Article Contents

Industry Insight: Thin Led Strip

Thin LED strips have emerged as a transformative solution in commercial and industrial lighting, offering exceptional design flexibility, energy efficiency, and reliable performance in demanding environments. Their low-profile form factor enables seamless integration into architectural coves, under-shelf displays, high-bay fixtures, and machine vision systems, where space constraints and precision illumination are critical. With growing emphasis on safety and regulatory compliance, leading installations now require thin LED strips that are ETL and CE certified—ensuring adherence to rigorous North American and European safety, electromagnetic compatibility, and performance standards. These certifications are not just regulatory checkboxes but markers of product integrity, especially in industrial settings where durability and long-term stability are paramount.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance LED strips for commercial and industrial applications, Beauty STC combines advanced thermal management, consistent color rendering, and robust construction to meet the evolving needs of professional lighting projects. As an ETL- and CE-certified manufacturer, the company is committed to delivering products that combine cutting-edge technology with the highest standards of quality and safety—making Beauty STC a trusted partner for engineers, designers, and contractors worldwide.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. engineers ultra-thin LED strips designed for demanding architectural and decorative applications where minimal profile and high-quality light output are critical. Our standard thin strip format measures 4.0mm in width, utilizing high-density 2835 or 3535 SMD LEDs mounted on a flexible FPC substrate with a total profile typically under 2.0mm when unencapsulated. Regarding Lumens per Watt (lm/W), our thin strips achieve industry-leading efficacy ratings between 120 lm/W and 140 lm/W under standard operating conditions at 25°C ambient temperature. This efficiency is maintained through the use of premium Epistar or Seoul Semiconductor LED chips, optimized constant-current drivers, and proprietary thermal management pathways within the FPC design. It is important to note that efficacy in ultra-thin formats is inherently lower than standard 10mm-wide strips due to tighter thermal constraints and reduced copper weight; however, our engineering focus ensures we maximize output within these physical limitations without compromising longevity.

Color Rendering Index (CRI) performance is a core differentiator for Beauty STC products. We exclusively utilize LED bins rated CRI Ra ≥ 90, with most standard offerings achieving Ra 92-95. Crucially, we prioritize high R9 values (deep red rendering) consistently above 50, which is essential for accurate skin tones and vibrant color representation in retail and hospitality settings. This is achieved through stringent LED binning protocols and advanced phosphor formulations, avoiding the common industry practice of using lower-cost, lower-R9 LEDs that meet only the minimum Ra threshold. All high-CRI strips undergo spectrophotometer verification during production, with full spectral data and TM-30 reports available upon request. We emphasize that genuine CRI >90 performance in thin strips requires precise manufacturing control – cheaper alternatives often misrepresent CRI values through inadequate testing or spectral manipulation.

For environmental protection, Beauty STC offers multiple IP-rated configurations. Our base flexible strip is IP20 (unprotected), suitable for dry indoor installations. For damp or outdoor use, we provide factory-applied silicone encapsulation achieving IP65 (dust-tight and low-pressure water jets) with a standard 3mm silicone coating thickness. For submersion or high-moisture environments like cove lighting near pools or marine applications, we manufacture IP67-rated strips using a dual-layer silicone overmolding process tested to 1 meter depth for 30 minutes. All encapsulated strips maintain optical clarity and UV stability through our proprietary silicone formulation, which prevents yellowing and delamination – a critical quality factor where competitors often fail. IP rating validation is performed per IEC 60529 standards with third-party lab reports available.

Beauty STC’s commitment to quality is embedded in every production stage. Our Shenzhen facility operates under ISO 9001 and IATF 16949 certified processes, with 100% automated optical inspection (AOI) of LED placement and solder joints. We enforce strict thermal aging protocols where strips undergo 1,000-hour burn-in at 60°C ambient, rejecting any batch showing >3% lumen depreciation. Unlike commodity manufacturers, we use only UL-listed 1oz copper FPCs with 99.99% pure electrolytic copper, ensuring stable current distribution and preventing hotspots that degrade CRI and efficacy over time. Our silicone encapsulants are Dow Corning-sourced and meet UL 94 V-0 flammability standards. This rigorous approach delivers L70/B50 lifespans exceeding 50,000 hours at 25°C ambient – a benchmark verified through TM-21 accelerated testing. When specifying thin LED strips, insist on certified test data; Beauty STC provides full LM-79 and LM-80 reports for every product code, demonstrating our transparency and technical superiority in the high-performance thin strip market.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern and well-equipped facility dedicated to the production of high-quality LED lighting products. Strategically located in an industrial hub known for its robust manufacturing ecosystem, the Jiangmen factory leverages advanced automation and strict quality control processes to meet both domestic and international market demands.

