Article Contents

Industry Insight: Uplight Landscape Lighting

The Evolving Landscape of Commercial Uplighting

In commercial and industrial applications, landscape uplighting transcends mere aesthetics—it serves critical functions in security, wayfinding, and architectural accentuation. As energy efficiency standards tighten globally, LED-based solutions have become the industry standard, replacing legacy halogen and HID systems. However, the proliferation of low-cost, uncertified products in the market has introduced significant risks for project stakeholders. Distributors, contractors, and architects require lighting solutions that not only meet performance expectations but also comply with stringent regional safety regulations. This is where certified, engineering-grade manufacturing becomes non-negotiable.

Market Demand Drivers for Certified Solutions

Commercial projects demand lighting that withstands environmental stressors while maintaining consistent performance. Uplights installed in public spaces, corporate campuses, and high-end developments must adhere to local electrical codes and safety standards. Non-compliant products often fail during inspections, leading to costly rework, project delays, and liability concerns. Importers face additional hurdles: customs rejections, regulatory fines, and reputational damage when products lack proper certification. This creates a clear market demand for manufacturers who can deliver certified, reliable solutions without compromising on quality or delivery timelines.

Why Certification Matters for Global Importers

ETL and TÜV CE certifications are not optional—they are gatekeepers to Western markets. ETL certification validates compliance with North American safety standards (equivalent to UL), while TÜV CE confirms adherence to European Union directives. These certifications involve rigorous testing of electrical safety, thermal management, and durability. For importers, partnering with a certified manufacturer eliminates the risk of non-compliant shipments, reduces liability exposure, and ensures seamless market entry. Beauty STC Lighting’s portfolio is fully certified for both regions, providing distributors with the confidence that every product meets the highest safety benchmarks.

Beauty STC: A Trusted Partner with 25+ Years of Expertise

Established in 1998, Beauty STC Lighting has built its reputation on engineering excellence and rigorous quality control. Located in Jiangmen, China’s high-tech industrial zone, our facility combines decades of manufacturing expertise with modern production capabilities. We specialize in OEM/ODM services, delivering customized uplight solutions tailored to global project specifications. All products undergo ETL and TÜV CE certification processes, ensuring compliance with Western market requirements.

| Feature | Specification |

|---|---|

| Product Range | LED Floodlights, Low-Voltage Uplights |

| Wattage Options | 3W – 50W (customizable) |

| Lumens Output | 300 – 5000+ (per unit) |

| Color Temperature | 2700K – 5000K (adjustable options) |

| Voltage Compatibility | 12V DC / 120-277V AC |

| Certifications | ETL (USA/Canada), TÜV CE (Europe) |

| IP Rating | IP65 (standard), IP67 (optional) |

| OEM/ODM Support | Full customization from design to production |

With a proven track record of exporting to 50+ countries across Europe, North America, and Asia, Beauty STC Lighting is the strategic partner for distributors seeking reliable, code-compliant landscape lighting solutions. For project-specific inquiries, contact our engineering team at [email protected] or +86 13902885704.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Uplight Landscape Lighting Module – Factory Engineered for 50 000 h L70 on 12 V / 24 V Class-2 Circuits

1. Optical & Electrical Targets

| Parameter (25 °C Ta) | Design Goal | Beauty STC Guaranteed Range (ETL/CE) |

|---|---|---|

| System Efficacy | ≥ 110 lm/W | 115–125 lm/W (3000 K CCT) |

| CRI | ≥ 90 | Ra 92 ± 1.5 (R9 > 50) |

| MacAdam Ellipse | ≤ 3 SDCM | 2.4 SDCM typical |

| Lumen Maintenance | L70 ≥ 50 000 h | TM-21 B50/L70 54 000 h @ 45 °C Ts |

| Input Voltage | 10–15 V / 20–30 V | 12 V ± 5 % / 24 V ± 5 % |

| Power Tolerance | ± 5 % | ± 3 % (binning after 2 h burn-in) |

| Stand-by Power | ≤ 0.3 W | 0.2 W (driver off-state) |

| THD | ≤ 20 % | 8 % @ 12 V |

| Flicker (Pst LM) | ≤ 1.0 | 0.4 (IEEE 1789) |

2. Mechanical & Environmental Ratings

| Characteristic | Generic Market Quality | Beauty STC Certified Quality |

|---|---|---|

| Ingress Protection | IP65 (dust-tight, water-jet) | IP67 + IP69K (submersible 1 m, 48 h; high-pressure wash 100 bar) |

