Article Contents

Industry Insight: Track Light Led Power On The Side

Introduction & Market Demand for Commercial LED Track Lighting

Commercial and industrial environments demand precision lighting solutions that balance adaptability, reliability, and regulatory compliance. Track lighting systems have become indispensable for retail displays, gallery exhibitions, office spaces, and hospitality venues due to their directional control and modular flexibility. However, the global market is saturated with low-cost alternatives that compromise on safety, thermal management, and long-term performance. For importers targeting Western markets, the distinction between compliant and non-compliant products isn’t merely technical—it directly impacts project timelines, regulatory approvals, and brand reputation.

The Critical Role of Certification in Global Track Lighting Procurement

Importing track lighting into the U.S., Canada, or Europe requires rigorous adherence to safety and performance standards. ETL certification (recognized by OSHA in the U.S.) and TÜV CE certification (mandatory for EU markets) are non-negotiable gatekeepers to market access. These certifications validate that products meet stringent electrical safety, thermal management, and electromagnetic compatibility requirements. Without them, shipments face customs holds, costly rework, or outright rejection. Beauty STC Lighting’s products undergo third-party testing and certification, ensuring seamless compliance for global projects. This eliminates hidden risks and guarantees that installations meet local regulatory requirements from day one.

Industry Challenges in Track Lighting Procurement

The commercial lighting sector faces persistent challenges:

Inconsistent quality control from unverified suppliers, leading to premature failures or inconsistent performance.

Limited customization options for project-specific needs, such as beam angles, color temperatures, or mounting configurations.

Supply chain vulnerabilities, including inconsistent lead times and lack of technical support for complex installations.

Thermal design flaws in uncertified products, causing reduced lifespan and increased maintenance costs.

For project managers and distributors, partnering with a manufacturer that has a proven track record of quality and reliability is critical to maintaining project integrity and client trust.

Beauty STC Lighting: 25+ Years of Engineering Excellence

Since 1998, Beauty STC Lighting has engineered lighting solutions for global commercial applications. Headquartered in Jiangmen’s High-Tech Industrial Zone, Guangdong, China, our facility combines ISO-compliant manufacturing processes with rigorous quality assurance protocols. All products—including our track lighting systems—carry ETL and TÜV CE certifications, ensuring compliance with North American and European safety standards. As a dedicated OEM/ODM partner, we provide tailored solutions for diverse project requirements, from standard commercial installations to specialized industrial applications.

| Feature | Specification |

|---|---|

| Power Input Position | Side-Mounted for Flexible Installation |

| Input Voltage | 100–277V AC |

| Power Factor | ≥0.9 |

| Color Temperature | 2700K–6500K (Adjustable) |

| Beam Angle | 15°–60° (Customizable) |

| Certifications | ETL, TÜV CE |

| IP Rating | IP20 (Indoor Use) |

| Warranty | 5 Years |

Our commitment to technical excellence ensures that every product meets the exacting standards required for commercial and industrial environments. For project-specific inquiries, contact our engineering team at [email protected] or +86 13902885704.

Technical Specs & Certifications (ETL/CE)

Technical Specifications & Quality Standards

Track-Light LED – Power-on-the-Side Configuration

H3 1. Electrical & Photometric Baseline

| Parameter (typ. 20 W module) | Beauty STC Design Window | Tolerance Band in Mass Production | Verification Method |

|---|---|---|---|

| Input | 220-240 Vac 50/60 Hz (120 V upon request) | ±10 % | 100 % Hi-pot & ground bond |

| Luminous flux | 2800 lm @ 4000 K (140 lm W⁻¹) | ±5 % | 2 m integrating sphere, 25 °C |

| Efficacy | 135-145 lm W⁻¹ (driver & LED included) | ±3 % | IEC 62717 |

| CRI | Ra ≥ 90 (R9 > 50) | ±1 point | 300-780 nm spectro-radiometer |

| SDCM | ≤ 3 steps MacAdam | 100 % binning | 3 nm resolution |

| Flicker | <1 % @ 100 Hz (IEEE 1789) | ±0.2 % | IDR300 |

| Power factor | >0.95 at 50-100 % load | ±0.02 | IEC 61000-3-2 |

| THD | <10 % | ±1 % | IEC 61000-3-2 |

H3 2. Mechanical & Thermal Architecture – “Power-on-the-Side”

Driver placement: Remote constant-current pack mounted on the side of the track adapter; LED module stays <65 °C Tc-point, guaranteeing L70 > 50 000 h @ 25 °C ambient (TM-21 calculator, 6000 h data set).