The factory is outfitted with state-of-the-art SMT (Surface Mount Technology) production lines, which are central to the precision assembly of LED components onto flexible and rigid circuit boards. These SMT machines are high-speed, fully automated systems capable of placing LEDs, resistors, capacitors, and other surface-mount devices with exceptional accuracy and consistency. The use of advanced pick-and-place machines, coupled with automated optical inspection (AOI), ensures minimal defect rates and high throughput, especially critical for compact and high-density LED strip designs.

A key aspect of quality assurance at the Jiangmen facility is its comprehensive aging and reliability testing procedures. Finished LED strip products undergo rigorous aging tests under controlled thermal and electrical conditions, typically operating at full power for extended durations—often 24 to 72 hours. This process helps identify early-life failures, ensures long-term stability, and verifies performance under real-world operating conditions. Additional tests include waterproof testing for outdoor-rated strips, solderability checks, and environmental stress screening to meet international standards such as CE, RoHS, and UL.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly in the production of ‘thin LED strips’—a popular product category used in architectural lighting, signage, and decorative applications. The factory can customize these strips in various dimensions, densities (e.g., 60, 120, or 240 LEDs per meter), colors (including RGB, RGBW, and tunable white), and IP ratings (from non-waterproof to IP65/IP67). Clients can also request private labeling, custom packaging, and tailored reel lengths. The engineering team works closely with partners to adapt designs, modify circuit layouts, and ensure compatibility with specific drivers or control systems.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to innovation, scalability, and quality. With its advanced SMT infrastructure, disciplined aging protocols, and flexible OEM services, the facility is well-positioned to support both large-volume orders and specialized custom projects in the competitive LED lighting market.

Application Scenarios

Thin LED strips, defined at Beauty (STC) as flexible strips under 10mm width and typically 4-8mm thickness with a high-density LED layout, excel in commercial environments where discreet, even illumination and space constraints are critical. Their minimal profile allows integration into architectural details where bulkier lighting would be visible or impractical, making them ideal for premium hospitality and retail settings demanding clean aesthetics.

In hotels, prioritize thin strips for cove lighting in lobbies to wash walls or ceilings with ambient light without revealing the source, creating an expansive, welcoming feel. Integrate them beneath floating vanities in bathrooms for soft, shadow-free task lighting around mirrors, ensuring IP67-rated strips are used for moisture resistance. Within guest rooms, embed them under bed frames for subtle night-time orientation lighting or within custom millwork like headboard niches for accent illumination that enhances perceived room quality without visual clutter. Avoid direct downlighting; always use indirect methods to prevent glare and maintain a restful atmosphere.

Malls benefit significantly from thin strips in storefront displays, where they highlight product edges within glass cabinets or shelving without obstructing views, using 24V strips to minimize voltage drop across long display runs. Apply them along the inner edges of suspended ceiling coves in corridors to provide uniform, glare-free general illumination that guides customer flow while maintaining a modern, uncluttered ceiling appearance. For feature walls or digital signage integration, conceal thin strips behind translucent panels to create even backlighting that enhances visual merchandising impact. Ensure all strips are housed in aluminum channels with diffusers in high-traffic areas to protect against physical damage and provide consistent light output.

For offices, implement thin strips within the plenum space above suspended ceiling grids to deliver indirect ambient light that reduces eye strain and improves spatial perception, selecting 4000K CCT for balanced task performance. Use them to under-cabinet lighting in kitchenettes or reception desks for functional task illumination that avoids harsh shadows. In meeting rooms, integrate them into the underside of tables for subtle occupancy indication or within partition systems for wayfinding. Crucially, avoid placing strips where they cause direct glare on workstations; always position them to bounce light off surfaces rather than shine directly into occupants’ eyes.

