Article Contents

Industry Insight: Uv A Led Lamp

In the rapidly evolving landscape of commercial and industrial lighting, UV-A LED lamps have emerged as a critical solution across a diverse range of applications—from curing processes in manufacturing and printing to non-destructive testing and forensic inspection. These high-performance lamps offer significant advantages over traditional UV sources, including longer lifespans, reduced energy consumption, instant on/off functionality, and minimal heat emission. As industries increasingly prioritize efficiency, safety, and regulatory compliance, UV-A LED technology has become a cornerstone of modern operational workflows.

A key factor in the widespread adoption of UV-A LED systems is adherence to rigorous safety and performance standards. Products bearing ETL and CE certifications ensure compliance with North American and European regulatory requirements, respectively, providing assurance of electrical safety, electromagnetic compatibility, and environmental resilience—critical considerations for industrial end users.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advanced LED lighting innovation for over two decades. Specializing in commercial and industrial-grade solutions, Beauty STC combines precision engineering with stringent quality control to deliver reliable, code-compliant UV-A LED lamps trusted by professionals worldwide. With a strong commitment to research, sustainability, and customer-driven design, Beauty STC continues to set benchmarks in performance and durability across demanding industrial environments.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. provides high-performance UV-A LED lamps designed for industrial, scientific, and specialized applications such as curing, counterfeit detection, and fluorescence inspection. It is critical to address a fundamental technical point upfront: UV-A radiation (315-400 nm) falls outside the visible light spectrum. Consequently, standard photometric metrics like lumens (which measure perceived brightness by the human eye) and Color Rendering Index (CRI, which assesses visible light color fidelity) are physically meaningless for UV-A sources. UV-A lamps do not produce visible lumens, making lumens per watt (lm/W) an inapplicable efficiency metric. Similarly, CRI >90 is irrelevant as UV-A does not render visible colors. Efficiency for UV-A LEDs is correctly measured in Wall-Plug Efficiency (WPE), expressed as optical radiant power output (watts) per electrical watt input, or more commonly as irradiance (W/m² or mW/cm²) at a specified distance.

For UV-A LED lamps, the relevant technical specifications focus on optical power and spectral characteristics. Beauty STC UV-A lamps typically operate at peak wavelengths of 365 nm, 385 nm, or 395 nm, with spectral bandwidths (FWHM) of 10-15 nm to ensure precise application performance. Radiant flux output ranges from 500 mW to over 10 W per module depending on configuration, with WPE values typically between 15% and 25% for high-end industrial-grade emitters. Irradiance levels are application-specific but can exceed 10,000 mW/cm² at 10 mm for focused curing systems. Thermal management is paramount; Beauty STC employs advanced aluminum-core PCBs and active cooling in high-power fixtures to maintain wavelength stability and extend LED lifespan beyond 20,000 hours at 70% output.

Regarding environmental protection, Beauty STC UV-A lamps are engineered with robust ingress protection. Standard industrial models achieve IP65 rating (dust-tight and protected against low-pressure water jets), suitable for factory environments with particulates or occasional splashes. For harsher conditions such as outdoor use or washdown areas, IP67 (dust-tight and immersion up to 1m) or IP68 variants are available through custom engineering. All enclosures utilize UV-stable polycarbonate or tempered glass lenses with specialized anti-reflective coatings to maximize UV transmission and resist solarization. Sealing employs multi-layer gasketing with silicone O-rings rated for continuous UV exposure.

Beauty STC’s quality commitment is evident in our rigorous manufacturing standards. Every UV-A lamp undergoes 100% spectral validation using calibrated spectroradiometers to ensure wavelength accuracy within ±2 nm and consistent radiant power. We implement MIL-STD-883 thermal cycling tests and 85°C/85% RH accelerated life testing to guarantee reliability in demanding conditions. Our ISO 9001-certified production lines feature automated optical inspection for solder joint integrity and hermetic sealing verification. Unlike commodity UV products, Beauty STC lamps use phosphor-free InGaN die on ceramic submounts to prevent output degradation, backed by a 3-year warranty on critical performance parameters. This focus on precision engineering ensures stable UV output for mission-critical applications where inconsistent irradiance could compromise processes like adhesive curing or forensic analysis.

