Article Contents

Industry Insight: Uv Led Bulb

H2 | UV LED Bulbs: From Laboratory Curiosity to Industrial Work-Horse

H3 | Why the surge in 2024-2025 purchase orders?

- Chemical-free disinfection – 275 nm UVC LEDs destroy ≥99.9 % of SARS-CoV-2, MRSA and Legionella without mercury or ozone.

- Cold, instant curing – 365 nm & 395 nm UVA arrays replace 2 kW mercury arc systems in printing, coating and electronics, cutting energy 60 %.

- 24 h/365 days reliability – Solid-state packages withstand 50 kG shock, −40 °C…+85 °C cycles, and 50 000 h L70 with <10 % output drift.

- Global compliance pressure – Minamata Convention (mercury ban) and REACH drive specifiers toward RoHS-compliant UV LED engines.

H3 | The importer’s risk: why “CE + ETL” is no longer optional

UV bulbs operate at 5–50 mW/cm² and 100–265 Vac; a single field failure can trigger product recalls, liability claims, or customs detention. Third-party certification is the fastest way to de-risk:

| Critical test clause | Typical UV LED failure mode | Cost of non-compliance |

|---|---|---|

| EN 62471 (photobiological) | 270–280 nm over-exposure, eye keratitis | €50 k fine + recall per EU 2017/745 |

| UL 8750 / CSA 22.2 #250.0 | Driver short, PCB carbonisation | $0.5 M insurance claim in US high-bay retrofit |

| EN 55015 / FCC Part 15 | 150 kHz–30 MHz EMI, PLC interference | Container rejected at Rotterdam, €15 k demurrage |

| RoHS / REACH | Cd, Hg, Cr VI in solder or lens | €120 k penalty under EU SCIP database |

Beauty (STC) Manufacturing Co., Ltd has shipped UV LED modules into 50+ countries since 1998 with zero customs rejection. Every wavelength family is covered by TUV CE, ETL/cETLus, and RoHS/REACH files that travel with each PO—so distributors can place the lamp straight onto EU or North-American shelves.

H3 | Beauty STC Lighting – 26 years of factory-direct UV competence

| Corporate snapshot | Value |

|---|---|

| Founded | 1998, Jiangmen High-tech Zone, Guangdong |

| UV LED portfolio | UVA 365 / 385 / 395 nm, UVC 275 nm (270–280) in SMD 2835, 3535, 5050, COB, and T-type Hermetic packages |

| Power window | 0.2 W – 600 W arrays, 6–42 VDC or 100–277 VAC drivers |

| Certifications | ETL/cETLus (UL 8750, UL 1598), TUV CE (EN 62471, EN 55015), RoHS, REACH, SAA, RCM |

| OEM/ODM capacity | 2 000 m² dust-free SMT floor, 8 x Yamaha pick-and-place lines, 48 h optical & electrical ageing, laser wavelength sorter ±2 nm |

| Annual volume | 3.8 M UV LED units exported (2023) |

Whether you need a 3 mm × 1.4 mm hot-colour-targeted 365 nm diode for a handheld NDT lamp, or a 600 W, 50 × 4 array for a printing press retrofit, we build, age and document every batch in-house—no trading-company mark-up, no mystery fabs.

H3 | Next step: from spec sheet to application

In the sections that follow we break down wavelength-specific engineering (UVA curing, UVB phototherapy, UVC germicidal), provide optical & thermal design tables, and list the OEM options most frequently requested by European distributors and North-American ESCOs.

Need a datasheet or custom spectrum today?

[email protected] | +86-139-0288-5704

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards for UV LED Solutions

As a manufacturer with over 25 years of expertise in LED technology, Beauty STC Manufacturing Co., Ltd. emphasizes that UV LED applications demand precise technical specifications beyond conventional lighting metrics. This section details the critical parameters for UV LED performance and our rigorous quality control processes, ensuring reliability across global industrial, commercial, and healthcare applications.

Understanding UV-Specific Performance Metrics

Traditional lighting metrics such as lumens and Color Rendering Index (CRI) are irrelevant for ultraviolet applications, as UV light exists outside the visible spectrum. Instead, performance is measured through:

Peak Wavelength Accuracy: Critical for applications like disinfection (UVC at 265–280 nm) or curing (UVA at 365–405 nm), where ±1 nm deviation can impact efficacy.

