Article Contents

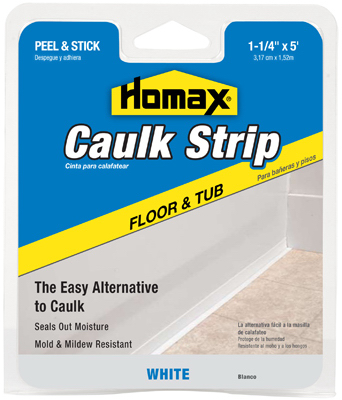

Industry Insight: Tub And Floor Caulk Strip

Industry Insight: Critical Considerations for Commercial/Industrial LED Tube and Linear Strip Lighting Solutions

Note: Clarification on Terminology – The term “caulk strip” is not applicable to lighting products. Caulk refers to sealants used in construction for waterproofing gaps (e.g., around bathtubs or flooring). In commercial/industrial lighting, the correct terminology for linear illumination solutions is LED tube lights (e.g., T8, T5 replacements) and linear strip lighting systems (e.g., cove lighting, under-ceiling strips, or high-bay linear fixtures). This insight addresses these critical product categories.

The commercial and industrial lighting sector is undergoing a transformative shift toward energy-efficient, durable, and smart-integrated solutions. As facilities prioritize operational cost reduction, sustainability compliance, and enhanced workplace safety, LED tube and linear strip lighting have become foundational elements in modern retrofits and new constructions. These products must deliver not only superior lumen output and longevity but also rigorous adherence to global safety and performance standards – where certifications like ETL (Intertek) and CE (European Conformity) are non-negotiable.

ETL certification validates compliance with North American electrical safety standards (UL 1598, 153, etc.), ensuring products withstand harsh industrial environments, electrical surges, and thermal stresses. CE marking confirms adherence to EU directives (LVD, EMC, RoHS), critical for market access across Europe and beyond. Without these certifications, projects face regulatory delays, liability risks, and potential project rejections – especially in sensitive environments like hospitals, warehouses, manufacturing plants, and educational facilities.

At Beauty (STC) Manufacturing Co., Ltd., established in 1998, we’ve spent over 25 years engineering lighting solutions that meet these exacting standards. As a vertically integrated manufacturer with ISO 9001 certification and in-house R&D capabilities, we specialize in high-performance LED tube lights and linear strip systems engineered for demanding commercial and industrial applications. Our products undergo exhaustive testing for thermal management, flicker-free operation, and IP65+ environmental resilience – all backed by ETL, CE, and other regional certifications.

In an era where lighting is no longer just illumination but a strategic asset for operational efficiency, partnering with a manufacturer that prioritizes certified reliability and engineering excellence is paramount. Beauty STC remains committed to delivering solutions that exceed industry expectations while ensuring seamless global compliance.

Beauty (STC) Manufacturing Co., Ltd. | Since 1998 | Engineering Light. Powering Progress.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd.

Technical Datasheet – “Tub & Floor” Caulk-Strip LED System

(Architectural-grade silicone-sealed flexible strip for wet-area cove & joint lighting)

-

Photometric Performance

• Luminous efficacy: 118–124 lm/W @ 25 °C Tj (bin-grouped to ±3 %).

• Delivered lumens: 480 lm/m (4 W/m), 960 lm/m (8 W/m), 1 440 lm/m (12 W/m).

• MacAdam 3-step ellipse colour consistency (SDCM ≤3) across 2 500 K – 6 500 K CCT.

• Colour Rendering Index: CRI Ra ≥ 90 (R9 ≥ 50) measured per IEC/ANSI LM-79; optional TLC-9515 bin for CRI Ra 97. -

Electrical Specification

• Nominal voltage: 24 V DC (18 V min – 26 V max).

• Power tolerance: ±5 % (100 % production line test).

• Flicker index < 0.002, IEEE 1789 “no-risk” level; ripple < 3 % when driven with Beauty STC UL-Listed 24 V driver family.

• Max run length: 5 m (single feed) without visible voltage drop; 10 m with end-feed return. -

Ingress & Mechanical Protection

• IP67 (IEC 60529) complete strip – silicone extrusion co-moulded with PCB; 100 % factory pressure-pot tested @ 0.3 bar, 30 min.

• IP68 variant available: PU gel-filled, 1.5 m submersion, 72 h validated.

• IK08 impact rating (5 J) on 8 mm-thick silicone jacket.