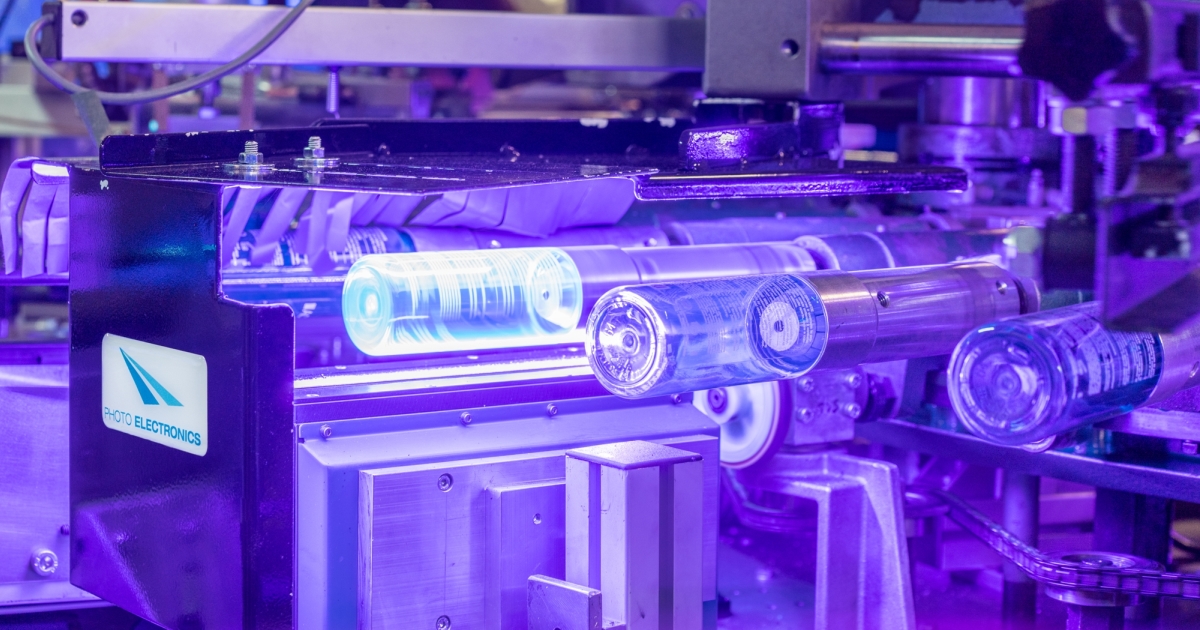

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, designed to support high-volume production of LED lighting products with strict quality control and advanced automation. The factory is equipped with state-of-the-art SMT (Surface Mount Technology) production lines, which enable precise and efficient placement of electronic components onto printed circuit boards. These SMT machines are fully automated, offering high-speed placement accuracy and consistency, essential for manufacturing reliable LED lighting products such as UV-A LED lamps. The integration of automated optical inspection (AOI) systems ensures that each PCB assembly meets stringent quality standards before moving to the next stage of production.

To guarantee long-term performance and reliability, the factory conducts comprehensive aging tests on all finished LED products. UV-A LED lamps undergo extended burn-in procedures under controlled thermal and electrical conditions, typically operating at full power for 24 to 72 hours. This aging process helps identify early-life failures and ensures product stability before shipment. Environmental testing, including thermal cycling and humidity exposure, may also be performed to validate durability under various operating conditions.