Heat sink: 1070 aluminium extrusion, 1.4 W m⁻¹ K⁻¹ thermal interface sheet, anodised to 12 µm for 500 h salt-spray resistance.

Track compatibility: Global 3-circuit 4-wire (I, L, N, PE) copper bus; stainless-steel clamping shoe, 20 A rated, <4 mΩ contact resistance after 500 mating cycles.

Rotation: 358 ° horizon, 180 ° vertical; torque retention ≥ 2 Nm after 1000 movements (internal life-test jig).

H3 3. PCB & Component Grade

Substrate: Double-sided FR-4, 1.6 mm, 2 oz Cu, thermal conductivity 1.5 W m⁻¹ K⁻¹; via-in-pad technology for <0.1 mm² thermal resistance.

Solder: SAC305 under nitrogen reflow; AOI + 3-D SPI eliminate 99.5 % of joint anomalies.

LED package: 2835 mid-power, 3 V, 0.5 W, LM-80 report 12 000 h, 105 °C.

Binning: 1/9 ANSI bin; reels traced by barcode to pick-and-place programme—guarantees CCT consistency within one production lot.

H3 4. Ingress & Safety Ratings

| Environment | Market Option | Beauty STC Standard | Certification |

|---|---|---|---|

| Dry retail | IP20 | IP20 (all plastics 94-V0) | ETL / CE |

| Gallery/food | IP20 | Optional IP44 front ring & silicone gasket | TUV CB |

| Damp | Often omitted | IP44 driver enclosure standard | EN 60598-1/-2-1 |

H3 5. Production Consistency Controls (Factory-Direct)

- Incoming: LEDs 100 % flux & chromaticity check vs LM-80 data; drivers 100 % burn-in 2 h @ 265 Vac.

- In-process: Solder-paste height monitored by 3-D SPI; AOI after reflow; thermal-couple profiling every 2 h.

- Final: 3 m sphere batch test (AQL 0.65); 100 % functional at 230 Vac & 120 Vac; 100 % 1.5 kV hipot between L-N & earth.

- Traceability: Serial number → driver IC lot → LED reel → operator ID; archived 10 years for OEM recalls.

H3 6. Specification Snapshot – Beauty STC vs Generic Market

| Attribute | Generic Market “Track-LED” | Beauty STC Certified | Reference Standard |

|---|---|---|---|

| Luminous efficacy | 95-110 lm W⁻¹ | 135-145 lm W⁻¹ | IEC 62717 |

| CRI | 80-83 | ≥ 90 (R9 ≥ 50) | CIE 13.3 |

| SDCM | 5-7 | ≤ 3 | ANSI C78.377 |

| Flicker | 10-20 % | <1 % | IEEE 1789 |

| Lifetime claim | 30 000 h | 50 000 h L70 @ 25 °C | TM-21 |

| PCB Cu weight | 1 oz | 2 oz | IPC-6012 |

| Safety mark | Self-declaration | ETL/cETL + TUV CE | UL 1570 / EN 60598 |

| Warranty | 2 yr | 5 yr (OEM/ODM) | Factory Ts & Cs |

| Production lot variation | Visible to eye | <1/9 ANSI bin | In-house SPC |

H3 7. Certification & Factory Credentials

ETL listed for US & Canada (file 5020280), complies with UL 1570 & CSA C22.2 No. 9.

TUV CB, CE-LVD, CE-EMC, RoHS, REACH for 27 EU members.

ISO 9001:2015 since 2003; ISO 14001 environmental system since 2015.

25 000 m² Jiangmen facility, 25 SMT lines, monthly capacity 1.2 M pcs track heads.

OEM/ODM since 1998; tooling shop, dark-room photometry, 6 kN vibration table, -40 → +120 °C thermal chamber.

H3 8. Part-Number Builder (example)

TRK-20W-40K-90-120-BLK-SIDE

20 W | 4000 K | CRI 90 | 120 V input | Black | Side-power

Custom optics (15°, 24°, 36°, 60°), finishes (WHT / SIV / custom RAL), Zhaga-compatible LED engines, and DALI-2 or 0-10 V drivers available on request.

