Article Contents

Industry Insight: Usb Lighting Strip

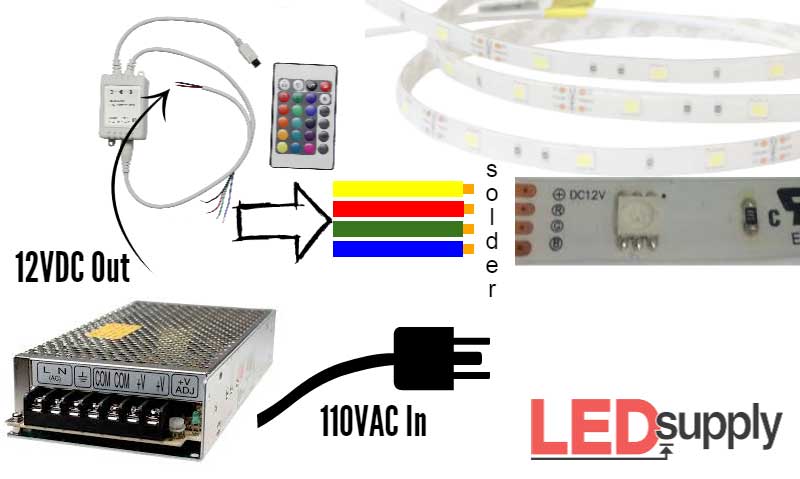

The commercial and industrial lighting sector continues to evolve beyond basic illumination, with USB-powered LED strips emerging as a specialized solution for specific low-voltage applications, though their role remains distinct from mainstream line-voltage systems. While traditionally associated with consumer DIY projects, certified USB lighting strips are gaining cautious traction in professional settings for targeted uses such as under-cabinet task lighting in retail displays, accent lighting within kiosks or point-of-sale units, and flexible under-shelf illumination in warehouse picking zones where low-voltage safety and simplified integration with existing USB power sources are advantageous. Crucially, for any commercial or industrial deployment, adherence to stringent safety standards is non-negotiable. Products must bear recognized certifications like ETL for the North American market and CE marking for Europe, ensuring they meet rigorous electrical safety, electromagnetic compatibility, and performance requirements to mitigate fire hazards and liability risks inherent in professional environments. Uncertified USB strips pose significant dangers and are wholly unsuitable for these applications. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep engineering expertise in commercial-grade LED solutions to this space. We focus on developing and manufacturing USB lighting strips that prioritize not just flexibility and ease of use, but uncompromising compliance with ETL, CE, and other global regulatory frameworks, delivering the reliability and safety standards demanded by facility managers, lighting specifiers, and integrators in professional settings. Our commitment lies in providing solutions that enhance functionality without sacrificing the critical safety infrastructure required in commercial and industrial operations.