Beauty STC has strong OEM capabilities and actively supports custom development for UV-A LED lamp projects. The company can accommodate client-specific requirements including optical design, thermal management, housing materials, power configurations, and branding. With in-house engineering support for optical, electronic, and mechanical design, the Jiangmen factory is well-equipped to deliver tailored UV-A LED solutions for applications such as curing, inspection, medical therapy, and industrial processes. From prototype development to mass production, Beauty STC offers end-to-end OEM services with flexible MOQs, ensuring scalability and rapid time-to-market for its partners.

Application Scenarios

UV-A LED lamps serve specific non-disinfection purposes primarily in entertainment, security, and specialized visual applications within commercial environments. It is critical to distinguish UV-A (315-400 nm) from germicidal UV-C (100-280 nm). UV-A does not effectively kill pathogens and should never be marketed or used as a disinfection tool in these settings. Misapplication poses significant health risks including eye damage and skin irritation with prolonged exposure.

In hotels, UV-A LED lamps find limited but valid use in designated entertainment venues such as nightclubs or themed bars where blacklight effects create visual appeal for fluorescent decor, body paint, or special events. Some high-end spas may incorporate them cautiously in controlled nail curing stations, though dedicated nail lamps are preferable. Reception areas might utilize them strictly for currency or ID validation under shielded counters where staff are trained to minimize exposure. Crucially, UV-A lamps must never be installed in guest rooms, hallways, lobbies, or public relaxation areas due to uncontrolled occupant exposure risks and potential guest complaints regarding unintended fluorescence of personal items.

Within malls, UV-A applications are almost exclusively confined to security and retail functions. Currency validation stations at cashier desks or security checkpoints use shielded UV-A sources to detect security threads in banknotes. Certain retail displays, particularly in novelty stores or children’s sections featuring glow-in-the-dark merchandise, may employ discreetly mounted UV-A lamps to enhance product visibility under controlled conditions where direct viewer exposure is brief and incidental. General mall lighting, food courts, restrooms, or common walkways are entirely inappropriate locations for UV-A installation due to the constant public presence and lack of exposure control.

Offices present the most restricted legitimate uses. UV-A lamps may be installed in specific security or finance department workstations solely for document verification under shielded task lighting, ensuring no direct line of sight to occupants. Laboratories within corporate facilities might use them for material inspection or fluorescence microscopy, but this requires stringent engineering controls. Open-plan offices, meeting rooms, restrooms, cafeterias, or executive suites are absolutely unsuitable environments for UV-A lamps. The risk of chronic low-level exposure to employees during standard work hours is unacceptable and violates occupational safety standards in most jurisdictions.

Installation must prioritize human safety above all else. Never mount UV-A lamps in open fixtures where direct or reflected UV radiation can reach eyes or skin. Always use fully enclosed, interlocked fixtures with physical shielding that blocks UV emission outside the intended target area. Install at heights and angles preventing line-of-sight exposure to occupants, typically above 2.4 meters with downward baffling. Include prominent warning labels indicating UV radiation hazard per IEC 62471 standards. Implement automatic shut-off mechanisms via motion sensors or timers in unattended areas. Crucially, verify local building and occupational safety codes as many regions strictly regulate or prohibit public UV-A exposure. Conduct radiometric testing post-installation to confirm UV levels in occupied zones remain below 3 mW/m² for chronic exposure as per ACGIH guidelines. Staff operating near these installations require specific UV safety training and appropriate protective eyewear rated for UV-A. Remember that UV-A’s primary role here is functional or aesthetic—not health-related—and reckless deployment invites liability and health incidents.

Why Choose Beauty STC Lighting

Discover the power of advanced UV A LED technology with Beauty STC, a trusted leader in innovative lighting solutions. Our high-performance UV A LED lamps are engineered for reliability, efficiency, and superior output, making them ideal for a wide range of industrial, medical, and cosmetic applications. As a global manufacturing partner, Beauty STC combines cutting-edge research with scalable production to deliver custom solutions that meet your exact needs.

Partner with us to bring your UV lighting projects to life. For inquiries or to discuss your requirements, contact us today at [email protected]. Let Beauty STC illuminate your success with precision-engineered UV A LED lamps.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.