light quality varies significantly across environments. Our STC linear systems include pre-angled channels specifically designed for mirror applications to simplify this process.

Why Choose Beauty STC Lighting

Transform your space with Beauty STC’s premium wall strip mirrors—designed for elegance, precision lighting, and modern appeal. Whether for residential, commercial, or hospitality projects, our mirrors combine sleek aesthetics with advanced LED technology to deliver superior performance and style.

Partner with Beauty STC, a trusted leader in innovative lighting solutions, and elevate your product offerings with custom-designed wall strip mirrors built to meet global standards. Our engineering expertise, flexible manufacturing capabilities, and dedicated support ensure seamless collaboration from concept to delivery.

To learn more or discuss a custom project, contact us today at [email protected]. Let’s create something beautiful together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.