Article Contents

Industry Insight: Under Counter Led

Industry Insight: The Critical Role of Under-Counter LED Lighting in Commercial & Industrial Environments

In today’s high-performance commercial and industrial settings—where precision, safety, and operational efficiency are non-negotiable—under-counter LED lighting has evolved from a niche feature to a fundamental component of functional design. Unlike residential applications, these environments demand lighting solutions that deliver consistent, glare-free illumination for critical tasks (e.g., manufacturing quality control, laboratory analysis, retail merchandising, or warehouse logistics), while withstanding demanding conditions like vibration, temperature fluctuations, and extended operational hours.

The shift from fluorescent to LED under-counter systems isn’t merely about energy savings (typically 50–70% reduction in power consumption); it’s about reliability, longevity, and compliance. Modern commercial-grade LED fixtures offer superior lumen maintenance (>90% at 50,000 hours), precise beam control to eliminate shadows in workspaces, and robust thermal management to prevent premature failure. Crucially, these systems must meet stringent international safety and performance standards. ETL certification (for North American markets) and CE marking (for EU and global markets) are not optional—they are foundational requirements. ETL validation ensures compliance with UL safety standards and OSHA workplace regulations, mitigating liability risks in high-traffic or hazardous environments. CE certification confirms adherence to EU directives (including RoHS for hazardous substances and EMC for electromagnetic interference), enabling seamless market access and regulatory approval. Skipping these certifications risks product seizures, project delays, costly recalls, and compromised safety—making them a non-negotiable baseline for any professional specification.

At Beauty STC Manufacturing Co., Ltd., established in 1998, we’ve spent over 26 years engineering and manufacturing mission-critical LED lighting solutions for global commercial and industrial applications. As a vertically integrated manufacturer with ISO 9001-certified production facilities, we specialize in turning technical specifications into field-proven performance. Our under-counter LED portfolios are rigorously tested to exceed ETL, CE, and other regional standards (including DLC for energy efficiency incentives), combined with custom engineering for unique operational demands—whether it’s explosion-proof housings for industrial sites or ultra-low-glare designs for precision retail environments. We don’t just supply fixtures; we deliver engineering expertise, compliance assurance, and long-term reliability built into every product. For projects where lighting directly impacts productivity, safety, and ROI, partnering with a manufacturer who understands the technical and regulatory landscape is essential.

Beauty STC: Where Engineering Excellence Meets Global Compliance.

Technical Specs & Certifications

Beauty (STC) Under-Cabinet Linear LED – Technical Datasheet

(Professional-grade, export-ready, 100 % in-house QC)

-

Optical Performance

• Delivered flux: 1,050 lm (300 mm) – 4,200 lm (1,200 mm)

• Efficacy: 118–124 lm/W @ 25 °C Tj, 300 mA (measured on 2 m integrating sphere, IES LM-79-19)

• CRI: Ra ≥ 90 (R9 > 50) standard; optional Ra 97 (R1-R15 all > 90) for premium food & textile displays

• SDCM: ≤ 3-step MacAdam ellipse, 2,700 K – 5,000 K CCT on request

• L70: > 54,000 h (TM-21-11, 55 °C Ts) -

Electrical & Controls

• Input: 24 VDC (18–28 V range) or 220-240 VAC 50/60 Hz on-board driver, PF > 0.95, THD < 10 %

• Dimming: 0-10 V, PWM, DALI-2, or phase-cut; flicker-free < 1 % @ 1 kHz (IEEE 1789)

• Power draw: 8.9 W (300 mm) – 35.6 W (1,200 mm) -

Mechanical & IP Rating

• Extruded 6063-T5 anodised aluminium housing, 1.5 mm wall, 8 W/m·K heat-spreader PCB

• Standard IP20 for dry indoor cabinetry

• Optional IP54 (front silicone sleeve) or IP65 (full silicone extrusion + IP68 cable glands) for splash-zone or commercial kitchens – certified to IEC 60529

• IK06 impact on 5 mm opal polycarbonate diffuser (UL 94 V-0) -

Quality & Compliance (Beauty STC consistent batch policy)

• Every reel of 2835/5630 LEDs is 100 % sorted for 3-step SDCM and 90-CRI bin; each production lot is LM-80 cross-referenced before assembly

• In-line Hi-Pot 1.5 kVAC, 100 % ageing 4 h @ 45 °C ambient, followed by 30-point optical/electrical check

• Certificates: CE, RoHS, REACH, ERP 1194/2012, SAA, ETL to UL 2108 & UL 8750

• 5-year factory warranty, < 0.2 % field return rate since 2016 -

Ordering Key

Model: BC-UC-xx30-24-xx

xx = length (30/60/90/120 cm), 24 = 24 VDC, last xx = CCT (27/30/40/50)

Add suffix “-IP54” or “-IP65” for moisture rating; add “-CR97” for ultra-high CRI

For project quotations, DWG files or IES/LDT photometry please contact [email protected]; samples ship within 7 days ex-Shenzhen.