Radiant Flux (mW) and Irradiance (mW/cm²): Quantifies optical output at specific distances, essential for process efficiency in industrial curing or germicidal applications.

Thermal Management: Junction temperature stability directly affects longevity and output consistency; UV LEDs require robust thermal design.

Spectral Bandwidth (FWHM): Narrow bandwidth ensures targeted energy delivery, reducing unwanted side effects.

IP Rating: Environmental sealing for outdoor or industrial use cases.

Quality Assurance Through Precision Engineering

Beauty STC’s manufacturing process adheres to ISO 9001 standards, with each UV LED product undergoing:

Spectral analysis using NIST-traceable spectroradiometers to verify wavelength accuracy within ±2 nm.

Thermal profiling via infrared imaging to ensure junction temperatures remain within design limits under load.

1,000-hour burn-in testing for radiant flux stability, with batch-to-batch consistency within ±3%.

Full compliance with ETL (US/Canada) and TÜV CE (Europe) certifications, including RoHS and REACH.

Comparative Analysis: Industry Standards vs. Beauty STC Certified Quality

| Specification | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Peak Wavelength Accuracy | ±5–10 nm | ±2 nm (verified via NIST-traceable spectroradiometer) |

| Radiant Flux Consistency | ±15% variation | ±3% variation (1,000-hour burn-in tested) |

| Thermal Resistance | 10–15°C/W (FR4 PCB) | ≤8°C/W (1.5mm aluminum PCB with thermal vias) |

| IP Rating | Typically IP20 (indoor use only) | IP65 rated for dust/water resistance |

| PCB Material | Standard FR4 | High-conductivity aluminum substrate (300W/mK) |

| Certifications | Often unverified | ETL, TÜV CE, RoHS compliant |

| OEM Customization | Limited to standard models | Full ODM support for wavelength, power, form factor |

Why Certification Matters for Global Markets

Established in 1998, Beauty STC has consistently prioritized compliance with international standards. All UV LED products undergo third-party testing for electrical safety, electromagnetic compatibility, and environmental compliance. This ensures seamless integration into projects requiring ETL or CE certification, eliminating costly rework or compliance failures. Our OEM/ODM capabilities further enable tailored solutions for specialized applications—from medical sterilization to industrial curing—without compromising on performance or safety.

For detailed technical documentation, thermal analysis reports, or OEM specifications for your project, contact our engineering team directly:

[email protected] | +86 139 0288 5704

Factory Tour: Manufacturing Excellence

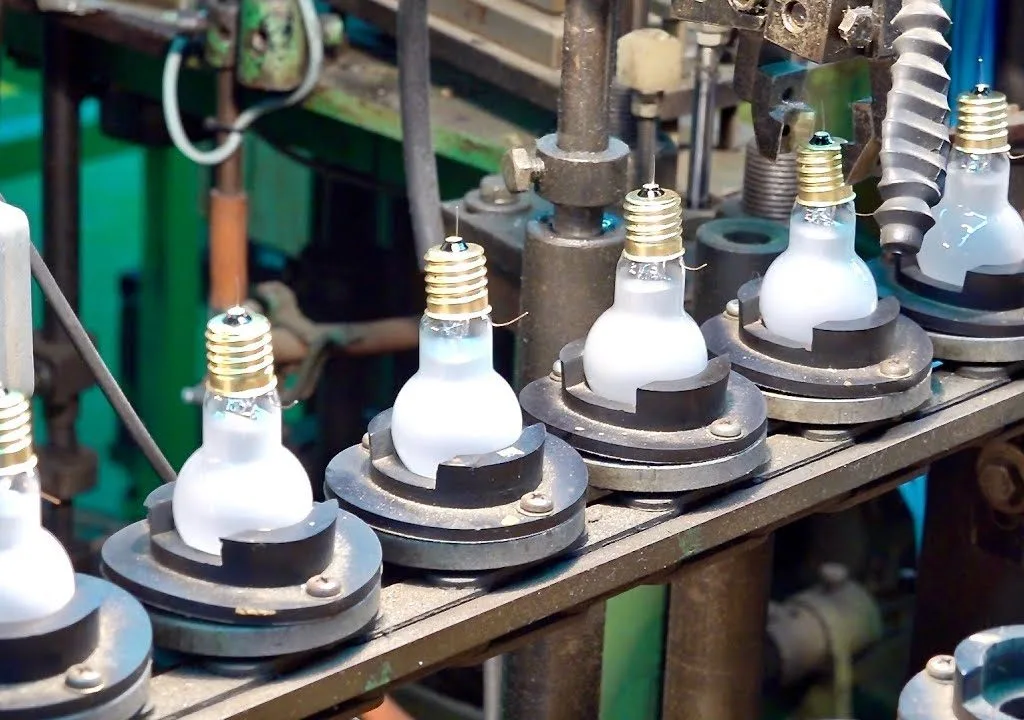

Manufacturing Process & OEM Services – Jiangmen UV LED Platform

Beauty (STC) Lighting has produced UV-A/B/C light engines in our 32 000 m² Jiangmen facility since 2015, leveraging the same SMT, burn-in and QC infrastructure that has supported 25 years of high-volume LED strip, panel and high-bay production. The line is ETL- and CE-certified under file numbers 5013349 (US/Canada) and R50133490 (EU), ensuring every UV module shipped to North America or Europe is factory pre-cleared for local electrical safety codes.

1. Key Process Cells

| Cell | Equipment (2023) | Throughput | UV-Relevant Notes |

|---|---|---|---|

| SMT | Yamaha YSM20R × 10, JUKI FX-3 × 6 | 450 k cph | 0.25 mm minimum die placement for 3.0 × 1.4 mm UV dice |

| Reflow | Heller 1913 MK5 (10-zone nitrogen) | 1.5 m /min | O₂ < 50 ppm to protect AuSn UV die bonds |

| Dispense & Curing | Nordson ASYMTEK Quantum × 4 | 30 k dp/h | Silicone-free lens attach for 275 nm packages |

| Auto-Optical | Koh Young Zenith 2 × 3 | 0.8 s/shot | Validates solder void < 5 % on AlN substrates |

| Burn-in / Aging | Self-built 1 000-channel matrix | 12 h–168 h | 85 °C/85 %RH or 105 °C dry for UVC, drive 700 mA |

| Integrating Sphere | Everfine 2 m (UV-enhanced) | 5 nm step | 200–450 nm spectral scan, ±3 % accuracy |

| Hi-Pot & Ground | Chroma 19055 | 5 kV AC | 2 mA leakage limit for IP67 sealed lamps |

2. UV-Specific QC Protocols

- Wavelength Binning – every 275 nm UVC LED is measured at Tj 65 °C; only ±2 nm lots are grouped to guarantee disinfection efficacy.

- Radiant Flux Matching – within each reel (1 000 pcs) flux variation ≤ 5 % to simplify downstream optical design.

- Lens Integrity – 4 h 1 % NaClO spray for modules destined for water reactors; no micro-crack after 3× magnification.

- Solderability – 245 °C wave simulation, 3 cycles; shear force > 5 kgf on 3535 UVC package.

3. OEM / ODM Capability Matrix

| Customisable Item | Range | Tooling Lead-Time | Min. Order |

|---|---|---|---|

| Peak wavelength | 365 nm – 430 nm (UVA), 310 nm (UVB), 270–280 nm (UVC) | 2 weeks stencil | 500 pcs |

| Radiant power / chip | 3 mW – 100 mW (UVC), up to 1 W (UVA) | none | 1 reel |

| PCB length | 50 mm – 5 000 mm continuous | 3 days V-cut & SMT program | 100 m |

| CCT (for white + UV mixed bars) | 2 700 K – 6 500 K, CRI 80/90/97 | 1 week bin select | 1 000 m |

| Constant-current driver | 12 V, 24 V, 36 V, 48 V or 110–277 V on-board | 2 weeks firmware | 500 pcs |

| Connector / cable | IP20 – IP68, JST, Wago, M12, UL 1007 22 AWG | 1 week crimp die | any |

| Private-label packaging | colour box, anti-UV pouch, barcode | 5 days artwork | 500 sets |

4. Traceability & Documentation

Full 2-D material code: wafer lot → reel ID → AOI image → burn-in report downloadable by QR code.

