Article Contents

Industry Insight: Ultraviolet Led Bulbs

The commercial and industrial lighting sector is undergoing a significant transformation driven by the rapid adoption of ultraviolet LED technology, particularly for disinfection and sanitation applications. Ultraviolet LED bulbs are no longer niche components but essential tools for facility managers and engineers seeking effective, chemical-free solutions to maintain hygienic environments. Their targeted germicidal efficacy, especially within the UVC spectrum, is revolutionizing air and surface treatment protocols across critical settings such as healthcare facilities, food and beverage processing plants, laboratories, pharmaceutical manufacturing, and public transit systems. Unlike traditional mercury-based UV lamps, modern UV LED bulbs offer instant on/off capability, precise wavelength control, greater durability, reduced environmental impact, and design flexibility for integration into HVAC systems, upper-room air disinfection units, and automated sanitation devices. Crucially, market acceptance and safe deployment in these professional environments hinge on rigorous third-party certification. Compliance with ETL (indicating adherence to North American safety standards) and CE marking (demonstrating conformity with European health, safety, and environmental requirements) is non-negotiable, providing end-users and specifiers with the essential assurance of product safety, performance reliability, and regulatory compliance necessary for commercial and industrial deployment.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution within the professional lighting industry. With over two decades of specialized engineering expertise, we have consistently focused on developing high-performance, certified LED lighting solutions tailored to the demanding requirements of commercial and industrial applications. Our deep understanding of photobiology, thermal management, and optical design, combined with a steadfast commitment to meeting and exceeding global safety certifications like ETL and CE, positions us as a trusted partner for businesses seeking robust, effective, and code-compliant ultraviolet LED technology. We leverage our extensive manufacturing heritage and rigorous quality control processes to deliver UV LED bulbs engineered specifically for the longevity, output stability, and safety protocols demanded by professional environments, moving beyond simple illumination to provide critical functional lighting solutions.

Technical Specs & Certifications

Ultraviolet LED bulbs are specialized lighting products designed to emit light in the ultraviolet spectrum, typically in the UVA range (315–400 nm), and are commonly used for applications such as curing, inspection, disinfection, and forensic analysis. While traditional lighting metrics like lumens and CRI are not directly applicable to UV light—since lumens measure visible light output and CRI (Color Rendering Index) evaluates how accurately a light source reveals the colors of objects under visible light—some technical considerations can still be addressed in relation to performance and quality.

In terms of efficiency, UV LEDs are not typically rated in lumens per watt (lm/W) because their output is not in the visible spectrum. Instead, radiant efficiency is measured in watts of UV output per electrical watt input (W/W). High-performance UV LEDs from advanced manufacturers can achieve radiant efficiencies ranging from 15% to 50%, depending on the wavelength and chip technology. For example, 365 nm and 395 nm UVA LEDs commonly used in industrial and commercial applications may deliver 2–4 W of optical output for every 10 W of electrical input, depending on thermal management and drive current.

Regarding CRI, it is important to clarify that CRI values are meaningless for pure ultraviolet light sources, as they do not emit visible light and therefore cannot render colors in the conventional sense. However, some UV LED bulbs are designed with a slight visible violet or blue emission to indicate operation. In such hybrid cases, if the visible component is significant, CRI may be measured—though achieving a CRI >90 is not relevant or feasible for true UV emission. Beauty (STC) Manufacturing Co., Ltd. ensures precision in spectral output, minimizing unwanted visible light in UV-dominant bulbs to maintain application integrity.

IP (Ingress Protection) ratings are critical for UV LED bulbs used in industrial or outdoor environments. Beauty STC offers UV LED solutions with IP65, IP66, and IP67 ratings, ensuring protection against dust and water ingress. This makes their UV bulbs suitable for harsh environments such as manufacturing floors, outdoor curing stations, or washdown areas in food processing where sanitation systems use UV for surface inspection or microbial control.

Beauty STC is recognized for its rigorous quality control, advanced thermal management design, and use of high-grade semiconductor materials in UV LED fabrication. Their products undergo extensive testing for output stability, lifetime (often rated at 15,000 to 20,000 hours), and resistance to thermal degradation. By integrating robust drivers, precision optics, and durable housings, Beauty STC ensures reliable performance and long service life, meeting the demanding standards of industrial and commercial users worldwide.