For project quotations or OEM datasheets, contact:

[email protected] | +86-13902885704

Factory Tour: Manufacturing Excellence

Manufacturing Process & OEM Services

Integrated Production Infrastructure

Beauty STC Lighting’s Jiangmen facility, established in 1998, operates across a 10,000+ square meter industrial zone site. This dedicated production hub integrates automated assembly lines, precision testing equipment, and ISO-compliant quality control protocols. With 25+ years of experience in LED manufacturing, our facility is optimized for high-volume production while maintaining strict adherence to international standards for Western markets. All operations comply with ETL (USA/Canada) and TUV CE (Europe) certification requirements, ensuring seamless integration into global supply chains.

Precision SMT Assembly Process

All PCB assembly for track lighting systems utilizes state-of-the-art Surface Mount Technology (SMT) lines. High-precision pick-and-place machines ensure component placement accuracy within ±0.05mm tolerance, followed by automated optical inspection (AOI) for solder joint integrity. Reflow soldering profiles are calibrated to meet IPC-A-610 standards, minimizing defects in critical electronic components. This process ensures consistent performance and longevity for track head electronics, critical for commercial applications requiring reliability under continuous operation.

Rigorous Quality Assurance Protocols

Quality control is embedded at three critical stages:

- Incoming Material Inspection: Raw materials and components are tested for compliance with RoHS and REACH regulations before production.

- In-Process Testing: During assembly, electrical continuity checks and thermal stress simulations validate component functionality.

- Final Product Validation: Each unit undergoes 48-hour continuous aging tests under 110% rated load, followed by photometric and electrical safety tests per IEC 60598. All products are certified to ETL (North America) and TUV CE (Europe) standards, with full documentation provided for each batch.

OEM/ODM Customization Capabilities

Beauty STC Lighting provides end-to-end customization for track lighting systems, from mechanical design to packaging. Our engineering team collaborates directly with clients to tailor specifications to project requirements, including:

Track length and circuit configurations (single, dual, or triple circuit)

CCT options from 2700K to 5000K with ±50K tolerance

Beam angles ranging from 15° to 120°

Housing materials (anodized aluminum, powder-coated steel, polycarbonate)

Custom mechanical features (vertical tilt up to 180°, horizontal rotation up to 358°)

Packaging solutions including OEM-branded retail boxes and bulk shipping configurations

The following table outlines standard customization parameters for commercial track lighting systems:

| Parameter | Standard Options | Customization Range |

|---|---|---|

| CCT Range | 2700K, 3000K, 3500K, 4000K, 5000K | 2700K–5000K (±50K tolerance) |

| Beam Angle | 15°, 24°, 36°, 60°, 120° | 10°–120° (adjustable via optics) |

| Circuit Configuration | Single, Dual (20A/circuit), Triple | Configurable per project requirements |

| Track Length | Standard 1m–6m sections | Custom lengths up to 8m (with engineering review) |

| Housing Material | Anodized Aluminum, Powder-Coated Steel | Material selection based on environmental requirements |

| Tilt/Rotation | 180° vertical, 358° horizontal | Adjustable within mechanical limits |

All custom designs undergo rigorous prototyping and validation to ensure compliance with ETL/CE certifications. Our ODM services include full product development support, from concept to production-ready designs.

For technical specifications or project-specific requirements, contact our engineering team at [email protected] or +86 13902885704.

Installation & Application Scenarios

Where to Specify “Power-on-the-Side” LED Track Systems

(ETL & CE-certified, Factory-Direct since 1998)

H2 Application Matrix – Commercial & Architectural

| Segment | Typical Lux Target | CCT Range Used | Mounting Height | Beam Notes | OEM/ODM Value-Add |

|---|---|---|---|---|---|

| Flagship Retail (apparel, jewellery) | 800–1 200 lx on merchandise | 3000 K–4000 K | 2.7–4 m | 15–24° narrow spots for contrast | Custom CRI 95+ COB, private-label driver box colour |

| Shopping-Mall Aisles | 300–500 lx general | 3500 K neutral | 3–5 m | 24–36° medium flood, 1 m spacing | 3-circuit track pre-wired to local 220-240 V junction |

| Hotel Lobbies & Corridors | 200–300 lx ambient, 500 lx accent | 2700 K–3000 K | 3–6 m | Wall-wash adapters for marble façade | DALI / 0-10 V dimming logo on side power cover |

| Corporate Offices (track over workstations) | 300–500 lx UGR <19 | 4000 K | 2.5–3 m | 36–60° flood, micro-louver | Integrated sensor node (day-light + PIR) inside side housing |

| Gallery / Museum | 50–200 lx on artefact (CIE 197) | 2700 K–3000 K | 2.5–4 m | 8–15° spots, CRI 97, TM-30 Rf 95 | Bluetooth Casambi module clipped to side power entry |

| Facade Soffit (cold climate) | 100 lx average | 3000 K–4000 K | 4–8 m | 10–30° asymmetrical wall-wash | IP54 gasket kit, -40 °C driver option, side entry keeps water away from live parts |

H2 Why “Power-on-the-Side” Matters on Site

- Low-ceiling clearance – Driver box sits lateral to the track, not below; maintains 2 m minimum head-room in corridors.

