Article Contents

Industry Insight: Uv Vs Led

The commercial and industrial lighting sector faces increasingly complex decisions when selecting illumination technologies, particularly when contrasting traditional ultraviolet (UV) systems with modern light-emitting diode (LED) solutions. While UV lighting, primarily deployed for specialized applications like germicidal irradiation (UV-C) in healthcare settings, water treatment, or surface disinfection within food processing facilities, serves critical niche functions, it operates under fundamentally different principles and constraints compared to the broad-spectrum visible light delivered by LED technology. Key distinctions emerge regarding energy consumption, operational lifetime, safety protocols, and crucially, compliance with mandatory safety certifications such as ETL (Electrical Testing Laboratories) and CE (Conformité Européenne), which are non-negotiable requirements for any lighting product deployed in professional environments to ensure electrical safety and electromagnetic compatibility. UV systems, especially those generating germicidal wavelengths, carry inherent risks requiring stringent shielding and safety interlocks, demanding rigorous third-party validation through these certifications to mitigate hazards like skin and eye damage, alongside concerns over mercury content in traditional UV lamps. Conversely, LED technology has revolutionized mainstream commercial and industrial illumination – from high-bay fixtures in warehouses and manufacturing plants to street lighting and retail spaces – offering exceptional energy efficiency, minimal maintenance due to long lifespans exceeding 50,000 hours, instant-on capability, and precise optical control, all while inherently meeting ETL and CE standards for general lighting applications without the radiological hazards associated with UV-C. Understanding this technological divergence is paramount for facility managers and specifiers who must balance specialized operational needs against the overwhelming advantages of LED for general illumination, always prioritizing certified, safe, and cost-effective solutions. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep expertise in designing, engineering, and manufacturing high-performance, certified LED lighting solutions specifically engineered to meet the demanding requirements of global commercial and industrial markets.

Technical Specs & Certifications

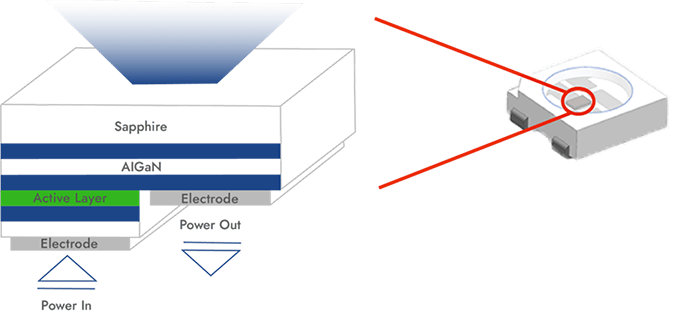

When comparing UV lighting to LED lighting—particularly in the context of general illumination and specialty applications—it’s important to clarify that UV (ultraviolet) and LED (light-emitting diode) are not direct equivalents. UV refers to a segment of the electromagnetic spectrum (typically 100–400 nm), while LED is a technology used to produce light across various wavelengths, including visible and UV ranges. However, in practical discussions, “UV vs LED” often implies traditional UV sources (like mercury vapor or fluorescent UV lamps) versus modern solid-state UV-LEDs or visible LEDs used in lighting. Below are the technical specifications focused on lumens per watt, CRI above 90, and IP ratings, with an emphasis on high-quality manufacturing standards such as those upheld by Beauty (STC) Manufacturing Co., Ltd.

Lumens per Watt (Efficacy):

For visible white light applications, modern LED lighting delivers significantly higher luminous efficacy compared to traditional UV-based lighting systems such as fluorescent tubes or mercury vapor lamps, which are inefficient and emit substantial energy as heat or non-visible radiation. High-quality LEDs from manufacturers like Beauty STC achieve efficacies ranging from 120 to 180 lumens per watt, depending on color temperature and optical design. In contrast, traditional UV sources used for lighting (e.g., blacklights) produce minimal visible lumens and are not rated meaningfully in lumens per watt for illumination purposes. UV-LEDs, while improving, are typically less efficient than visible LEDs—especially in the UVC range (<280 nm)—with efficacies often below 50 lumens per watt when converted for visible perception. Beauty STC focuses on high-efficiency visible spectrum LEDs optimized for architectural, commercial, and industrial lighting, ensuring maximum light output with minimal energy consumption.

