Article Contents

Industry Insight: Uv Light Led

Introduction & Market Demand

The Growing Demand for UV LED Solutions in Commercial and Industrial Sectors

UV LED technology has transitioned from niche applications to critical infrastructure components across healthcare, manufacturing, and environmental sectors. UVC (260–280nm) is now standard for air, water, and surface disinfection in hospitals, labs, and public facilities—accelerated by post-pandemic hygiene protocols. UVA (315–400nm) dominates industrial curing processes for inks, coatings, and adhesives, while also enabling non-destructive testing (NDT) for aerospace, automotive, and forensic applications. Unlike traditional mercury-based UV lamps, UV LEDs offer superior energy efficiency, instant on/off capability, mercury-free operation, and precise wavelength control. Global market demand for UV LED systems is projected to grow at 12.4% CAGR through 2030 (Source: Market and Markets), driven by regulatory shifts toward sustainable technologies and stricter safety standards.

Why ETL and CE Certifications Are Non-Negotiable for Importers

For global distributors and project managers, compliance with regional safety standards is non-negotiable. ETL certification (USA/Canada) verifies adherence to UL 61010-1 and IEC 62471 photobiological safety standards, ensuring electrical safety and UV radiation limits for human exposure. TUV CE certification (EU) confirms compliance with the Low Voltage Directive (LVD) and EMC Directive, critical for market access in 30+ European nations. Without these certifications:

Products face customs delays or rejection at ports of entry.

Liability risks escalate if safety failures occur during installation or operation.

End-user projects (e.g., healthcare facilities, industrial plants) may fail regulatory audits.

Beauty STC Manufacturing Co., Ltd. addresses these risks through rigorous third-party testing. All UV LED products undergo pre-shipment validation for electrical safety, thermal management, and UV output consistency—ensuring seamless integration into international supply chains.

Beauty STC: Your Trusted Partner for Certified UV LED Solutions

Established in 1998, Beauty STC has delivered over 25 years of industrial-grade lighting innovation to 50+ countries across Europe, North America, and Asia-Pacific. As a vertically integrated manufacturer, we control every stage of production—from chip-level design to final assembly—ensuring consistent quality for mission-critical UV applications. Our ETL and TUV CE certifications are not merely compliance checkboxes; they reflect a commitment to reliability in environments where failure is not an option.

Core UV LED Product Specifications

| Feature | Specification |

|---|---|

| Wavelength Range | UVA: 365nm ±5nm (standard), 395nm, 405nm; UVC: 265–280nm |

| Radiant Power | 1W–500W per module; scalable arrays up to 1,000W+ |

| Beam Angle | Adjustable 10°–120° for focused or diffuse illumination |

| Certifications | ETL (USA/Canada), TUV CE (EU), RoHS compliant |

| Lifespan | UVA: L70 >50,000 hours; UVC: L70 >10,000 hours |

| Operating Temperature | -40°C to +125°C (industrial-grade thermal management) |

| OEM/ODM Support | Full customization of optics, housings, power supplies, and firmware |

Our modular UV LED systems are engineered for integration into diverse applications:

UVC disinfection: Water treatment plants, HVAC systems, and medical device sterilization.

UVA curing: High-speed printing presses, automotive coating lines, and electronics assembly.

NDT inspection: Crack detection in aerospace components, forensic evidence analysis, and counterfeit currency verification.

As a responsible manufacturer, we prioritize sustainable production practices and transparent supply chains. All products undergo 100% burn-in testing and spectral analysis before shipment—ensuring performance parity between prototypes and mass-production units.

Contact us for technical specifications, compliance documentation, or OEM project consultations:

Email: [email protected]

Phone: +86 13902885704

Address: 41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards – UV LED Solutions from Beauty (STC) Manufacturing Co., Ltd

1. Mono-Wavelength Precision & Radiometric Output

All Beauty STC UV LED engines are binned at ±2 nm from the stated peak to guarantee process repeatability.

