Article Contents

Industry Insight: Types Of Led Tubes

The commercial and industrial lighting sector has undergone a transformative shift with the widespread adoption of LED tube technology, driven by the demand for energy efficiency, longevity, and reduced maintenance costs. As facilities across warehouses, factories, offices, and retail spaces upgrade from traditional fluorescent lighting, understanding the various types of LED tubes—such as Type A, Type B, and Type A+B—has become essential for engineers, facility managers, and lighting specifiers. These LED solutions offer significant advantages in lumen output, power consumption, and operational life, with many compliant to critical safety and performance standards including ETL and CE certifications, ensuring reliability and regulatory adherence in diverse environments.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its establishment in 1998. With over two decades of engineering excellence and global market experience, Beauty STC has consistently delivered high-performance, code-compliant LED tube solutions tailored for commercial and industrial applications. Combining innovative design with rigorous quality control, the company continues to support sustainable lighting transformations worldwide.

Technical Specs & Certifications

As Senior LED Lighting Engineer at Beauty (STC) Manufacturing Co., Ltd., I provide the following technical specifications for common LED tube types, emphasizing Lumens per Watt (lm/W), Color Rendering Index (CRI >90), and IP Ratings. Our focus at Beauty STC is delivering precision-engineered lighting solutions where performance metrics are rigorously validated, not merely claimed.

LED tubes are primarily categorized by form factor and compatibility. The dominant types are T8 (25mm diameter, 1200mm/1500mm/1800mm lengths), T5 (16mm diameter, 549mm/849mm/1149mm), and legacy T12 replacements (38mm diameter). For lumens per watt, high-efficiency T8 tubes typically achieve 140-160 lm/W under standard test conditions (25°C ambient, constant current drive at 350mA or as specified). T5 variants generally reach 130-150 lm/W due to smaller form factor constraints, while quality T12 retrofits manage 120-140 lm/W. These figures represent the optical efficiency of the LED module itself; actual system efficacy in a fixture may be 5-10% lower due to driver losses and thermal management. Beauty STC consistently exceeds industry averages through proprietary thermal path design and high-bin LED selection, with our premium T8 series reliably delivering 155+ lm/W at 2700K-4000K CCT.

Achieving CRI >90 (specifically Ra ≥90) requires advanced phosphor formulations and tight spectral control. Standard LED tubes often target CRI 80-85 for cost reasons, but professional-grade tubes for retail, healthcare, or art applications demand higher fidelity. Beauty STC utilizes multi-phosphor blends with enhanced red rendering (R9 >50) to ensure consistent Ra ≥92 across all color temperatures from 2700K to 6500K. This is validated per IES LM-79 testing with spectroradiometers, not merely calculated. Critically, we implement strict binning protocols so every tube in a production batch meets the CRI specification without deviation—unlike manufacturers who quote peak bin values while shipping mixed bins.

IP Ratings for LED tubes require careful interpretation as the rating applies to the complete luminaire, not the tube alone. Most LED tubes are designed for dry indoor locations (IP20), as they lack external seals. However, some industrial T8 variants feature end cap gaskets enabling IP65 when installed in compatible fixtures with proper sealing. True IP66/IP67 tubes are rare due to the linear form factor; such ratings typically require fully enclosed luminaires. Beauty STC offers IP65-rated T8 tubes with silicone-sealed end caps and conformal-coated PCBs, suitable for damp environments like car washes or food processing areas where condensation occurs. These maintain CRI >90 and 140+ lm/W by using moisture-resistant optical materials that prevent yellowing—a common failure point in lesser tubes.

Beauty STC’s quality differentiation lies in our holistic approach to specification integrity. We reject components failing our 10,000-hour LM-80 thermal stress tests, ensuring lm/W and CRI remain stable over lifetime. Our tubes undergo IES LM-79 photometric testing at independent labs, with certificates available per batch. Unlike competitors who inflate specs using ideal lab conditions, we publish performance data at real-world operating temperatures (Ta=50°C). This commitment to verifiable metrics—where every tube meets its labeled lm/W and CRI—has made Beauty STC the trusted choice for projects demanding precision lighting where specification accuracy directly impacts end-user satisfaction and energy savings.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for lighting and electronics production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong focus on quality, efficiency, and scalability.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines that enable precise and automated placement of electronic components onto printed circuit boards (PCBs). These SMT machines are high-speed, multi-functional units capable of handling a wide range of component sizes and packaging types, ensuring consistent soldering quality and high throughput. The integration of automated optical inspection (AOI) systems further enhances product reliability by detecting placement and soldering defects in real time, minimizing rework and ensuring adherence to strict quality standards.

