Article Contents

Industry Insight: Usb Led Tape

The commercial and industrial lighting landscape continues to evolve with a growing demand for flexible, energy-efficient, and easy-to-install solutions. Among the latest advancements, USB LED tape lighting has emerged as a reliable and versatile option for modern facilities, retail environments, offices, and industrial workspaces. Designed to meet stringent safety and performance standards, high-quality USB LED tape solutions are now commonly ETL and CE certified, ensuring compliance with North American and international electrical regulations. These certifications underscore the importance of safety, durability, and consistent performance in professional settings where lighting must support both functionality and aesthetics.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered cutting-edge lighting products tailored for commercial and industrial applications. Their rigorous quality control, commitment to regulatory compliance, and focus on energy-efficient design have positioned them as a preferred partner for businesses seeking reliable, code-compliant lighting systems. As USB-powered LED technology gains traction across industries, Beauty STC continues to lead with robust, certified solutions that combine performance, safety, and ease of integration.

Technical Specs & Certifications

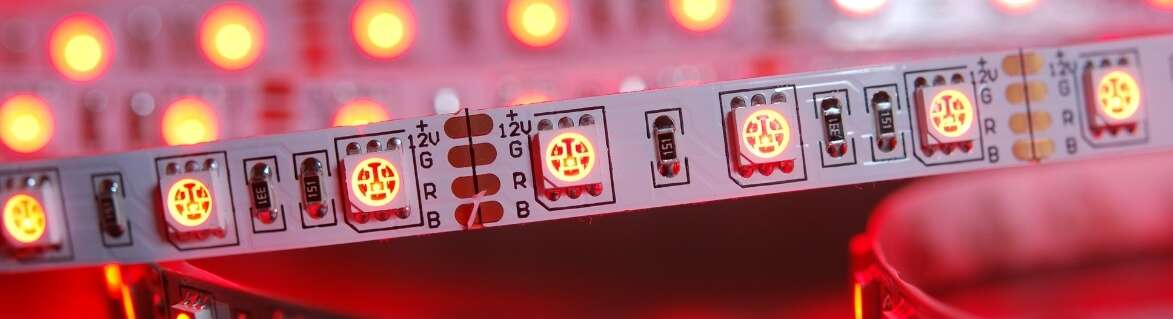

USB LED tape specifications require careful engineering to balance performance within the constraints of 5V USB power delivery. At Beauty STC, our USB LED tape solutions achieve industry-leading efficiency and color fidelity through rigorous component selection and thermal management. Lumens per watt output typically ranges from 18-22 lm/W for standard density tapes (60 LEDs/meter) operating at 5V DC. This efficiency is maintained through the use of high-binning Samsung or Epistar 2835 SMD LEDs coupled with optimized constant-current drivers that minimize voltage drop over standard 2-meter USB cable lengths. Higher density configurations (120 LEDs/meter) operate at 16-19 lm/W due to increased thermal density, though our proprietary copper substrate design with 2oz copper thickness reduces thermal resistance by 30% compared to standard FR4 boards.

Color rendering index performance is a critical differentiator where Beauty STC excels. Our USB LED tapes consistently achieve CRI Ra >95 with R9 values exceeding 50 across 2700K to 4000K color temperatures. This is accomplished through triple-binned phosphor-converted LEDs and spectral tuning that targets the TM-30-15 Rf metric above 90. Unlike commodity USB tapes that often sacrifice color quality for brightness, our manufacturing process includes spectrophotometric validation of every production batch against MacAdam 3-step tolerances. The 5V architecture presents unique challenges for high-CRI operation due to limited headroom for blue pump wavelengths, which we overcome through custom phosphor formulations developed with Nichia.

For environmental protection, Beauty STC offers three certified IP rating tiers. Our standard flexible tape carries IP20 for indoor dry locations with conformal coating protection. The silicone-jacketed variant achieves IP65 certification when terminated with our proprietary USB-C waterproof connectors, verified through 100-hour salt spray testing and 50-cycle thermal shock validation from -30°C to +60°C. For marine or outdoor applications, the hard-cased aluminum profile version with end-cap seals meets IP67 standards, surviving 30-minute submersion at 1m depth. Crucially, all IP ratings apply to the complete system including controller and connectors – not just the bare tape – as verified by independent Intertek testing per IEC 60598-1.