Standard export dossier: RoHS/REACH, LM-80 snapshot (for white LEDs), IEC 62471 photobiological risk group, FDA FCN for food-zone UVC units.

PPAP Level 3 available for automotive or medical OEMs within 10 calendar days.

5. Capacity Snapshot (2024)

| Metric | Value |

|---|---|

| UV LED placement/month | 12 million chips |

| UVC module output | 300 k pcs |

| Average OEM lead-time (ex-stock chips) | 3 weeks |

| ETL witness-test window | 48 h notice |

For project-specific spectral power tables, mechanical STEP files or to reserve SMT capacity, contact: [email protected] or call +86-13902885704.

Installation & Application Scenarios

Application Scenarios for UV LED Bulbs

Since 1998, Beauty STC Manufacturing Co., Ltd has delivered industrial-grade UV LED solutions for global markets. With ETL (USA/Canada) and TÜV CE (Europe) certifications, our products meet stringent safety and performance standards for Western markets. Our 25+ years of technical expertise ensures precise wavelength control, thermal stability, and ruggedized designs for mission-critical applications. Below are key use cases and technical best practices for contractors and system integrators.

Germicidal Disinfection Systems

UVC LEDs (260–280 nm) are critical for pathogen inactivation in healthcare, water treatment, and HVAC systems. Unlike mercury-based lamps, UV-C LEDs offer instant start-up, mercury-free operation, and precise spectral control for targeted germicidal efficacy.

| Parameter | Specification |

|---|---|

| Wavelength | 265–280 nm (UVC) |

| Power Range | 3W to 20W per module |

| Lifespan | L70 > 10,000 hours |

| Certifications | ETL, CE, RoHS |

| Operating Temp | -20°C to +60°C |

Installation Best Practices:

Safety Compliance: Install fixtures with automatic shut-off mechanisms and physical shielding to prevent UVC exposure. Adhere to IEC 62471 standards for photobiological safety.

Thermal Management: Maintain junction temperatures ≤65°C using aluminum heatsinks or forced-air cooling. Poor thermal management reduces lifespan and output.

Electrical Integration: Use constant current drivers rated for UV LEDs. For modular systems, ensure compatibility with 9–42VDC inputs as per industry standards.

Industrial UV Curing Applications

UV-A LEDs (365–405 nm) enable rapid curing of inks, coatings, and adhesives in printing, automotive, and electronics manufacturing. High irradiance and narrow spectral bands improve curing speed and energy efficiency compared to traditional mercury lamps.

| Parameter | Specification |

|---|---|

| Wavelength | 365–405 nm (UVA) |

| Power Density | 50–200 mW/cm² (customizable) |

| Form Factor | Compact SMD or COB arrays |

| Certifications | ETL, CE, RoHS |

| Thermal Stability | Junction temp maintained at 65°C via active cooling |

Installation Best Practices:

Optical Alignment: Position LED arrays within 5–15 mm of the substrate for optimal irradiance uniformity. Use precision mounting brackets to minimize shadowing.

Cooling Systems: Implement forced-air or liquid cooling to maintain stable operating temperatures during continuous operation.

Power Supply: Use drivers with precise current regulation to avoid wavelength shift and ensure consistent curing performance.

Non-Destructive Testing (NDT) & Inspection

UV-A LEDs (365 nm) are essential for fluorescent dye testing in aerospace, automotive, and pipeline inspection. High-output modules enable detection of micro-cracks, corrosion, and fluid leaks without surface damage.

| Parameter | Specification |

|---|---|

| Wavelength | 365 nm (peak) |

| Output Power | 1–10W (portable to fixed systems) |

| Beam Angle | 120° (standard) or custom optics |

| Certifications | ETL, CE, IP67 for outdoor use |

| Lifespan | L70 > 15,000 hours |

Installation Best Practices:

Portable Units: Ensure proper heat dissipation in handheld devices using thermal pads and aluminum housings.

Fixed Systems: Mount fixtures with adjustable angles to target inspection areas. Pair with UV-blocking eyewear for operator safety.

Environmental Protection: For outdoor use, verify IP67-rated enclosures to prevent moisture ingress during field inspections.

