Article Contents

Industry Insight: Uv-C Led

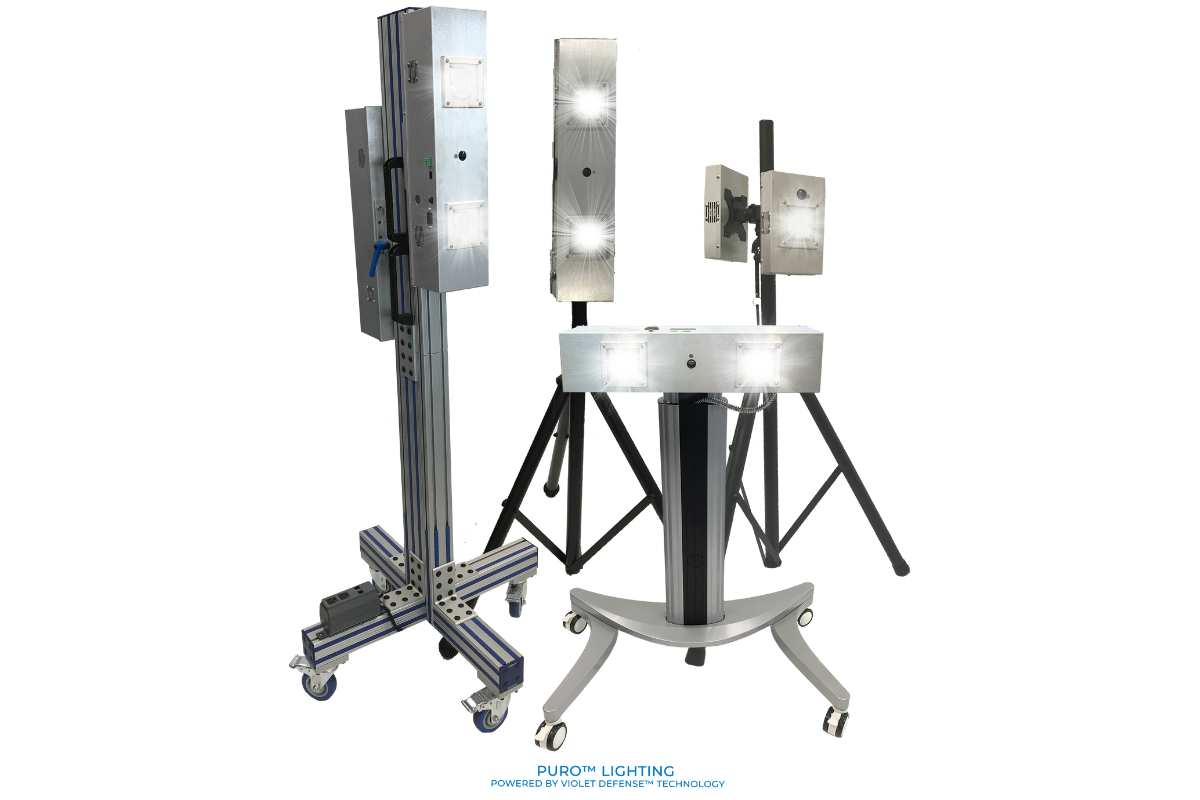

The commercial and industrial lighting sector is experiencing a significant shift as UV-C LED technology emerges as a critical solution for germicidal applications, moving decisively beyond traditional mercury-vapor lamps. Driven by stringent hygiene demands in healthcare facilities, food processing plants, HVAC systems, and public transit, the need for effective, chemical-free surface and air disinfection is accelerating adoption. However, integrating UV-C LEDs into mission-critical infrastructure demands more than just technological capability; it requires absolute reliability and rigorous validation. Compliance with safety and performance standards like ETL and CE is not merely a regulatory checkbox but a fundamental prerequisite for commercial viability, ensuring devices operate safely within specified parameters and deliver consistent germicidal efficacy without posing risks to personnel or equipment. This landscape demands partners with deep technical expertise and unwavering commitment to quality validation. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized engineering and manufacturing excellence to this evolving field. We focus exclusively on developing robust, certified UV-C LED lighting solutions engineered to meet the exacting demands of industrial and commercial environments, where performance, safety, and regulatory adherence are non-negotiable.