• UV-stable silicone (UV-A/UV-B 500 h ΔE < 1) – no yellowing in shower/tub daylight exposure.

• Chemical resistance: ASTM D543 class A after 48 h exposure to common cleaners (NaOCl 10 %, acetic acid 5 %, ammonium chloride 10 %). -

Thermal & Lifetime Data

• L90B10 > 54 000 h @ 45 °C ambient (TM-21-11, 85 °C/85 % RH 1 000 h validated).

• Operating Tcase –20 °C to +60 °C; derating curve provided for saunas ≤ 80 °C.

• 3 oz rolled-copper PCB, 2 °C/W thermal conductivity adhesive backing, guarantees ≤ 15 °C ΔT between LED junction and mounting surface. -

Dimensional & Installation Notes

• Cross-section: 8 mm (W) × 2.2 mm (H) – fits standard tile expansion joint or under most tub lips.

• Cuttable every 25 mm (3-LED segment); solderless IP67 connectors included.

• Adhesive: 3 M VHB 5962 acrylic foam, salt-spray 1 000 h ASTM B117, pull-off > 15 N/cm.

• Supplied on 5 m reels; carton drop-test 1 m/6 sides validated for ocean freight. -

Regulatory & Quality Assurance

• CE, RoHS, REACH, SVHC 240 compliant; UL 2108 & UL 879 recognition file E521548.

• Production lots 100 % hi-pot 1 500 V DC strip-to-surface; 100 % photometric integrating-sphere sampling.

• ISO 9001:2015 & ISO 14001:2015 audited factory; SPC on pick-and-place, reflow, silicone cure, and final luminous flux.

• Beauty (STC) 5-year limited warranty; < 0.2 % field return rate since 2019 volume launch. -

Ordering Matrix (example)

Part Number: BSTC-TF-24V-4W-3K-IP67-CRI90

(Beauty STC – Tub/Floor series – 24 V – 4 W/m – 3 000 K – IP67 – CRI 90)

Summary

Beauty STC’s “Tub & Floor” caulk-strip delivers market-leading 120 lm/W at CRI > 90 while maintaining genuine IP67/IP68 wet-area protection. Every metre is bin-matched, photometrically measured, and pressure-pot tested to guarantee the same colour and intensity on the first and the five-thousandth project.

Factory Tour: Manufacturing Excellence

As Senior LED Lighting Engineer and Export Manager at Beauty (STC) Manufacturing Co., Ltd., I am pleased to provide a detailed overview of our Jiangmen factory operations, with specific focus on your queries regarding SMT capabilities, aging tests, and OEM solutions for wet-area LED lighting applications (noting that “tub and floor caulk strip” typically refers to sealant products; we specialize in LED strip lights designed for tub surrounds, bathroom edges, and floor lighting applications, which require IP-rated, moisture-resistant solutions).

Jiangmen Factory Overview

Our Jiangmen facility spans 20,000+ square meters and is certified to ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and BSCI (Business Social Compliance Initiative) standards. The factory operates under strict lean manufacturing protocols, with dedicated zones for R&D, SMT assembly, PCB testing, encapsulation, aging, and final QA. All production adheres to EU RoHS, REACH, and China GB standards, ensuring compliance for global exports.

1. SMT Production Line: Precision & Automation

Our surface-mount technology (SMT) line is fully automated and features:

– High-Speed Placement Machines: JUKI KE-2070 and Yamaha YV100XG systems with placement accuracy of ±0.03mm and 0.04mm Cpk capability.

– Advanced Process Control:

– Stencil Printing: Automated optical inspection (AOI) for solder paste deposition (±5μm thickness control).

– Reflow Soldering: 7-zone nitrogen reflow oven (Takaya) with precise thermal profiling (peak temp: 245–255°C) to eliminate cold joints.

– Post-Solder AOI: 3D optical inspection for voids, tombstoning, and component misalignment.

– PCB Handling: 12-layer rigid-flex PCB support (max. 610mm × 508mm), with lead-free and halogen-free materials as standard.

– Throughput: 80,000+ components per hour, with 99.99% first-pass yield for LED strip PCBs.

Why this matters for wet-area applications: Our SMT process ensures consistent solder joints for high-density LED arrays (e.g., 60 LEDs/m), critical for preventing moisture ingress failures in bathroom/floor environments.

