Article Contents

Industry Insight: Trailing Edge Dimmer

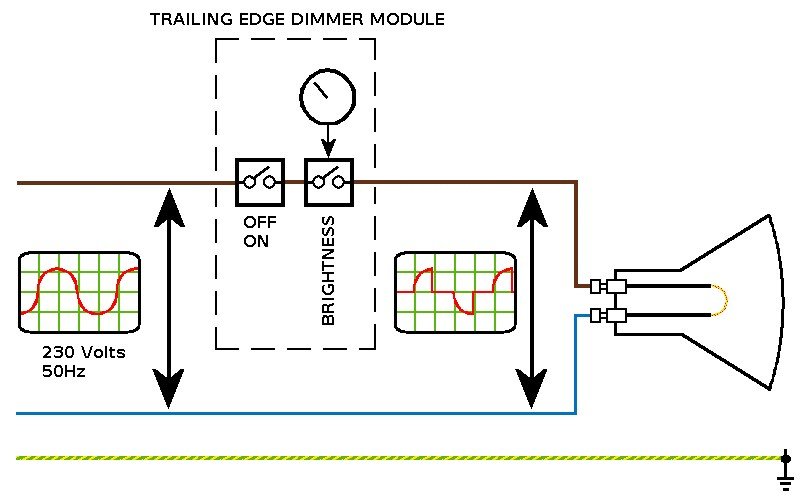

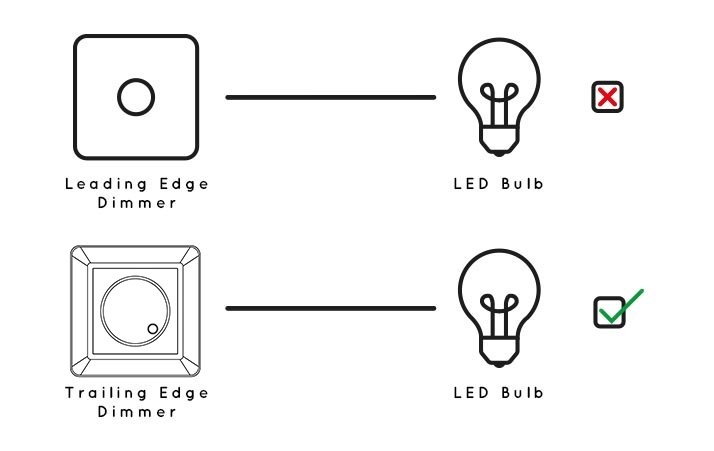

Trailing edge dimming has become an increasingly vital technology in commercial and industrial lighting applications, offering smooth, flicker-free control for modern LED systems. Unlike traditional leading edge dimmers, trailing edge dimmers utilize advanced electronic components such as MOSFETs or IGBTs to precisely cut the latter portion of the AC waveform, resulting in quieter operation, higher efficiency, and improved compatibility with low-wattage LED loads. This makes them particularly well-suited for environments where lighting performance, energy savings, and user comfort are paramount—such as offices, retail spaces, warehouses, and industrial facilities.

As building standards evolve and energy regulations tighten, compliance with safety and performance certifications like ETL and CE has become essential. These certifications ensure that dimming solutions meet rigorous electrical, electromagnetic compatibility (EMC), and safety requirements for use in North American and international markets. In this context, selecting dimming components from trusted, certified manufacturers is critical to achieving reliable system integration and code compliance.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED driver and dimming technology for over two decades. Specializing in high-performance solutions for commercial and industrial lighting, Beauty STC delivers innovative trailing edge dimming products that combine precision control, robust durability, and full compliance with global standards including ETL and CE. With a commitment to engineering excellence and scalable manufacturing, Beauty STC continues to support the evolving needs of the modern lighting industry.