- Continuous row optics – No vertical gap between heads; achieves clean “beam-to-beam” retail wall wash.

- Tool-less live feed – 20 A, 2-circuit copper bus pre-fed from end or side tap; reduces cable loops in ceiling void.

- Future circuit separation – Emergency (circuit 1) vs. normal (circuit 2) without extra trunking; meets BS 5266 / NEC 700.

- ETL & CE separation of driver – Class I earth path isolated from Class II track conductors; passes 4 kV surge per IEEE C62.41.

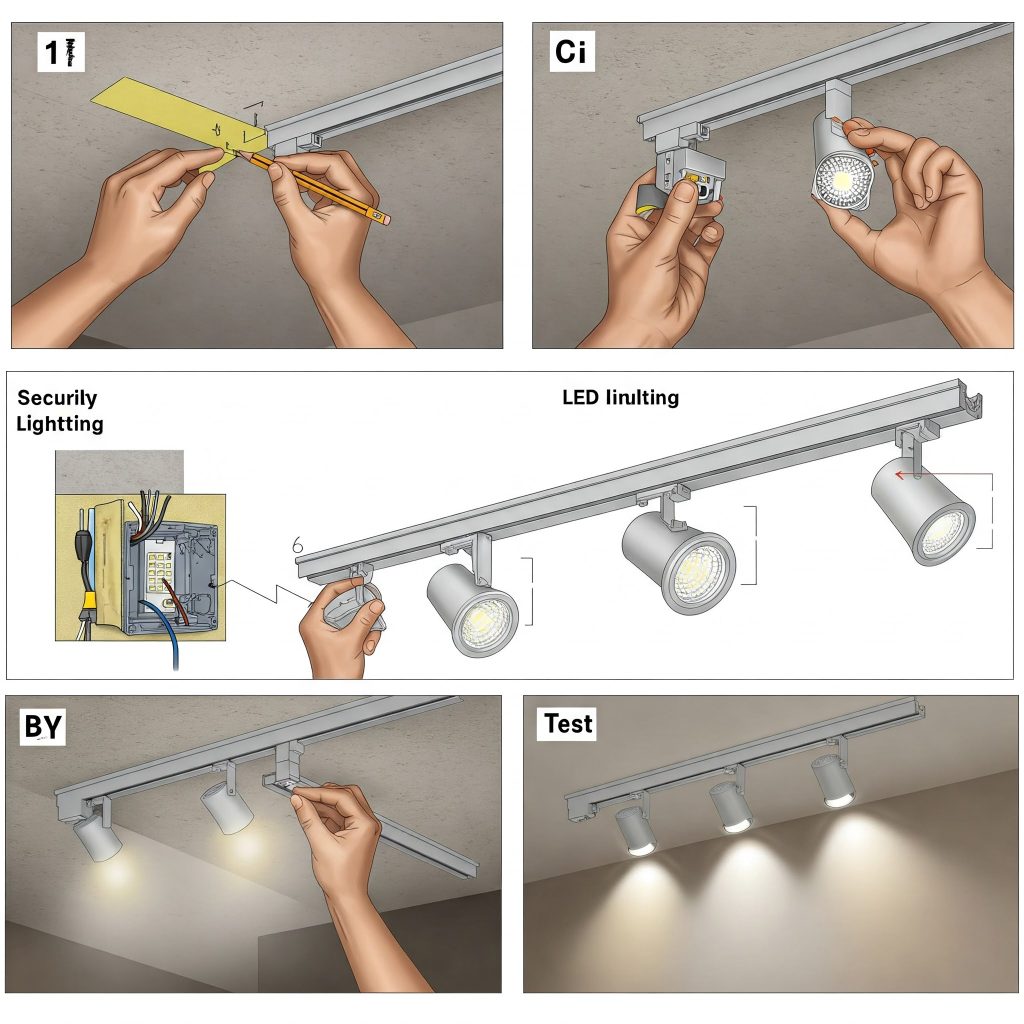

H2 Contractor Installation Checklist

(Factory-direct kit shipped from Jiangmen since 1998)