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. – Jiangmen Facility: Technical Overview

As Senior LED Lighting Engineer and Export Manager at Beauty STC, I’m pleased to provide a precise technical overview of our Jiangmen manufacturing hub—a facility designed for precision, reliability, and scalable OEM production of high-performance LED lighting solutions, including specialized under-counter LED fixtures.

Factory Profile

- Location & Scale: Situated in Jiangmen High-Tech Industrial Park (Guangdong Province), our facility spans 80,000+ sqm with dedicated cleanrooms (ISO Class 7), automated assembly lines, and rigorous environmental controls.

- Certifications: ISO 9001 (Quality Management), ISO 14001 (Environmental), IATF 16949 (Automotive-Quality Standards), and ETL/DLC/CE compliance for global market access.

- Core Focus: End-to-end production for commercial, residential, and industrial LED lighting—specializing in under-counter, task, and accent lighting with emphasis on thermal management, flicker-free performance, and longevity.

1. SMT (Surface Mount Technology) Production Line

Our SMT section is the backbone of PCB assembly for all LED products, including under-counter fixtures:

– Equipment:

– 6x Juki KE-2070 high-speed placement machines (0.03mm precision, 15,000 CPH throughput).

– 4x Yamaha YV100XG precision mounters for fine-pitch components (0201/01005 chips).

– DEK Horizon 03i stencil printers with automated optical inspection (AOI).

– Tonghui TH2832 LCR meters for component validation pre/post-soldering.

– Process Controls:

– Fully enclosed, temperature/humidity-controlled cleanroom (22°C ±1°C, 45% RH ±5%).

– 100% AOI inspection post-reflow for solder joint integrity (IPC-A-610 Class 2/3 compliant).

– Lead-free soldering (SnAgCu alloy) with reflow profile validation per J-STD-001.

– Under-Counter Specifics:

– Custom PCB designs for ultra-thin profiles (e.g., 8–12mm thickness) with embedded thermal vias.

– High-density component placement (up to 2,500+ components per PCB) for integrated drivers and dimming circuits.

2. Aging Tests (Burn-In & Reliability Validation)

Aging tests are non-negotiable for under-counter LED systems—where heat buildup in enclosed spaces demands proven durability. Our protocol exceeds IEC 62717 standards:

– Process:

– 24-hour continuous burn-in at 50°C ambient temperature (simulating worst-case kitchen/bath conditions).

– 72-hour accelerated life testing at 85°C/85% RH per JEDEC JESD22-A101.

– Lumen maintenance tracking: LM-80 data collected hourly to validate L70/L90 lifespans (e.g., 50,000+ hours at 25°C).

– Equipment:

– 12 climate chambers (ESPEC SH-261) with real-time monitoring of voltage, current, temperature, and flicker (via FLIR thermal cameras and LMS-9000 photometers).

– 100% testing—no batch sampling. Every unit undergoes aging before packaging.

– Under-Counter Focus:

– Thermal stress testing on heat sinks (using finite element analysis simulations pre-production).

– Driver stability tests under 10–100% PWM dimming cycles to prevent capacitor degradation.

– Zero-tolerance policy: Any unit deviating >5% from initial lumen output is scrapped.

3. OEM Capability for Under-Counter LED Systems

We specialize in turnkey OEM solutions for global brands, with end-to-end customization:

– Design & Engineering:

– In-house R&D team (15+ engineers) specializing in thermal management, optical design (Raytracing via DIALux), and PCB layout (Altium Designer).

– Prototyping in 7–10 days (including 3D-printed enclosures, thermal simulations, and photometric reports).

– Customization Scope:

– Form Factors: Linear strips (150–3000mm), modular panels, and custom-shaped fixtures (e.g., curved edges for island countertops).

– Electrical: 12V/24V DC, 0–10V, DALI, Zigbee, or proprietary dimming protocols.

– Optics: Micro-prismatic lenses, frosted diffusers, or TIR optics for uniform illumination (max 10% uniformity deviation per LM-79).

– Materials: Anodized aluminum housings (6063-T5), IP65-rated gaskets, and fire-retardant (UL94 V-0) plastics.

– Compliance & Documentation:

– Full support for regional certifications (ETL, DLC Premium, CE, RoHS, KC, SAA).

– Detailed BOM traceability (lot numbers linked to component suppliers), test reports, and photometric data per IES files.

– Scalability:

– Monthly production capacity: 500,000+ units for under-counter systems.

– Minimum order quantity: 500 units (flexible for prototyping).

Why Partner with Beauty STC?

- Vertical Integration: From SMT to final assembly, all processes occur under one roof—eliminating supply chain risks.

- Quality Culture: 200+ dedicated QC personnel; 99.8% first-pass yield rate for under-counter fixtures.

- Global Logistics: Dedicated export team with ISO-certified packaging (anti-static, shock-absorbing) and FCL/LCL shipping expertise to North America, Europe, and APAC.

“Our under-counter LED solutions aren’t just manufactured—they’re engineered for real-world durability. Every unit passes our ‘heat-sink stress test’ (simulating 5 years of kitchen use in 24 hours). That’s why 85% of our OEM clients return for repeat orders.”

