Article Contents

Industry Insight: Trailing Edge Dimmer Switch

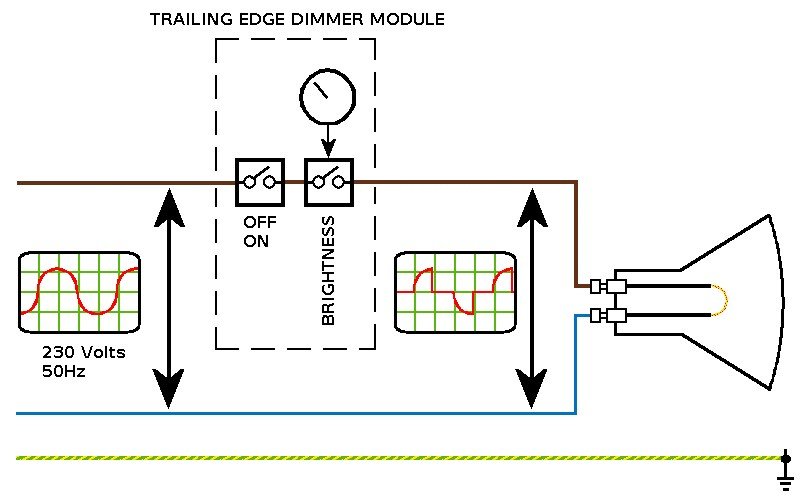

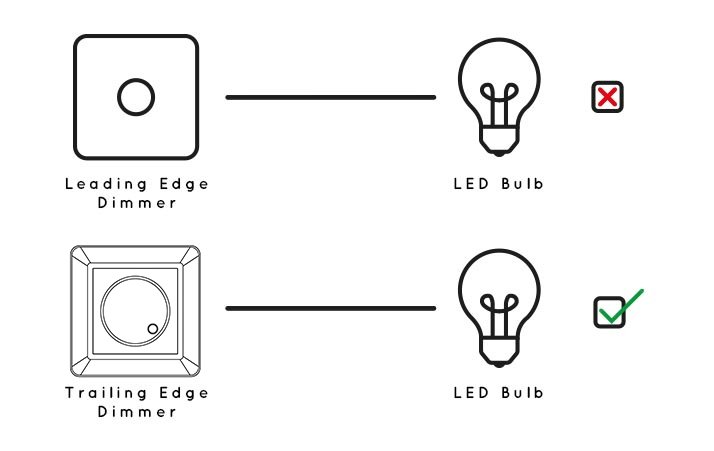

In commercial and industrial lighting applications, the demand for energy efficiency, precise light control, and compatibility with modern LED systems has driven widespread adoption of trailing edge dimmer switches. Unlike traditional leading edge dimmers, trailing edge technology offers smoother dimming performance, reduced audible noise, and enhanced compatibility with low-wattage LED and electronic low-voltage (ELV) lighting loads—making it an ideal solution for offices, retail spaces, warehouses, and industrial facilities where lighting quality and operational reliability are paramount. As building standards evolve toward smarter, more sustainable designs, specifying dimming solutions that meet rigorous safety and performance certifications such as ETL and CE becomes increasingly critical. These certifications ensure compliance with North American and international electrical standards, providing assurance of safety, durability, and consistent performance in demanding environments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in advanced LED lighting control solutions. With over two decades of engineering expertise, Beauty STC specializes in developing high-performance dimming technologies tailored for commercial and industrial applications. Their trailing edge dimmer switches are designed to deliver silent operation, wide dimming range, and seamless integration with modern LED systems, all backed by comprehensive ETL and CE certifications. Committed to innovation, quality, and sustainability, Beauty STC continues to support the global shift toward intelligent, energy-efficient lighting infrastructure.

Technical Specs & Certifications

Trailing edge dimmer switches themselves do not possess lumens per watt (lm/W) ratings or Color Rendering Index (CRI) values. These specifications are inherent characteristics of the LED light fixtures being controlled, not the dimmer switch. A trailing edge dimmer is an electronic control device designed to regulate the power delivered to compatible LED loads by modifying the AC waveform. Its primary technical specifications relate to electrical compatibility, performance, and physical protection, not the light output metrics of the connected luminaire.