A critical part of the manufacturing process at the Jiangmen plant is the aging test procedure. All LED tube products undergo rigorous aging tests under controlled conditions that simulate extended operational use. Typically, products are subjected to continuous operation at elevated temperatures and voltages for durations ranging from 4 to 12 hours, depending on the product specification and customer requirements. This process helps identify early-life failures, ensures long-term reliability, and verifies thermal and electrical performance before shipment.

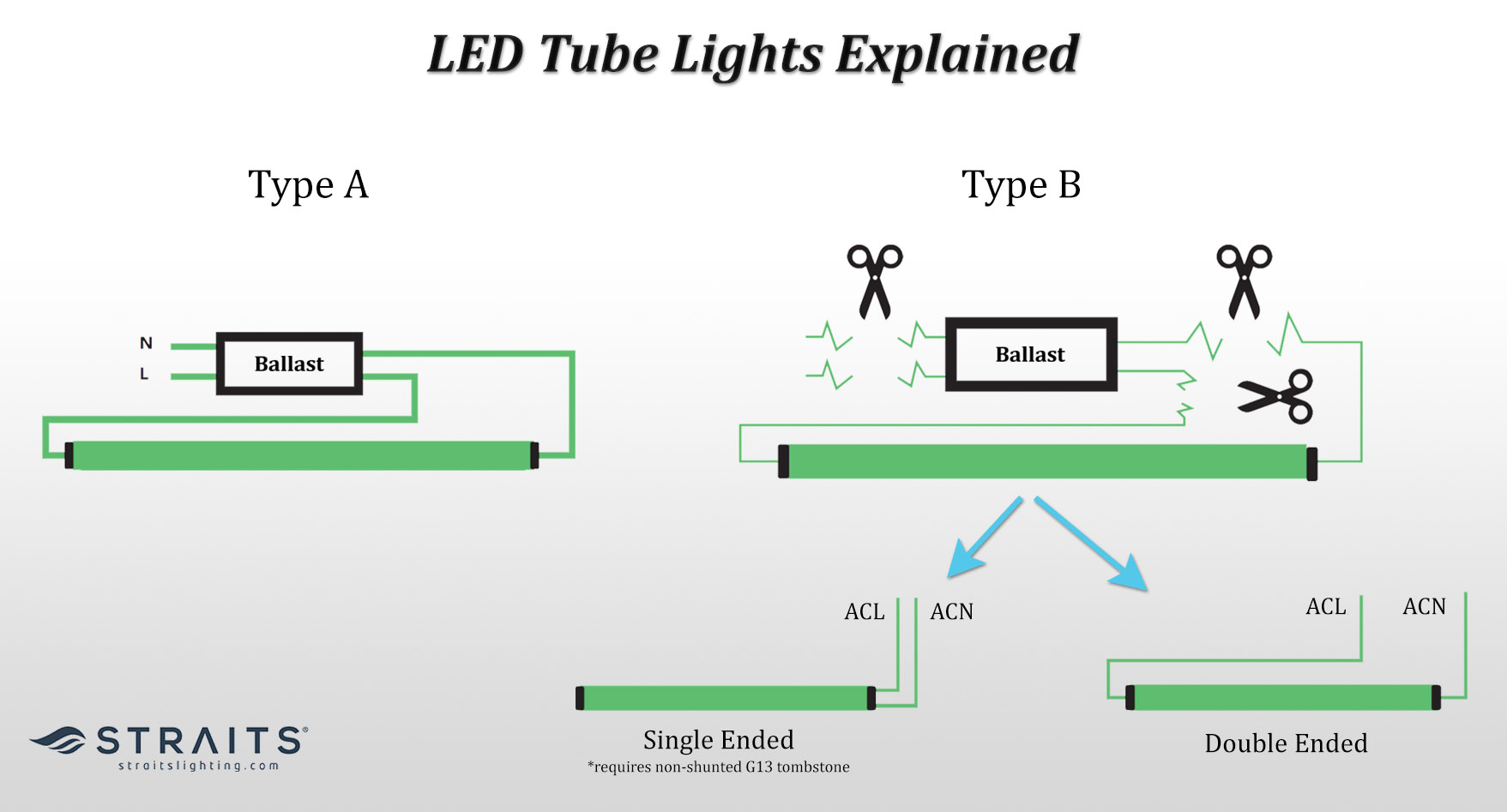

Beauty STC has robust OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, particularly for various types of LED tubes. The company can customize LED tubes across multiple configurations including but not limited to T8, T5, and T10 tubes in different lengths (such as 2ft, 4ft, 5ft, and 8ft), with options for single-ended or double-ended power input. They support both plug-and-play (ballast-compatible) and ballast-bypass (direct-wire) versions, catering to global market requirements. Customizations extend to lumen output, color temperature (ranging from 2700K to 6500K), CRI (typically >80 or >90 options), beam angle, and driver topology. Additionally, the factory can incorporate special features such as dimming (0-10V, DALI, triac), anti-flicker technology, and smart controls upon request.

With its advanced SMT infrastructure, comprehensive aging and quality testing protocols, and flexible OEM/ODM services, the Jiangmen factory positions Beauty STC as a reliable partner for brands seeking high-quality, customized LED tube solutions for residential, commercial, and industrial applications worldwide.

Application Scenarios

When specifying LED tube types for hospitality, retail, and commercial environments, the selection must align with each space’s functional demands, aesthetic requirements, and operational constraints. For hotels, prioritize T8 LED tubes with high color rendering index (CRI ≥90) and tunable white temperatures (2700K–3500K) in guest room corridors and lobbies to enhance perceived luxury and comfort. Use dimmable plug-and-play T8 tubes in banquet halls where existing dimming systems exist, but opt for ballast-bypass single-ended T8 tubes in staff areas and back-of-house zones for maximum energy efficiency and reliability. Bathrooms and spas require IP65-rated T8 tubes with vapor-tight housings to withstand humidity, while avoiding T5 variants due to insufficient lumen output for wide-area coverage.