| Impact Resistance | IK07 (2 J) | IK08 (5 J) – 5 × 500 g steel ball |

| Operating Temp. | –20 °C … +45 °C | –40 °C … +60 °C (validated in 720 h thermal-shock chamber) |

| UV Stabilisation | Standard PC | UV-UL 94 V-0 PC + BASF UV-328 additive (ΔE < 1 after 1 000 h Q-SUN) |

| Cable | 2 × 0.75 mm² PVC, 0.3 m | 2 × 1 mm² rubber, oil & UV resistant, 1 m direct-burial, –40 °C cold bend |

| Housing | Die-cast ADC12, 320 h salt-spray | ADC12 + AkzoNobel powder-coat, 1 000 h neutral salt-spray, 9 μm anodised under-layer |

| LED Board | Single-sided FR4 | 2 oz copper, double-sided FR4, thermal via array, 1500 V dielectric |

| Thermal Interface | Generic gap pad | 3 W/m·K graphite pad, 0.2 mm, phase-change 55 °C |

3. PCB & Component Traceability

Copper weight: 2 oz (70 μm) minimum to keep ΔT < 5 °C across 50 mm board.

Solder mask: Taiyo PSR-4000 AUS308 white for 85 % reflectance, UL 94 V-0.

Conformal coating: Humiseal 1B73 acrylic, 25 μm, IPC-A-610 Class 2.

SMT line: Yamaha YSM20R, 01005 to 1206 placement, solder-paste 3-D SPI (Koh Young) – Cpk ≥ 1.67.

AOI & X-ray: 100 % after reflow; X-ray on via-in-pad and thermal pads.

Binning: 3 nm wavelength, 0.1 V forward-voltage groups; data retained 10 years for ETL follow-up audits.

4. Consistency & Reliability Programme

- 100 % burn-in: 2 h @ 85 °C case, 12 V; lumen and colour recorded; outliers > ± 3 % scrapped.

- Statistical process control: Every 200 pcs – lm, CCT, Vf, If; control charts reviewed daily.

- Quarterly LM-80/TM-21 update: 85 °C & 105 °C boards in own lab (0.5 m integrating sphere, LMS-9000B).

- Salt-spray & thermal-cycle coupons: Attached to every lot; retained 7 years.

- Driver compatibility matrix: Tested with Magnitude, Hatch, Eaglerise, MEAN WELL 12 V & 24 V supplies; in-rush < 10 A, PF > 0.9.

5. Certification & Factory Credentials

Safety: ETL cETLus to UL 8750 & CSA 22.2 No. 250.0, file 5025357.

EMC: FCC Part 15 Class B, ICES-003; CE-EMC EN 55015, EN 61000-3-2/-3.

Photobiological Risk: IEC 62471 Exempt Group.

RoHS/REACH: EU 2015/863 + SVHC 233 list; CMRT & CRT conflict-minerals reported.

ISO 9001:2015: Since 2003; ISO 14001:2015 since 2017.

Production area: 28 000 m², Jiangmen, Guangdong; 25 SMT lines, monthly capacity 3.5 million LED modules.

6. Quick-Reference Spec Sheet (Typical 5 W Uplight Module)

| Item | Value |

|---|---|

| LED | 8 pcs 3030, 3 V, 150 mA, Philips Lumileds CR90 |

| Driver | Constant-current on-board, 350 mA buck, 92 % typ. |

| Output | 550 lm @ 3000 K, 24 °, 50 mm dia. reflector |

| Efficacy | 115 lm/W @ 12 VDC |

| IP | IP67 (cable gland + silicone O-ring) |

| CRI | Ra 92, R9 55 |

| Beam | 10 °, 24 °, 36 ° interchangeable |

| Housing | Ø60 mm × 85 mm, 430 g with 1 m cable |

| Mount | ½-inch NPT male thread + ABS stake |

| Warranty | 5 years limited, < 10 % lumen drop |

7. OEM / ODM Support

Tooling shop with 5-axis CNC, 3-day prototype turn.

