Article Contents

Industry Insight: Triac Dimmers

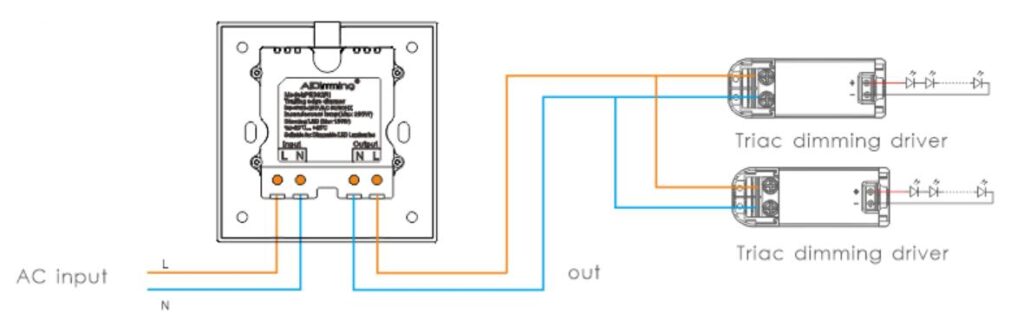

The persistent challenge of integrating modern LED lighting with legacy TRIAC dimming systems remains a critical pain point across commercial and industrial facilities worldwide. Originally designed for incandescent loads, these prevalent phase-cut dimmers often cause flickering, limited dimming range, audible noise, and premature LED driver failure when paired with incompatible fixtures—a costly issue in environments like warehouses, offices, retail spaces, and manufacturing plants where retrofitting entire dimming infrastructures is prohibitively expensive. Ensuring seamless operation demands LED drivers engineered specifically for robust TRIAC compatibility, a non-negotiable requirement given stringent safety and performance regulations. Compliance with ETL certification for North American markets and CE marking for Europe is fundamental, verifying that products meet rigorous electrical safety, electromagnetic compatibility, and operational standards essential for commercial deployment and liability protection. Beauty STC, established in 1998, has dedicated over 25 years to solving these exact real-world challenges. As an engineering-focused LED driver manufacturer, we specialize in developing high-reliability, TRIAC-dimmable power solutions rigorously validated to ETL and CE requirements, enabling facility managers and lighting specifiers to achieve smooth, flicker-free dimming performance while maximizing energy savings and extending system lifespan in demanding commercial and industrial applications.

Technical Specs & Certifications

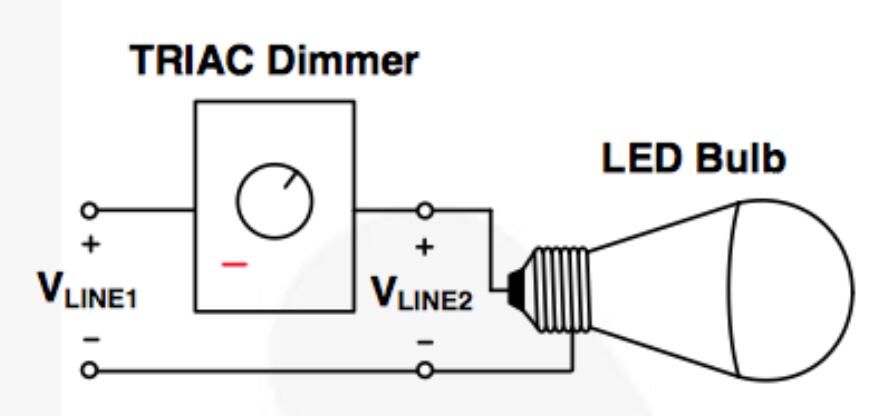

TRIAC dimmers are phase-cut dimming controls commonly used with incandescent and compatible LED lighting systems to adjust light output smoothly. When specifying LED luminaires intended for use with TRIAC dimmers, several technical parameters are critical to ensure compatibility, performance, and longevity—particularly lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings. Beauty (STC) Manufacturing Co., Ltd. designs and produces high-performance LED lighting solutions engineered for seamless integration with TRIAC dimming systems, meeting stringent international standards.