Color Rendering Index (CRI >90):

CRI measures a light source’s ability to reveal colors accurately compared to natural light. A CRI above 90 is considered excellent and is essential in retail, healthcare, and design environments. Beauty STC’s premium LED luminaires utilize high-CRI phosphor blends and tightly binned LEDs to consistently deliver CRI values exceeding 90, with some products offering CRI >95 and R9 (saturated red) values above 50. Traditional UV lamps, especially those emitting in the UVA range (315–400 nm), do not produce balanced visible white light and therefore cannot achieve high CRI values. They often distort color perception, making them unsuitable for applications requiring accurate color rendering. UV-LEDs used for curing or disinfection also do not serve as visible white light sources and thus are not evaluated for CRI. Beauty STC’s commitment to optical quality ensures color consistency, minimal deviation in chromaticity, and superior rendering across all high-CRI LED product lines.

IP Ratings (Ingress Protection):

IP ratings define a fixture’s resistance to dust and moisture, critical for durability in harsh environments. Beauty STC designs and tests its LED luminaires to meet stringent IP standards, with common ratings including IP65, IP66, and IP67—ensuring complete dust tightness and protection against water jets or temporary immersion. These ratings are achieved through precision-engineered housings, high-quality silicone gaskets, and rigorous testing protocols. For outdoor, industrial, and wet-location applications, such protection is essential. Traditional UV lamps, particularly older fluorescent types, often lack robust ingress protection and are not built for demanding environments. While UV-LED modules are increasingly being packaged with higher IP ratings for use in disinfection systems, they generally do not integrate the same level of thermal management, optical control, and long-term reliability found in Beauty STC’s architectural LED fixtures.

Beauty STC’s Quality Commitment:

Beauty (STC) Manufacturing Co., Ltd. is recognized for engineering LED lighting solutions that combine high efficiency, superior color quality, and rugged construction. Every product undergoes strict quality control, including thermal cycling, photometric testing, and long-term lumen maintenance verification. Components are sourced from trusted suppliers, and thermal management is optimized to ensure LED drivers and chips operate within safe temperature ranges, extending product life beyond 50,000 hours (L70). The company adheres to international standards such as IEC, UL, and EN, with certifications supporting global deployment. Whether for indoor ambient lighting or outdoor area illumination, Beauty STC delivers reliable, high-performance LED systems where traditional UV-based technologies fall short in efficiency, color quality, and durability.

In summary, while UV lighting serves niche applications like disinfection or fluorescence, modern LED technology—especially as engineered by Beauty STC—outperforms in lumens per watt, enables CRI >90 for true color representation, and achieves high IP ratings for robustness. For general illumination, LED is the superior choice in performance, efficiency, and quality.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a core component of our integrated production capability, specifically engineered for high-volume, precision LED lighting and related optoelectronic products. The Jiangmen factory is a modern, ISO 9001-certified site designed with controlled environments to support the stringent demands of electronic assembly and optical component manufacturing. Its layout prioritizes workflow efficiency from component intake through final testing, featuring dedicated clean zones for sensitive processes and robust infrastructure supporting both standard and specialized production lines.

Surface Mount Technology (SMT) forms the backbone of our PCB assembly operations at this facility. We operate multiple high-speed, multi-functional SMT lines capable of handling components from ultra-miniature 0201 passives up to large power LEDs and complex ICs. These lines utilize advanced placement machines from leading manufacturers, ensuring micron-level accuracy and high throughput. The process is tightly controlled with automated optical inspection (AOI) stations integrated immediately after reflow soldering to detect defects such as tombstoning, misalignment, or solder bridging in real-time. This SMT capability is fundamental to producing the dense, thermally efficient driver and control boards required for modern LED luminaires, including those incorporating UV LED sources.

Aging and burn-in testing is a critical, non-negotiable phase in our quality assurance protocol at the Jiangmen plant. Completed luminaires and critical sub-assemblies undergo rigorous aging processes under controlled thermal and electrical conditions. Standard aging cycles typically run for a minimum of 48 to 72 hours at elevated temperatures, often simulating worst-case operating environments. During this period, units are continuously powered and monitored for critical parameters such as lumen output stability, color consistency, thermal performance, and driver functionality. This extended operational stress test effectively identifies early-life failures or component weaknesses that might not be caught in shorter functional checks, significantly enhancing field reliability and ensuring our products meet the stringent longevity expectations of the LED lighting market.