Factory Tour: Manufacturing Excellence

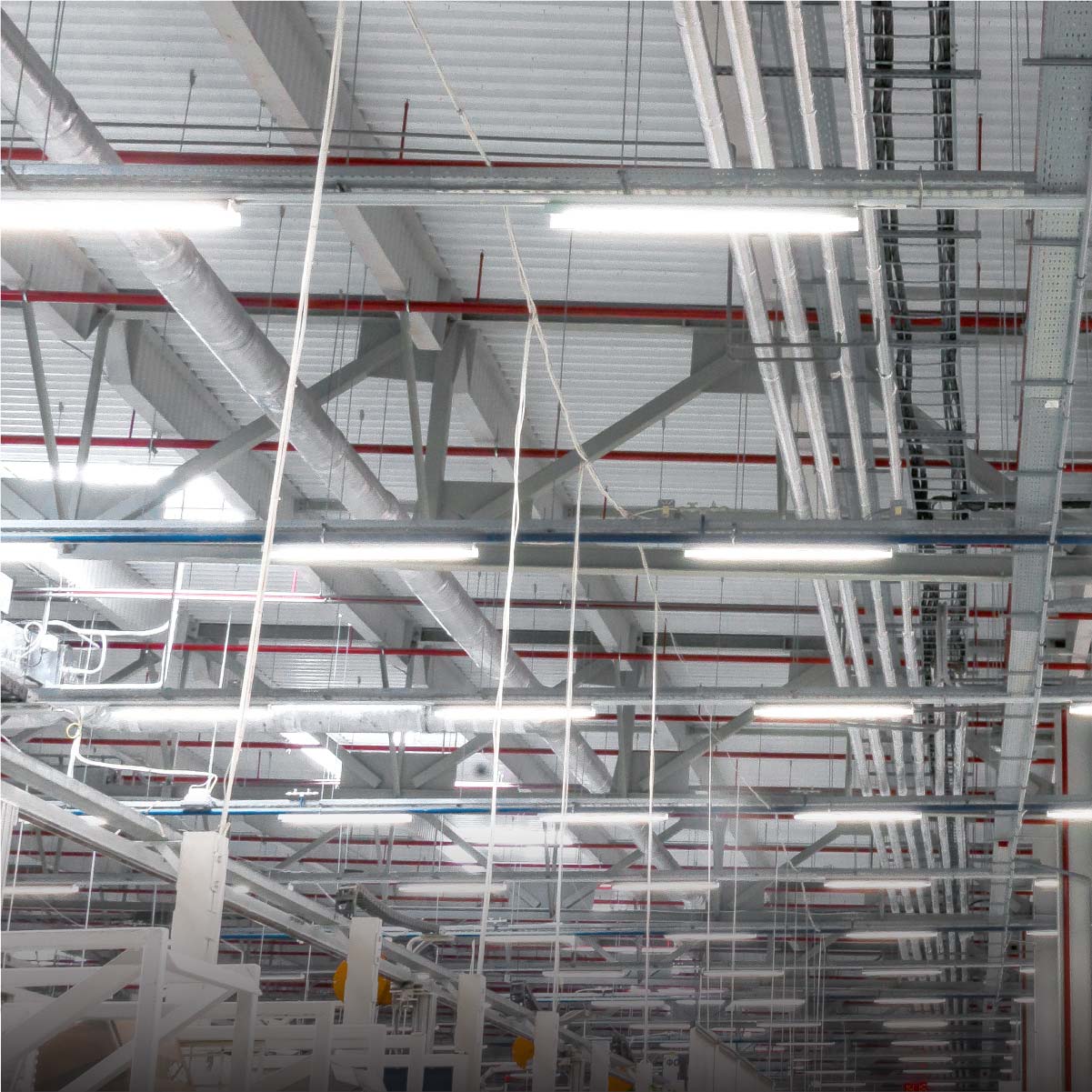

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant operational hub for the company’s LED lighting production. Strategically located within one of China’s key industrial regions, the Jiangmen factory benefits from robust infrastructure and supply chain access while maintaining strict adherence to international manufacturing standards. The facility is designed for efficiency and scalability, featuring dedicated cleanroom environments for critical assembly processes and comprehensive quality control checkpoints throughout the production flow. This setup ensures consistent output of high-reliability lighting products, including specialized ultraviolet LED solutions.

The factory employs advanced Surface Mount Technology (SMT) production lines as the cornerstone of its assembly capability. These lines integrate high-speed Fuji NXT III series pick-and-place machines capable of handling ultra-fine pitch components down to 0201 package sizes, essential for modern LED driver and control circuitry. Each SMT line operates with automated solder paste printers, nitrogen-reflow soldering ovens with precise thermal profiling, and multi-stage Automated Optical Inspection (AOI) systems for real-time defect detection. Throughput exceeds 80,000 components per hour per line, with dual-lane configurations supporting parallel production runs. This precision assembly infrastructure is particularly critical for ultraviolet LED bulb manufacturing where thermal management and component placement accuracy directly impact UV output stability and product lifespan.