Typical radiant flux density (Ee) at 25 °C T-case:

| Peak λ (nm) | Application Band | Radiant Flux (mW) @ 350 mA | Wall-Plug Efficiency (%) | Viewing Angle (FWHM) |

|---|---|---|---|---|

| 365 | UVA – curing, NDT | 1 000 – 3 500 | 42 – 48 | 60° / 30° / 15° |

| 395 | UVA – adhesive | 1 200 – 4 000 | 50 – 55 | 60° / 30° / 15° |

| 275 | UVC – germicidal | 15 – 70* | 3,5 – 5,5 | 120° (flat window) |

*Per 3,5 × 3,5 mm SMD device; multi-chip arrays scale proportionally.

2. Thermal & Optical Management

Junction-to-case RθJC ≤ 3 °C/W (UVA) and ≤ 6 °C/W (UVC) keeps TJ < 85 °C at 50 000 h L70.

2 oz double-layer copper PCB, 0,2 mm thermal dielectric (κ ≥ 2 W/m·K) → ΔT < 5 °C across 500 mm strip.

Optional 3 mm Al-metal-core PCB for IP67/IP68 flood or bar formats.

Solder-mask optimised for 365–405 nm reflectance (> 90 %) to reduce self-absorption.

3. Ingress & Mechanical Ratings

| Format | Standard IP | Tested to | Cable Gland | Front Window |

|---|---|---|---|---|

| Flexible strip | IP65 | IP66 | — | UV-transparent PU sleeve |

| Linear bar | IP67 | IP69K | M12 | Tempered quartz glass |

| Flood module | IP68 | 1 m, 24 h | M16 | High-purity fused silica |

4. Electrical Characteristics (Representative 50 W UVA Module)

Input voltage: 24 VDC ±10 % (constant-voltage) or 36 VDC (constant-current)

Power tolerance: ±3 % (binning at 0,5 m, 25 °C)

Surge withstand: 1 kV differential / 2 kV common (IEC 61000-4-5)

RoHS & REACH compliant, PFAS-free.

5. Quality Benchmark – Beauty STC vs. Generic Market

| Parameter (25 °C) | Generic Market Range | Beauty STC Certified | Test Method / Reference |

|---|---|---|---|

| Wavelength tolerance (nm) | ±5 … ±10 | ±2 | CI-E UV spectroradiometer |

| Radiant flux tolerance (%) | ±15 | ±5 | 300 mm integrating sphere, NIST traceable |

| Thermal resistance, junction-case (°C/W) | 4 – 8 | ≤ 3 (UVA) / ≤ 6 (UVC) | JEDEC JESD 51-14 |

| L70 lifetime (h, TJ ≤ 85 °C) | 20 000 – 30 000 | ≥ 50 000 | IES LM-80-20 + in-house TM-21 |

| PCB copper weight (oz) | 1 | 2 (std), 3 (option) | IPC-6012D |

| Dielectric breakdown (kV) | 1,5 | ≥ 3 | IPC-TM-650 2.5.6.3 |

| IP rating verification | Design only | 100 % pressure & dust test | IEC 60529 |

| Safety / EMC | Self-declaration | ETL cETLus, TUV CE, EMC (EN 55015, EN 61000-3-2) | Third-party annual audit |

| Factory calibration traceability | Not common | 0.5 m integrating sphere calibrated 12-monthly by NVLAP lab | ISO/IEC 17025 |

6. Consistency Controls in Jiangmen Plant

- Die bonding: ASM high-precision (±7 µm) flip-chip to minimise junction temperature spread.

- Automated optical & electrical binning: every reel is bar-coded; data uploaded to MES for full reel-to-order traceability.

- Solder reflow: 10-zone Heller with O2 < 50 ppm; AOI checks voiding < 5 % on thermal pad.

- 100 % burn-in: 2 h @ 1,2 × rated current; units failing ±3 % radiometric window are rejected and analysed.

- Pre-ship sampling: 0,5 % of order pull-tested for 500 h in 85 °C / 85 % RH; CpK > 1,33 required for release.

7. Certification & Compliance Summary

North America: ETL listed to UL 1598 & UL 8750, FCC Part 15 Class A.

Europe: TUV CE, EN 62471 photobiological risk group Exempt (UVA) or Risk 3 (UVC with required safeguards), RoHS (EU) 2015/863, REACH 219 SVHC.

ISO 9001:2015 quality system since 2003; ISO 14001:2015 environmental management since 2017.

8. OEM / ODM Flexibility

Wavelengths 365 – 420 nm (UVA) and 265 – 285 nm (UVC) available in any PCB length up to 3 m, or in COB arrays to 600 W.