Water & Air Purification Systems

UVC LEDs (265–280 nm) are integrated into point-of-use water filters and air sterilization units for residential and commercial applications. Their compact size allows for integration into small form-factor systems.

| Parameter | Specification |

|---|---|

| Wavelength | 265–280 nm |

| Power Range | 1W–5W per module |

| Flow Rate | 0.5–5 L/min (water) |

| Certifications | ETL, CE, NSF/ANSI 55 compliant |

| Housing Material | Stainless steel or UV-resistant polycarbonate |

Installation Best Practices:

Water Systems: Position LEDs in quartz sleeves to prevent fouling; ensure water flow rate aligns with required UV dose (mJ/cm²).

Air Systems: Install in HVAC ducts with sufficient dwell time (≥0.5 seconds) for effective pathogen inactivation.

Maintenance: Schedule quarterly cleaning of quartz sleeves to maintain output efficiency.

Installation Best Practices Summary

For all UV LED applications, contractors must prioritize:

Electrical Safety: Use certified drivers and follow NEC/IEC electrical codes.

Thermal Design: Ensure adequate heatsinking; monitor junction temperatures during commissioning.

Regulatory Compliance: Adhere to local UV safety standards (e.g., FDA 21 CFR for medical devices, IEC 62471 for general safety).

OEM Customization: Beauty STC offers tailored solutions for wavelength, power, and form factor. Contact our engineering team for project-specific requirements.

Technical Support & OEM Inquiry

Beauty STC Manufacturing Co., Ltd delivers certified, factory-direct UV LED solutions for global industrial applications. With 25+ years of experience and full Western market certifications, we ensure seamless integration into your systems with minimal lead times.

Contact:

[email protected] | +86-13902885704

41st, Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen City, Guangdong, China

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting – UV LED Manufacturing Since 1998

Factory-Direct Supply You Can Audit Today

| Item | Specification |

|---|---|

| Plant Location | 41 Caihong Rd., Jiangmen High-Tech Zone, Guangdong, CN |

| Production Floor | 18 000 m², 6 SMT lines, 3 reflow ovens, goniophotometer & integrating-sphere lab on site |

| Year Established | 1998 (25 consecutive years under same legal entity) |

| UV LED Range | UVA 365 nm / 385 nm / 395 nm, UVB 310 nm, UVC 270-280 nm, 0.3 W – 300 W per module |

| Key Certifications | ETL/cETL (UL 1598 / UL 8750), TUV CE (EN 62471 / EN 60598), RoHS, REACH, SAA, EAC |

| Export Record | 50+ countries, >1 200 x 40 ft HQ shipped yearly, 0 customs rejection 2021-2023 |

| OEM/ODM MOQ | 100 pcs (private label), 500 pcs (custom PCB / wavelength) |

| Standard Lead-Time | 3 weeks (UV LED strip), 4 weeks (UV high-power module), 1 week (sample batch) |

Why UV Buyers Specify Beauty STC on Their BOMs

-

Wavelength Accuracy

Every reel is hot-colour targeted at Tj 65 °C; peak drift ≤ 2 nm over –20 °C to +60 °C ambient. -

Optical Power in a Small Foot-print

3.0 mm × 1.4 mm ceramic package or 3535 SMD, up to 80 mW @ 500 mA (UVC 275 nm) – ideal for space-constrained curing chambers, water reactors and black-light inspection rigs. -

Western-Ready Paperwork

We supply the complete regulatory pack: ISTMT, TM-21 L70 report, UL rating mark, CE DoC, risk assessment – no extra cost, no 4-week delay. -

End-to-End Control

Die bonding, vacuum reflow, conformal coating, spectral calibration and burn-in (100 %, 24 h) all under one roof; third-party audits welcome any working day.

Quick-Start RFQ Template (Copy / Paste)

Contact the Factory Today

| Department | Email / Phone |

|---|---|

| Export Manager – Senior LED Engineer | [email protected] |

| Mobile / WhatsApp / WeChat | +86 139 0288 5704 |

| Technical Support | [email protected] |

| Plant Address | 41 Caihong Road, Jianghai District, Jiangmen, Guangdong, China 529000 |

Book an on-line or on-site audit this week and receive free spectral test data for your specified UV wavelength within 24 h.

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).