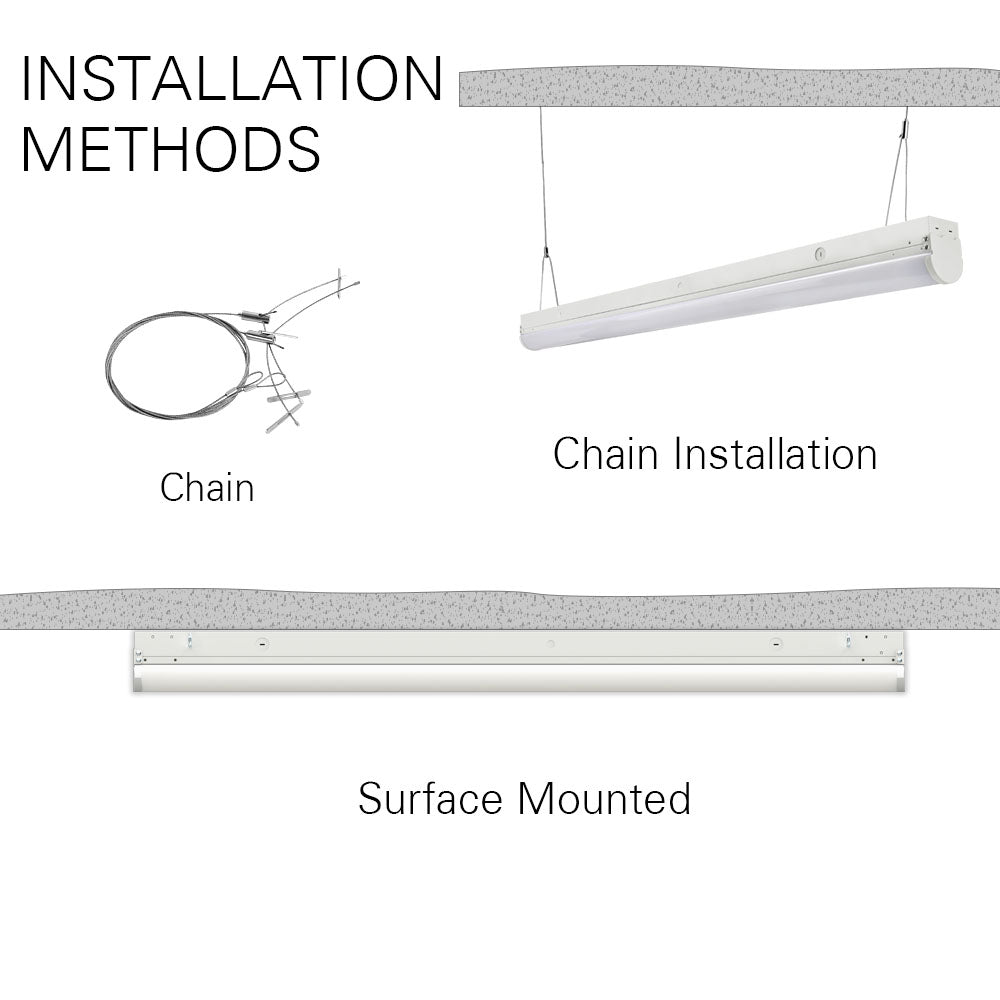

Installation requires meticulous surface preparation: thoroughly clean all mounting surfaces with isopropyl alcohol to remove oils and dust, ensuring the adhesive bonds reliably. Always use aluminum mounting channels with a frosted polycarbonate diffuser to manage heat, protect the strip, and eliminate individual LED hotspots—never rely solely on the strip’s self-adhesive tape for permanent installations in commercial settings. For runs exceeding 5 meters, especially with 12V strips, inject power at multiple points to prevent color shift and dimming at the far end; 24V strips are preferable for mall corridors exceeding 10 meters. Verify all strips come from the same production bin code to guarantee color consistency across large installations, and conduct a full-power burn-in test for 15 minutes before final sealing to identify early failures. In humid areas like hotel bathrooms, use only strips with full silicone encapsulation rated IP67 or higher, and avoid sharp bends tighter than the manufacturer’s specified radius to prevent LED damage.

Why Choose Beauty STC Lighting

Discover the future of lighting with Beauty STC’s premium thin LED strips—sleek, energy-efficient, and perfect for modern architectural and decorative applications. Engineered for flexibility and high performance, our thin LED strips deliver consistent illumination with easy installation across a wide range of environments.

Partner with Beauty STC, a trusted leader in innovative LED solutions, and elevate your lighting projects with reliable, high-quality products tailored to your needs.

For collaboration opportunities or product inquiries, contact us today at [email protected] and let’s brighten the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.