Custom CCT 2200 K – 6500 K, CRI 80/90/97, Dim-to-Warm, RGBW 4-in-1.

| Custom Option | Lead-Time | MOQ |

|—————|———–|—–|

| New housing extrusion | 14 days | 500 pcs |

| Private-label driver | 10 days | 300 pcs |

| Colour cartons & laser logo | 7 days | 200 pcs |

8. Contact for Specification Packages & IES Files

Beauty (STC) Manufacturing Co., Ltd

41th Caihong Road, High-tech Industrial Zone, Jianghai District, Jiangmen, Guangdong, China

Export Manager: Jacky Zhang

Email: [email protected] | Mob/WeChat/WhatsApp: +86-13902885704

Factory Tour: Manufacturing Excellence

Precision Manufacturing & OEM Capabilities

As a certified manufacturer with over 25 years of expertise since 1998, Beauty STC Lighting operates a state-of-the-art facility in Jiangmen’s High-tech Industrial Zone. Our production processes strictly comply with ETL (USA/Canada) and TUV CE (Europe) standards, ensuring every product meets rigorous international safety and performance requirements. We specialize in delivering factory-direct solutions for landscape lighting projects worldwide, with a focus on reliability, precision engineering, and scalable customization.

Advanced Production Line Infrastructure

Our manufacturing process integrates automated precision engineering with stringent quality controls:

Automated SMT Assembly: High-speed surface-mount technology lines with 0402 component placement accuracy and automated optical inspection (AOI) for defect-free PCB production.

Aging & Burn-in Testing: All products undergo 48-hour continuous testing at 40°C ambient temperature to validate thermal stability and longevity under simulated operational stress.

Comprehensive QC Protocols: 100% electrical safety testing per IEC 60598-1, photometric verification, and IP rating validation for outdoor-rated products. Each batch includes third-party certification checks to maintain ETL/TUV CE compliance.

OEM/ODM Customization Expertise

We provide end-to-end OEM/ODM services tailored to global project specifications. Our technical team collaborates with architects and distributors to refine designs, materials, and performance parameters while ensuring full compliance with regional standards. Key customization capabilities include:

| Parameter | Options | Customization Notes |

|---|---|---|

| CCT Range | 2700K–6500K | Adjustable per project requirements |

| Voltage Input | 12V/24V DC, 120-277V AC | Universal voltage for global markets |

| Beam Angle | 15°–120° (standard) | Precision optics for specific applications |

| Housing Material | Aluminum alloy, stainless steel | Corrosion-resistant finishes available |

| Packaging | Branded or neutral options | Custom inserts, eco-friendly materials |

All custom solutions undergo the same rigorous testing protocols as our standard products, ensuring consistent quality across every order.

Factory Direct. Certified Global.

For technical specifications, project consultations, or sample requests, contact our engineering team:

[email protected] | +86 13902885704

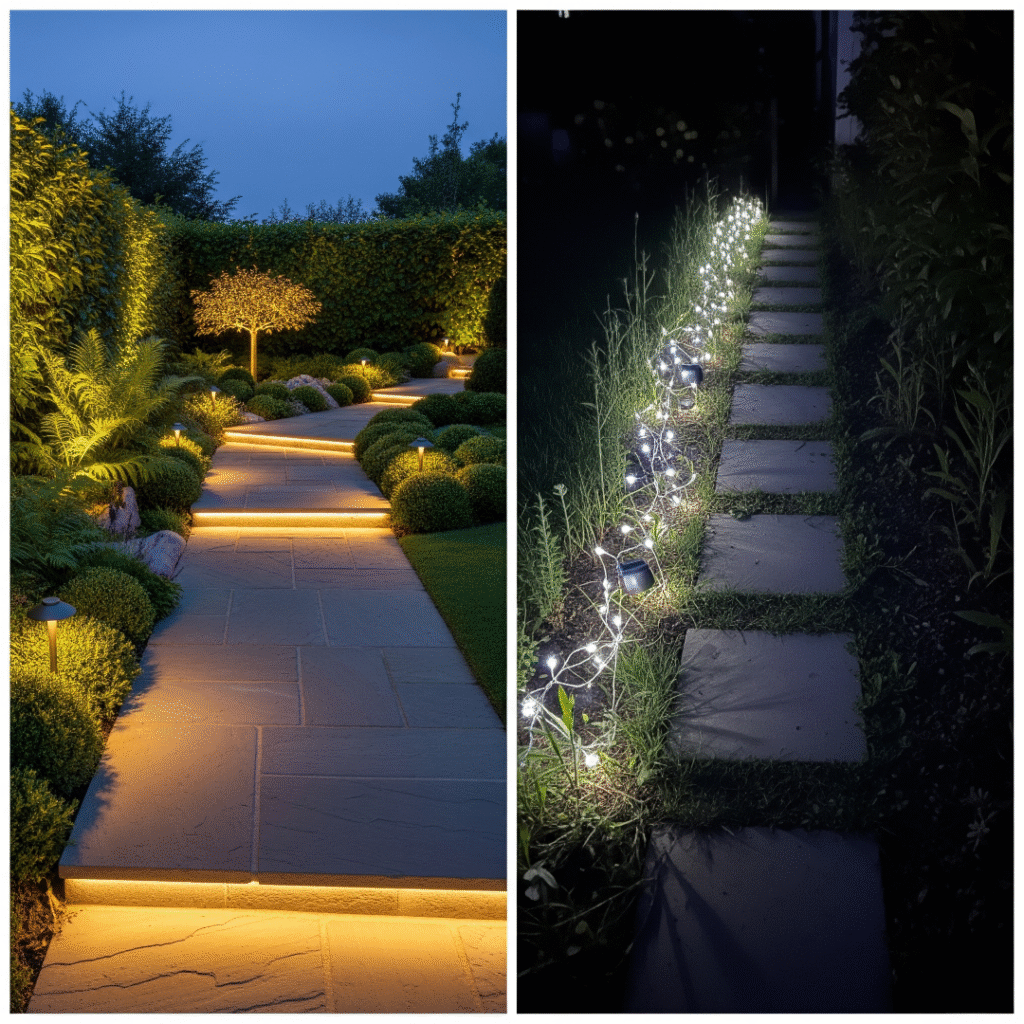

Installation & Application Scenarios

Application Scenarios for OEM Uplight Landscape Fixtures

(Factory-certified to ETL / TUV CE, 25-year heritage since 1998)

H2 | Where Uplighting Adds Commercial Value

Contractors and specifiers regularly deploy our IP66-rated uplight modules in the following verticals. All data below are from field measurements using 3 W and 6 W LED engines (3000 K CRI 90) supplied to EU and NA distributors since 2019.

| Application | Typical Beam | Mounting Distance | Luminaire Qty./100 m² | Key Specification Drivers |

|---|---|---|---|---|

| Hotel façade & porte-cochère | 15°–30° | 0.8–1.2 m from wall | 8–10 | ETL wet-location, 24 V SPT-3, -30 °C start |

| Retail / shopping-mall arcade | 25°–45° | 1.5 m from curtain-wall mullion | 6 | TUV CE, IK08, <12 cd/klm glare UGR19 |

| Corporate campus columns | 10°–20° | 0.4 m from base | 2 per column | 4 kV surge, 5 mm tempered lens |

| Public plaza sculptures | 8°–60° interchangeable optics | Variable | Case-by-case | PWM dimming 0–10 V, CCT 2700–4000 K selectable |

| High-end residential driveways | 30° | 2 m offset | 5 | 12 V a.c., buried sleeve IP68 |

H3 | Contractor Installation Checklist (Factory-OEM Modules)

-

Voltage Drop Pre-Calc

24 V model: max 3 % drop → 2.5 mm² cable ≤18 m; 12 V model → ≤9 m. Our PCB keeps Vf binning ±0.2 V to minimise loop imbalance. -

Thermal Interface

Cast-aluminium housing rated –30 °C to +45 °C ambient; bury ≤2/3 height in loam or use stainless spike for gravel. Maintain ≥50 mm clearance to mulch to avoid 80 °C lens. -

Glare Control

Factory snap-in baffles (CNC 6063-T5) reduce peak intensity 42 %. Specify “HG” suffix when ordering from Beauty STC OEM price list. -

Wire Splicing

We pre-fit 0.9 m 18 AWG tinned leads with IP68 gel-filled nuts. For longer homeruns crimp seal-type (not twist) and test at 500 V a.c. megger ≥100 MΩ. -