Technical Specs & Certifications

UV-C LED technology operates in the ultraviolet spectrum, specifically within the 200–280 nm wavelength range, and is primarily used for germicidal applications such as disinfection, water purification, and air sterilization. Unlike visible light LEDs, UV-C LEDs do not produce lumens in the traditional sense because lumens measure visible light output as perceived by the human eye, and UV-C radiation is invisible. Therefore, the efficacy of UV-C LEDs is measured in radiant flux (milliwatts or watts) per electrical watt input, commonly referred to as Wall-Plug Efficiency (WPE), rather than lumens per watt. Current high-performance UV-C LEDs achieve WPE values ranging from 5% to 15%, depending on wavelength and chip design, translating to tens of milliwatts of UV-C output per watt of electrical input.

Color Rendering Index (CRI) is not applicable to UV-C LEDs. CRI evaluates how accurately a light source renders colors in the visible spectrum relative to natural light, and since UV-C radiation lies outside the visible range, it does not contribute to color rendering. Therefore, a CRI greater than 90 is not relevant or achievable for UV-C LEDs. This metric is typically associated with visible white LEDs used in general lighting applications.

Regarding Ingress Protection (IP) ratings, UV-C LED modules themselves are components and do not carry IP ratings independently. However, when integrated into complete luminaires or disinfection systems, the overall fixture can be designed to meet specific IP standards. For example, UV-C disinfection units used in harsh environments such as hospitals, laboratories, or industrial settings may be housed in enclosures rated IP65 or higher to ensure protection against dust and water ingress. The choice of IP rating depends on the application and installation environment.

At Beauty (STC) Manufacturing Co., Ltd., we maintain rigorous quality control standards in the production of LED components and lighting systems. While our expertise includes high-efficiency visible-spectrum LEDs with excellent lumen-per-watt performance and high CRI values, our approach to UV-C LED integration emphasizes reliability, thermal management, and long-term output stability. We partner with leading UV-C LED chip suppliers and incorporate robust driver circuitry, precision optics, and thermally efficient designs to ensure consistent germicidal performance. All our assembled systems comply with international safety and performance standards, reflecting our commitment to engineering excellence and product durability in demanding applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is located in Jiangmen, Guangdong Province, China. This strategically positioned factory serves as our core production and engineering hub, operating within a modern, purpose-built complex spanning approximately 300,000 square feet. The Jiangmen site is certified to ISO 9001 and ISO 14001 standards, reflecting our commitment to quality management and environmental responsibility throughout the manufacturing process.

The surface mount technology (SMT) production lines within the Jiangmen factory are equipped with high-precision, automated machinery to ensure consistent component placement and soldering quality for LED assemblies. Key equipment includes multiple Yamaha YS24 series SMT placement machines, known for their speed, accuracy, and suitability for handling the diverse component sizes used in LED lighting, including miniature LEDs and complex driver circuitry. These lines are supported by automated optical inspection (AOI) systems for real-time quality verification and reflow soldering profiles meticulously calibrated for lead-free processes, essential for meeting global environmental regulations and ensuring long-term solder joint reliability.

Aging and reliability testing represent a critical phase in our quality control protocol, particularly for demanding applications like UV-C LED products. The Jiangmen facility houses extensive dedicated aging chambers capable of subjecting finished products and critical sub-assemblies to controlled high-temperature, high-humidity, and continuous operational stress tests. For UV-C LED modules and luminaires, we implement rigorous aging procedures typically spanning 1000 hours or more under full operational load. During these tests, we continuously monitor and record key parameters including optical output (radiant flux), forward voltage, thermal performance at the LED junction, and overall electrical stability. This data is essential for validating product lifespan projections, identifying early failure modes, and ensuring the stringent reliability required for germicidal applications where consistent UV-C output is non-negotiable.

Regarding OEM capability for UV-C LED products, Beauty STC’s Jiangmen factory possesses comprehensive in-house engineering and manufacturing resources to support full turnkey solutions. We offer extensive OEM services covering the complete product lifecycle from initial concept and optical/thermal/mechanical design through prototyping, regulatory compliance testing (including IEC 62471 for photobiological safety), and high-volume production. Our expertise includes integrating specialized UV-C LEDs from leading suppliers into custom optical systems, designing robust thermal management solutions critical for UV-C LED longevity, and developing application-specific driver electronics with precise current control. The factory maintains dedicated cleanroom areas for UV-C module assembly to prevent contamination that could degrade performance, and we have the capacity to handle complex secondary optics integration and final product assembly for diverse form factors, from compact water disinfection modules to larger air purification systems. Our engineering team works closely with OEM partners to tailor designs to specific performance requirements, target markets, and cost structures while ensuring adherence to all relevant safety and efficacy standards for UV-C technology.