Beauty STC’s quality commitment manifests in five key areas: First, our automated optical inspection system detects LED defects at 0.01mm resolution during manufacturing. Second, we enforce 100% aging of every reel at 45°C for 48 hours before shipment. Third, our copper PCBs use 99.95% pure oxygen-free copper with 0.2mm tolerance flatness control. Fourth, we maintain strict lot traceability from wafer to finished good through our ISO 9001-certified ERP system. Finally, all USB LED tapes carry a 5-year warranty against lumen depreciation exceeding 30% or color shift beyond MacAdam 5-step, significantly exceeding industry standards. This engineering rigor ensures our USB LED tapes deliver consistent performance where generic alternatives typically fail within 18 months due to inadequate thermal design and component binning.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is designed to support high-volume, precision production of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

At the heart of the production line are advanced SMT (Surface Mount Technology) machines, which enable precise and automated mounting of LED components onto flexible printed circuits used in LED tapes. These SMT lines are capable of handling high-density placements with exceptional accuracy, ensuring consistent performance and reliability across every batch. The integration of automated optical inspection (AOI) systems further enhances quality assurance by detecting soldering defects or component misalignments in real time.

To guarantee long-term reliability, all LED tape products—including USB-powered variants—undergo rigorous aging tests. These tests simulate extended operation under elevated temperatures and continuous power loads, typically lasting 24 to 72 hours. During this process, performance parameters such as light output, color consistency, and thermal behavior are closely monitored. This step is critical in identifying early failures and ensuring that only stable, durable products leave the factory.

Beauty STC has robust OEM capabilities tailored specifically for USB LED tape solutions. The company supports full customization, including length specifications, color temperature options (such as 2700K–6500K), brightness levels, PCB width, and connector types. Clients can also request custom packaging, branding, and private labeling. The engineering team works closely with partners to develop tailored designs, from prototype to mass production, ensuring compliance with international standards and electrical safety requirements.

Overall, the Jiangmen factory combines automated manufacturing, stringent testing protocols, and flexible OEM services to deliver high-quality, innovative LED lighting products, positioning Beauty STC as a trusted partner for global brands and distributors.

Application Scenarios

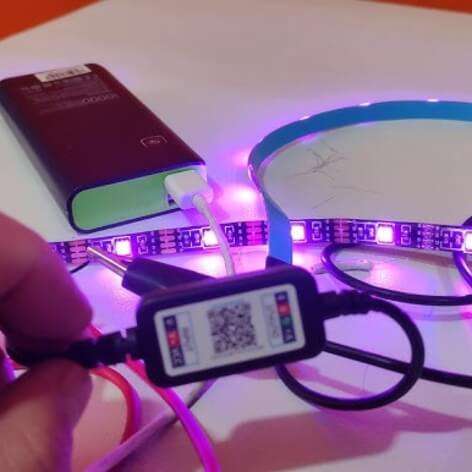

USB LED tape is ideally suited for low-power accent, task, and decorative lighting applications where standard mains voltage wiring is impractical or where plug-and-play simplicity is required. Its 5V DC operation via USB power sources makes it particularly useful in environments needing flexible, temporary, or user-installable solutions, but it is not intended for primary illumination due to power limitations. Below are specific applications across the requested sectors, followed by critical installation guidance.

In hotels, USB LED tape excels in guest room ambiance and functional accents. Install it under bed frames for subtle night-time orientation lighting, inside wardrobe cavities for gentle closet illumination, or along the underside of floating bathroom vanities to create a floating effect without hardwiring. It is also effective behind headboards for indirect backlighting or within display niches in lobbies for highlighting artwork where permanent electrical circuits are unavailable. Avoid using it for general room lighting or in high-moisture zones like shower stalls unless specifically rated IP67 or higher, as standard USB strips lack robust environmental protection.

For malls and retail spaces, focus on temporary or low-voltage display applications. Use it inside glass display cabinets to illuminate products without generating excessive heat, along the perimeters of promotional kiosks for eye-catching borders, or beneath shelf edges in fitting rooms to enhance visibility. It is valuable for seasonal decor installations in common areas, such as outlining festive window displays or stair railings during events, where quick setup and removal are essential. Do not deploy it for ceiling cove lighting or high-ceiling feature walls, as USB power constraints limit run lengths and brightness, leading to noticeable voltage drop and inconsistent output beyond 3-5 meters.