Technical Specs & Certifications

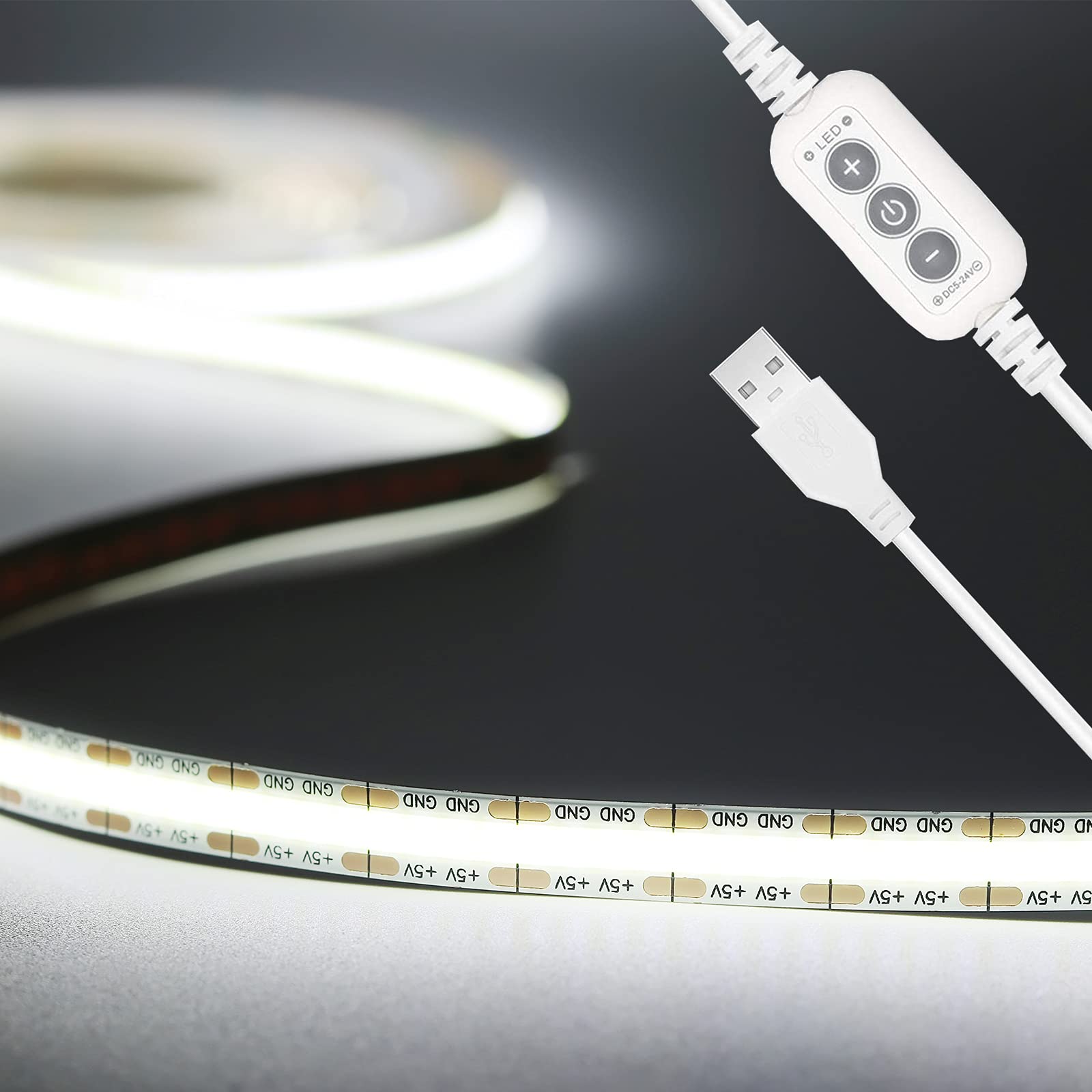

The USB lighting strip offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high efficiency, exceptional color accuracy, and reliable performance in a wide range of applications. Designed with precision and built using premium components, these strips deliver outstanding value in compact, low-voltage lighting solutions.