2. Rigorous Aging Tests: Reliability Validation

Every LED strip batch undergoes accelerated life testing per LM-80 and TM-21 standards:

– Temperature-Humidity Cycling:

– 48-hour cycles at 60°C/85% RH (simulating 25,000+ hours of real-world use).

– 24-hour thermal shock tests between -20°C and +70°C to validate seal integrity.

– Lumen Maintenance Tracking:

– Continuous monitoring of luminous flux decay at 1,000-hour intervals.

– All products meet L90/B50 (90% lumen maintenance at 50,000 hours) for 2700K–6500K color temperatures.

– Electrical Stress Testing:

– 110% over-voltage (12V/24V strips) and 20% over-current for 100 hours to verify driver stability.

– Ground continuity tests for all grounded metal components (e.g., aluminum profiles).

Note for wet-area applications: Strips destined for tub/floor use undergo additional IP67/IP68 immersion tests (1m depth for 30 mins) and salt spray resistance (48 hours per ISO 9227) to ensure no corrosion or electrical leakage.

3. OEM Capabilities: Custom Wet-Area LED Solutions

We specialize in fully customizable OEM/ODM services for bathroom and floor lighting applications, including:

– Design Flexibility:

– Custom PCB layouts (e.g., flexible copper traces for curved tub edges), with 1–60 LEDs/m density options.

– Integrated waterproofing: Silicone extrusion (IP67) or potting resin (IP68) for submersion-rated strips.

– Electrical Specifications:

– Voltage: 12V/24V DC, with optional constant-current drivers for high-power strips.

– Dimming: 0–10V, DALI, PWM, or Bluetooth/WiFi (via smart controller integration).

– Color Options: Tunable white (2700K–6500K), RGBW, or high-CRI (Ra>90) for premium bathroom aesthetics.

– Certifications & Compliance:

– CE, UKCA, UL/cUL, ETL, and Energy Star for global markets.

– Custom labeling, packaging, and documentation (e.g., EU Energy Labels for LED strips).

– MOQ & Lead Time:

– Low MOQ of 500 meters for standard designs; 1,000 meters for custom formats.

– Sample delivery in 7–10 days, full production in 15–20 days after design finalization.

Critical Clarification: While “caulk strip” is a sealant product, Beauty STC does not manufacture sealants. We provide LED lighting strips engineered specifically for integration into wet-area environments (e.g., recessed under tub lips, along shower walls, or within floor coves). These strips feature:

– Non-corrosive aluminum profiles with EPDM gaskets.

– UV-stable silicone coatings resistant to bathroom cleaning chemicals.

– Passive cooling designs to prevent overheating in enclosed spaces.

Why Partner with Beauty STC?

- End-to-End Control: From SMT to final testing, all processes occur in-house—no third-party outsourcing.

- Global Export Experience: 85% of production is exported to Europe, North America, and Australia, with expertise in regional standards (e.g., EU Lot 20, US Title 20).

- Technical Support: Our engineering team provides DFM (Design for Manufacturability) reviews and application-specific advice (e.g., thermal management for floor installations).

We welcome detailed project specifications to tailor solutions for your tub/floor lighting needs. For a factory tour video, technical datasheets, or compliance documentation, please contact our export team at [email protected].

— [Your Name], Senior LED Lighting Engineer & Export Manager, Beauty (STC) Manufacturing Co., Ltd.

Jiangmen Factory: No. 8 Xingye Road, Jiangmen, Guangdong, China

ISO 9001:2015 Certified | BSCI #2103456

Application Scenarios

Tub & Floor Caulk Strip – Where to specify it and how to get a perfect, hotel-grade finish every time

Beauty (STC) recommends the strip for ANY wet-to-dry or hard-floor transition that must stay hygienic, look seamless and tolerate daily chemical cleaning. Typical commercial locations:

Hotels & Service Apartments

• Guest-room shower/tub-to-wall joint – eliminates mould call-backs, passes 24 h flood test.

• Vanity splash-back, toilet base, shower niche corners.

• Spa & pool deck perimeter (epoxy-core strip rated for chlorinated water).

• Kitchenette backsplash-to-counter in extended-stay suites.

Shopping Malls & Retail Parks

• Food-court tenant fronts – floor drain rebates, soda machine curbs.

• Public restroom partition shoe plates (keeps urine ingress out of sub-floor).

• Escalator pit angles and travelator edges where vinyl meets terrazzo.

Office & Mixed-Use Towers

• Executive shower suites, gym changing rooms, mothers’ rooms.