Application Scenarios

UV-C LED technology is increasingly being adopted across various commercial environments due to its germicidal properties, which effectively inactivate bacteria, viruses, and other pathogens by disrupting their DNA. When applied correctly, UV-C LEDs offer a chemical-free method of air and surface disinfection. Below are recommended applications in hotels, malls, and offices, followed by essential installation tips.

In hotels, UV-C LEDs can be integrated into HVAC systems to disinfect air circulating throughout guest rooms and common areas, helping maintain indoor air quality and reducing the risk of airborne infections. They are also effective in restrooms, especially inside ventilation ducts or near exhaust fans, to minimize mold and odors. Additional applications include UV-C disinfection inside elevator cabins, on high-touch surfaces such as door handles (using enclosed UV-C systems), and in laundry rooms to sanitize linens during washing cycles.

In malls, where large volumes of people gather, UV-C LEDs are best used within central air handling units and rooftop units to continuously treat air in high-traffic zones like food courts, restrooms, and escalator landings. Standalone or ceiling-mounted UV-C fixtures with motion sensors can be installed in restrooms and fitting rooms to activate only when unoccupied, ensuring safety while maintaining hygiene. UV-C can also be applied in trash compactor areas and waste collection rooms to reduce microbial growth and control odors.

In offices, UV-C LEDs are ideal for integration into ducted or fan coil units within HVAC systems to improve air quality across open-plan workspaces, meeting rooms, and break areas. Desktop or under-desk UV-C air purifiers with safety interlocks can provide localized disinfection. Additionally, UV-C can be used inside printer rooms, server rooms (to prevent dust and microbial buildup on equipment), and in conference room ventilation systems to enhance cleanliness, especially in shared environments.

When installing UV-C LEDs, several critical tips must be followed to ensure effectiveness and safety. First, ensure that UV-C exposure is limited to unoccupied spaces or fully enclosed systems, as direct exposure to skin and eyes can be harmful. Use motion sensors or timers to disable UV-C when people are present. Second, position UV-C LEDs to maximize exposure to target surfaces or airflow—typically perpendicular to airflow in ducts or aimed at reflective surfaces to increase coverage. Third, maintain proper distance between the UV-C source and the target; output intensity decreases with distance, so follow manufacturer guidelines for irradiance levels and exposure time. Fourth, ensure fixtures are easily accessible for routine inspection and cleaning, as dust accumulation on LED surfaces significantly reduces output. Fifth, use UV-C LEDs with appropriate wavelength (typically 260–280 nm) and sufficient irradiance to achieve the required microbial kill rate. Finally, integrate UV-C systems with building management systems (BMS) where possible for monitoring, scheduling, and maintenance alerts.

By carefully selecting application points and following safe installation practices, UV-C LED systems can significantly enhance hygiene and air quality in hotels, malls, and offices, contributing to healthier indoor environments.

Why Choose Beauty STC Lighting

Unlock the full potential of germicidal UV-C LED technology for your product portfolio by partnering with Beauty STC. Our engineering team delivers rigorously tested UV-C LED solutions designed for maximum efficacy in air, surface, and water disinfection applications. We prioritize precise 265-280nm wavelength output, superior thermal management, and extended operational lifespans to ensure reliable performance in demanding environments. By integrating our components, you gain access to advanced optical designs and strict compliance with international safety standards, empowering your end products with scientifically validated disinfection capabilities that meet evolving market demands.

Elevate your competitive edge through a partnership built on Beauty STC’s decade-long expertise in specialized LED manufacturing. We provide comprehensive technical support, customizable form factors, and scalable production capacity to align with your specific application requirements and volume needs. Let us help you bring innovative, high-performance UV-C lighting solutions to market faster while maintaining the highest quality benchmarks. Contact our dedicated partnership team today at [email protected] to discuss how our UV-C LED technology can drive your next generation of disinfection products.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.