Technical Specs & Certifications

Trailing edge dimmers, also known as electronic low voltage (ELV) dimmers or reverse phase dimmers, are specialized control devices designed for compatibility with modern LED drivers and low-voltage lighting systems. It is critical to clarify that lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings are specifications of the LED lamps or luminaires being controlled, not inherent properties of the dimmer switch itself. The dimmer’s role is to enable smooth, flicker-free dimming of compatible LED loads meeting these performance criteria. Beauty STC Manufacturing Co., Ltd. engineers its trailing edge dimmers to ensure optimal performance with high-efficiency, high-CRI LED fixtures while maintaining robust build quality.

Lumens per watt (lm/W) is a measure of the LED source’s efficacy, indicating light output per unit of electrical power consumed. High-quality LED fixtures commonly achieve 100-150+ lm/W. Beauty STC trailing edge dimmers are meticulously designed to support these efficient LED drivers without introducing significant power loss or instability at low dimming levels. Our dimmers feature precise zero-crossing detection and advanced waveform shaping to maintain stable operation even with the low minimum load requirements of high-efficacy LEDs, ensuring the fixture delivers its rated lm/W performance consistently across the dimming range. We rigorously test with leading high-efficacy LED modules to guarantee compatibility and prevent issues like drop-out or flicker that could undermine the fixture’s energy-saving potential.

Color Rendering Index (CRI) exceeding 90 is a hallmark of premium LED lighting, essential for applications demanding accurate color representation such as retail, hospitality, and healthcare. Beauty STC trailing edge dimmers are engineered to preserve this high CRI performance throughout the dimming curve. Poorly designed dimmers can cause spectral shifts or color inconsistency, particularly at lower light levels. Our dimmers incorporate sophisticated filtering and stable current control to prevent harmonic distortion and ensure the LED driver receives a clean, consistent signal. This engineering focus prevents color shift and maintains the fixture’s specified CRI >90, a critical factor validated through extensive in-house photometric testing with high-CRI LED sources during our quality assurance process.

Ingress Protection (IP) ratings define a fixture’s resistance to dust and moisture ingress, with common ratings like IP20 (indoor use), IP44 (splash resistant), or IP65+ (outdoor/damp locations). The dimmer switch itself carries its own IP rating (typically IP20 for standard wall-mounted units). Beauty STC trailing edge dimmers are constructed with high-grade materials and sealed internal components to meet or exceed relevant safety standards for their designated installation environment. Crucially, our dimmers are tested to ensure they do not compromise the IP integrity of the connected luminaire. For instance, when controlling IP65-rated outdoor fixtures, our dimmers maintain stable dimming performance without inducing electrical noise or thermal issues that could affect the fixture’s sealed housing or driver reliability. Beauty STC emphasizes thermal management within the dimmer housing and robust electrical isolation to prevent any degradation of the overall system’s environmental resilience.

Beauty STC’s commitment to quality is evident in every trailing edge dimmer. We utilize premium components including high-reliability triacs, precision-tuned snubber circuits, and thermally stable PCB substrates. Each unit undergoes 100% functional testing, rigorous thermal cycling, and compatibility validation with a wide range of leading high-CRI, high-efficacy LED drivers. Our dimmers feature superior electromagnetic compatibility (EMC) filtering to prevent interference with other building systems and are built to withstand demanding electrical environments. This meticulous attention to engineering detail ensures long-term reliability, silent operation, and seamless integration with the most demanding LED specifications, upholding Beauty STC’s reputation for delivering dimming solutions that enhance, rather than hinder, the performance of premium lighting installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is designed to support high-efficiency production of LED lighting products, with a strong emphasis on quality control, automation, and scalable manufacturing processes.

The facility is outfitted with advanced Surface Mount Technology (SMT) production lines, featuring high-precision SMT machines from leading global manufacturers. These machines enable accurate placement of surface-mounted components onto PCBs, ensuring consistent product quality and high throughput. The SMT lines are integrated with automated optical inspection (AOI) systems to detect soldering and component placement defects in real time, minimizing errors and enhancing overall yield.

To ensure long-term reliability, the factory conducts comprehensive aging tests on finished LED products. Units are subjected to extended operational cycles under controlled thermal and electrical conditions, simulating real-world usage over prolonged periods. This aging process helps identify early-life failures and ensures that only products meeting stringent durability standards are shipped to customers.