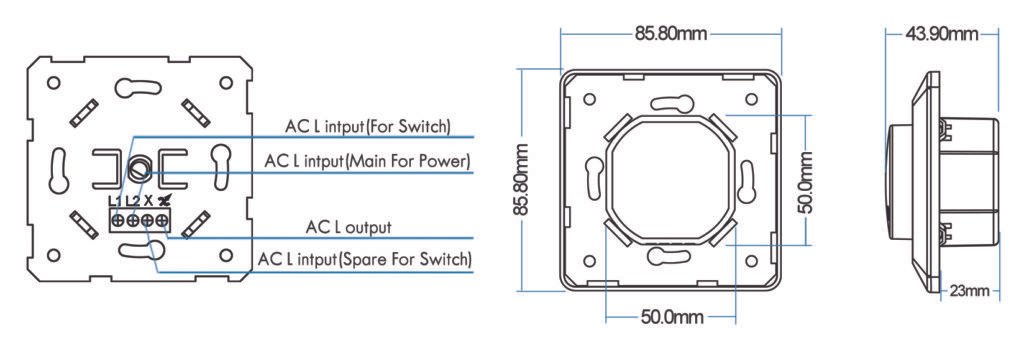

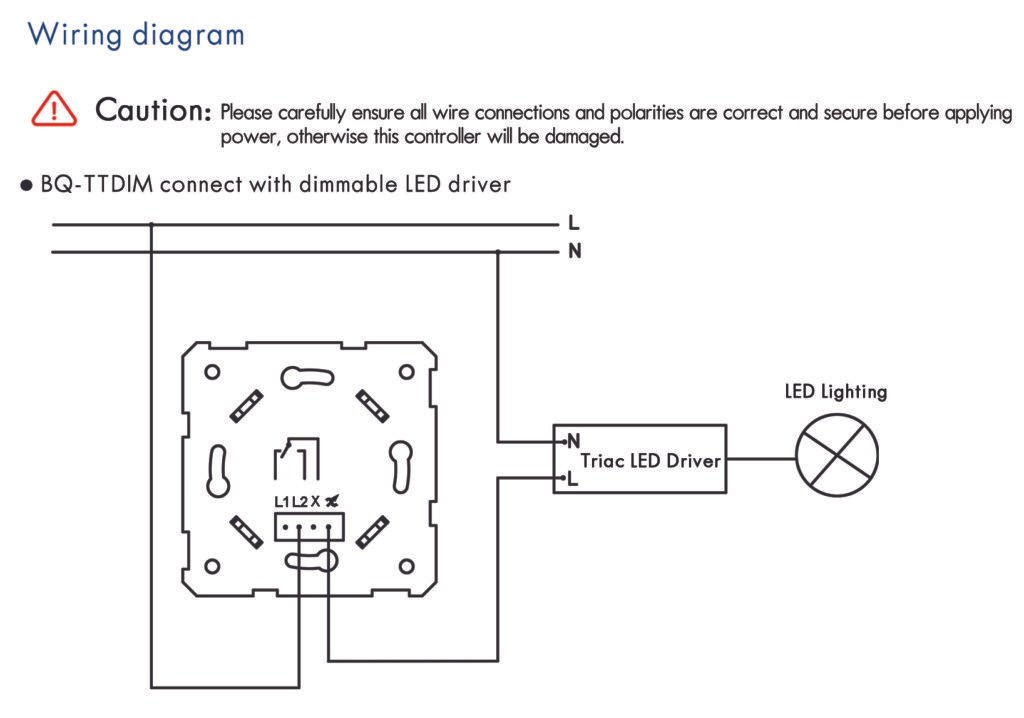

The critical specifications for a trailing edge dimmer switch relevant to high-performance LED systems focus on ensuring it can properly and smoothly dim fixtures that do achieve high lm/W efficiency and CRI >90. Key dimmer specifications include a low minimum load requirement, typically 5W to 25W, to function correctly with modern, highly efficient LED fixtures that draw minimal power. Compatibility with a wide range of constant current reduction (CCR) or pulse width modulation (PWM) LED drivers is essential, as these drivers power high-CRI LEDs. The dimmer must support phase-cut dimming specifically designed for capacitive electronic low-voltage (ELV) or trailing edge compatible LED drivers, avoiding the inductive loads associated with leading edge (TRIAC) dimmers. Thermal management within the dimmer is crucial; robust heat sinking and high-quality semiconductor components prevent overheating during operation, which is vital for maintaining consistent dimming performance and longevity, especially when controlling multiple high-efficiency fixtures. Electrical noise suppression circuitry minimizes interference that could otherwise disrupt sensitive driver electronics within high-CRI LED systems.

Regarding IP ratings, trailing edge dimmer switches installed within wall boxes are typically rated IP20, indicating basic protection against finger contact and larger solid objects but no specific moisture resistance. For applications requiring environmental protection, such as outdoor locations under eaves or in damp indoor areas like bathrooms (outside specific wet zones), dimmers with higher IP ratings like IP44 (splash resistant) or IP65 (dust tight and protected against low-pressure water jets) are available. Beauty STC Manufacturing Co., Ltd. rigorously tests its dimmer switches to ensure the stated IP rating is met under real-world conditions, utilizing sealed housings and gaskets where required. This commitment to verified ingress protection ensures reliable operation in challenging environments without compromising dimming performance.

Beauty STC’s quality assurance for trailing edge dimmer switches is paramount. We utilize premium semiconductor components from Tier-1 suppliers and implement stringent in-circuit testing during manufacturing to verify precise phase-control timing, thermal stability, and compatibility across a broad spectrum of certified LED loads. Our dimmers undergo extended life testing under maximum load and elevated temperatures, significantly exceeding standard requirements, to guarantee consistent performance over tens of thousands of cycles. This focus on robust component selection, rigorous production validation, and comprehensive reliability testing ensures our dimmers maintain smooth, flicker-free dimming essential for preserving the high lm/W efficiency and exceptional CRI >90 performance of the connected LED fixtures throughout the product’s operational life. Beauty STC dimmers are designed not just to meet but to exceed international safety standards including UL 1472 and IEC 60669-2-1, providing installers and end-users with confidence in safety and long-term functionality within demanding lighting installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped factory located in Jiangmen, Guangdong Province, China. The facility is strategically situated within the Pearl River Delta, an area renowned for its strong manufacturing ecosystem and efficient supply chains, enabling swift production and logistics operations.