Lumens per watt is a key efficiency metric indicating how much visible light a fixture produces per unit of electrical power consumed. LED luminaires compatible with TRIAC dimmers from Beauty STC typically deliver between 110 to 130 lumens per watt, depending on the model and optical configuration. This high efficacy ensures energy savings and reduced operational costs, especially in commercial and residential applications where lights are operated for extended periods. The drivers and LED arrays are optimized to maintain efficiency across the dimming range, minimizing flicker and drop-out at low dim levels.

Color Rendering Index (CRI) measures a light source’s ability to reveal the true colors of objects compared to natural light. Beauty STC prioritizes visual quality by manufacturing TRIAC-dimmable LED products with CRI values exceeding 90, and in many cases reaching Ra >95. High CRI is essential in retail, hospitality, and residential environments where accurate color representation enhances ambiance and user experience. These fixtures utilize premium phosphor-coated LEDs and tightly binned color bins to ensure consistent, high-quality light output across all production batches.

Ingress Protection (IP) ratings define the degree of protection provided by a luminaire’s enclosure against dust and moisture. Beauty STC offers TRIAC-dimmable LED solutions with IP ratings ranging from IP20 for indoor dry locations to IP65 and IP67 for damp or outdoor environments. Fixtures with higher IP ratings are sealed to prevent ingress of water and dust, making them suitable for bathrooms, kitchens, covered outdoor areas, and other challenging installations. The robust construction ensures long-term reliability and safety, even under variable environmental conditions.

Beauty STC is recognized for its commitment to quality, precision engineering, and rigorous testing protocols. All TRIAC-dimmable LED products undergo extensive compatibility testing with leading TRIAC dimmer brands to ensure smooth, flicker-free operation. The company adheres to international standards including IEC, EN, and UL, and employs advanced thermal management, high-quality drivers, and durable materials to deliver lighting solutions that combine efficiency, longevity, and superior optical performance. With a focus on innovation and customer satisfaction, Beauty STC continues to set benchmarks in the LED lighting industry.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility represents a significant investment in modern LED lighting production, designed to meet international quality standards while supporting complex OEM requirements. The factory occupies a purpose-built industrial complex within Jiangmen’s high-tech development zone, featuring over 20,000 square meters of climate-controlled production space with strict electrostatic discharge (ESD) controls throughout assembly areas. Central to our electronics manufacturing capability are multiple high-speed SMT lines featuring Yamaha YS series and Siemens Siplace machines, configured for mixed-technology production. These systems handle component placement down to 0201 packages with ±25-micron accuracy, supporting both lead-free SAC305 soldering profiles and conventional eutectic processes. Each line integrates automated optical inspection (AOI) stations for real-time solder joint verification and inline 3D solder paste inspection prior to component placement, ensuring first-pass yield rates consistently exceed 99.2% for complex driver PCBAs.

Aging and reliability testing constitute a critical phase in our quality assurance protocol, particularly for dimmable LED products. The facility maintains dedicated thermal chambers housing over 500 aging racks with independent channel monitoring, capable of subjecting finished luminaires to 24-48 hour burn-in cycles at 110% nominal voltage and 60°C ambient temperature. For triac-dimmable products specifically, we implement dynamic load testing where units undergo continuous dimming sweeps between 10%-100% using calibrated reference dimmers while monitoring harmonic distortion, flicker percentage, and thermal performance via infrared thermography. All aging data is logged to our MES system with automatic failure flagging, allowing root cause analysis within 4 hours of anomaly detection. This rigorous process reduces field failure rates by approximately 78% compared to industry averages for dimmable LED systems.