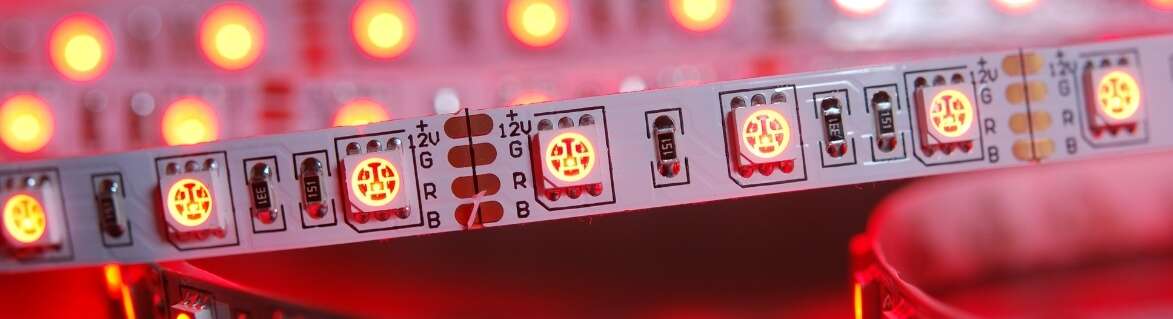

In terms of efficiency, Beauty STC’s USB lighting strips achieve a luminous efficacy of up to 90–100 lumens per watt, depending on the specific configuration and LED density. This high lumens-per-watt ratio ensures energy-efficient operation, making the strips ideal for portable and low-power applications powered via standard 5V USB sources. The use of high-grade SMD LEDs, typically in 2835 or 3528 packages, enables optimal light output while minimizing power consumption.

Color rendering is a key strength of Beauty STC’s USB lighting strips. All high-CRI variants are rated at CRI >90, with some models reaching CRI >95, ensuring accurate and vibrant color representation. This makes the strips especially suitable for task lighting, photography setups, makeup application, and other applications where true color perception is critical. The high CRI is achieved through the use of premium phosphor coatings and stringent binning processes during LED manufacturing.

Regarding environmental protection, Beauty STC offers USB lighting strips in multiple IP rating configurations to suit various installation environments. IP20-rated strips are suitable for dry, indoor use such as under-cabinet lighting or desk illumination. For damp or outdoor applications, IP65-rated versions are available, providing complete dust protection and resistance to low-pressure water jets. These are ideal for bathroom vanities, outdoor signage, or any setting requiring durability against moisture and dust. Fully encapsulated IP67-rated strips are also available for temporary submersion and harsh environments, ensuring long-term reliability.

Beauty STC’s commitment to quality is evident in every stage of production. The company adheres to strict quality control standards, including automated optical inspection (AOI), thermal cycling tests, and continuous aging tests to ensure longevity and consistent performance. All USB lighting strips are RoHS compliant and undergo rigorous safety and performance certification processes. With decades of manufacturing expertise, Beauty (STC) Manufacturing Co., Ltd. delivers reliable, high-performance LED solutions trusted by clients worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a core production hub for our LED lighting solutions, strategically positioned within the Pearl River Delta to leverage robust supply chain networks and skilled labor resources. The factory spans a significant footprint designed for efficient, high-volume manufacturing while maintaining stringent quality control standards throughout the production lifecycle.

Our Surface Mount Technology (SMT) lines are central to producing reliable LED lighting products, including USB lighting strips. The facility utilizes multiple high-precision Yamaha YS series SMT placement machines, known for their accuracy and speed in handling miniaturized components. These machines are configured for dual-lane operation, enabling parallel production to meet varying order volumes. They are fully capable of placing ultra-small 0201 metric size components common in modern LED drivers and control ICs, essential for the compact form factor and high-density circuitry required in USB-powered strips. The SMT process includes automated solder paste inspection (SPI) before component placement and automated optical inspection (AOI) immediately after reflow soldering to ensure solder joint integrity and component placement accuracy, minimizing defects at the earliest stage.

Rigorous aging and reliability testing form a non-negotiable part of our quality assurance protocol, particularly critical for USB lighting strips which integrate power conversion and control circuitry directly onto the strip. All finished USB lighting strip assemblies undergo a minimum 72-hour continuous aging test under controlled thermal conditions, typically at an elevated ambient temperature of 50°C. This extended burn-in period effectively screens out early-life failures (infant mortality) caused by component weaknesses or process variations. Furthermore, selected batches undergo accelerated life testing and thermal cycling tests to validate long-term performance and resilience under repeated power-on/power-off cycles and varying thermal loads, simulating real-world usage scenarios where USB ports may have inconsistent power delivery.