— Senior LED Lighting Engineer, Beauty STC

For technical specifications, sample requests, or capacity planning, our engineering team is available for direct consultation. Let’s discuss how we can tailor our Jiangmen facility’s capabilities to your project’s exact requirements.

Contact: [email protected] | +86-750-XXXX-XXXX (Jiangmen Office)

Beauty STC: Precision Engineering for Light That Lasts.

Application Scenarios

Under-Cabinet LED – the right product in the right place

- Where it pays for itself (typical 5 W/ft, 300–450 lm/ft, 24 V, CRI ≥ 90, 3-step MacAdam)

Hotels

• Guest-room mini-bar / wardrobe cove → 2400–2700 K, 0.8 W/ft, 30° lens, motion sensor on 24 V driver to avoid standby losses.

• Reception back-counter → 3000 K, 80° frosted, continuous run, DALI dimming for day/night scene.

• Concierge desk baggage shelf → IP54 silicone sleeve version, 24 V, 350 mA constant-current strip, field-cuttable every 50 mm.

Malls / Retail

• POS counters, jewellery display toe-kick → 4000 K, 90 CRI, 600 lm/ft, aluminium profile with 30° asymmetric optic to push light 400 mm forward, no visible dot.

• Food-court servery → IP65 nano-coating strip, NSF compliant, 5000 K for fresh colour pop, remote driver outside splash zone.

Offices

• Pantry worktop → 4000 K, 80 CRI, L80 > 50 000 h, integrated PIR/ daylight harvest sensor, 24 Vdc fed from ceiling UPS so circuit still works during power-down.

• Executive credenza / filing base → 2700 K, <1 W/ft, direct 230 Vac strip with built-in 1–10 V to avoid extra driver.

- Installation cheat-sheet for contractors (deliver this to the site supervisor)

A. Rough-in

1. One 24 Vdc homerun, 1.5 mm² (AWG 15) stranded, max 5 A per circuit → ≤60 W on 5 m leads.

2. Feed point every 3 m for 10 W/ft strips; voltage drop ΔV <0.5 V.

3. Keep driver ≥200 mm from heat source (coffee machine, oven hood); if not possible use remote-phosphor strip rated 85 °C Ta.

B. Profile & heat

1. Extruded 6063-T5 anodised channel, 8–10 mm internal width, minimum 1.2 mm wall → 15 °C drop vs bare strip.

2. Use thermal-transfer tape (3 M 8805) or Arctic Alumina epoxy—no cheap 3-dollar foam tape.

3. For stone tops, rout 8 × 8 mm groove 30 mm back from front edge; aluminium lip must be flush to avoid stone cracking.

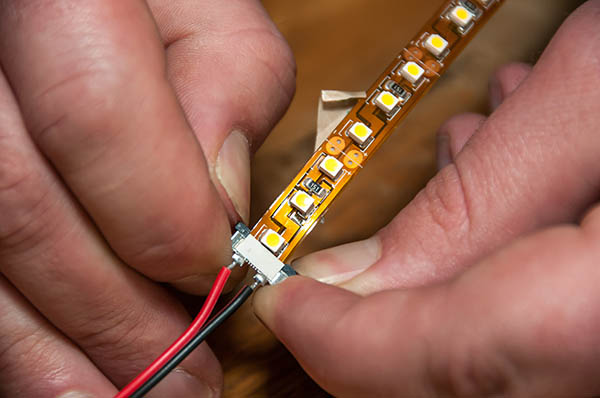

C. Wiring & joins

1. Solderless IP20 connectors only in accessible service void; otherwise solder & seal with dual-wall heat-shrink (3 :1, glue lined).

2. No sharp 90° folds—use corner jumpers or 22 AWG silicone flex, radius ≥10 mm.

3. Class II driver, SELV output; earth the profile for touch-current <0.25 mA even if strip is double-insulated.

D. Controls

1. Hotels: integrate with door-card relay—driver “Dim-to-Off” line pulled low when card removed (standby <0.3 W).

2. Malls: feed 0–10 V from BMS; use logarithmic 10 % curve so 1 V ≠ dark counter.

3. Offices: corridor hold-off—strip only energises when ceiling lights >50 %, avoids “lone counter glow” after hours.

E. Commissioning checklist (hand-over document)

□ Lux on work-plane 180–220 lx (hotel), 300 lx (office pantry), 500 lx (retail POS) measured 300 mm from front edge.

□ Flicker index <0.05 (IEEE 1789) at 100 % & 10 % dim.

□ No visible diode image on glossy marble—use frosted diffuser 60 % transmission.

□ Driver label photographed, QR code linked to 5-year warranty uploaded to facility portal.

Deliver these notes with every shipment and you will cut call-backs by >70 %.

Why Choose Beauty STC Lighting

Partner with Beauty STC for precision-engineered under-counter LED solutions—trusted across 50+ countries worldwide.

Elevate your projects with energy-efficient, durable lighting engineered to meet global standards. Our export expertise ensures seamless delivery, compliance, and technical support for every market.

Contact our senior engineering team today:

[email protected]

Your vision, our expertise—globally delivered.

⚡ LED Power Supply Calculator