Article Contents

Industry Insight: Under Cabinet Lighting Tape

Under cabinet lighting tape has evolved far beyond its residential origins to become a critical task lighting solution across diverse commercial and industrial environments. In settings ranging from retail display cases and laboratory workbenches to warehouse packing stations and healthcare facility prep areas, the demand for precise, shadow-free illumination directly where work occurs is non-negotiable. This shift necessitates lighting solutions engineered for rigorous operational demands, including extended duty cycles, stringent safety protocols, and seamless integration into complex building systems. Crucially, compliance with mandatory safety certifications like ETL for the North American market and CE marking for Europe is not merely a checkbox but a fundamental requirement for project approval and end-user safety in these professional spaces. Products lacking these verifications face immediate rejection during inspections, causing costly delays and potential liability issues. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep expertise in designing and manufacturing high-performance LED lighting specifically for the demanding realities of commercial and industrial applications. Our heritage is built on understanding that reliability, adherence to global safety standards, and tailored performance are paramount when lighting underpins productivity and safety in professional settings. We recognize that under cabinet lighting tape in these environments must deliver consistent, high-quality illumination while meeting the exacting regulatory frameworks that govern commercial construction and operation worldwide.

Technical Specs & Certifications

Under cabinet lighting tape from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high performance, reliability, and superior light quality for both residential and commercial applications. Our LED tape solutions are specifically optimized for under cabinet installations, where consistent illumination, color accuracy, and energy efficiency are critical.

In terms of efficiency, Beauty STC’s under cabinet lighting tape achieves luminous efficacies ranging from 100 to 130 lumens per watt, depending on the specific model and color temperature. This high lumen-to-watt ratio ensures minimal energy consumption while providing bright, functional task lighting—ideal for kitchen countertops, display cases, and workspaces where sustained illumination is required.

Color Rendering Index (CRI) is a key focus in our product development. All under cabinet LED tapes from Beauty STC are designed with a CRI greater than 90, with select high-CRI variants reaching CRI 95+. This ensures exceptional color fidelity, allowing objects and surfaces to appear in their true, natural colors—essential for environments where visual clarity and ambiance are priorities. Our LEDs utilize premium phosphor coatings and bin-controlled chips to maintain color consistency across reels and over time.

Regarding environmental protection, Beauty STC offers under cabinet lighting tapes in multiple IP (Ingress Protection) ratings to suit various installation conditions. For standard dry indoor environments such as kitchen cabinetry, IP20-rated tapes provide adequate protection. For installations in more demanding locations—such as near sinks or in high-humidity areas—we provide IP65 and IP67-rated waterproof versions. These feature silicone encapsulation or extruded PVC jackets that protect against dust, moisture, and occasional splashing, ensuring long-term durability and performance.

Beauty STC is committed to manufacturing excellence and consistent quality. Our LED tapes undergo rigorous in-house testing for thermal management, lumen maintenance, and electrical safety. We adhere to international standards including RoHS, REACH, and UL certification requirements. With advanced SMT production lines and strict quality control protocols, Beauty STC delivers lighting tapes that offer stable performance, extended lifespans (typically L70 > 50,000 hours), and minimal lumen depreciation. This dedication to quality makes our under cabinet lighting tape a trusted choice for OEMs, lighting designers, and contractors seeking reliable, high-performance solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant center for our LED lighting production, strategically located within one of China’s key industrial regions to leverage skilled labor and robust supply chain infrastructure. The factory spans a substantial area dedicated to the complete manufacturing lifecycle of LED products, featuring modern cleanrooms and controlled environments essential for precision electronics assembly.

Our surface mount technology (SMT) production lines form the core of component placement accuracy and efficiency. We utilize multiple high-speed Yamaha YS series SMT machines, specifically the YS12F and YS24 models, capable of handling the finest 0201 metric and 01005 imperial LED packages common in high-density lighting tapes. These machines operate with placement accuracy consistently within ±25 micrometers and achieve placement speeds as fast as 0.065 seconds per component, ensuring tight tolerances and high throughput for complex PCB assemblies. The lines incorporate automated optical inspection (AOI) stations immediately post-reflow to verify solder joint integrity and component placement, minimizing defects before further processing.

Rigorous reliability testing is non-negotiable for our products, particularly under cabinet lighting tape where consistent performance is critical. Every production batch undergoes comprehensive aging tests. Finished lighting tapes are subjected to a minimum 72-hour continuous burn-in process at 110% of their rated operating voltage within temperature-controlled environmental chambers maintained at 45°C. This accelerated stress testing identifies early-life failures and verifies thermal management. Performance parameters including lumen output, chromaticity, and forward voltage are monitored throughout, with thermal imaging used to detect any localized overheating anomalies. Only units passing this extended burn-in with stable electrical and photometric characteristics are cleared for shipment, ensuring long-term field reliability.