Regarding OEM capabilities for “UV vs LED,” it is essential to clarify the technological distinction. Beauty STC specializes in solid-state lighting solutions, meaning our core expertise and OEM manufacturing services are focused exclusively on LED-based products, including UV LED technology. We do not manufacture or offer OEM services for traditional mercury-vapor UV lamp systems. Our Jiangmen factory is fully equipped to design, prototype, and mass-produce custom UV LED solutions as part of our broader LED portfolio. This includes applications such as UV curing, disinfection, counterfeit detection, and horticultural lighting. Our OEM service encompasses the full spectrum from initial optical and thermal design through SMT assembly, specialized aging protocols tailored to UV LED characteristics, and final validation testing. Clients seeking UV solutions benefit from our deep understanding of UV LED drive requirements, thermal management challenges specific to shorter wavelengths, and material compatibility issues, all delivered within the same quality-controlled manufacturing framework we apply to visible LED products. We clearly differentiate between legacy UV lamp technology and modern UV LED systems, positioning our OEM strength firmly within the advanced solid-state domain.

Application Scenarios

The choice between UV and LED lighting depends on the application, purpose, and environment. While both technologies involve light, they serve very different functions—UV (ultraviolet) lighting is primarily used for disinfection, curing, or special effects, whereas LED (light-emitting diode) lighting is used for general illumination, energy efficiency, and design flexibility. Understanding where to use each is crucial for safety, performance, and cost-effectiveness in commercial environments such as hotels, malls, and offices.

In hotels, LED lighting is the standard for guest rooms, lobbies, corridors, and exterior areas due to its energy efficiency, long lifespan, and ability to create inviting atmospheres through color tuning and dimming. LEDs can enhance aesthetics with accent lighting in reception areas or ambient lighting in restaurants and spas. UV lighting has limited but important applications in hotels—mainly in HVAC systems for air disinfection, in laundry rooms to sanitize linens, or in restrooms for surface sterilization. However, direct UV exposure to occupants must be avoided, so UV systems should be installed in enclosed or unoccupied spaces, such as inside air ducts or in automated cleaning devices that operate when rooms are vacant.

In malls, LED lighting is essential for both functional and decorative purposes. High-output LED fixtures illuminate walkways and common areas efficiently, while track and display lighting highlight retail spaces. LED’s low heat output and design versatility make it ideal for large atriums and signage. UV lighting may be used in mall HVAC systems to maintain air quality, especially in high-traffic areas, and in waste management zones to reduce odors and microbial growth. Some malls may incorporate UV-C robots for overnight disinfection of restrooms and escalator handrails. Safety is paramount—UV installations must be interlocked or scheduled to operate only when the area is unoccupied.

In offices, LED lighting supports productivity and well-being. Tunable white LEDs that mimic natural daylight help regulate circadian rhythms, improving alertness and comfort. Recessed panels, under-cabinet lights, and task lighting are all commonly LED-based. UV lighting has niche uses in office buildings, such as in air handling units to prevent mold and bacteria buildup in cooling coils, or in printer rooms to cure inks in specialized equipment. Any germicidal UV application should be professionally installed with safety controls to prevent accidental exposure.

When installing LED lighting, ensure compatibility with existing controls like dimmers and sensors. Use high CRI (Color Rendering Index) LEDs in areas where color accuracy matters, such as retail or lobbies. Plan layouts to minimize glare and shadows. For UV installations, especially germicidal UV-C, always consult lighting and HVAC professionals. Fixtures must be placed out of direct line of sight, with shielding or motion sensors to disable UV when people are present. Regular maintenance is critical—UV lamps lose effectiveness over time and must be replaced according to manufacturer guidelines. Additionally, ensure all UV systems comply with local safety regulations and come with proper warning labels.

In summary, LED lighting is the go-to solution for illumination across hotels, malls, and offices due to its efficiency, versatility, and safety. UV lighting serves specialized roles in sanitation and air quality but requires careful, controlled installation to avoid health risks. Combining both technologies thoughtfully—LED for visibility and comfort, UV for hygiene—can enhance the functionality and safety of commercial spaces when applied correctly.

Why Choose Beauty STC Lighting

Stop compromising between safety and performance when comparing UV and LED lighting solutions. At Beauty STC Manufacturing Co., Ltd., we engineer advanced LED systems that eliminate the mercury hazards and regulatory complexities of traditional UV technology while delivering superior energy efficiency, longer operational lifespans, and precise spectral control tailored to your specific application. Our rigorously tested LED platforms meet global safety standards including IEC 62471 and exceed industry benchmarks for output stability and thermal management, ensuring reliable performance in demanding environments. Partner with Beauty STC to transition from outdated UV systems to future-proof LED technology designed for sustainability and operational excellence. Let us collaborate to develop a lighting solution that reduces your total cost of ownership while meeting stringent environmental and performance requirements. Reach out to our technical management team today to discuss your project specifications and discover how our engineering expertise can transform your lighting infrastructure. Contact [email protected] to initiate a technical consultation. Let’s engineer your lighting evolution together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.