| Step | Action | Code / Best Practice |

|---|---|---|

| 1 | Verify track polarity marks before lifting; side power module is factory-polarity keyed. | NEC 410.102 / IEC 60598-2-1 |

| 2 | Support every 0.9 m (3 ft) with threaded rod or #12 wire; max 5 kg per m including side feed. | ASTM E580 |

| 3 | Torque side-feed screws to 0.8 N·m; over-torque deforms 2.5 mm² copper bus. | Factory spec sheet rev. 7 |

| 4 | Leave 100 mm service loop at side entry for OEM driver swap (<3 min) | TIA-568 visual only |

| 5 | Post-installation hipot 1.5 kV for 1 s between line-earth; record in QC sheet for ETL audit trail. | UL 1598 §19.6 |

H2 Specification Snapshot – OEM Module from Beauty STC Lighting

| Electrical | Mechanical | Light Engine |

|---|---|---|

| Input: 120–277 V, 50/60 Hz | Track: 3-wire (2-circuit) or 4-wire (3-circuit) | COB 10–40 W, 110 lm/W @ 3000 K |

| Driver: 0-10 V / DALI, -30…+50 °C | Side power box: 102 × 62 × 28 mm Al extrusion | CRI 90/93/97 optional, MacAdam 3-step |

| Surge: 4 kV diff., 6 kV common | Finish: Anodised silver / matte black | Beam: 15° / 24° / 36° / 60° reflector or zoom |

| Certifications: ETL/cETL, TUV CE, RoHS, REACH | IP20 standard; IP54 with side gasket | Lifetime: L80 >54 000 h, TM-21 report on file |

H2 Take-away for Distributors & Specifiers

One SKU covers 120 V North-America to 240 V Europe—driver programmed at Jiangmen factory; no field change required.

Side-entry keeps ceiling plenum open for HVAC & sprinkler conflict—valuable in retrofit malls.

Tool-less head rotation & lock (358° pan, 180° tilt) tested 2 000 cycles—documented for hotel PM schedules.

OEM colour box, laser logo, and cable length shipped in 3-week lead-time—25-year production backbone since 1998.

For project quotations or custom photometric files, contact:

[email protected] | +86-13902885704

Why Choose Beauty STC Lighting

Partner with Beauty STC Lighting: Industrial-Grade Track Lighting Solutions

Global Compliance & Quality Assurance

All Beauty STC Lighting products undergo rigorous testing and certification to meet international standards. Our track lighting systems are certified with ETL (USA/Canada) and TUV CE (Europe), ensuring compliance with stringent safety and performance requirements across key global markets. This commitment to quality allows seamless integration into commercial projects worldwide, from retail spaces to high-end architectural installations.

25+ Years of Manufacturing Excellence

Since 1998, Beauty STC Lighting has built a reputation for reliability and precision in LED manufacturing. With over two decades of experience, we serve 50+ countries across Europe, North America, Southeast Asia, and beyond. Our vertically integrated production process ensures consistent quality control, from component sourcing to final assembly, delivering products that meet the highest industry standards.

Custom OEM/ODM Solutions

We specialize in tailored lighting solutions designed to meet specific project needs. Our engineering team works closely with clients to develop custom track lighting configurations, including voltage options, beam angles, color temperatures, and housing materials. Whether you require unique mounting solutions or specialized optics, our OEM/ODM services provide the flexibility to adapt to your exact specifications.

| Parameter | Specification |

|---|---|

| Input Voltage | 100–277V AC (Wide Range) |

| Power Options | 10W, 15W, 20W, 30W |

| Beam Angle | Adjustable 15°–60° |

| Color Temperature | 2700K, 3000K, 3500K, 4000K, 5000K |

| CRI | ≥90 Ra |

| Housing Material | Die-cast aluminum, powder-coated finish |

| IP Rating | IP20 (Indoor Use) |

| Certifications | ETL (USA/Canada), TUV CE (Europe), RoHS |

| Warranty | 5 Years |

Ready to Elevate Your Project?

Partner with a trusted manufacturer with proven global expertise. Contact Beauty STC Lighting today to discuss your commercial track lighting requirements. Our technical team provides expert guidance from design through delivery, ensuring your project meets the highest standards of performance and reliability.

Contact: [email protected] | 0086-13902885704

⚡ LED Power Supply Calculator

Calculate the required power supply for your LED strip project (includes 20% safety margin).