Choice of connectors (JST, Wago, M12, Molex), cable exit orientation, and integrated NTC / photo-diode feedback.

Private-label packaging, laser-marked heatsinks, and datasheet customisation supported by our 12-member R&D team (average 15 years in solid-state lighting).

For project-specific IES files, CAD drawings or lifetime calculations, contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

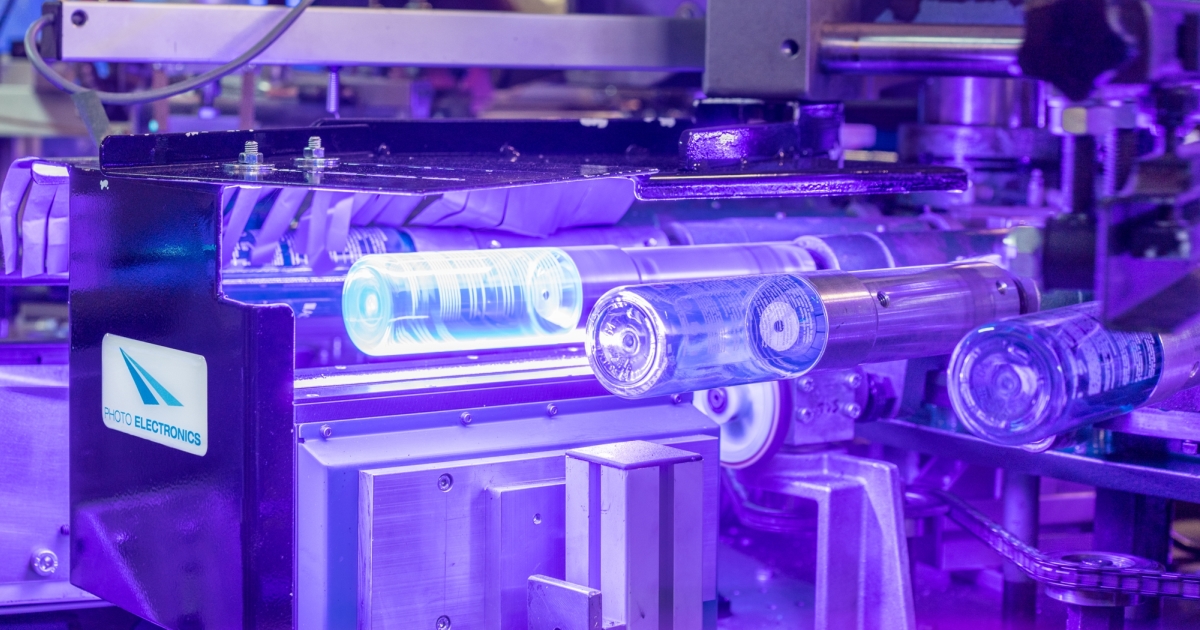

Precision Manufacturing Process for UV LED Solutions

Since 1998, Beauty STC Lighting has leveraged 25+ years of expertise in LED manufacturing to deliver high-reliability UV solutions. Our Jiangmen facility (41st Caihong Road, High-tech Industrial Zone) integrates advanced automation with rigorous quality protocols to meet the stringent demands of global industrial and commercial applications. All production adheres to ETL (USA/Canada) and TUV CE (Europe) standards, ensuring compliance with international safety and performance requirements.

Advanced SMT Production Line

Our surface-mount technology (SMT) line features fully automated pick-and-place systems and reflow soldering ovens with precision thermal profiling. This ensures consistent solder joint integrity for UV LED assemblies, critical for maintaining optical performance and reliability under high-power operation. Each production batch undergoes Automated Optical Inspection (AOI) to detect placement errors and solder defects before proceeding to assembly. The facility maintains ISO-classified cleanroom conditions for UV-sensitive components, minimizing contamination risks during chip bonding.

Rigorous Aging and Burn-in Testing

All UV LED products undergo a 72-hour continuous burn-in test at elevated temperatures (typically 60°C ambient) to accelerate potential early-life failures. Thermal cycling between -40°C and +85°C simulates real-world environmental stresses, ensuring operational stability across diverse climates. Performance metrics such as radiant flux and wavelength stability are recorded at 24-hour intervals to validate long-term reliability. This protocol exceeds IEC 62717 standards for LED lifetime testing.