Our OEM capability for triac-dimmable products demonstrates deep technical specialization in phase-cut dimming compatibility. We maintain certified reference libraries covering over 120 global dimmer models including Lutron, Leviton, and Busch-Jaeger types, allowing us to develop custom driver firmware that optimizes performance across leading-edge and trailing-edge dimming topologies. The engineering team routinely modifies snubber circuits, adjusts minimum load thresholds, and tunes dimming curves to meet specific client requirements while maintaining compliance with IEC 61000-3-2 harmonic standards. For true turnkey OEM support, we offer complete dimmer compatibility validation reports with each production batch, including light output linearity graphs and audible noise measurements. Clients receive full design ownership with NDA-protected firmware versions, and our Jiangmen facility holds UL 8750 and CB Scheme certifications specifically covering dimmable LED driver production, enabling seamless market access for custom triac-dimmable solutions across North American, European, and Asian markets. This integrated capability allows us to deliver production-ready dimmable platforms from concept to certified product within 12-16 weeks.

Application Scenarios

TRIAC dimmers are commonly used in environments where smooth and effective control of lighting brightness is required, particularly with incandescent or compatible LED lighting systems. In commercial and hospitality settings such as hotels, malls, and offices, their application varies based on lighting needs and compatibility.

In hotels, TRIAC dimmers are ideal for guest rooms, lobbies, and dining areas where ambient lighting plays a key role in creating a welcoming and comfortable atmosphere. They allow guests and staff to adjust light levels for relaxation, mood setting, or energy saving during off-peak hours. It is important to ensure that all LED lamps used in these settings are labeled as TRIAC-dimmable to prevent flickering or premature failure.