Beauty STC has robust OEM capabilities and can customize LED lighting solutions to meet specific client requirements. This includes engineering support for compatibility with various dimming technologies. In particular, the company is experienced in designing and manufacturing products compatible with trailing edge dimmers—also known as electronic low-voltage (ELV) dimmers. Their R&D and engineering teams can tailor driver circuits and thermal management systems to ensure smooth, flicker-free dimming performance with trailing edge dimmer controls, meeting international safety and performance standards.

Overall, the Jiangmen factory combines advanced automation, rigorous testing protocols, and flexible OEM support to deliver high-quality, dimmer-compatible LED lighting solutions for global markets.

Application Scenarios

Trailing edge dimmers are particularly well-suited for specific commercial lighting applications where smooth, low-noise dimming of modern LED loads is critical, especially in environments demanding high user comfort and precise light control. Within hotels, malls, and offices, their optimal use cases differ based on the lighting requirements and user experience goals.

In hotels, trailing edge dimmers are the preferred choice for guest room lighting circuits controlling low-voltage LED downlights, wall sconces, and bedside luminaires, particularly where smooth dimming down to very low levels is essential for creating ambiance and supporting sleep cycles. They are also ideal for dimming LED tape in cove lighting within lobbies, executive lounges, or high-end suite corridors where silent operation and flicker-free performance are non-negotiable for guest satisfaction. Avoid using them for high-wattage circuits like corridor emergency lighting or certain exterior signage where leading edge might be more robust, but prioritize trailing edge for all guest-facing, occupant-controlled dimming zones.

For malls, trailing edge dimmers excel in retail tenant spaces for accent lighting on displays, track lighting highlighting merchandise, and dimmable feature lighting within individual stores where silent operation prevents interference with audio systems and smooth dimming enhances the shopping experience. They are also appropriate for dimming decorative LED elements in common areas like food court feature walls or boutique entrance canopies where high-end aesthetics matter. However, they are generally less suitable for the main high-bay or plaza lighting in large common circulation areas due to the typically higher wattages and potential for less compatible legacy drivers; leading edge or 0-10V systems are often more practical there.

Within offices, trailing edge dimmers are the correct solution for private offices, meeting rooms, and executive suites where dimmable LED panels or downlights are used for presentation modes or creating adaptable work environments, as their silent operation prevents the audible transformer hum common with leading edge dimmers near workstations. They are also suitable for dimming task lighting at adjustable workstations and feature lighting in collaboration zones. Avoid them for open-plan office general lighting where centralized 0-10V or DALI control is standard, or for circuits powering large banks of non-dimmable or incompatible LED troffers where the dimmer’s minimum load requirements may not be met.