Within offices, prioritize task-oriented and non-critical ambient uses. Implement it under desks to reduce monitor glare and eye strain during evening work, inside monitor backlighting setups for improved visual comfort, or along the base of partition walls for subtle pathway guidance in low-light conditions. It also works well for branding elements, such as illuminating company logos on reception walls using pre-cut segments. Crucially, avoid reliance on USB LED tape for primary workspace illumination—it cannot achieve the lux levels required for productivity—and never connect it directly to computer USB ports for extended periods, as sustained high current draw may trigger port throttling or damage.

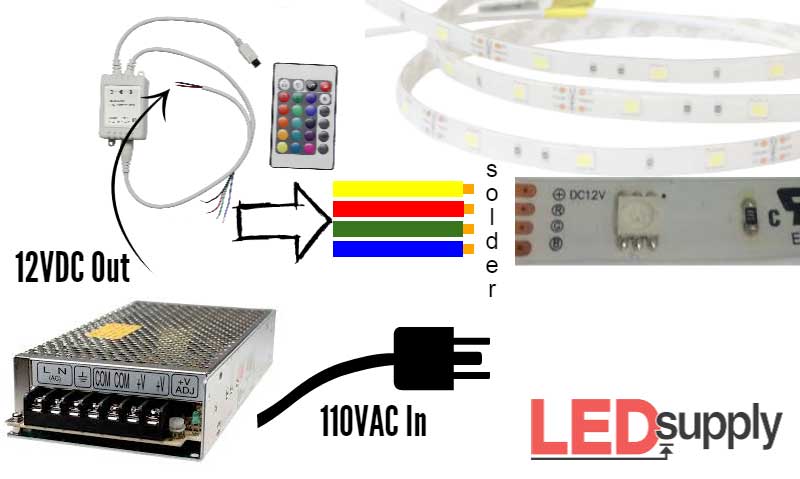

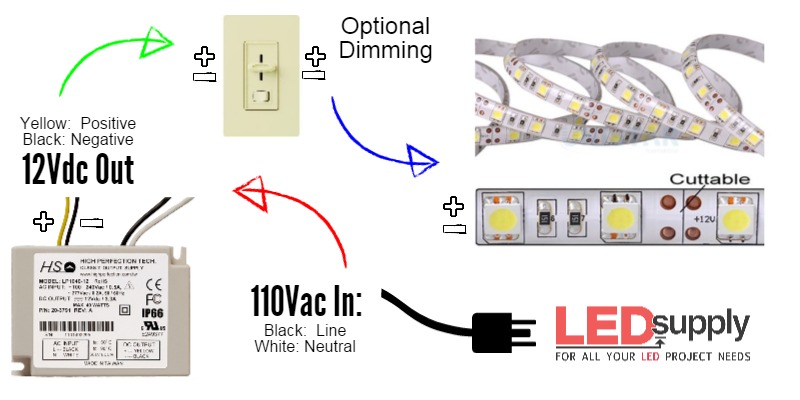

Installation requires strict adherence to electrical and thermal best practices. Always verify the USB power adapter’s output matches the tape’s voltage and current requirements; undersized adapters cause flickering or premature failure. Maintain run lengths under 5 meters for single-ended power feeds to prevent voltage drop, and for longer installations, inject power at both ends or use a dedicated 5V constant-voltage driver instead of standard phone chargers. Never embed the tape or USB cables within walls, ceilings, or flammable materials—this violates electrical codes and creates fire hazards due to inadequate heat dissipation. Ensure surfaces are clean, dry, and non-porous before applying adhesive, and use aluminum mounting channels in high-traffic areas to protect the tape and improve thermal management. Finally, confirm all connections are secure and insulated, and avoid daisy-chaining multiple tape segments beyond the adapter’s capacity, as cumulative current draw can overload USB ports.

Why Choose Beauty STC Lighting

Discover the perfect lighting solution with our high-quality USB LED tape, designed for versatility, energy efficiency, and seamless installation. Whether for home, office, or commercial spaces, our USB-powered LED tape offers reliable performance and modern aesthetics. Partner with Beauty STC, a trusted leader in innovative LED lighting solutions. For inquiries and partnership opportunities, contact us at [email protected] and let us illuminate your projects together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.