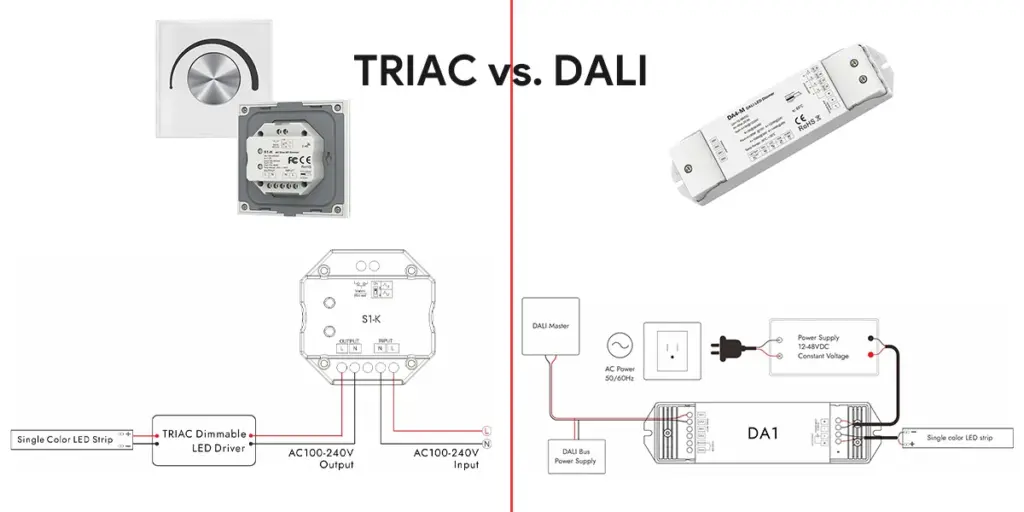

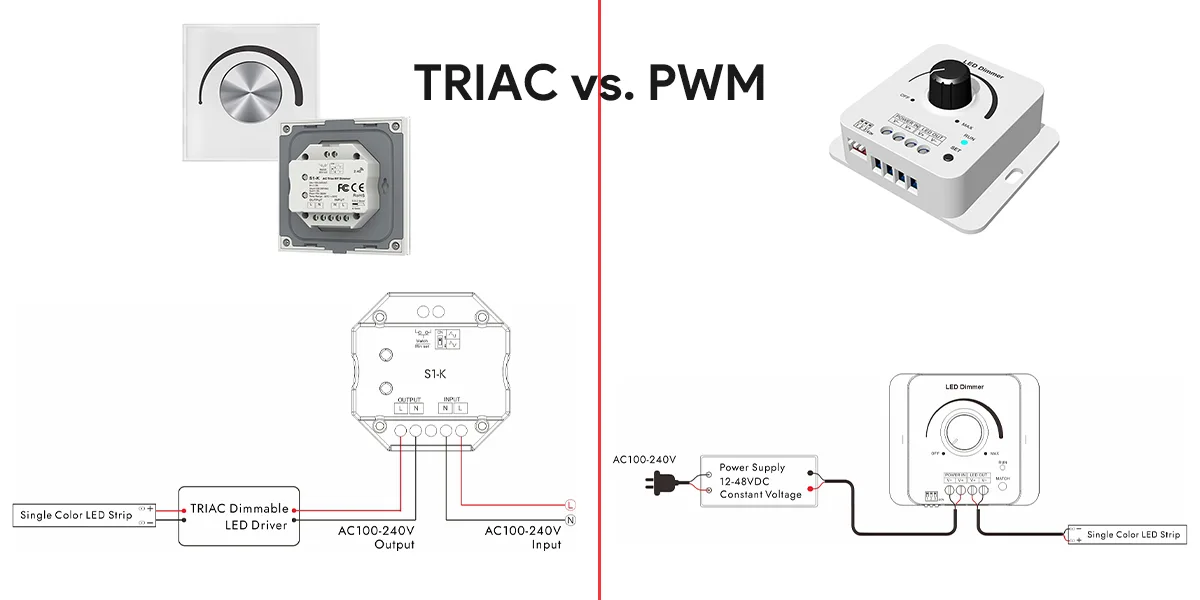

In malls, the use of TRIAC dimmers is more selective. They are typically applied in display lighting, restaurant zones, or lounge areas rather than general retail or high-ceiling spaces where other dimming methods like 0-10V or DALI are more suitable. TRIAC dimmers help accentuate product displays or create dynamic lighting scenes in food courts and entertainment areas.

In offices, TRIAC dimmers are less commonly used for general task lighting due to the need for consistent illumination. However, they can be effectively installed in meeting rooms, conference areas, or executive offices where adjustable lighting supports presentations or creates a more relaxed environment. Care should be taken to pair them with compatible LED drivers and bulbs to maintain performance.

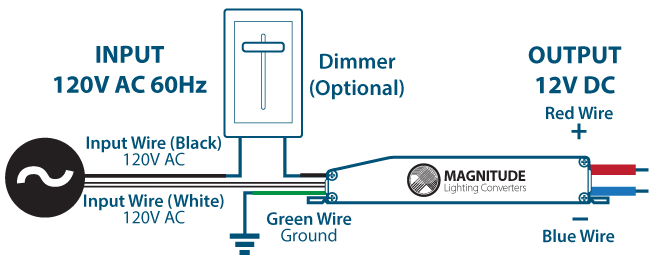

When installing TRIAC dimmers, several best practices should be followed. Always verify the compatibility between the dimmer and the connected light sources, especially with LED loads, as non-dimmable or incompatible LEDs can lead to operational issues. Ensure the total load is within the dimmer’s minimum and maximum wattage ratings—underloading may cause flickering, while overloading can damage the dimmer. Use short lead lengths and avoid running control wires parallel to high-voltage lines to reduce electromagnetic interference. For retrofit installations, check for neutral wire availability, as many modern TRIAC dimmers require a neutral for proper operation. Finally, follow local electrical codes and manufacturer guidelines, and consider professional installation to ensure safety and optimal performance.

Why Choose Beauty STC Lighting

Beauty STC delivers engineered TRIAC dimmer compatibility solutions that eliminate flicker and ensure smooth, reliable dimming performance across diverse LED installations. Our proprietary circuitry and rigorous testing protocols solve the pervasive compatibility challenges faced when integrating modern LED drivers with legacy and standard phase-cut dimming systems, providing specifiers and contractors with a truly plug-and-play experience. Partner with Beauty STC to access lighting components certified for broad dimmer compatibility, backed by UL/cUL safety listings and proven performance down to 5% light output. Ensure your projects achieve flawless dimming without costly callbacks or field modifications by leveraging our engineering expertise. Contact our technical sales manager directly at [email protected] to discuss your specific TRIAC dimming requirements and receive tailored support for your next lighting project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.