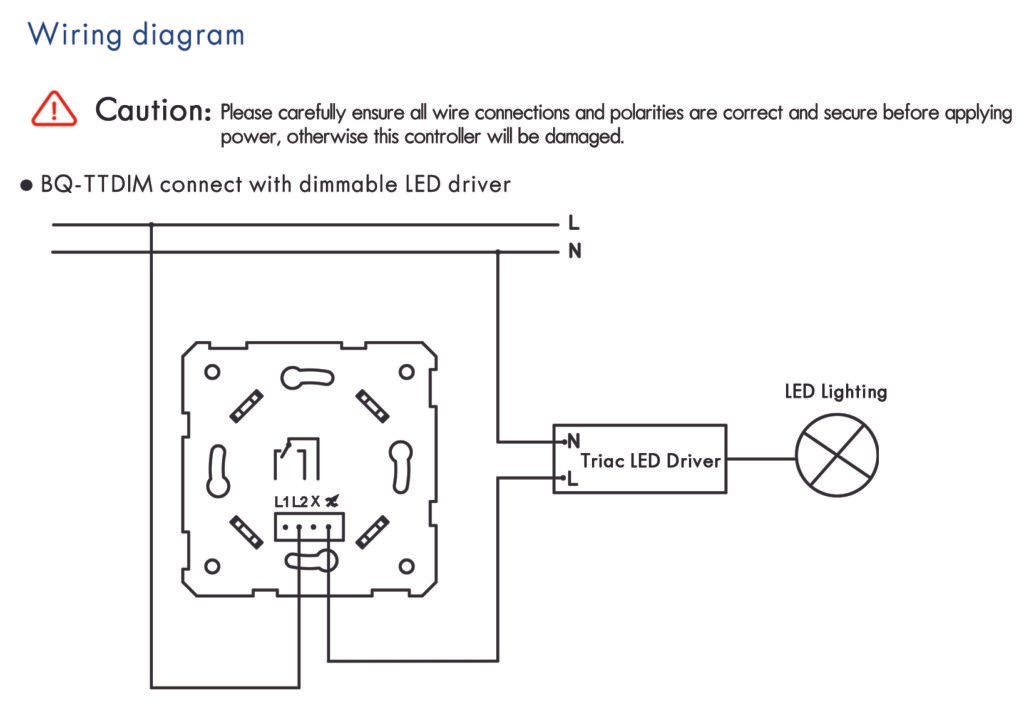

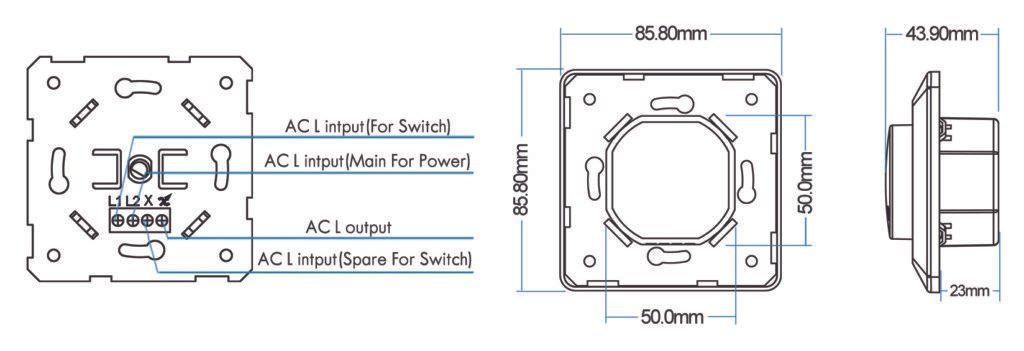

Critical installation tips for trailing edge dimmers in these commercial settings begin with verifying absolute compatibility between the dimmer model, the specific LED driver or luminaire, and the total connected load. Always consult the manufacturer’s compatibility tool or list; Beauty (STC) provides detailed online databases for our dimmers. Calculate the total load carefully, ensuring it exceeds the dimmer’s specified minimum load, typically 5-10W for trailing edge types, which is crucial when dimming a few low-wattage downlights or a short LED tape run – underloading causes flicker or dropout. Use a dedicated neutral wire for every dimmer; shared neutrals from multiple circuits cause erratic behavior and “ghost voltage” issues, a frequent problem in multi-gang boxes in hotel corridors or office walls. Keep the dimmer wire run as short as possible, especially the switched live to the灯具, and avoid running dimmer cables parallel to data or communication cables to prevent electrical noise interference, which can disrupt building management systems in offices or audio in malls. Finally, during commissioning, test each circuit at various dimming levels, particularly near the bottom end, to confirm smooth operation without flicker or buzz, as driver compatibility can vary even within the same luminaire model batch. Never assume compatibility based solely on “LED dimmable” labeling; specific driver-dimmer pairing is non-negotiable for reliable trailing edge performance.

Why Choose Beauty STC Lighting

Looking for reliable trailing edge dimmer solutions? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting technology. Our precision-engineered trailing edge dimmers ensure smooth, flicker-free performance and seamless integration with modern lighting systems. Designed for efficiency and durability, our products meet the highest industry standards.

Collaborate with us to elevate your lighting projects with innovative, high-quality solutions. Contact our sales manager today at [email protected] to discuss your requirements and discover how Beauty STC can support your business growth.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.