The factory is outfitted with advanced Surface Mount Technology (SMT) production lines that ensure high-precision assembly of LED lighting components. These SMT machines are automated and capable of placing small, complex electronic parts onto printed circuit boards with exceptional accuracy and speed. This level of automation enhances production efficiency, reduces human error, and supports consistent product quality. The SMT lines are complemented by automatic optical inspection (AOI) systems to verify soldering quality and component placement, ensuring reliability in every batch.

To guarantee long-term performance and durability, Beauty STC implements comprehensive aging tests as part of its quality control process. Finished LED lighting products undergo extended operational testing under simulated real-world conditions, typically running at elevated temperatures and full load for periods ranging from 4 to 12 hours or more. This aging process helps identify early failure modes, allowing for corrective actions before products are shipped to customers. The company also conducts electrical safety, thermal, and photometric testing to meet international standards such as CE, RoHS, and UL.

Beauty STC has strong OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, supporting custom lighting solutions tailored to client specifications. Regarding the ‘trailing edge dimmer switch’, the company can integrate compatible LED drivers and circuitry into its luminaires to ensure seamless operation with trailing edge dimming systems. These dimmers are commonly used with household lighting due to their quiet operation and compatibility with low-wattage LED loads. Beauty STC’s engineering team can customize driver design, dimming curves, and firmware to optimize performance with trailing edge dimmers, supporting various protocols such as ELV (Electronic Low Voltage) and TRIAC-based systems. The company can also label, package, and brand products according to client requirements, offering full turnkey solutions from design to delivery.

Application Scenarios

Trailing edge dimmer switches are specifically designed for modern low-wattage LED and CFL lighting loads where smooth, quiet dimming performance is critical. Their application in commercial settings like hotels, malls, and offices requires careful consideration of the specific space requirements and electrical characteristics. In hotel guest rooms, trailing edge dimmers are an excellent choice for bedside and ambient lighting circuits where occupants demand silent operation and flicker-free dimming down to very low light levels. The absence of the audible buzz common with leading edge dimmers is essential for guest comfort in quiet sleeping environments. However, they are generally not suitable for hotel ballrooms or large lobbies where high-wattage incandescent or halogen circuits might still exist or where centralized 0-10V or DALI systems are more appropriate for zone control.

For retail mall applications, trailing edge dimmers find their niche primarily in individual store tenant spaces rather than common areas. High-end boutique stores or restaurant tenant spaces within the mall can benefit from trailing edge dimmers for accent lighting, display cases, or dining areas where precise, quiet dimming enhances the customer experience. They are not typically recommended for the mall’s main corridors, atriums, or high-bay lighting due to the complexity of load management across vast areas and the prevalence of more scalable control systems like 0-10V or DALI. Office environments present the most consistent use case for trailing edge dimmers, particularly in private offices, executive suites, conference rooms, and training rooms. These spaces prioritize user-adjustable, quiet dimming for presentations, video conferencing, or individual comfort without the distraction of mechanical relay clicks or electronic buzzing. Open-plan office general lighting is better served by system-level controls, but task lighting or perimeter zones in private offices are ideal candidates.

Installation requires strict adherence to compatibility protocols to avoid common field failures. Always verify the specific trailing edge dimmer model is explicitly listed as compatible with the exact LED drivers or fixtures being installed, as driver circuitry varies significantly. Pay critical attention to the minimum load requirement; many trailing edge dimmers need a minimum of 5-10W per channel, which can be problematic with just one or two modern low-wattage LED lamps. Solutions include adding a compatible resistive dummy load or selecting a dimmer with an ultra-low minimum load specification. Never mix LED types or technologies on a single dimmer circuit, and absolutely avoid combining any incandescent or halogen lamps with LEDs on a trailing edge dimmer as this will cause erratic behavior and premature failure. Ensure the electrical circuit is properly grounded, as trailing edge dimmers are more susceptible to noise-induced flicker in poorly grounded commercial buildings. During commissioning, test the dimmer across its entire range with the actual installed fixtures under real-world conditions, not just at the panel, to catch any interaction issues before final handover. Remember that trailing edge dimmers require clean, stable input voltage and may malfunction on circuits shared with heavy machinery or large inductive loads common in commercial facilities.

Why Choose Beauty STC Lighting

Looking for reliable performance with your lighting controls? Upgrade to a trailing edge dimmer switch designed for smooth, flicker-free dimming with modern LED technology. At Beauty STC, we specialize in high-quality dimming solutions that deliver precision and durability. Partner with us to integrate superior dimming performance into your lighting projects. Contact our sales manager today at [email protected] to learn more and start a collaboration.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.