Multi-Stage Quality Control Protocols

Our QC process includes spectral analysis using integrating spheres to verify peak wavelength accuracy (±2nm tolerance), electrical safety testing per IEC 62471 for photobiological safety, and IP rating verification through dust and water ingress tests. Each batch is traceable via serial numbers, with full documentation of raw materials and process parameters for audit compliance. All finished products undergo 100% visual inspection for optical clarity and mechanical integrity before shipment.

OEM/ODM Customization Capabilities

Tailored UV Specifications for Global Applications

Beauty STC provides OEM/ODM solutions with precise wavelength customization across UVA (315-400nm), UVB (280-315nm), and UVC (100-280nm) ranges. Key customizable parameters include:

| Parameter | Standard Options | Customizable Range |

|---|---|---|

| Wavelength | UVC: 275nm ±5nm, UVA: 365nm ±5nm | 250nm – 400nm (UVC/UVA/UVB) |

| Power Output | 1W, 3W, 5W per chip | Up to 10W per chip |

| Beam Angle | 30°, 60°, 120° | 15° to 150° |

| Operating Voltage | 9-42VDC | Custom configurations |

| Operating Temp | -40°C to +85°C | Extended to +125°C |

| IP Rating | IP65, IP67 | Up to IP68 |

Flexible Form Factors and Packaging

We offer customization of physical dimensions for all product types, including flexible strips (lengths from 50mm to 10m), LED panels (custom sizes up to 600x600mm), and floodlight housings (aluminum or polycarbonate). Packaging options include anti-static trays, custom-branded boxes, and OEM-specific labeling. All designs comply with international shipping standards to prevent damage during transit.

Certification Compliance and Regulatory Support

Every UV LED product is manufactured to meet ETL (USA/Canada) and TUV CE (Europe) safety standards. We provide full regulatory documentation including RoHS compliance certificates, REACH reports, and photobiological safety testing per IEC 62471. Our engineering team assists clients with market-specific certification requirements, ensuring seamless integration into global supply chains. For project-specific technical validation, contact our engineering department at [email protected] or +86 13902885704.

Installation & Application Scenarios

Application Scenarios & Contractor Guidelines for UV LED Modules

(Factory-direct data sheet – Beauty (STC) Mfg. Co., Ltd. – ETL / TUV CE, est. 1998)

H2 | Where UV LED Makes Commercial Sense

UV-A (365 nm) and UV-C (275 nm) LED engines are no longer laboratory curiosities; they are specification-grade components that fit into the same aluminium extrusions, IP65 housings and DALI drivers we already use for white-light projects. Below are the segments where our OEM clients see fastest ROI and lowest field-call rate.

| Segment | Typical UV Type | Key Function | Fixture Form Factor Supplied by Beauty STC |

|---|---|---|---|

| Hotel back-of-house | 275 nm UV-C 30–120 mW | Coil-surface sterilisation in PTAC units, ice-machine chambers | IP67 strip 24 V, 2835 package, 120 LEDs/m |

| Shopping-mall restrooms | 275 nm UV-C 150–300 mW | Upper-air disinfection above 2.3 m | Recessed linear 1.2 m, 40 W, micro-reflector 60° |

| Office HVAC plenum | 275 nm UV-C 1–3 W | In-duct sterilisation, keeps MERV-13 filters bio-free | 6063-T5 aluminium bar, 38 mm profile, quick-connect terminals |

| Façade accent (heritage stone) | 365 nm UV-A 1 W | “Black-light” reveal of mineral fluorescence | IP66 flood 30 × 30 cm, 30° lens, 24 VDC input |

| Parking-garage security | 365 nm UV-A 5 W | Fluorescent ID-paint validation for authorised vehicles | 50 × 4 LED array, 9–42 VDC, 400 nm dominant |

| Art-gallery conservation | 365 nm UV-A 0.3 W/m | Low-irradiance inspection of varnish layers | Flexible strip 5 mm, 120 LEDs/m, CRI-neutral white + 365 nm on same PCB |

H2 | Installation Notes for Contractors

Beauty STC modules are shipped with open leads (AWG18, 300 mm) and are Class 2 SELV. Integrate exactly like our white LED strips—no mercury, no ozone below 240 nm, no warm-up.