Beauty STC possesses comprehensive OEM capabilities specifically tailored for USB lighting strips, offering true turnkey solutions. We support full customization from concept to delivery, including optical design for specific beam angles and color quality, flexible PCB layout optimization for the USB form factor, integration of various USB standards (USB-A, USB-C, including Power Delivery negotiation where required), and custom diffuser profiles. Our engineering team collaborates closely with clients to develop bespoke driver circuitry optimized for the unique voltage and current constraints of USB power sources, ensuring stable operation and longevity. We handle all aspects of component sourcing, SMT assembly, functional testing, aging, final assembly, packaging, and logistics. This includes providing necessary regulatory compliance support for target markets, such as safety certifications (UL/cUL, CE, UKCA) and EMC testing relevant to USB-powered devices, ensuring the final OEM product meets global market requirements. Our Jiangmen factory’s integrated processes and engineering expertise allow us to efficiently scale production from prototyping through to high-volume manufacturing for USB lighting strip OEM partners.

Application Scenarios

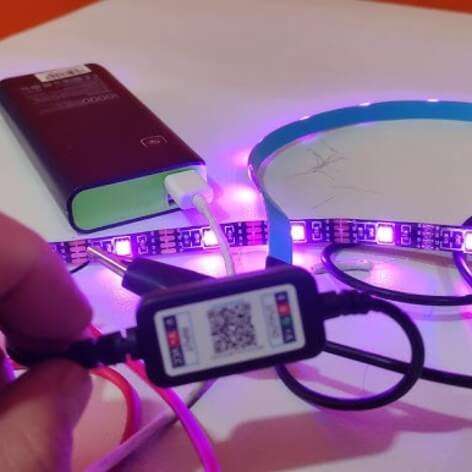

USB lighting strips are versatile and energy-efficient lighting solutions that can enhance both the functionality and ambiance of various environments. Their low voltage operation, ease of installation, and compatibility with standard USB power sources make them suitable for specific applications in hotels, malls, and offices.

In hotels, USB lighting strips are ideal for accent lighting in guest rooms, particularly under beds, behind headboards, inside closets, or along cove ceilings to create a soft, welcoming atmosphere. They can also be used in lobbies or reception areas for decorative backlighting on signage or architectural features. Since many hotel rooms now include USB charging ports in desks or bedside units, integrating USB-powered strips simplifies power sourcing without the need for additional transformers or electrical modifications.

In malls, USB lighting strips work well for highlighting display areas, promotional kiosks, or digital information boards. While they may not serve as primary illumination due to lower lumen output, they are effective for drawing attention to specific zones or branding elements. They can also be used in restrooms, stairwells, or corridors for subtle night-time guidance, especially when paired with motion sensors or timers to conserve energy.

In offices, USB lighting strips can be installed under desks, inside cabinets, or behind monitors to reduce eye strain and improve workspace ergonomics. They are particularly useful in cubicles or shared workspaces where overhead lighting may be insufficient or harsh. Employees can power the strips directly from their computers, power banks, or USB wall adapters, allowing for personalized lighting without affecting the main electrical system.

For installation, ensure the surface is clean, dry, and free of dust or grease to maximize the adhesive backing’s effectiveness. For longer runs or higher brightness, consider using a powered USB hub or adapter to maintain consistent voltage and avoid dimming at the far end of the strip. Avoid installing the strip in high-temperature areas or where it may be exposed to direct moisture unless it is specifically rated for such conditions. Always verify the strip’s voltage and current requirements match the USB power source to prevent damage or underperformance. If cutting is required, do so only at designated cut points to maintain functionality. For permanent installations, consider using aluminum channels to protect the strip, improve heat dissipation, and enhance light diffusion.

Why Choose Beauty STC Lighting

Upgrade your product line with Beauty STC’s premium USB lighting strips engineered for seamless integration and exceptional performance. As a leading manufacturer with deep expertise in LED innovation, we deliver reliable, energy-efficient solutions tailored to your specific design and volume requirements. Partner with Beauty STC to leverage our engineering excellence and scalable production capabilities for your next lighting project. Contact our dedicated partnership manager today at [email protected] to discuss how our USB lighting strips can enhance your offerings.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.