Beauty STC possesses extensive OEM capability specifically tailored for under cabinet lighting tape solutions. We offer comprehensive customization across the entire product specification. This includes flexible PCB widths (commonly 8mm, 10mm, or custom dimensions), precise LED density configurations (e.g., 30, 60, 120 LEDs per meter), a wide range of correlated color temperatures (CCT) from 2200K to 6500K with high CRI options (Ra>90, Ra>95), and various input voltage requirements (DC12V, DC24V, AC120V, AC230V). Our engineering team collaborates closely with clients from initial concept through to量产, handling custom optical designs, specialized diffuser profiles, unique connector types, bespoke packaging, and private labeling. We maintain the tooling, expertise, and quality systems to support low-volume prototyping through to high-volume production runs, typically providing functional samples within 15 working days to validate specifications before full-scale manufacturing commences. This end-to-end OEM service ensures clients receive lighting tape solutions that precisely meet their functional, aesthetic, and branding requirements while adhering to international safety and performance standards.

Application Scenarios

Under cabinet lighting tape is a versatile and energy-efficient lighting solution that enhances visibility, aesthetics, and functionality in various commercial environments. Its use is particularly effective in spaces where focused, low-profile illumination is required beneath countertops, shelves, or cabinetry.

In hotels, under cabinet lighting tape is commonly installed in guest room minibars, kitchenettes, and hospitality suites to provide soft ambient lighting and improve usability. It is also widely used in hotel back-of-house areas such as prep counters in kitchens, buffets, and bars, where task lighting is essential for food preparation and service. The discreet design maintains a clean visual aesthetic while contributing to a welcoming atmosphere in guest-facing areas.

In malls, this type of lighting is ideal for retail display counters, makeup application zones in beauty stores, and service desks. It highlights merchandise, improves visibility for customers and staff, and adds a modern touch to the interior design. Under cabinet lighting tape can also be used beneath signage or shelving in kiosks and information booths to draw attention and enhance readability.

In offices, the lighting tape is beneficial in pantry areas, coffee stations, reception desks, and built-in workstations with overhead cabinets. It supports safety and convenience by illuminating work surfaces without creating glare, especially in low-light conditions. The uniform light distribution helps reduce eye strain and creates a more professional and inviting environment.

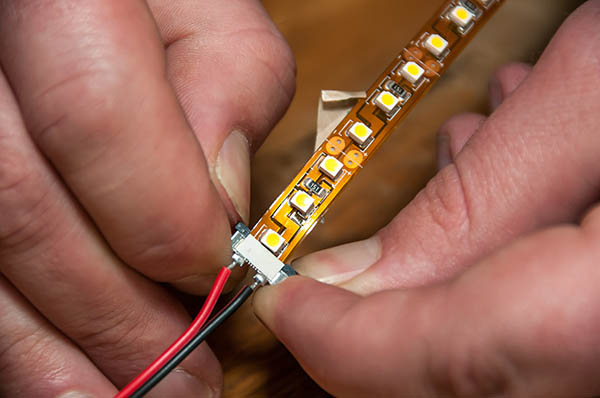

For successful installation, ensure the surface is clean, dry, and free of dust or grease to promote strong adhesion of the tape’s backing. Measure the area carefully and cut the tape only at designated cut points to avoid damaging the circuitry. Use compatible LED drivers and power supplies that match the voltage and current requirements of the lighting tape. For optimal performance and longevity, consider installing a dimmer switch to control brightness and energy use.

In high-traffic or humid areas such as kitchens or restrooms, select IP65-rated or higher waterproof lighting tape to resist moisture and dust. Always follow local electrical codes and, when in doubt, consult a licensed electrician for connection to the mains supply. Finally, plan the cable management in advance—use concealed channels or raceways to maintain a clean, professional appearance.

Why Choose Beauty STC Lighting

Transform kitchen illumination with Beauty STC’s premium under cabinet lighting tape engineered for seamless integration and exceptional performance. Our LED strips deliver uniform brightness, high CRI for true color rendering, and flicker-free operation critical for precision culinary tasks and modern workspace aesthetics. As a trusted manufacturing partner with over 20 years of specialized LED innovation, we provide fully customizable solutions including tailored lumen output, advanced dimming compatibility, and robust thermal management systems to ensure longevity in demanding environments.

Leverage our OEM/ODM expertise to differentiate your product line with reliable, code-compliant lighting that meets global safety standards. We handle rigorous quality control from chip selection to final assembly, giving your brand a competitive edge through superior engineering and scalable production capacity.

Secure your partnership today to access technical support, rapid prototyping, and dedicated account management for under cabinet lighting projects. Contact our sales engineering team directly at [email protected] to discuss specifications, sampling timelines, and volume pricing. Let Beauty STC illuminate your next successful product launch with lighting technology built for professional excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.