H3 | 1. Optical Safety

UV-C: Mount ≥ 2.3 m above finished floor or behind louvre so 180° field is inaccessible.

UV-A: Eye-risk distance for 1 W 365 nm flood is 600 mm; post ANSI Z136.1 signage.

H3 | 2. Thermal Management

| Wavelength | Max Tj | Recommended Ts (heat-sink) | Life L70 |

|---|---|---|---|

| 275 nm | 105 °C | ≤ 65 °C | 10 000 h |

| 365 nm | 125 °C | ≤ 75 °C | 50 000 h |

Use same 1.5 W/(m·K) gap pad we supply for white strips; extrusion width ≥ 20 mm per 10 W for passive cooling.

H3 | 3. Wiring & Control

Constant-current drivers tuned ±2 %; ripple < 5 % to avoid wavelength drift.

0–10 V or DALI option available—shares two-core with white channel (shared anode design).

Never dim UV-C below 30 %; below threshold current efficacy collapses while forward voltage remains, giving false “ON” status.

H3 | 4. Certification Pass-Through

All UV engines are built on the same UL 2108 / EN 62031 platform as our ETL-listed white strips. When you purchase complete luminaires from Beauty STC you inherit:

UL 1598 / CSA 22.2 No. 250.0 (ETL file 5005367)

EN 60598-1, -2-1 (TUV CE file 059100)

RoHS & REACH, IEC 62471 photobiological risk group “Exempt” for UV-A, “Risk Group 3” for UV-C (labelled accordingly).

H2 | OEM / ODM Checklist

✓ Wavelength tolerance ±3 nm (binning at 350 mA, 25 °C)

✓ Power levels 0.2–50 W on single MCPCB

✓ Integrate white, RGB or IR on same strip—multi-spectrum boards are our daily job since 1998.

✓ Private-label laser etching & ETL file update within 4 weeks.

Need a test batch? 3-week lead for 365 nm or 275 nm strip in 24 V, 3000 K neutral-white combo.

Contact: [email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Engineered UV LED Solutions for Global Markets

Decades of UV LED Manufacturing Expertise

Since 1998, Beauty STC Lighting has delivered precision-engineered LED solutions for industrial and commercial applications. With over 25 years of experience in LED manufacturing, we specialize in UV LED technologies that meet the demanding requirements of global markets. Our Jiangmen, China facility combines advanced production capabilities with rigorous quality control, ensuring consistent performance across all UV wavelength ranges.

Global Compliance & Certification Assurance

Our UV LED products undergo comprehensive testing to meet international safety and performance standards. Key certifications validate compliance for critical applications such as medical disinfection, industrial curing, and non-destructive testing (NDT):

ETL (USA/Canada): Compliance with NEC and UL standards for North American markets

TÜV CE (Europe): Meets IEC 62471 and EU RoHS directives

ISO 9001:2015: Quality management system certification

Tailored OEM/ODM Capabilities for UV Applications

We provide end-to-end customization for UV LED solutions, including wavelength-specific designs, thermal management, and application-specific form factors. Our engineering team collaborates directly with clients to optimize performance for:

UVC disinfection systems (260–280nm)

UVA curing and inspection (315–400nm)

Customized arrays for industrial and medical use

| Parameter | Specification | Compliance Standard |

|---|---|---|

| Wavelength Range | UVA: 315–400nm; UVC: 260–280nm | ISO 17025 certified testing |

| Power Output | 1W to 100W per module | RoHS 2.0 compliant |

| Beam Angle | Adjustable (15° to 120°) | IEC 62471 safety standards |

| Operating Temperature | -40°C to +85°C | ETL certified |

| Lifetime (L70) | >50,000 hours | TÜV CE marked |

| Customization | LED arrays, PCB designs, housings | OEM/ODM support |

Global Reach with Local Support

With exports to 50+ countries across Europe, North America, Southeast Asia, Australia, and beyond, our UV LED solutions are trusted by distributors, contractors, and project managers worldwide. Our dedicated export team ensures timely delivery and technical support tailored to regional regulatory and operational requirements.

Ready to integrate certified UV LED technology into your project?

Contact our engineering team to discuss your specifications and compliance needs.

Email: [email protected]

Phone: +86 13902885704

Address: 41st Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).