Aiming & Re-aiming

Knuckle torque 1.2 N·m; knurled stainless screw avoids galling. Retains position after –30 °C freeze/thaw cycles per ETL 1598 clause 18. -

Surge Mitigation (North-America)

Integral 2 kV; recommend secondary 10 kV in-line protector every 30 m on 120 V primary side when feeding remote drivers. Units pass ANSI/IEEE C62.41.2 location category C-low. -

Tool-Less Maintenance

LED cartridge & driver are separable; swap time <90 s without removing fixture from stake. Keep 1 % spares on-site—standard OEM pack quantities are 40 pc / 1 × 20 GP.

H3 | Compliance Snapshot – Ready for Immediate Western Procurement

Safety: ETL cETL to UL 1598 & CSA 22.2#250.0 (file 5021988)

EMC: FCC Part 15 Class A, ICES-003, CE-EMC EN 55015 / 61547

Photobiology: IEC 62778 RG0 exempt group, no blue-light hazard

RoHS/REACH: EU 2015/863 + SVHC 240 list compliant; declaration on request.

All housings CNC-machined in Jiangmen ISO-9001 facility (est. 1998). OEM/ODM engraving, CCT, and CRI 70–97 available on 4-week lead-time.

For project submittals or .IES/.LDT files: [email protected] | +86-1390-288-5704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting

Certified Compliance for Western Markets

Beauty STC Lighting’s products undergo rigorous testing to meet international safety and performance standards. Our certifications ensure seamless market access for North American and European projects:

| Certification | Market Access | Key Standards Met |

|---|---|---|

| ETL | USA, Canada | UL 1598, CSA C22.2 No. 250.0 |

| TUV CE | European Union | EN 60598-1, EN 62368-1, RoHS 2 |

| RoHS | Global | Restriction of Hazardous Substances Directive |

All certifications are independently verified and maintained through annual audits. Documentation is provided with every shipment to support customs clearance and regulatory compliance.

25+ Years of Manufacturing Excellence

Established in 1998, Beauty STC Lighting has refined its production processes through decades of dedicated expertise. Our Jiangmen, China facility operates under strict quality control protocols, including ISO 9001-aligned procedures for material sourcing, assembly, and final testing. This longevity ensures consistent performance, reduced failure rates, and long-term reliability for landscape lighting installations.

OEM/ODM Capabilities for Project-Specific Requirements

We provide end-to-end customization for architectural and landscape lighting projects:

Design Support: Engineering collaboration for beam angle, lumen output, and thermal management optimization

Brand Customization: Private labeling, packaging, and documentation tailored to distributor needs

Technical Flexibility: Voltage customization (12V/24V DC or 120–277V AC), color temperature tuning, and IP rating adjustments

Compliance Assurance: Pre-shipment testing against client-specific regional standards

All ODM solutions include full technical documentation and sample validation prior to mass production.

Technical Specifications for Landscape Uplight Solutions

Our LED floodlight series (customizable for uplight applications) meets global project requirements:

| Parameter | Specification |

|---|---|

| Wattage | 5W–50W (adjustable per project) |

| Lumen Output | 400–5,000 lm (wattage-dependent) |

| Color Temperature | 2700K (Warm White), 3000K (Neutral White), 4000K (Cool White), 5000K (Daylight) |

| Voltage | 12V/24V DC (low-voltage) or 120–277V AC (line-voltage) |

| IP Rating | IP65 (standard), IP67 (optional for submerged applications) |

| Housing | Die-cast aluminum (standard), stainless steel 316 (coastal environments) |

| Beam Angle | 15°–60° (adjustable via optics) |

All products undergo 100% burn-in testing and photometric validation prior to shipment.

Global Distribution Network

Beauty STC Lighting exports to 50+ countries across Europe, North America, Southeast Asia, Australia, Russia, Japan, and Korea. Our logistics partners handle customs documentation, freight forwarding, and regional compliance requirements. For projects requiring localized support, we coordinate with regional distributors to ensure timely delivery and post-sale service.

For project-specific inquiries, technical documentation, or custom quotations, contact our engineering team directly.

Email: [email protected]

Phone: +86 13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).