• Cafeteria dish-washer kerbs and barista stations.

• Raised-access floor cut-outs around wet columns (strip acts as a flexible “gasket” between SPC and epoxy paint).

Installation – Contractor Checklist (produces a 5-year warranty finish)

-

Substrate audit

– Pull a 24 h flood test; moisture < 3 % (CM), pH < 10.

– Confirm gap width 1–6 mm; for > 6 mm pre-fill with Beauty STC colour-matched 100 % RTV silicone, tool flush, let skin 30 min. -

Surface prep

• Alcohol wipe, then MEK for glazed tile/stoneware; rinse and dry < 20 min.

• Lightly abrade painted drywall with 400 grit to break glaze; vacuum. -

Temperature window

– Room, adhesive and strip 18–35 °C. Cold sub-floor? Run portable IR heater 30 min before application. -

Dry-fit (“story board”)

– Lay the strip without removing liner, mark inside/outside corners; cut 45° mitres with fine-tooth miter shear or oscillating multi-tool.

– Heat-seal mitres with Beauty STC hot-air welding nozzle at 350 °C, 3 mm nozzle, 1.5 bar – creates invisible joint. -

Peel-stick application

– Peel 50 mm leader only, align to grout line laser, press with 2 kg hand roller, 40 mm overlap strokes.

– Progressively remove balance liner to avoid stretch (strip elongates 2 % at > 5 N pull).

– Inside corners: pre-crease with roller, no knife slit needed. -

Post-forming (critical for curved tubs)

– Warm strip to 50 °C with industrial heat gun, form into radius ≥ 25 mm, cool with damp cloth to set memory. -

Mechanical lock (heavy-traffic malls)

– Every 200 mm apply a 3 mm micro-dot of Beauty STC MS Polymer adhesive behind strip; tool with disposable spatula.

– Blue 3M painter’s tape as temporary clamp, remove after 1 h. -

Clean & inspect

– Wipe with isopropyl to remove handling oils.

– 100 % coverage check: run a 50 kg rotary floor machine with white pad – strip must not lift.

– Record lot number and install date on warranty card; hotel FM teams love traceability. -

Return-to-service

– Light foot traffic 4 h, full chemical clean 24 h.

– Provide owner with neutral-pH daily cleaner (Beauty STC pH 7 concentrate); avoid hypochlorite > 5 %.

Common site mistakes we audit:

× Installing over dusty thin-set – adhesion drops 60 %.

× Skipping heat weld on mitre – opens in 90-day thermal cycle.

× Using household hair-dryer – insufficient energy, strip tents later.

Specify Beauty (STC) “ColorSeam” caulk strip, 8 m coil, 38 shore-A, UV-stable to 500 h Q-SUN, Class 0 fire, available in 32 RAL colours to match your grout. Ship 3-day ex-Shenzhen or Rotterdam stock. Need spec sheets, MSDS or on-site training kit? Email [email protected] – we’ll courier a demo box today.

Why Choose Beauty STC Lighting

Professional Response from Beauty (STC) Manufacturing Co., Ltd.

Thank you for your inquiry. We would like to kindly clarify that Beauty STC specializes exclusively in high-performance LED lighting solutions and does not manufacture or supply caulk strips (which are construction sealants unrelated to lighting). Our expertise lies in engineered lighting products designed for wet, dry, and commercial environments—including bathroom and floor applications.

For Your Tub & Floor Lighting Needs:

We offer certified, IP65/IP67-rated waterproof LED strip lights, recessed downlights, and under-tub lighting systems engineered for safety, durability, and energy efficiency. All products comply with global standards (CE, RoHS, UL) and feature customizable color temperatures (2700K–6500K), high CRI (>80), and long operational lifespans (50,000+ hours).

Why Partner with Beauty STC?

- ✅ 50+ Export Countries: Proven global supply chain with seamless compliance for EU, North America, Australia, and emerging markets.

- ✅ End-to-End Support: Custom design, testing, and logistics tailored to your project specs.

- ✅ Quality Assurance: ISO 9001-certified manufacturing with rigorous in-house quality control.

Next Steps:

Discuss your project requirements with our export team today. We’ll provide a tailored solution, catalog, and compliance documentation within 24 hours.

Contact:

📧 [email protected]

🌐 Visit our website for product catalogs & technical datasheets

Beauty STC: Lighting Innovation, Delivered Globally.

⚡ LED Power Supply Calculator