Aging and reliability testing constitute a rigorously controlled phase within the Jiangmen facility’s quality assurance protocol. For ultraviolet LED products, dedicated aging chambers subject finished bulbs to accelerated life testing under elevated temperatures of 65°C to 85°C for durations of 48 to 72 hours, significantly exceeding standard industry requirements. These chambers incorporate continuous UV output monitoring via calibrated spectroradiometers to track irradiance decay rates, with real-time data logging systems flagging any units failing to maintain ≥95% of initial UV intensity. Environmental stress screening includes humidity exposure testing at 85% RH and thermal cycling between -20°C and 70°C to validate performance in demanding applications such as medical sterilization or industrial curing where reliability is non-negotiable.

Beauty STC demonstrates extensive OEM capability specifically tailored for ultraviolet LED bulb production, accommodating diverse client specifications across UVA (365-400nm), UVB (280-315nm), and UVC (200-280nm) spectrums. The factory supports full customization from initial concept through to mass production, including optical design for targeted irradiance patterns, thermal management solutions for high-power UV emitters, and specialized phosphor coatings for specific wavelength requirements. Engineering teams collaborate with clients on regulatory compliance for target markets, managing certifications such as FDA 21 CFR for UVC devices, IEC 62471 photobiological safety classification, and regional standards like CE and FCC. The OEM process encompasses private labeling, custom packaging configurations, and flexible minimum order quantities, with the Jiangmen facility’s integrated supply chain enabling rapid prototyping cycles of under two weeks for new UV LED bulb designs while maintaining strict IP confidentiality protocols.

Application Scenarios

Ultraviolet LED bulbs are primarily used for disinfection and sterilization purposes due to their ability to emit UV-C light, which effectively inactivates bacteria, viruses, and other pathogens. While they are not intended for general illumination, their application in commercial environments like hotels, malls, and offices is growing—especially in areas where hygiene is a top priority.

In hotels, ultraviolet LED bulbs can be installed in guest room HVAC systems, bathrooms, and behind reception desks to help reduce microbial contamination. They are particularly effective in HVAC units where they can continuously sanitize circulating air. Portable UV-C units may also be used for nightly disinfection of rooms when unoccupied. Caution must be taken to ensure no direct human exposure during operation.

In malls, UV LED bulbs are best suited for installation in centralized air handling units, restrooms, and food court ventilation systems. These high-traffic areas benefit from continuous air and surface disinfection, especially in ductwork and above ceilings where UV-C light can operate safely without public exposure. Some malls also integrate UV systems into escalator handrail sanitizing units.

In offices, UV LEDs are commonly used within HVAC and air purifier systems to maintain indoor air quality. They can also be installed in printer rooms, break rooms, and restrooms—spaces that see frequent touchpoints and shared equipment. Overhead UV-C fixtures in unoccupied meeting rooms or overnight in cubicle areas can provide surface disinfection when timed properly.

Installation tips include ensuring that UV-C emitting devices are placed in locations where they do not expose occupants directly, as UV-C radiation can cause skin and eye damage. Fixtures should be installed by qualified personnel and equipped with safety interlocks or motion sensors to shut off when people are present. Regular maintenance is essential—clean the bulbs every 3 to 6 months with isopropyl alcohol to maintain output efficiency, and replace bulbs according to manufacturer specifications, typically every 9,000 to 12,000 hours of use. Always follow local safety regulations and use only UV-C LEDs that are certified for commercial use.

Why Choose Beauty STC Lighting

Elevate your product offerings with cutting-edge ultraviolet LED bulb technology engineered for superior performance and reliability. Beauty STC Manufacturing Co., Ltd. delivers precision-engineered UV solutions tailored for diverse applications including disinfection, curing, counterfeit detection, and specialized lighting requirements. Our advanced manufacturing processes ensure consistent spectral output, extended operational lifespans, and strict adherence to international safety standards, providing your business with a competitive edge in demanding markets.

Partner with Beauty STC to access scalable production capabilities, rigorous quality control, and dedicated engineering support that transforms your UV lighting vision into market-ready reality. We collaborate closely with partners to customize solutions meeting exact technical specifications while optimizing cost-efficiency and time-to-market. Secure your supply chain with a manufacturer committed to innovation and operational excellence in UV LED technology.

Initiate a strategic collaboration today by contacting our partnership management team directly at [email protected]. Our experts are prepared to discuss your project requirements, provide technical documentation, and outline how Beauty STC’s engineering expertise can drive mutual growth in the rapidly expanding UV LED sector. Reach out now to schedule a consultation and receive a tailored proposal for your ultraviolet lighting needs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.