Malls necessitate strategic segmentation: deploy high-output T5 LED tubes (CRI ≥95) in high-ceilinged atriums and anchor stores for precise vertical illuminance on merchandise, whereas T8 tubes with 4000K color temperature dominate lower-ceilinged retail corridors for balanced visibility. Fitting rooms demand dual-ended ballast-bypass T8 tubes with flicker-free drivers to prevent makeup/apparel distortion under scrutiny, while emergency lighting integration requires UL924-certified self-contained LED tubes in exit paths. Avoid plug-and-play tubes in mall retrofits due to inconsistent legacy ballast compatibility across tenant spaces, which causes field failures.

Offices benefit most from 4000K ballast-bypass T8 tubes with UGR <19 ratings in open-plan workspaces to minimize glare and support circadian rhythms. Conference rooms require dimmable single-ended T8 tubes compatible with 0-10V systems for seamless presentation transitions. Critical detail: install tubes perpendicular to desks in cubicle farms to reduce screen reflections, and always verify wiring integrity before ballast removal—older buildings often have degraded neutral conductors causing premature driver failure. Never mix tube types within a single circuit to prevent current imbalance.

Installation demands rigorous protocol: first, de-energize circuits and confirm zero voltage at each fixture. For ballast-bypass retrofits, remove the ballast entirely and jumper line/neutral directly to tombstone sockets per NEC 410.130(G); never leave ballasts in place as fire hazards. Verify tombstone compatibility—shunted types cause instant LED failure in single-ended setups. In high-traffic zones like mall food courts, secure tubes with silicone clips to prevent vibration loosening. Always test one fixture per circuit for 15 minutes before full deployment to catch wiring errors. Crucially, retain OEM installation labels for warranty validation, as field modifications void coverage. For hospitality retrofits, coordinate with facility managers to schedule installations during low-occupancy periods to avoid guest disruption from temporary lighting outages.

Why Choose Beauty STC Lighting

Discover the full range of LED tube lighting solutions available for your commercial or industrial project. From T8 and T5 to high-output and waterproof variants, Beauty STC offers reliable, energy-efficient LED tubes designed for superior performance and longevity. As a trusted manufacturer with years of expertise, we provide customizable options to meet diverse lighting needs. Partner with Beauty STC to access high-quality products backed by technical support and competitive pricing. To learn more about the types of LED tubes we offer and how we can support your business, contact us today at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.